A bending device for chip pins

A bending device and pin technology, applied in the field of chip pin bending devices, can solve the problems that the accuracy and consistency are difficult to meet the use requirements, affect the chip assembly quality, lead plating damage and other problems, so as to improve the assembly quality , Adjustable bending angle, avoid scratches or damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

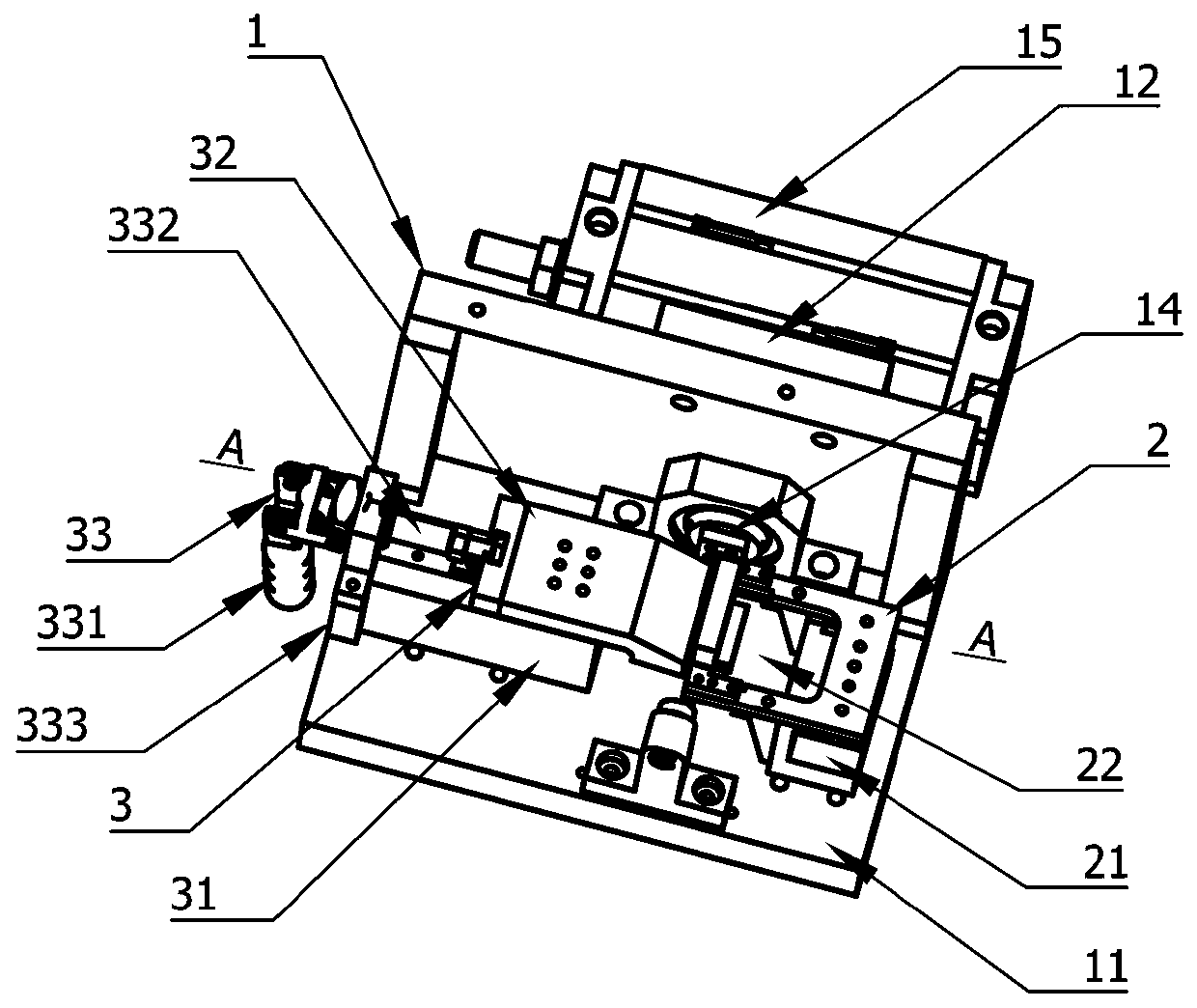

[0026] refer to figure 1 , figure 2 , the present invention includes a bending device 1, a tire frame 2 and a clamping device 3,

