Patents

Literature

44results about How to "Change bend angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

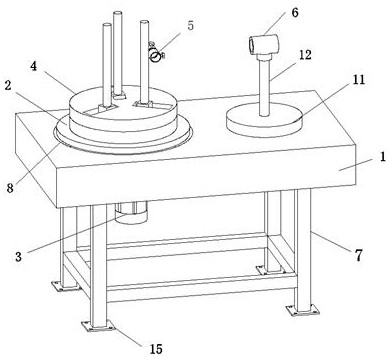

Copper pipe continuous bending device with discharging ejection device

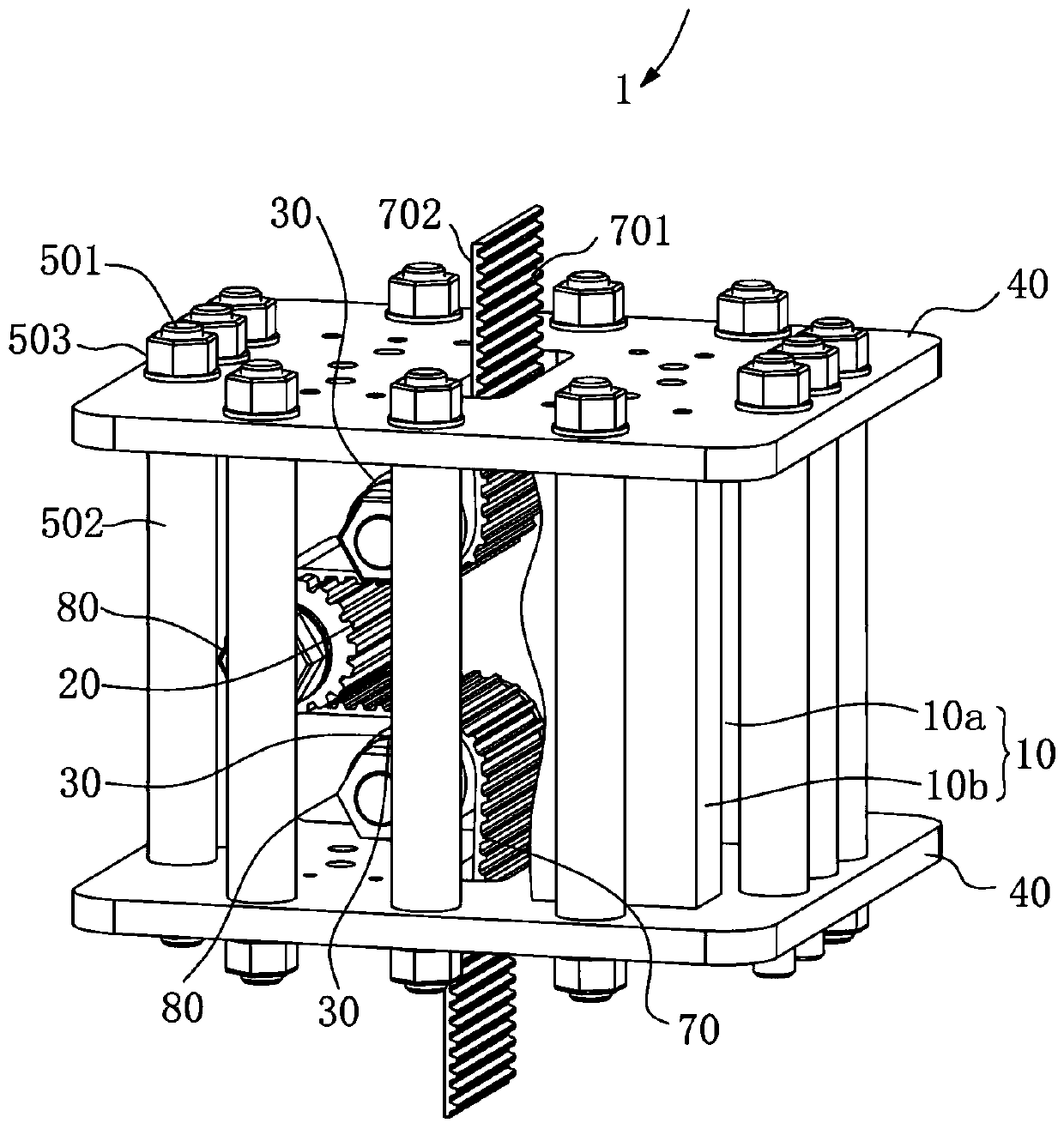

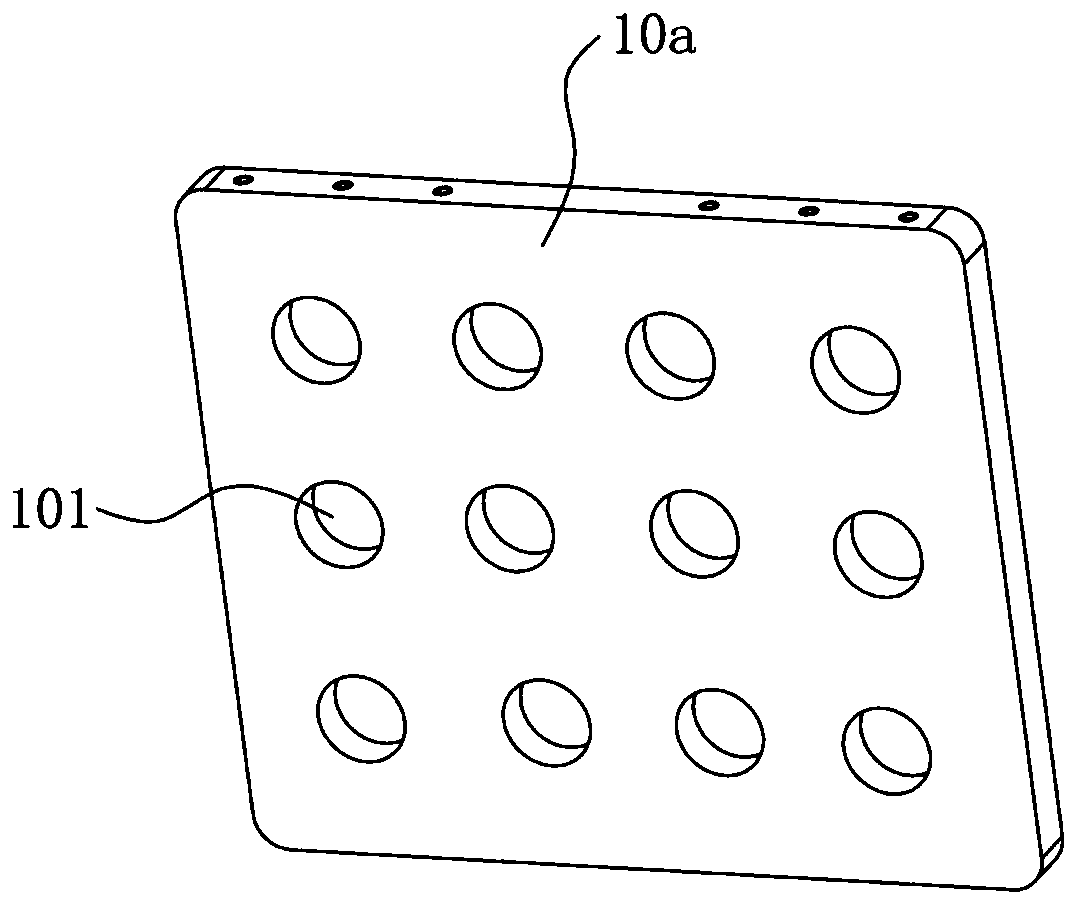

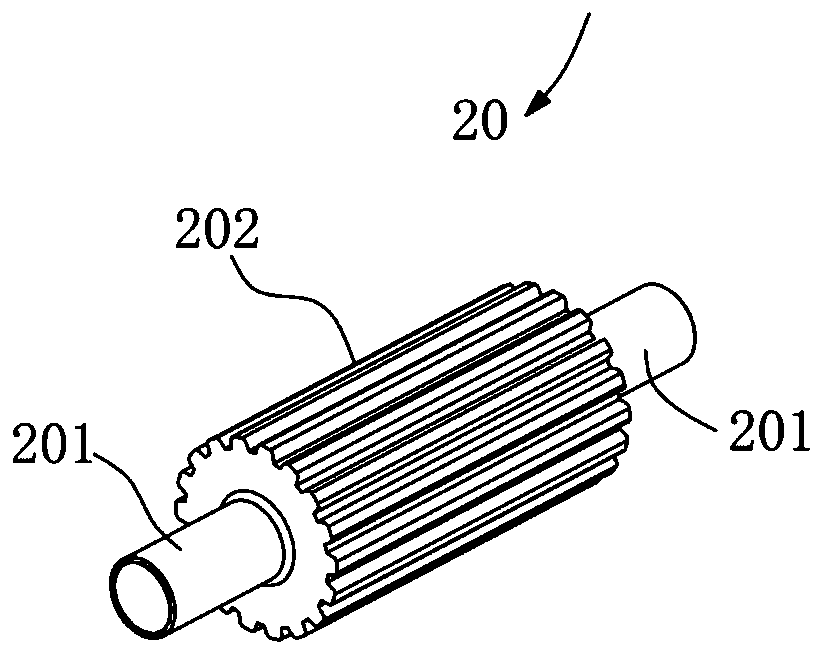

PendingCN109433874AReduce labor intensityChange bend angleShaping toolsMetal-working feeding devicesGear wheelEngineering

