Electronic part bending mechanism

A technology of bending mechanism and electronic parts, which is applied in the field of bending mechanism of electronic parts, can solve the problems of inaccurate control of the angle of bending feet, hidden dangers of quality, low efficiency, etc., so as to ensure the uniformity and stability of bending, and the bending speed And the effect of uniform strength and saving waiting waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

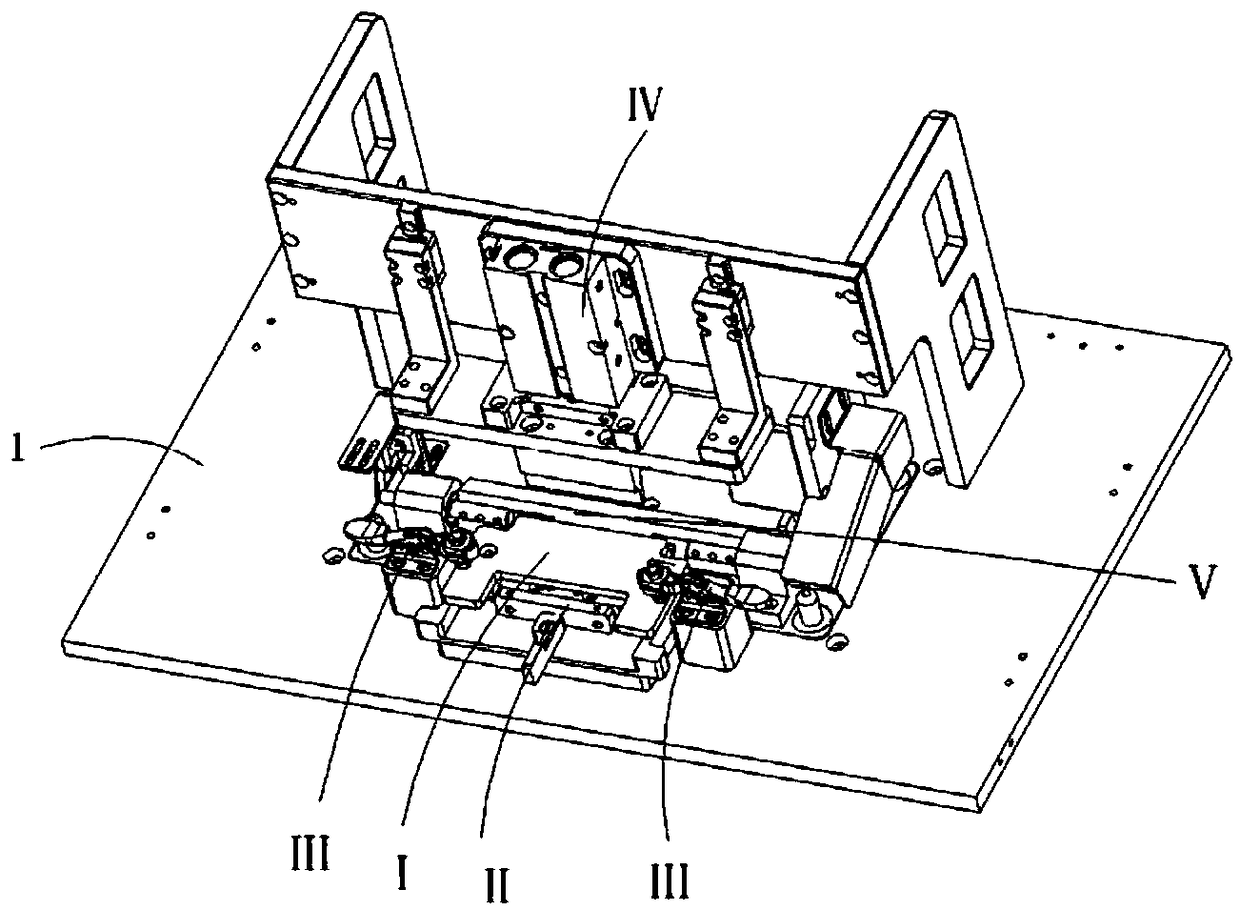

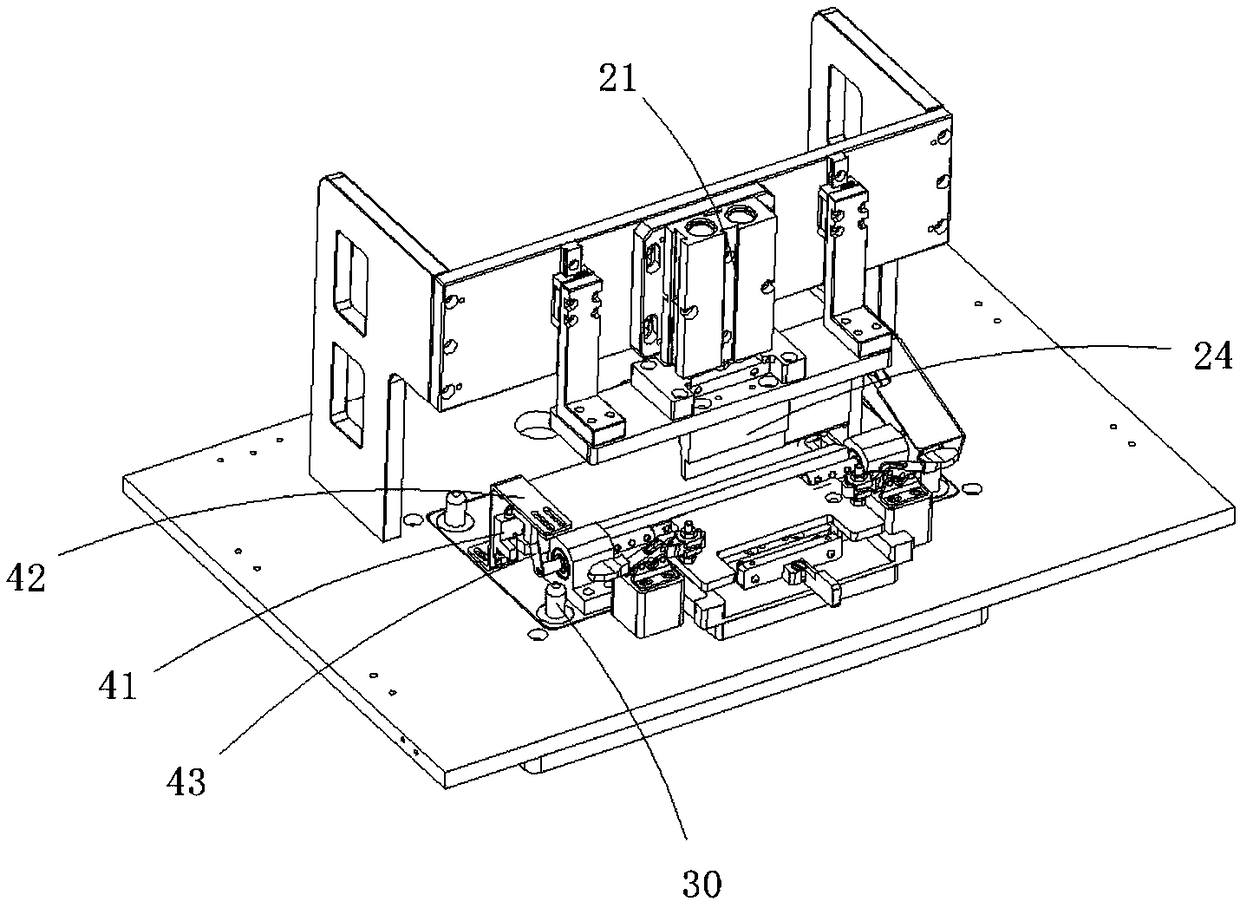