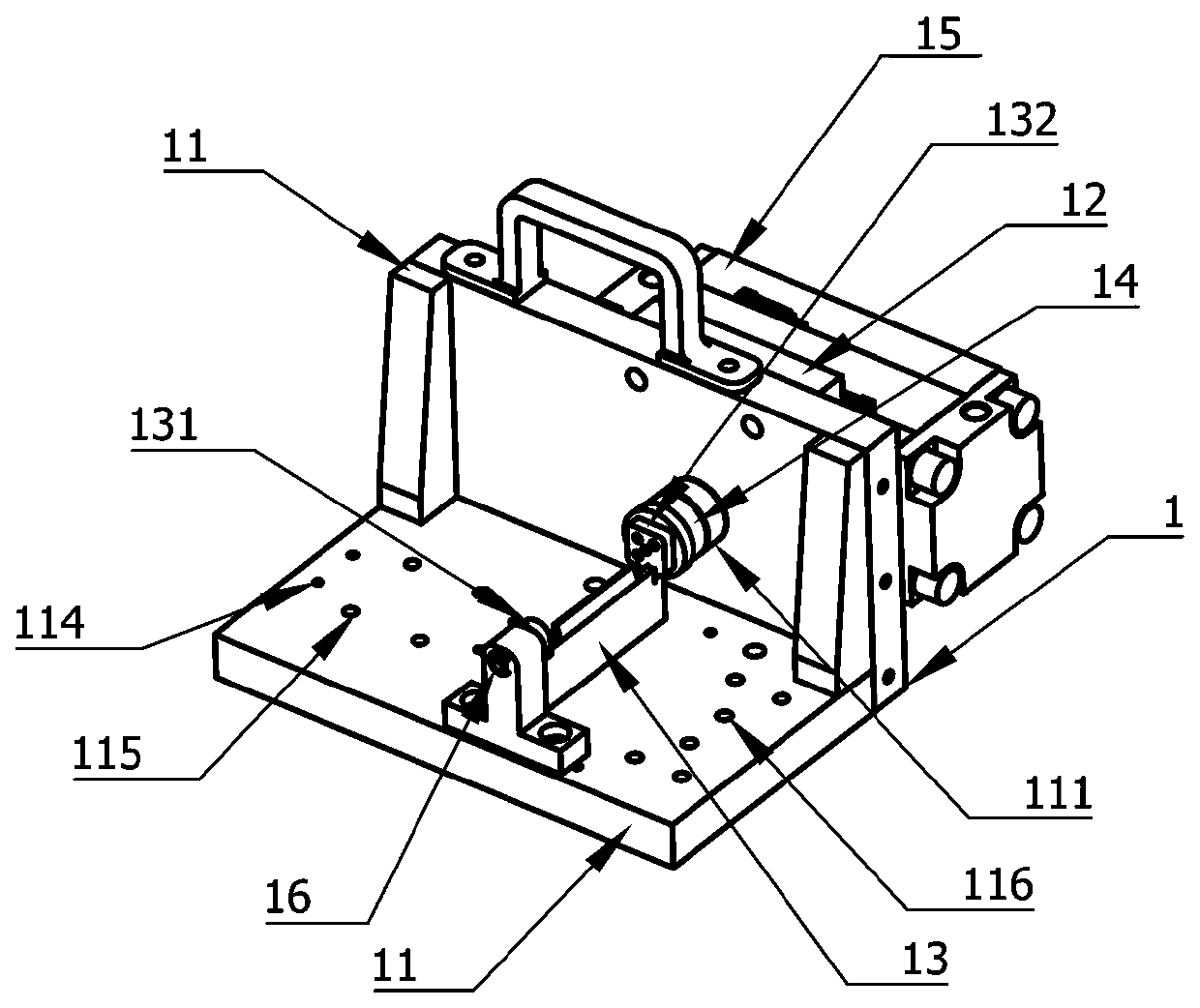

[0027] refer to figure 1 , image 3 , the bending device 1 is composed of a frame 11, a coupling 12, a bending plate 13, a main shaft 14, a rotary cylinder 15, and a secondary shaft 16; the frame 11 is arranged in an "L" shape by a base plate and a vertical plate , the main bearing seat 111 is provided on the vertical plate, the cylinder seat is provided on the outside of the vertical plate, the sub-bearing seat, the push rod seat 114, the guide rail seat 115 and the mold seat 116 are arranged on the base plate, the push rod seat 114, the guide rail The axes of the seat 115 and the tire seat 116 are collinear and the axis is parallel to the surface of the vertical plate.