The invention relates to the technical field of bending devices, and discloses a copper pipe continuous bending device with a discharging ejection device. The copper pipe continuous bending device comprises a machine body; a right supporting rod is fixedly installed on the right side of the top of the machine body, a motor is fixedly installed at the bottom of an inner cavity of the machine body,and a master gear is fixedly arranged on an output shaft of the motor in a sleeve mode; and the bottom end of the main gear is connected to a sub-gear in a meshed mode, a screw rod is fixedly arrangedin the middle of the sub-gear in a sleeve mode, the top end of the screw rod penetrates through the right supporting rod to extend into the interior of the right supporting rod, and a connecting rodpositioned inside the right supporting rod is arranged on the outer surface of the screw rod in a threaded mode. According to the copper pipe continuous bending device with the discharging ejection device, an ejection rod, an ejection head and an ejection spring are arranged, when the bending is completed, an upper bending head is separated from a copper pipe, the acting force of the ejection spring pushes the ejection rod and the ejection head to rise, so that the copper pipe is ejected out, and the labor intensity of workers is reduced.

Owner:XINGHUA CHUNDA COPPER IND

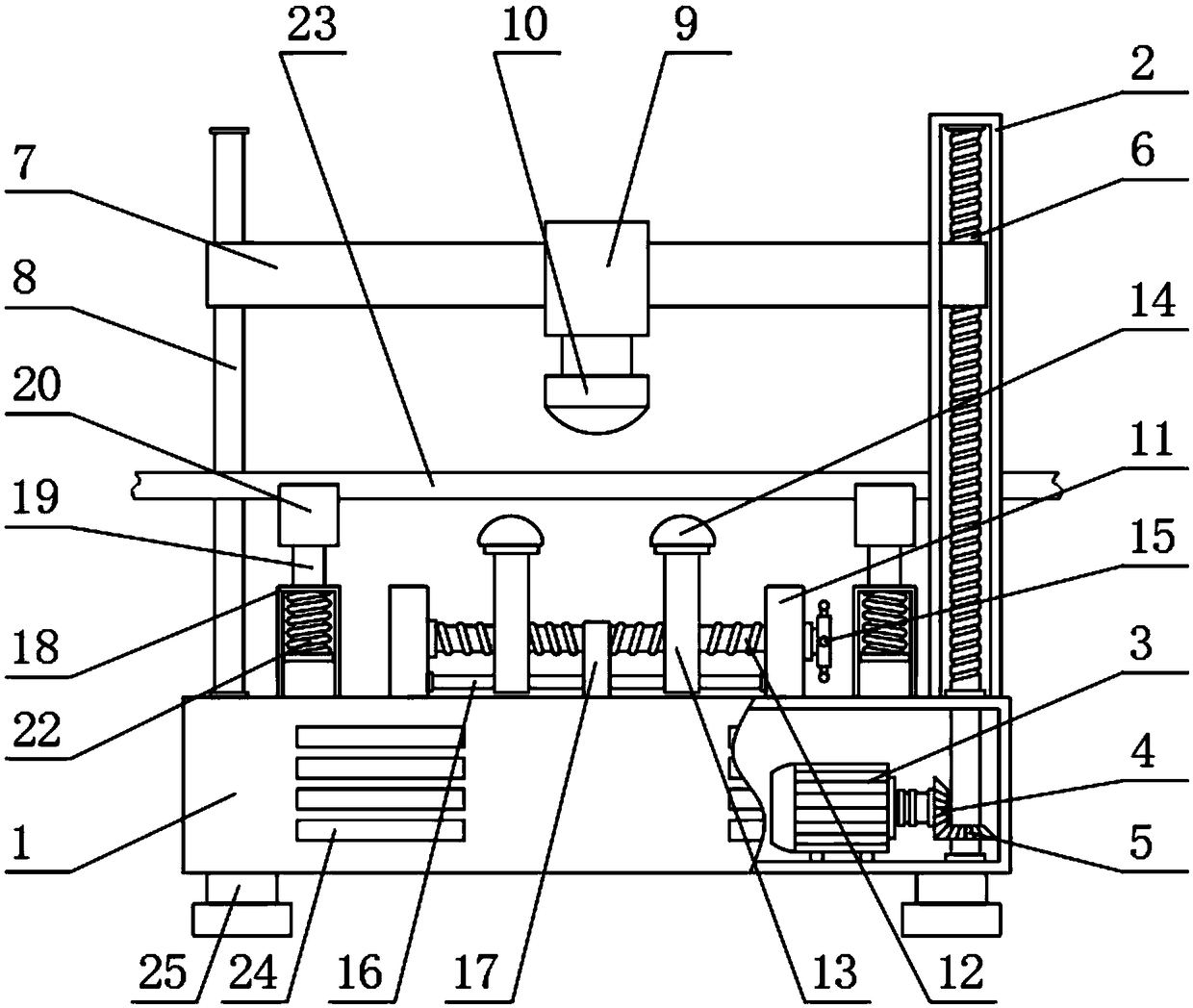

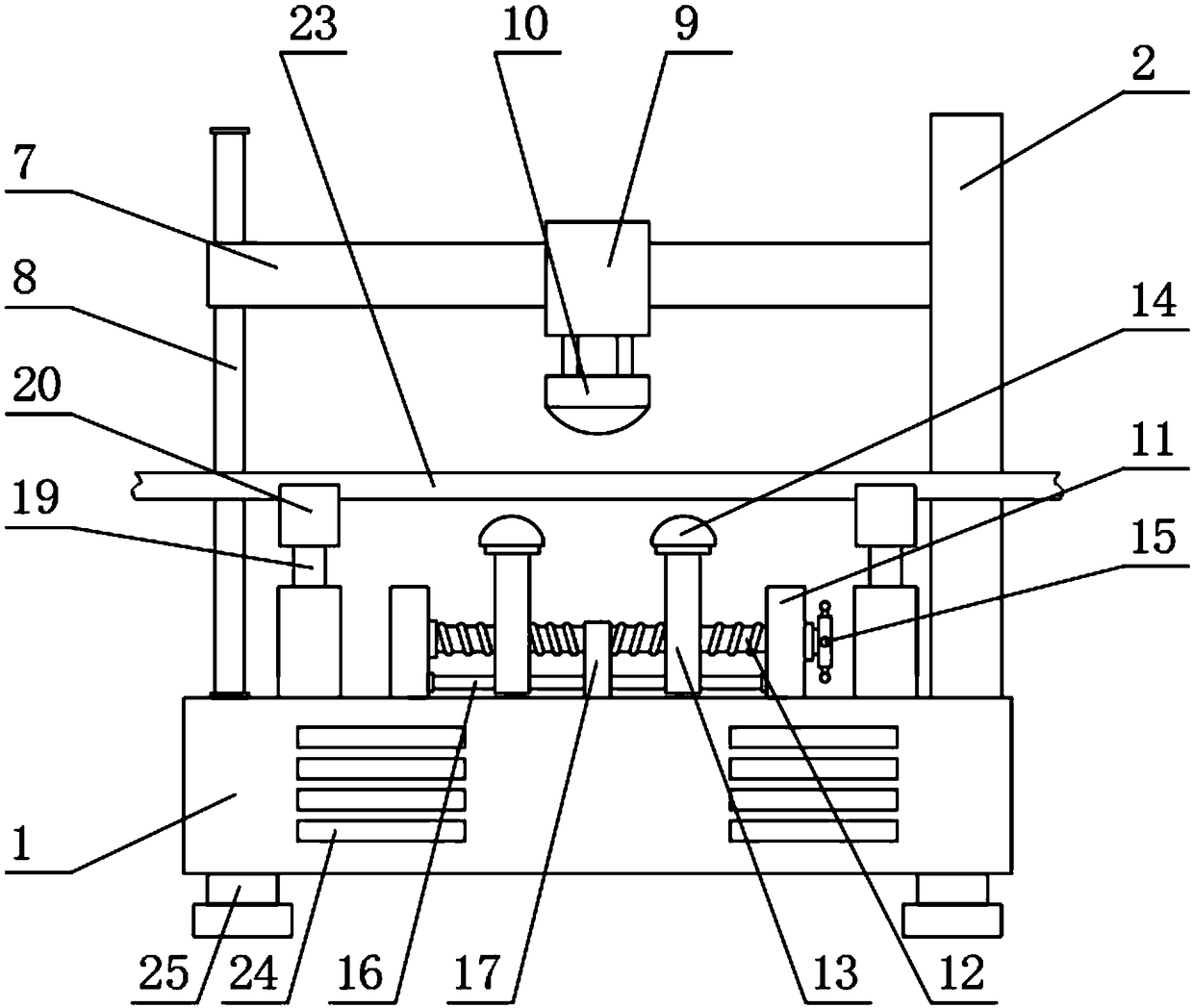

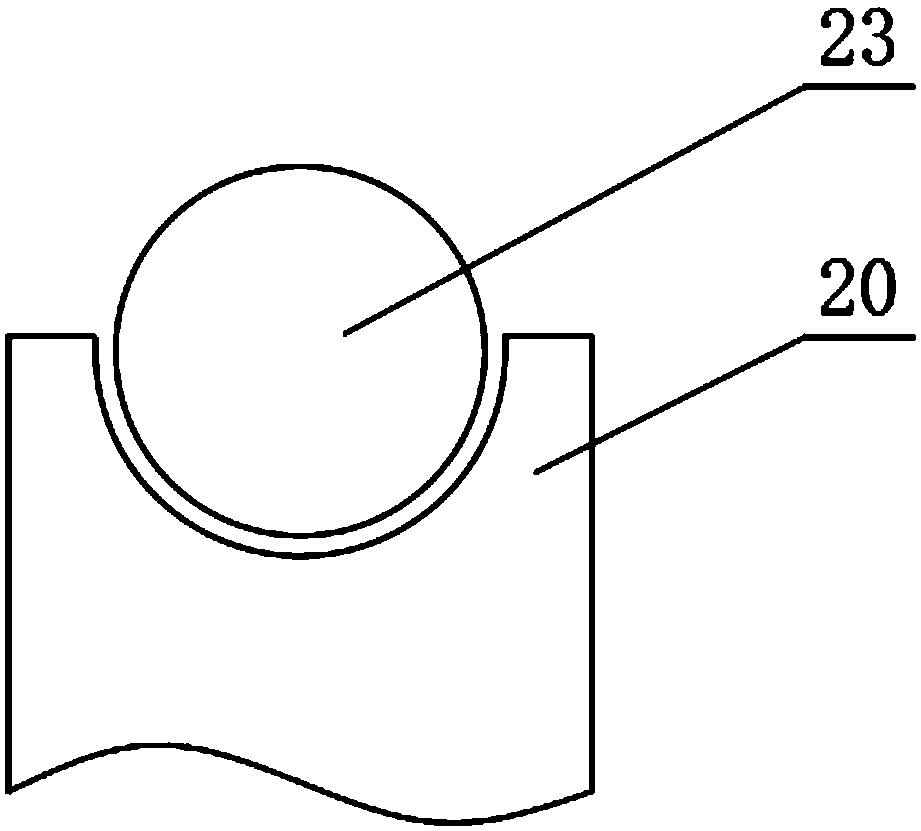

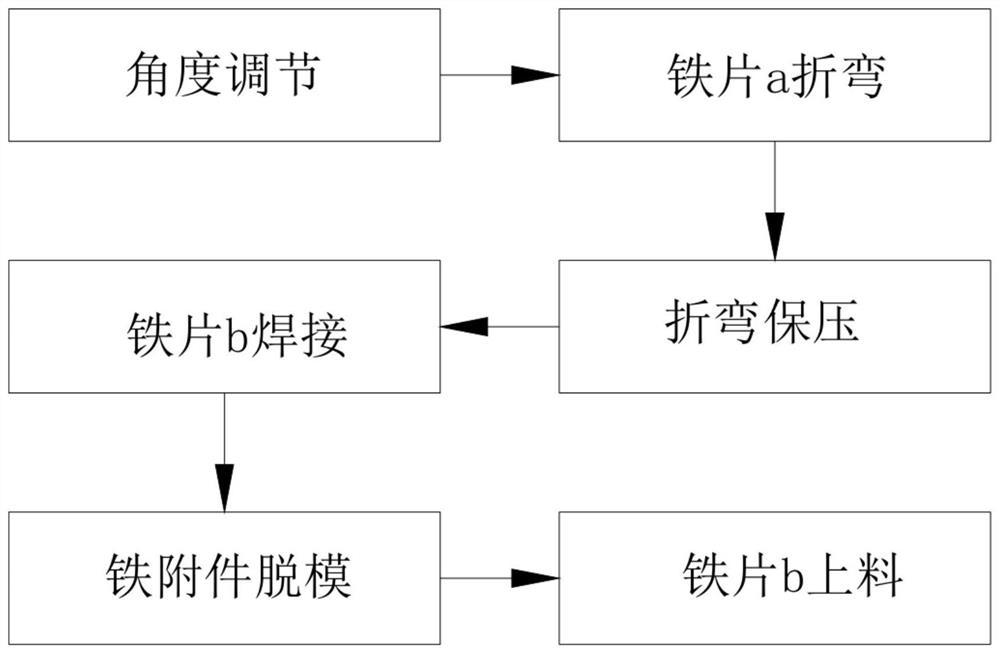

Iron accessory multi-angle bending method

