Elastic wire fatigue performance testing device and using method thereof

A technology of fatigue performance testing and elastic wire, which is applied in the direction of measuring devices, using repeated force/pulsation force to test the strength of materials, and analyzing materials, can solve the problems of rarely testing fatigue life and achieve a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

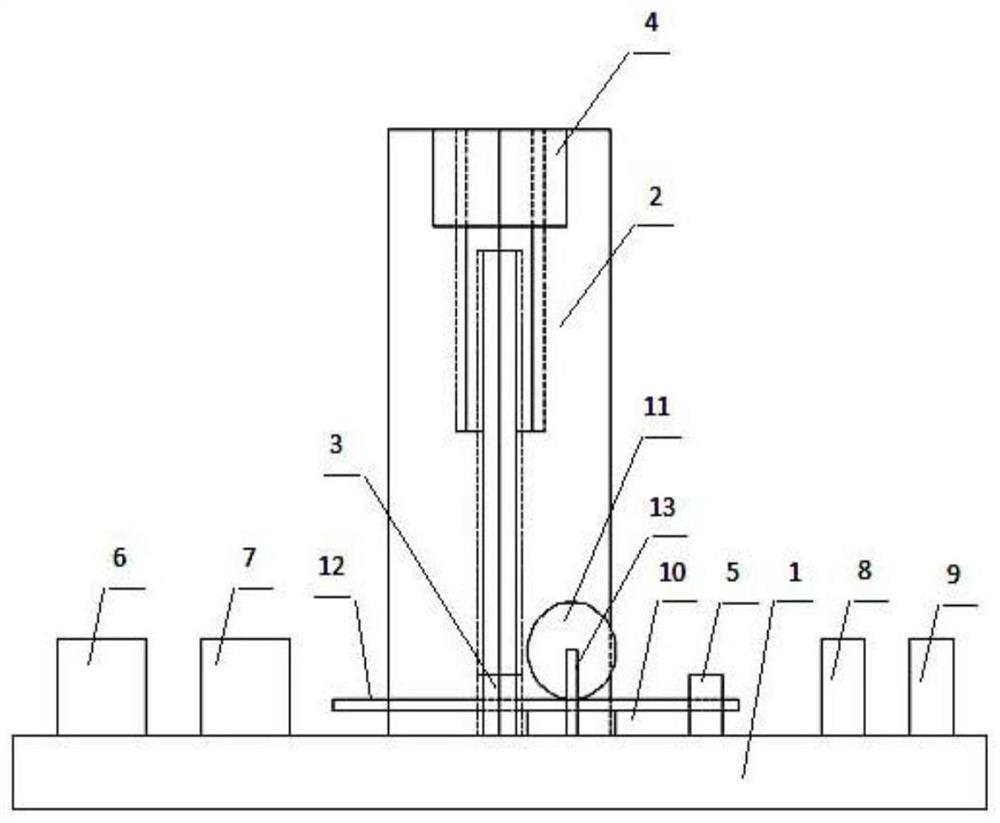

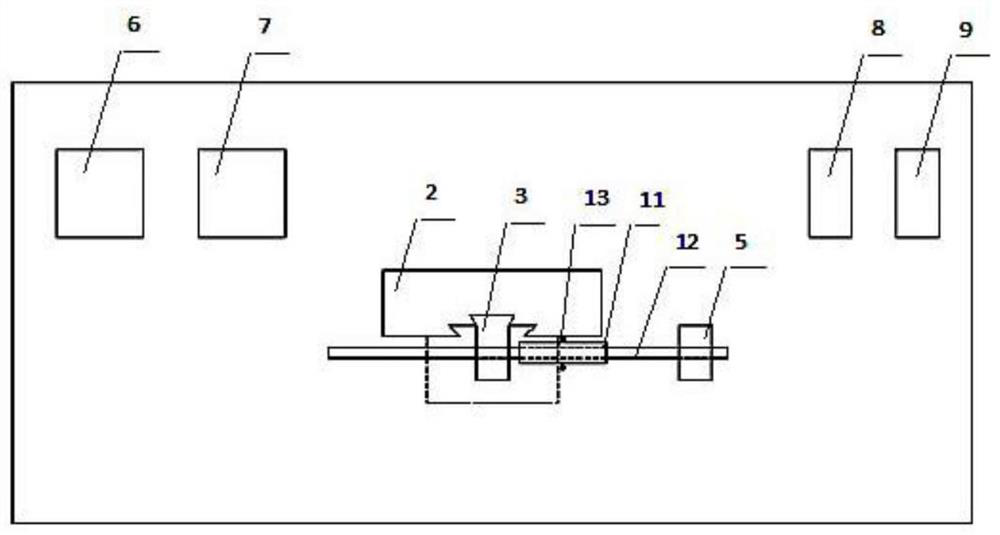

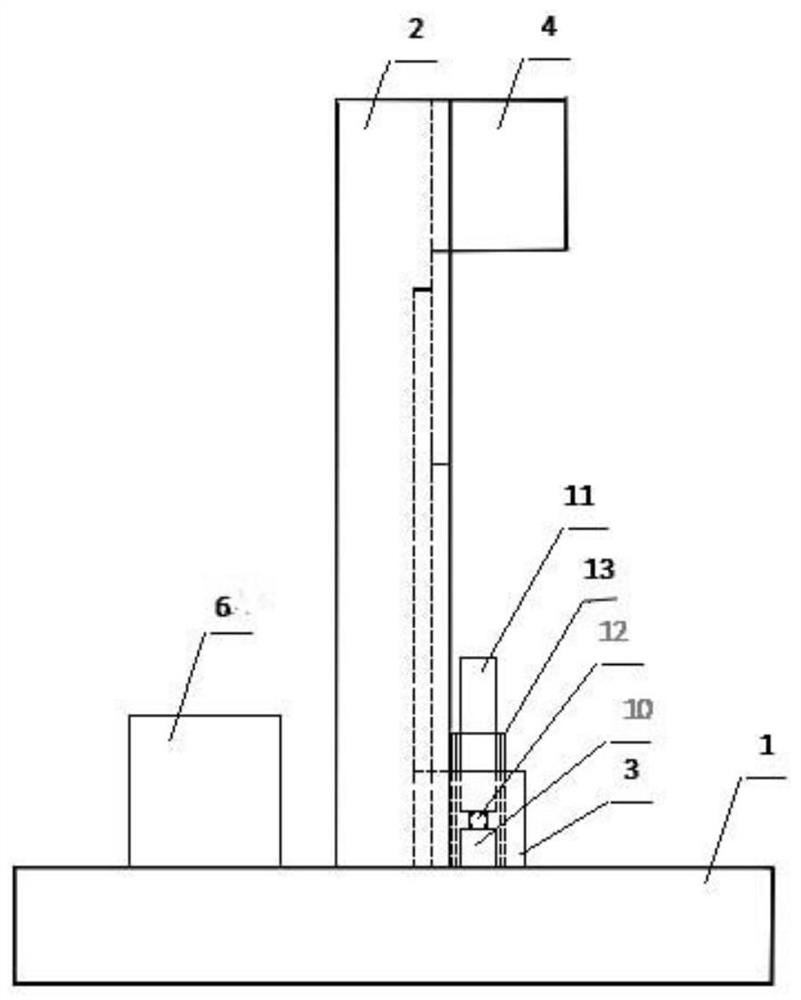

[0021] A device for testing the fatigue performance of elastic wire, such as Figure 1~3 As shown, it includes: base 1, slide table 2, magnetic slider 3, electromagnet 4, briquetting block 5, relay power supply 6, relay 7, timer 8, timer power supply 9, pad 10, measured wire 12 , mandrel fixing rod 13, mandrel 11;

[0022] Among them, the slide table 2 is erected vertically on the base 1, the slide block 3 that can slide up and down through the dovetail groove is installed at the bottom of the slide table 2, the electromagnet 4 with adjustable position is installed on the top of the slide table 2 through the dovetail groove, the relay power supply 6 and The relay 7 and the electromagnet 4 form a circuit. When the electromagnet 4 is energized, the magnetic slider 3 can slide up and down in the dovetail groove of the slide table 2 . The relay energization time interval is 3 seconds, the energization current is 2A, and the action distance of the magnetic slider is 5mm.

[0023]...

Embodiment 2

[0027] A device for testing the fatigue performance of elastic wire, such as Figure 1~3 As shown, including: base 1, slide table 2, slide block 3, electromagnet 4, briquetting block 5, relay power supply 6, relay 7, timer 8, timer power supply 9, pad 10, measured wire material 12, Mandrel fixing rod 13, mandrel 11;

[0028]Among them, the slide table 2 is erected vertically on the base 1, the slide block 3 that can slide up and down through the dovetail groove is installed at the bottom of the slide table 2, the electromagnet 4 with adjustable position is installed on the top of the slide table 2 through the dovetail groove, the relay power supply 6 and The relay 7 and the electromagnet 4 form a circuit. When the electromagnet 4 is energized, the magnetic slider 3 can slide up and down in the dovetail groove of the slide table 2 . The relay energization time interval is 2 seconds, the energizing current is 2A, and the slider action distance is 10mm.

[0029] The mandrel 11,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com