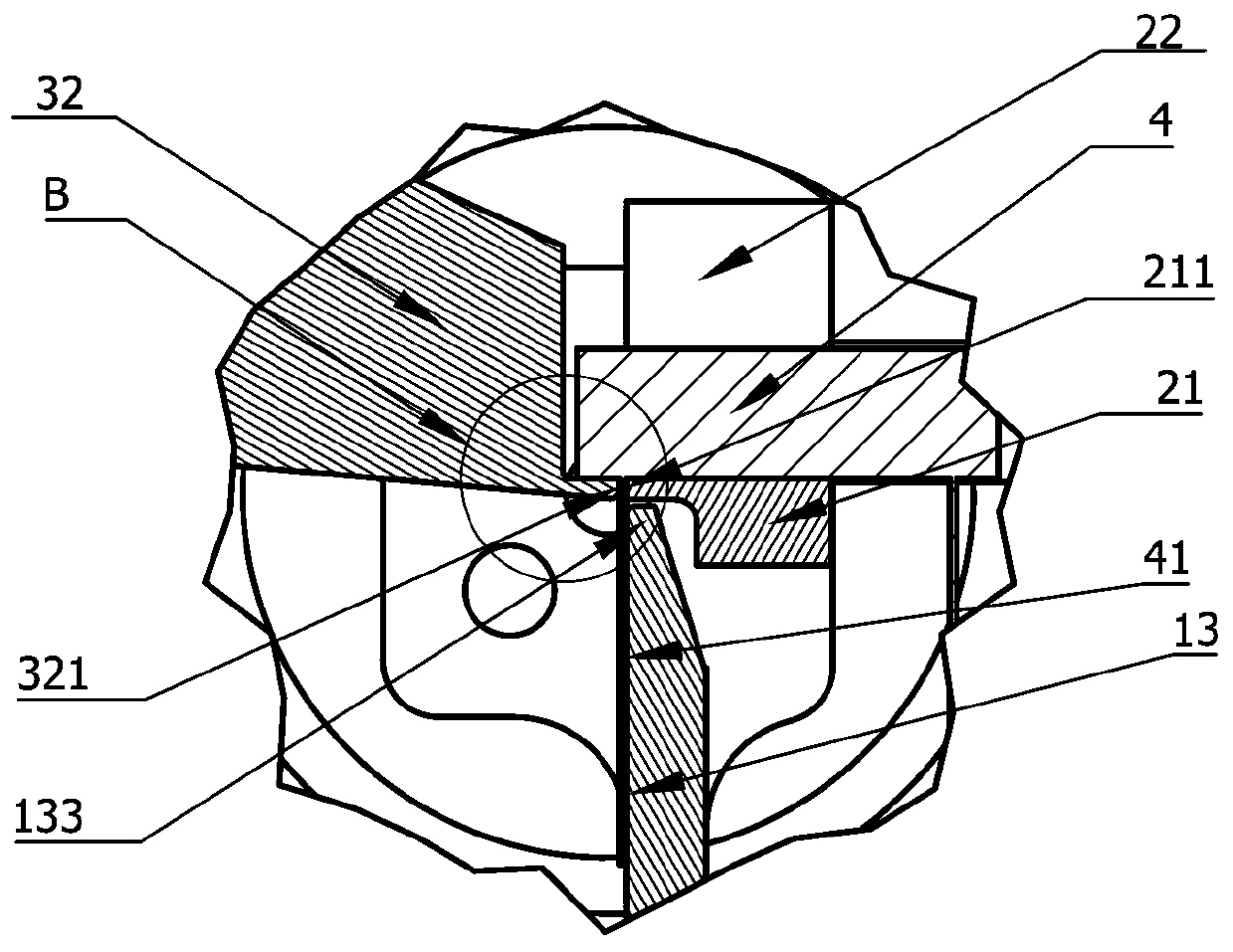

[0028] refer to figure 1 , image 3 , Figure 4 , the bent plate 13 is a plate with a shaft hole 131 at one end and a connection plate 132 at the other end;

[0029] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com