ActiveCN112828084AImprove bending accuracyAvoid displacementMetal-working feeding devicesWelding/cutting auxillary devicesEngineeringMechanical engineering

The invention relates to an iron accessory multi-angle bending method. The method comprises the following steps that angle adjustment is conducted, and a pin is inserted into a corresponding limiting hole according to the bending angle so as to change the height of a limiting frame matched with the pin on a support; an iron sheet a is bent, a fixing plate moves downwards, pressing plates make contact with the iron sheet a, and then ejector rods drive the pressing plates and bottom plates to rotate at the same time to bend the iron sheet a till the bottom plates abut against the limiting frame; bending and pressure maintaining are conducted, the fixing plate continues to move downwards, the ejector rods rotate, and the ends move along the upper surfaces of the pressing plates; an iron sheet b is welded, a transmission assembly a acts to drive a swing arm to rotate, a gripper places the iron sheet b on the iron sheet a, and then the iron sheet a and the iron sheet b are welded to form an iron accessory; a welded part is demolded, the fixing plate moves upwards, the pressing plates and the swing arm rotate and reset, and then a roll shaft rotates to drive the iron sheet a to move to the bottom plate and eject the iron accessory away; and the iron sheet b is fed, and an air cylinder drives the iron sheet b to be clamped into the gripper. By means of the iron accessory multi-angle bending method, continuous production of the iron accessory can be achieved.

