Lead frame bending device

A lead frame and bending device technology, applied in the directions of feeding device, positioning device, storage device, etc., can solve the problems of bending angle consistency error, unable to meet production requirements, affecting product quality, etc., to achieve good consistency, The effect of high production efficiency and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

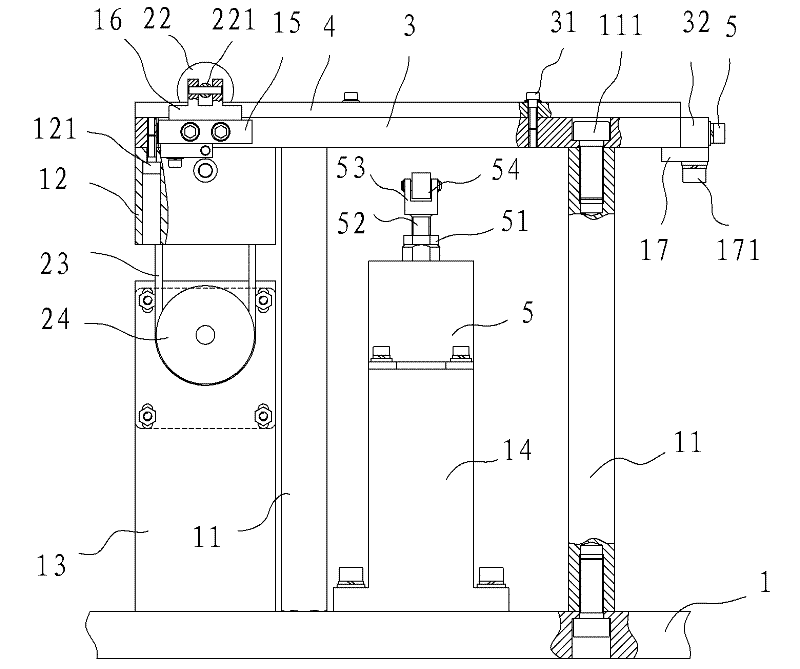

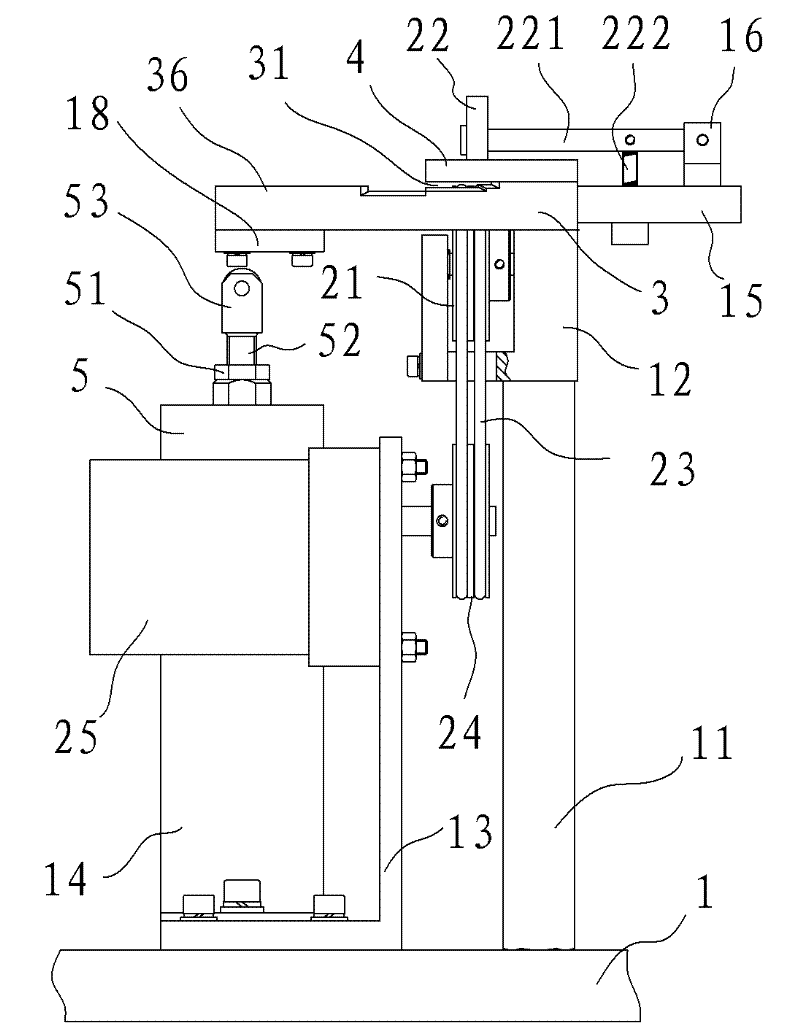

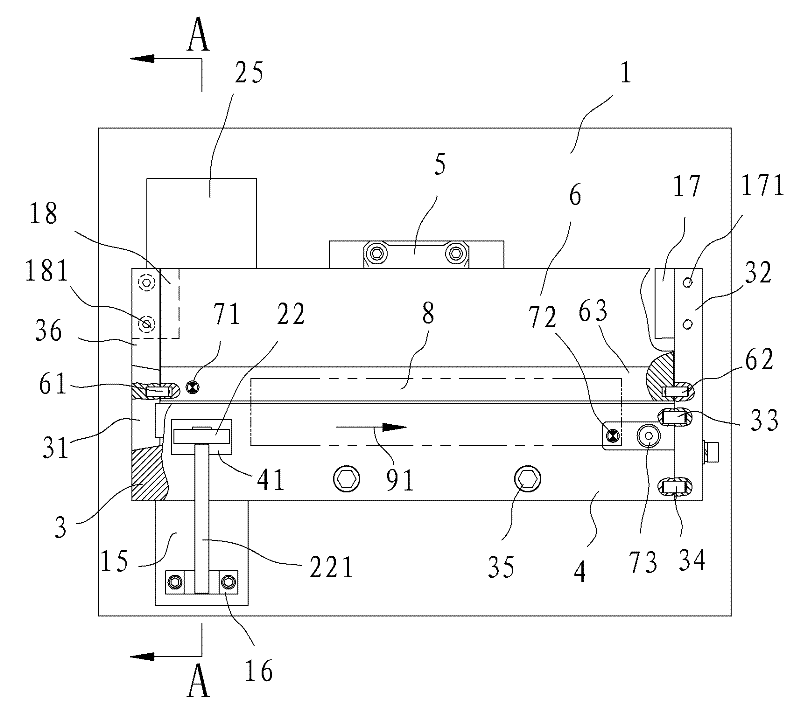

[0015] Such as Figure 1 to Figure 4 As shown, the feeding guide rail is composed of an upper guide rail 4 and a lower guide rail 3, the lower guide rail 3 is fixed on the frame 11 by screws 111, the frame 11 is fixed on the base 1, and the lower guide rail 3 is provided with a lead frame groove. When the guide rail 4 is fixed on the lower guide rail 3 by screws 31, the lead frame groove forms a horizontal slideway 31 that is open on the side wall of the guide rail and can pass through the pin portion 81 of the lead frame 8, and the lower guide rail 3 outside of the slideway 31 is provided with a support The movable guide rail 6 of the heat sink part 82 of the lead frame is provided with a chute 63 cooperating with the heat sink part 82 of the lead frame. The brackets 36, 32 of the feed port end are integrated with the lower guide rail 3, the feed port end bracket 32 is fixed on the lower guide rail 3 by two pins 33, 34, and the two ends of the movable guide rail 6 are adjac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com