On-site reinforcing steel bar bending adjusting system for construction machinery

A mechanical and on-site technology, applied in the field of on-site steel bar bending system, can solve problems such as the inability to accurately grasp the angle of steel bar bending, the difference in the angle of steel bars, and the laborious use, so as to achieve safe and convenient use, good effect, and scientific and reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

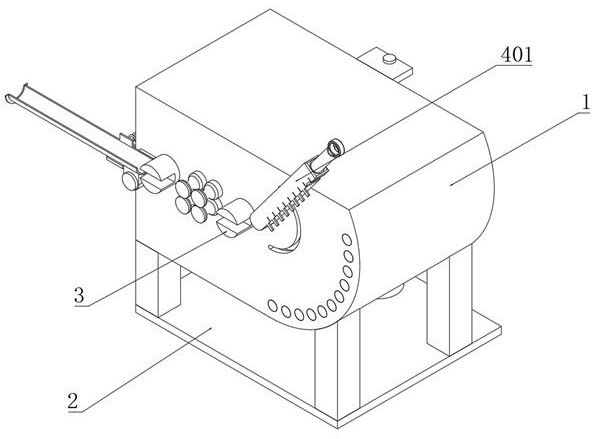

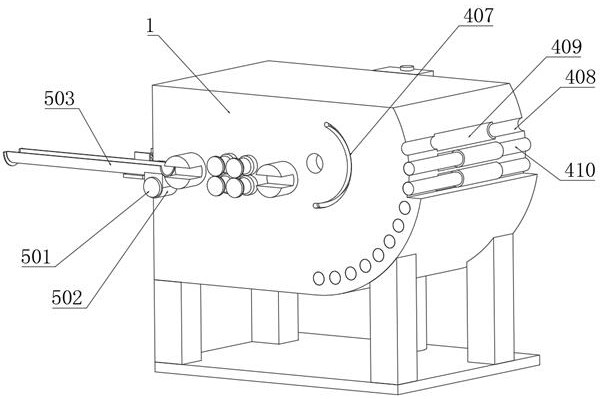

[0044] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, an on-site steel bar bending system for construction machinery, including a bending seat 1, a base 2 is installed on the bottom of the bending seat 1, and a front end of the bending seat 1 is installed There is a steel bar block 3, and the front end of the bending seat 1 is equipped with a bending assembly 4;

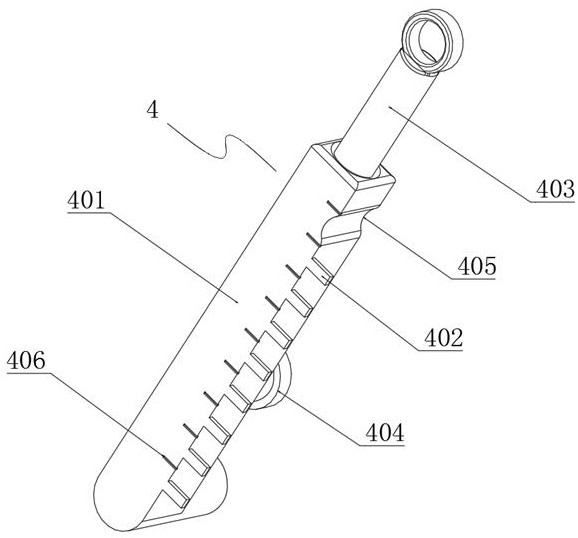

[0045] The bending assembly 4 includes a pressing rod 401, a stopper 402, a handle bar 403, a fixed block 404, a snap-in arc groove 405, a scale line 406, a rotating groove 407, a sliding hole 408, a limiting groove 409, a position limiting rod 410 and Limit cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com