Owner:HUZHOU COLLEGE

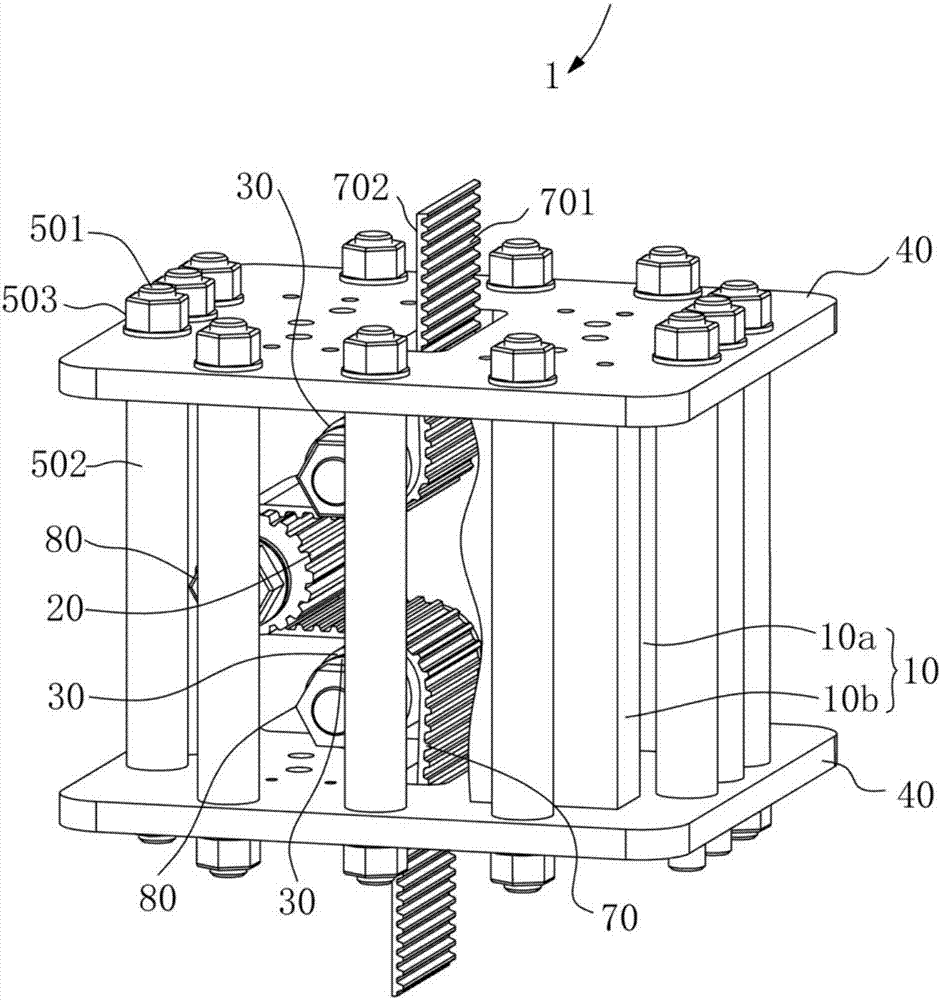

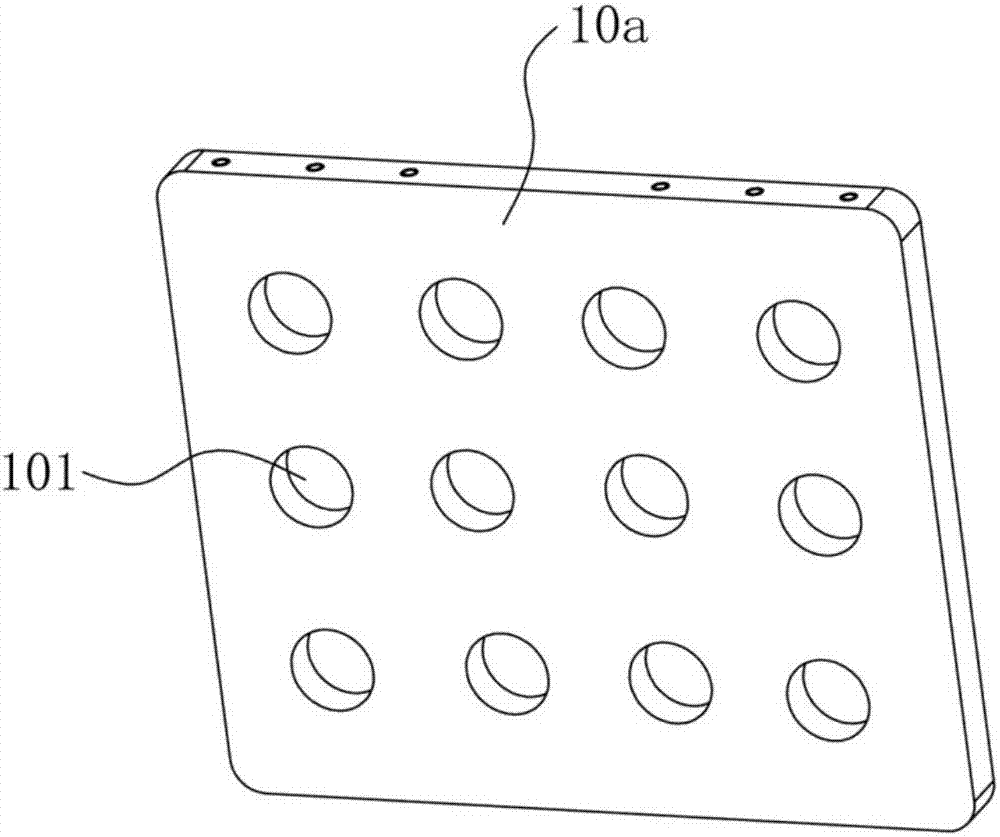

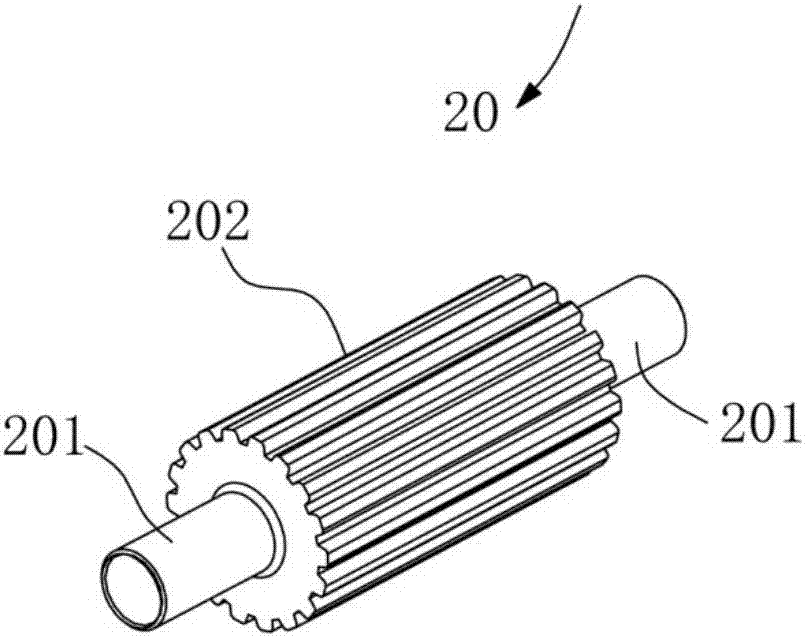

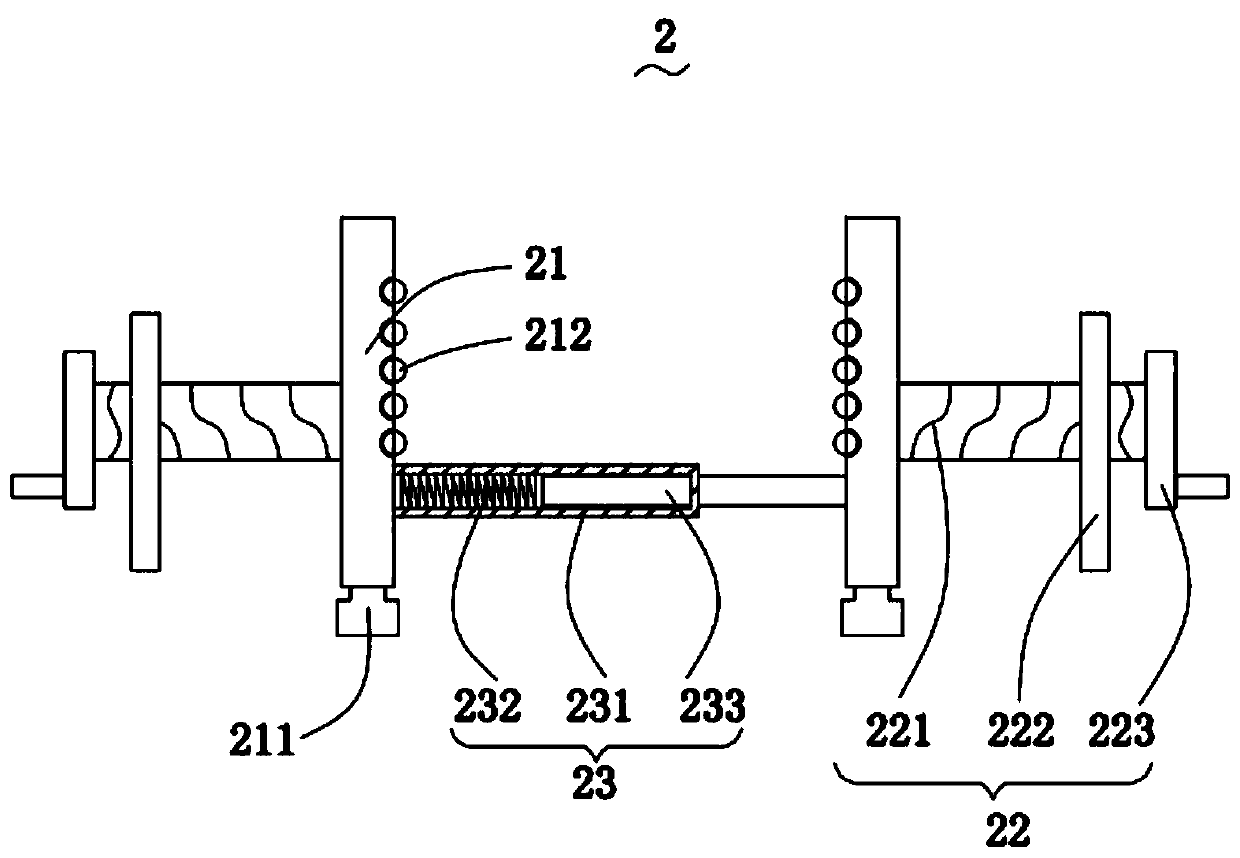

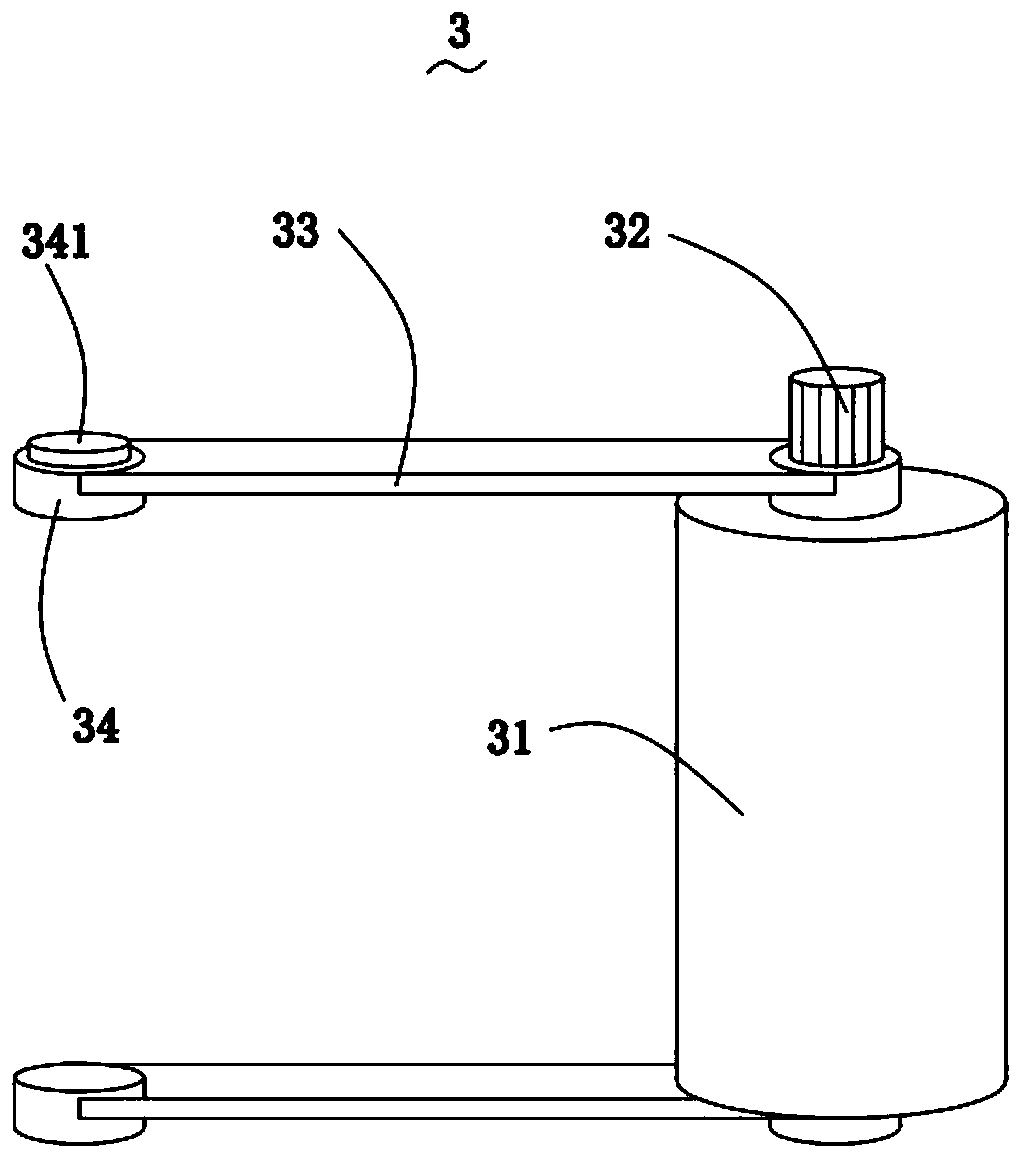

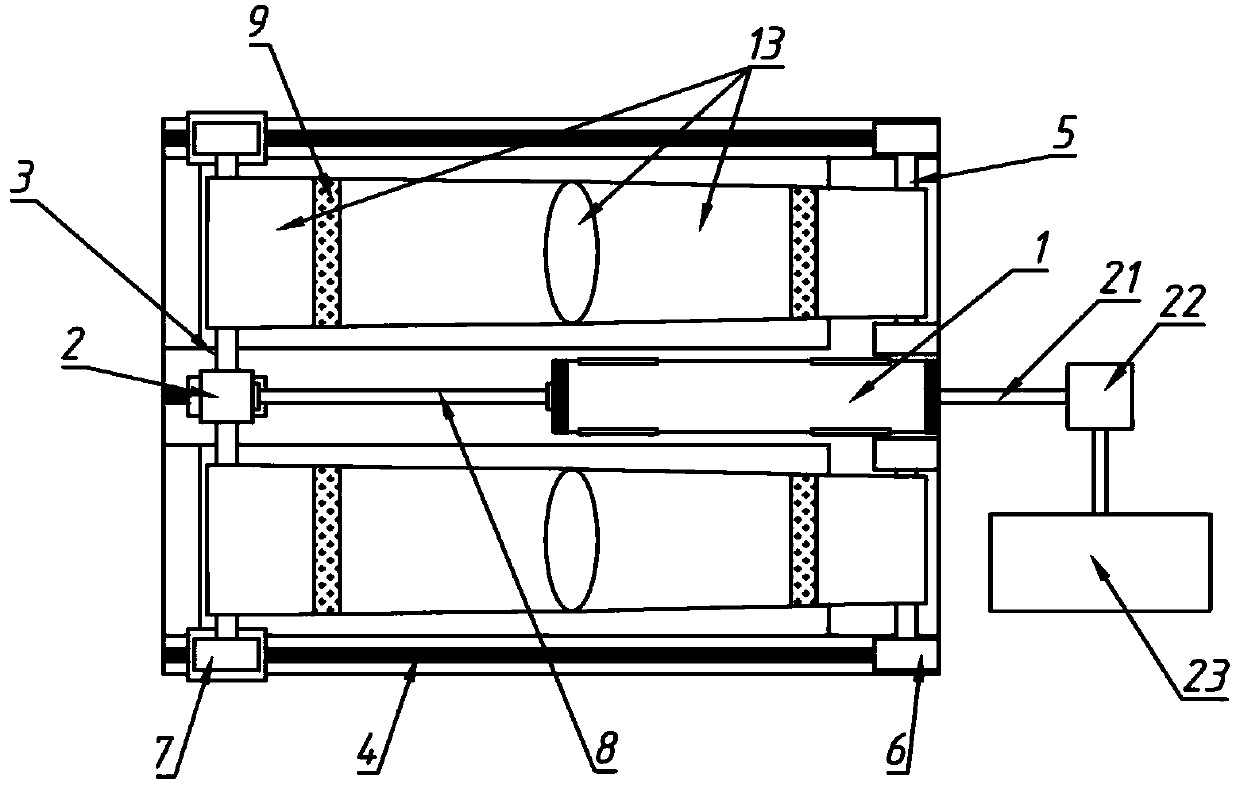

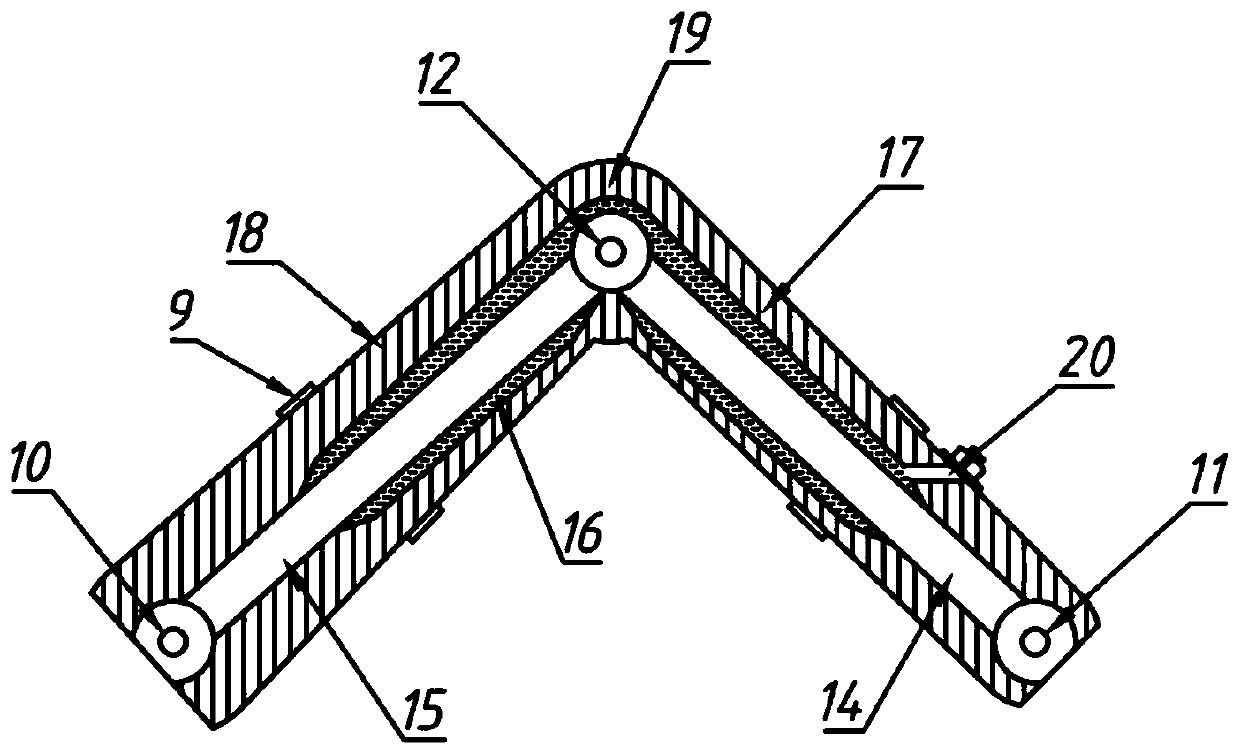

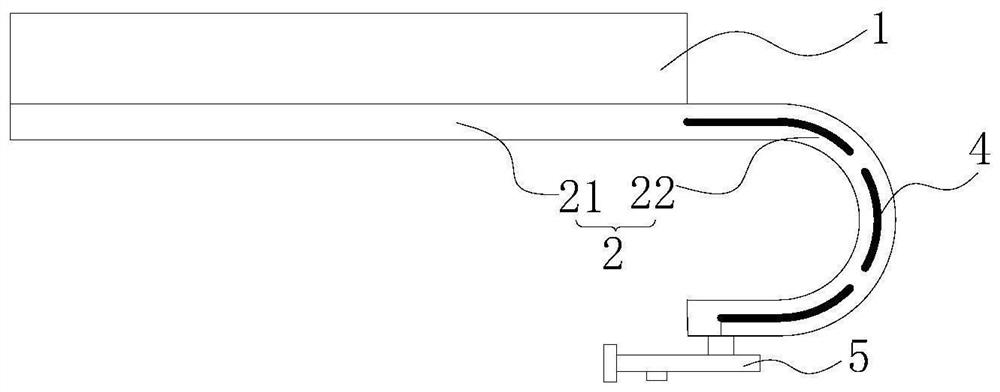

Driving belt fatigue testing tool, fatigue testing machine, and fatigue testing method

ActiveCN106969912AChange bend angleSatisfy fatigue propertiesMachine gearing/transmission testingEngineeringBending force

The invention relates to a driving belt fatigue testing tool, a fatigue testing machine, and a fatigue testing method, and the tool, machine and method are used for the fatigue testing of a driving belt. The tool comprises a supporting frame, a belt pulley, and a tension pulley. The supporting frame comprises an installation part, and the tension pulley and / or the belt pulley are / is connected to the installation part in an adjustable manner. The axis of the belt pulley and the axis of the tension pulley are parallel to each other, and the bending angle of a to-be-tested driving belt wound around the belt pulley and / or the tension pulley can be adjusted. Through the adjustment of the belt pulley and / or the tension pulley, the tool can change the bending angle of the to-be-tested driving belt wound around the belt pulley and / or the tension pulley, and can meet the demands of the testing of fatigue characteristics and service life of the driving belt in different bending force states.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

