Light emitting diode (LED) candle lamp

A technology of LED candle lamps and LED substrates, applied to lampshades, lighting devices, light sources, etc., can solve problems such as poor heat dissipation, easy failure, and repeated labor, and achieve improved stability and heat dissipation performance, and the bending angle can be adjusted The effect of adjusting and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present application is further described in conjunction with the following examples.

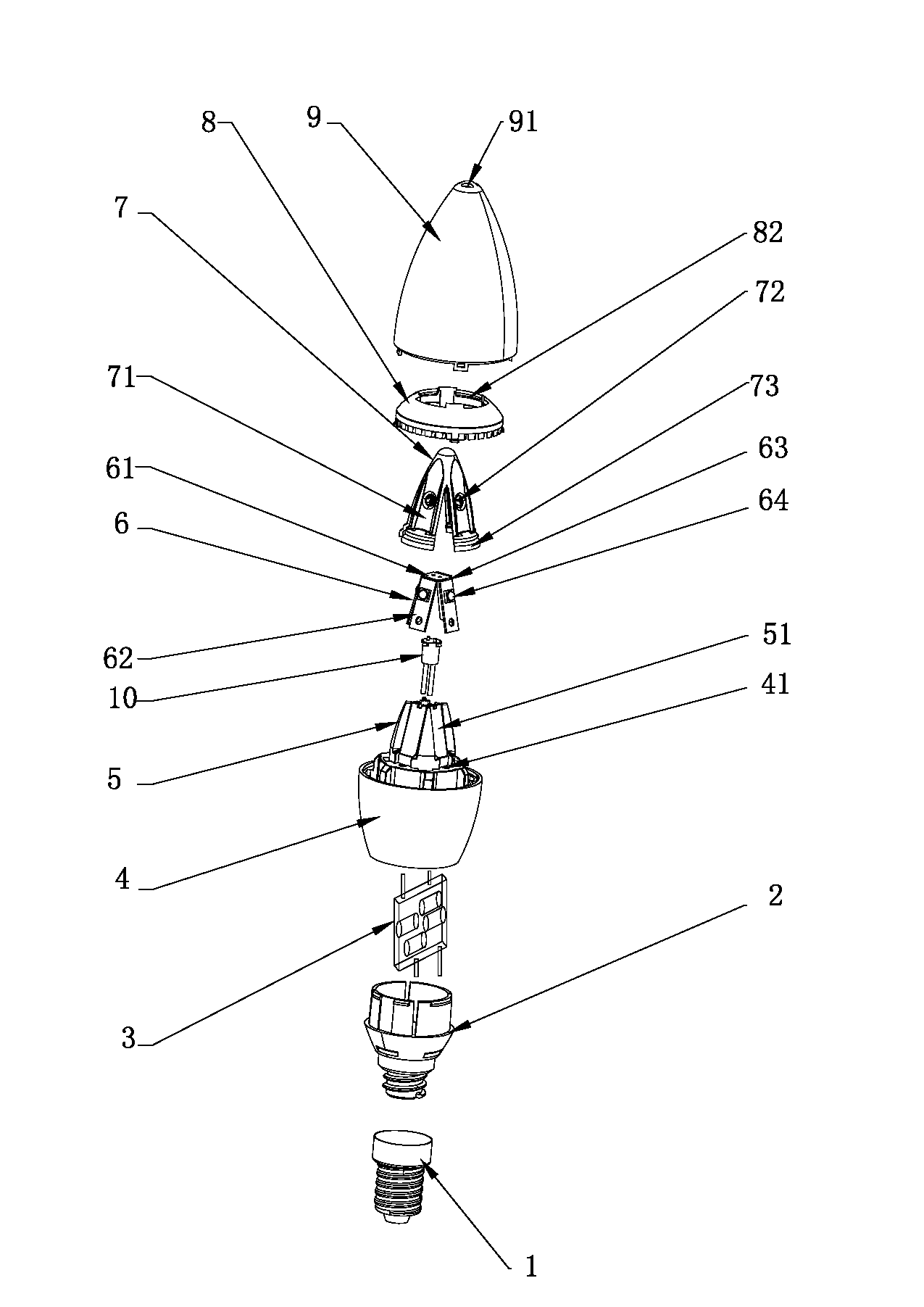

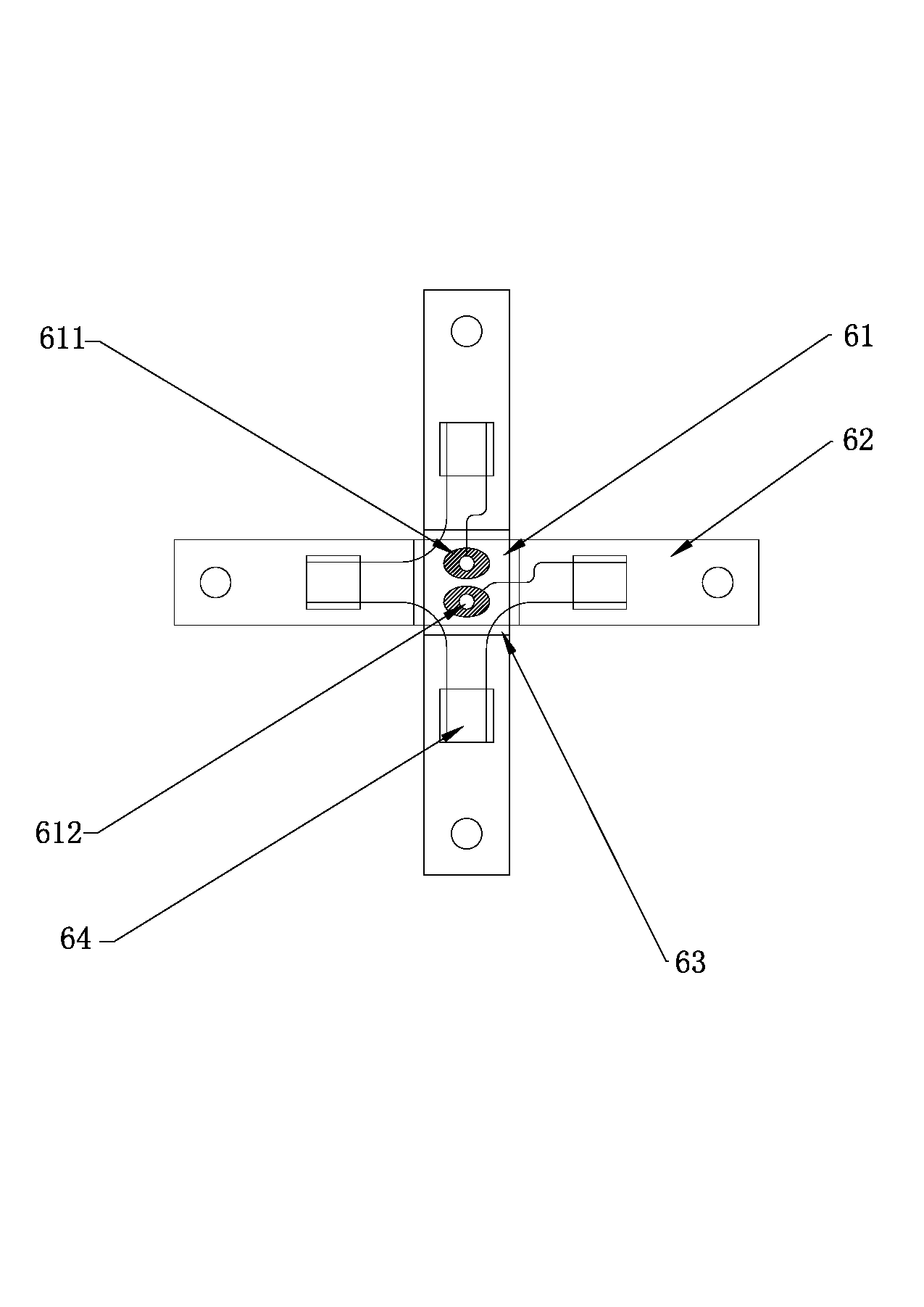

[0022] A specific embodiment of an LED candle lamp in the present application, such as figure 1 and figure 2 As shown, it includes: a base, a power supply assembly 3 is arranged inside the base, a radiator 4 is connected to one end of the base, and a heat conduction column 5 is fixedly arranged on the other end of the radiator 4, and the heat conduction column 5 is covered with A three-dimensional LED module substrate 6 formed by bending a flat plate is provided. The LED module substrate 6 includes a regular power connection area 61 and no less than two LED substrate areas connected to the power connection area 61 62, the connection between the power supply connection area 61 and the LED substrate area 62 is provided with a bendable crease area 63, and the power supply connection area 61 and the LED substrate area 62 sequentially include an aluminum base layer, an insulating lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com