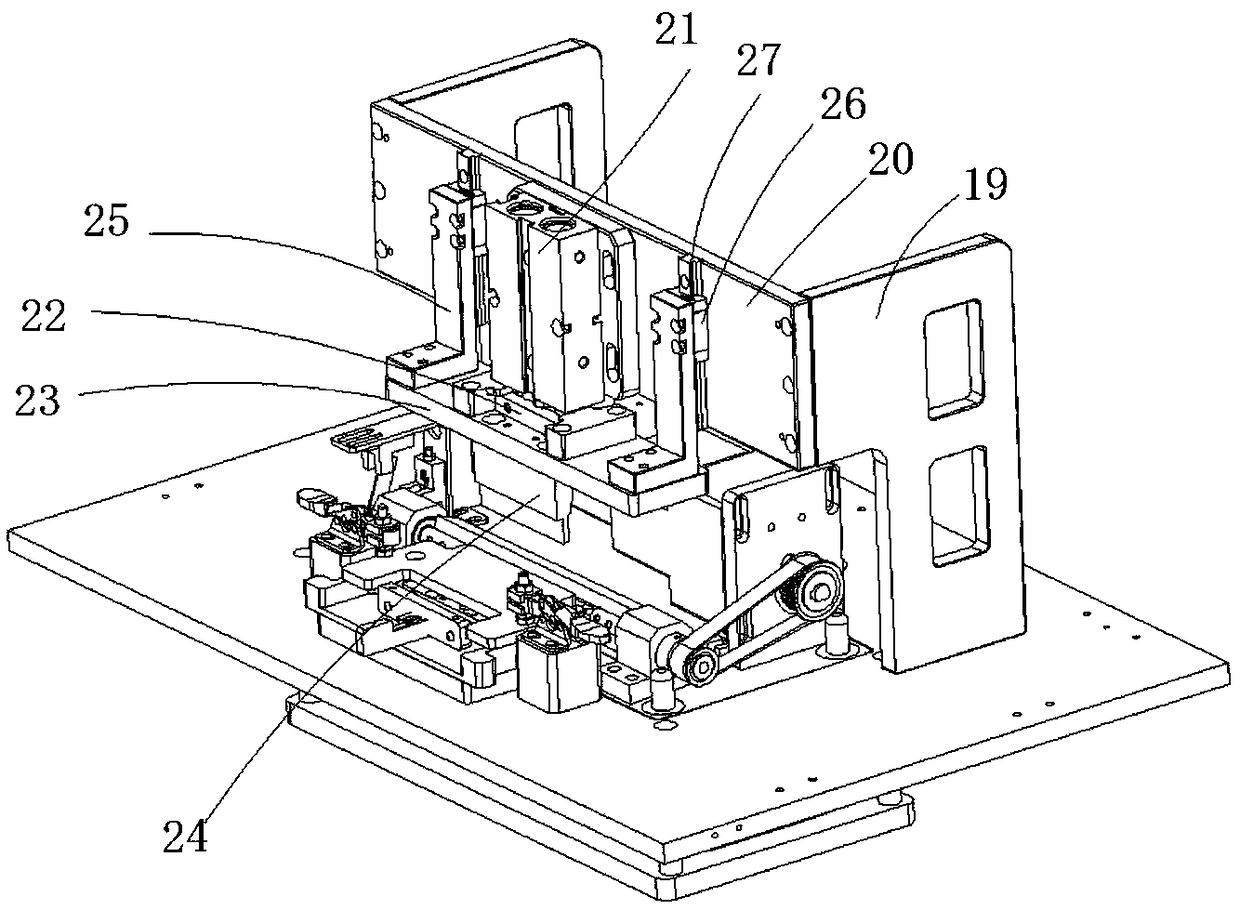

[0031] Examples, see attached Figure 1-10 , a bending mechanism for electronic parts, comprising a bottom plate 1, a carrier mechanism I is placed on the bottom plate, and a plurality of groups of electronic components 2 are arranged side by side in the carrier mechanism, the front ends of the electronic components are cylindrical structures, and the electronic components There are two pins 3 that need to be bent at the rear end of the component.

[0032] The carrier mechanism includes a carrier plate 4, and the carrier plate is provided with multiple sets of product placement slots 5, and electronic components 2 are placed in the product placement slots; the carrier plate is provided with a product limiting position behind the electronic components Device II, the carrier board is provided with a convex groove 6 at the position of the product limiting device, and the product limiting device includes a limiting fixed plate 7 fixed on the carrier plate by screws and a limiting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com