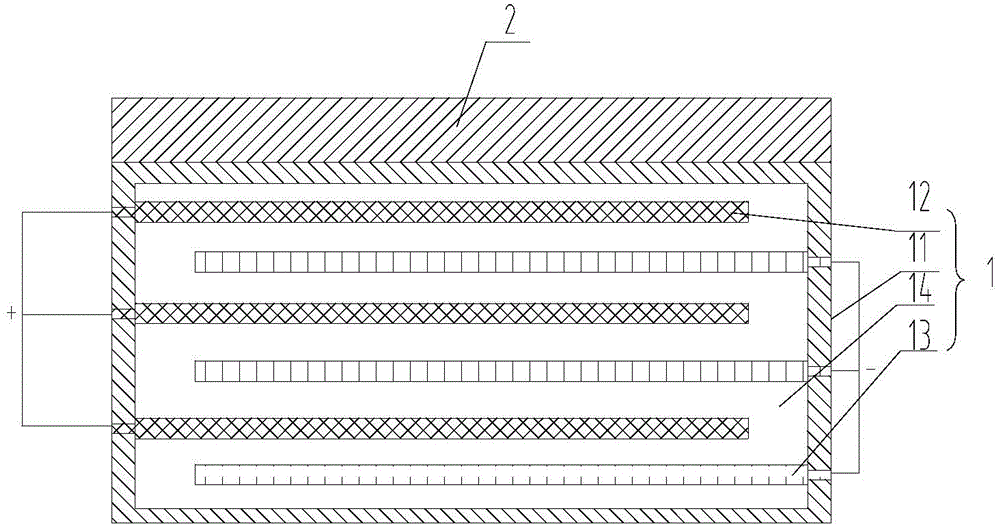

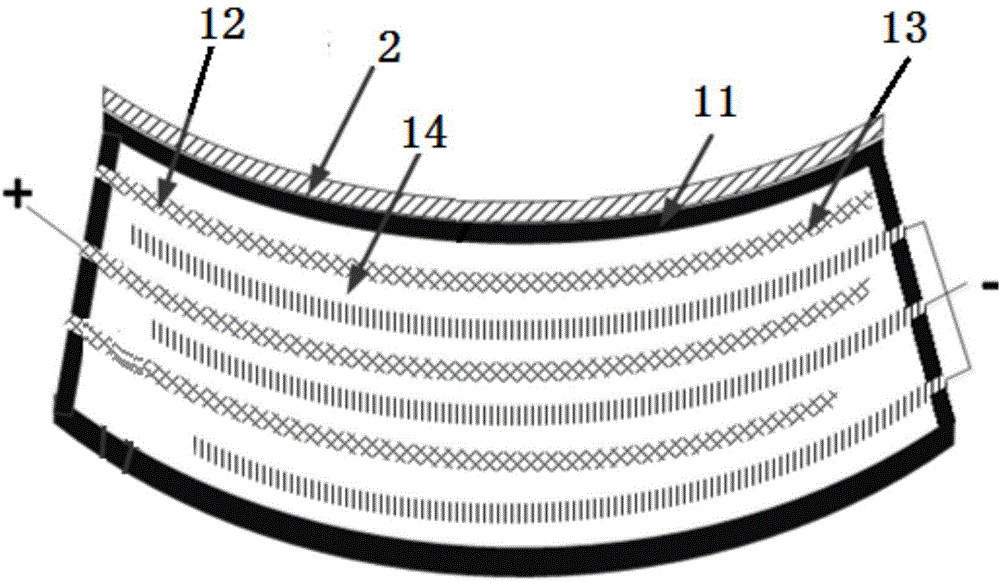

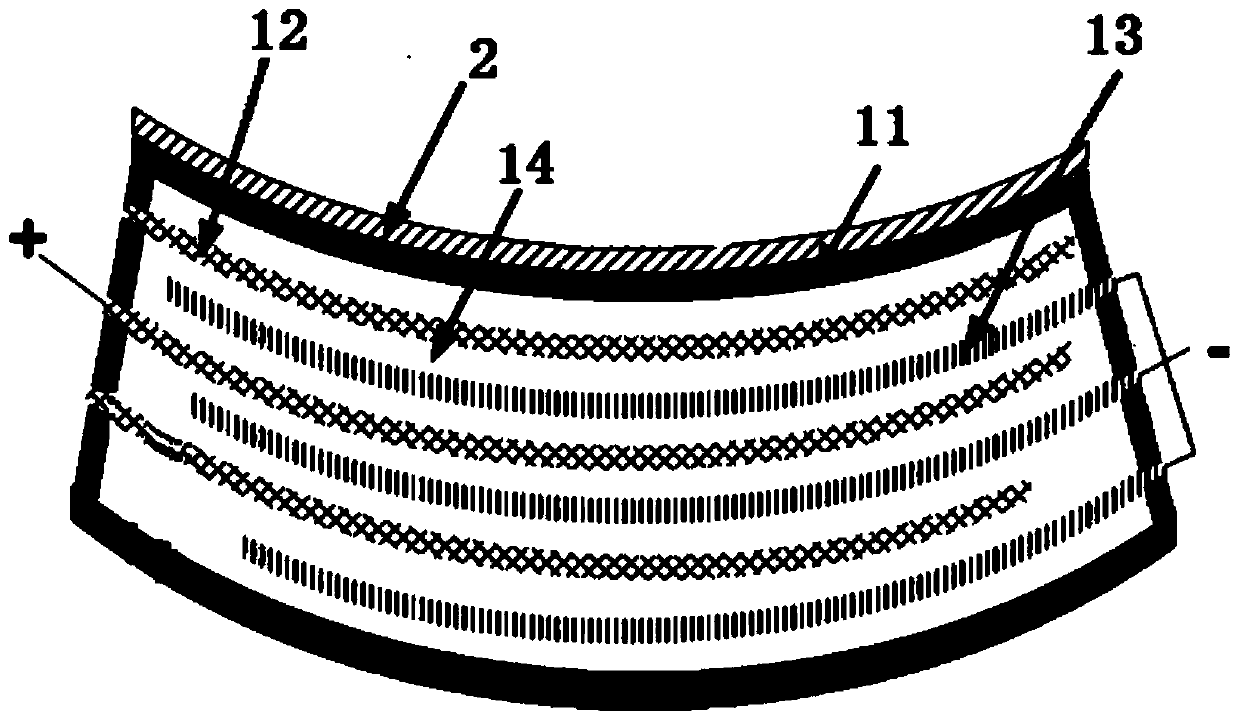

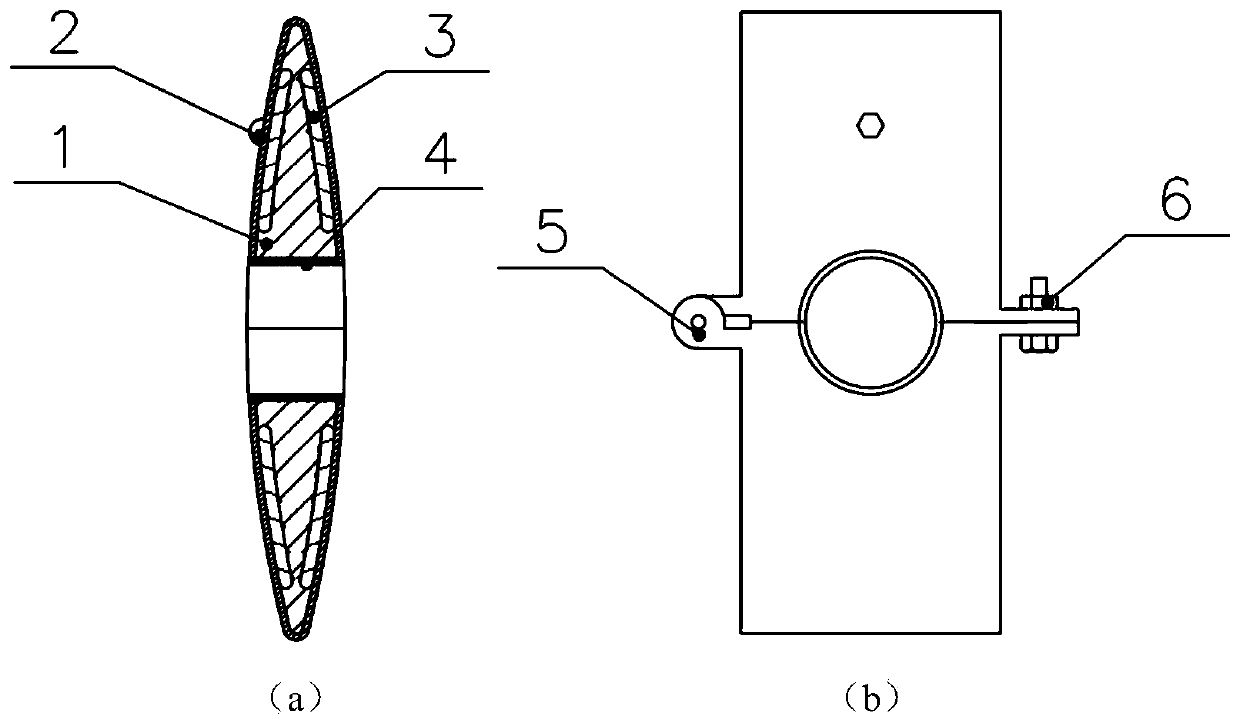

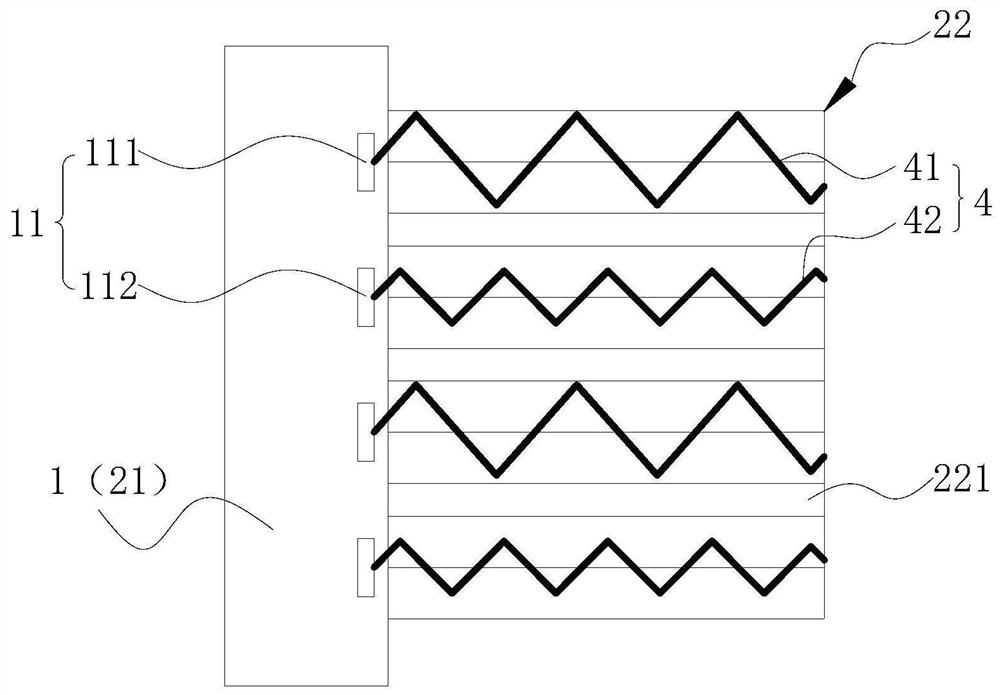

Flexible display device

InactiveCN104658430ARealize free switchingChange bend angleIdentification meansEngineeringFlexible display

The invention discloses a flexible display device. The flexible display device comprises a flexible screen body and a flexible support body, wherein the flexible screen body is attached to the flexible support body; the flexible support body comprises a cathode layer, an anode layer and a flexible coating structure for forming a sealed cavity; the cathode layer and the anode layer are arranged in the flexible coating structure at a certain interval, and are relatively fixedly connected with the flexible coating structure; a current variant is filled into the flexible coating structure. The anode layer and the cathode layer are arranged in the sealed cavity formed by the sealing coating structure, and are connected with a power supply respectively; voltage is applied between the anode layer and the cathode layer, and the static yield stress is increased after the current variant is electrified, so that the flexible coating structure formed by folding at a certain angle is supported in a limited way, and free switching of a flexible terminal between flexibility and inflexibility is realized; and the flexible display device can be fixed at any bending angle, so that the practicability of the flexible display device is enhanced.

Owner:BEIJING VISIONOX TECH

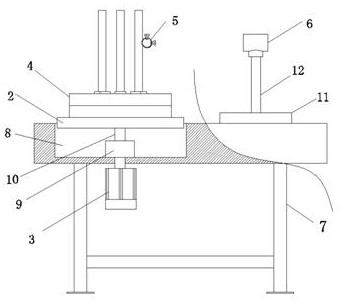

Sheet metal part bending forming equipment

ActiveCN112845704AImprove assembly accuracyImprove the pressing effectShaping toolsMetal-working feeding devicesEngineeringPhysics

The invention provides sheet metal part bending forming equipment. The equipment comprises a base, lifting equipment, an upper mold, a lower mold, an assembling device and a feeding device, wherein the upper mold comprises a pressing assembly and a bending assembly; the lower mold comprises a positioning assembly and an adjusting assembly; the assembling device comprises a feeding assembly and a conveying assembly; and the feeding device comprises a storage assembly and a driving assembly. According to the sheet metal part bending forming equipment, the bending assembly and the positioning assembly are driven through downward movement of the pressing assembly to rotate to carry out bending and pressure maintaining on an iron sheet a, and meanwhile, the pressing assembly is matched with the conveying assembly and the driving assembly to achieve part assembling and feeding and discharging work, so that the technical problem that in the prior art, pressure maintaining cannot be carried out on a bent sheet metal part is solved.

Owner:HUZHOU COLLEGE

Adjustable mechanical bending die

Owner:SUZHOU HUICHENG PRECISION MOLD

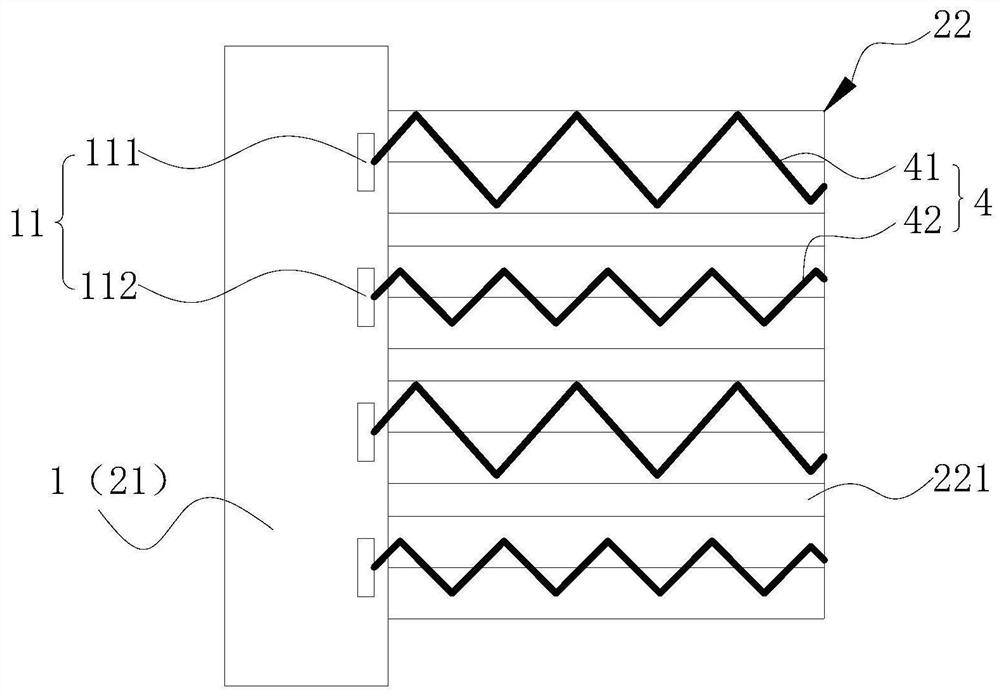

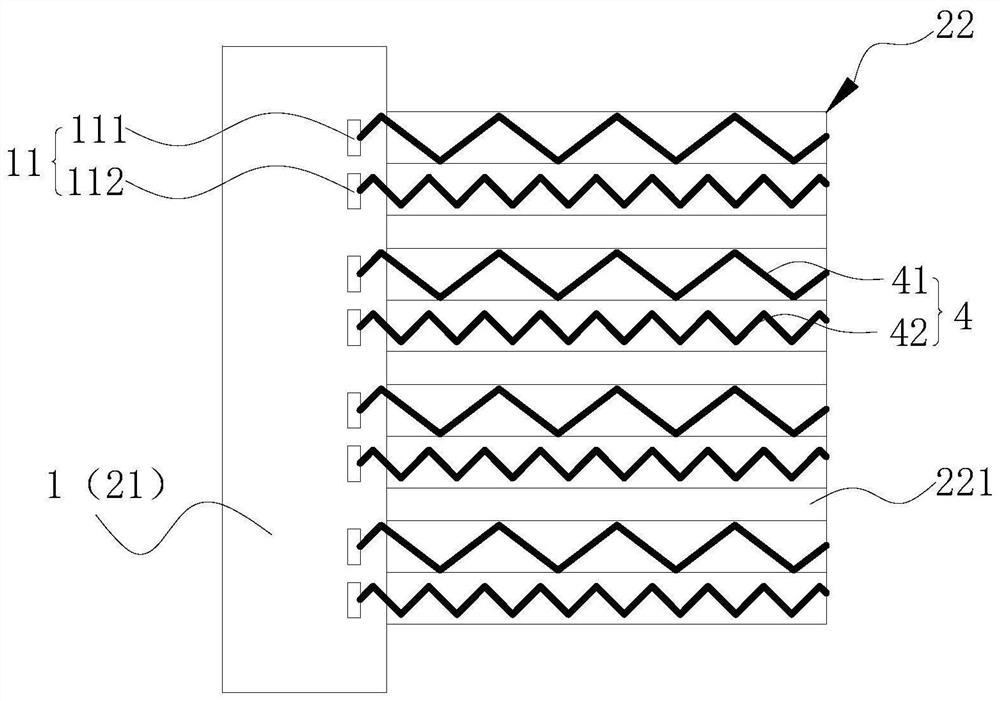

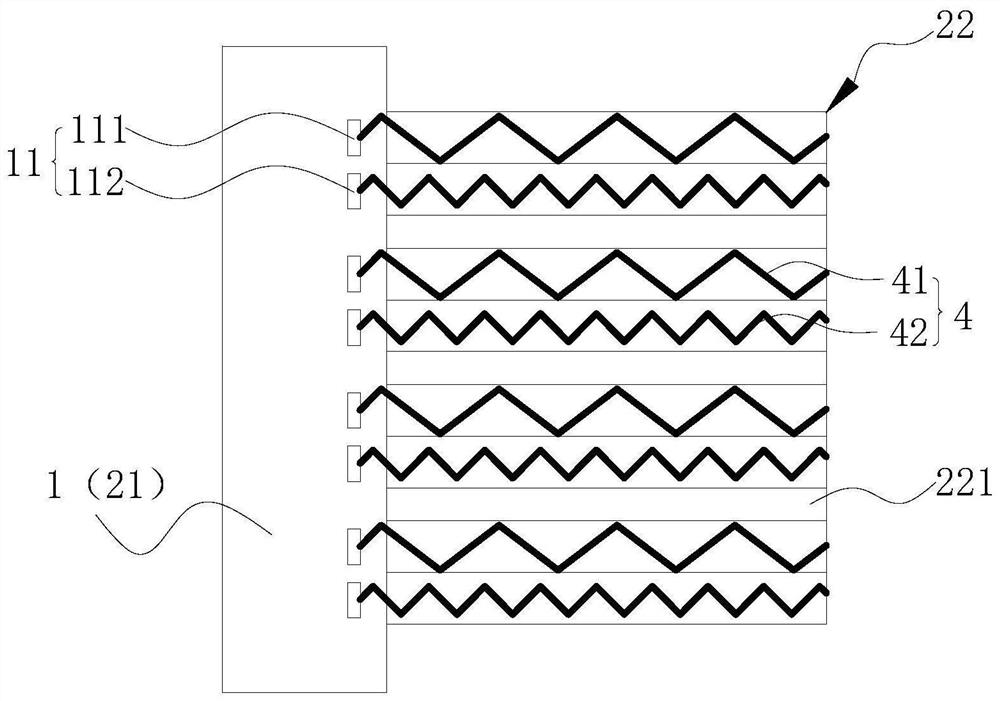

Display screen and display device

ActiveCN111627331AChange bend angleReduce the magnitude of the tensile stressPrinted circuit detailsIdentification meansDisplay deviceElectrical connection

The invention provides a display screen and a display device. The display screen comprises a display panel and a flexible substrate, the display panel comprises a plurality of adjacently-arranged gaskets, the flexible substrate comprises a display part and a bending part, a plurality of protrusions are arranged on the first surface of the bent part, at least one metal wire is arranged on the surface of each protrusion, and each metal wire is electrically connected with the corresponding gasket. On one hand, when the bending part is bent, the metal wire is attached to the surfaces of the protrusions to form a three-dimensional structure, so that the bending angle of the metal wire is changed, the tensile stress borne by the metal wire is reduced, and the stability of connection between thedisplay panel and a PCB is guaranteed; and on the other hand, the length of the metal wire can be increased, so that when the metal wire is bent, the increased length can effectively compensate for the increased length required by stretching of the metal wire.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

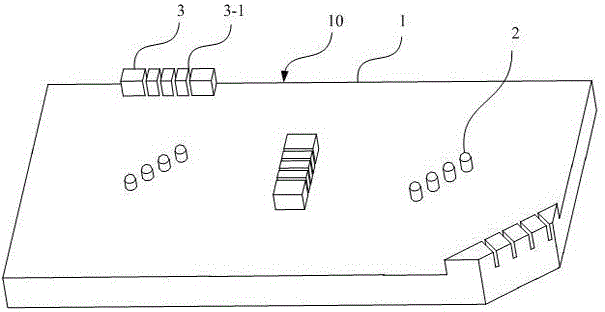

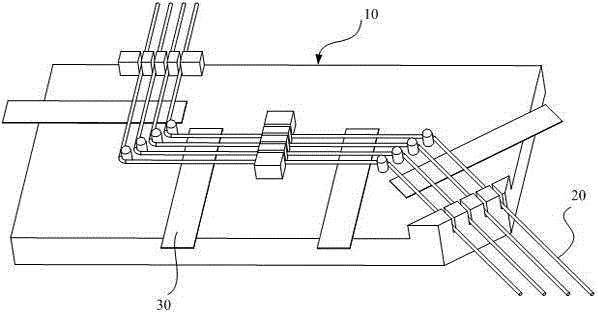

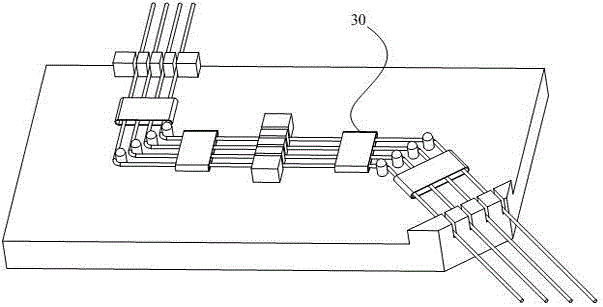

Conductive core wire harness moulding tool and moulding method

ActiveCN106252238AChange bend angleSimple structureSemiconductor/solid-state device manufacturingEngineeringCable harness

Owner:GEER TECH CO LTD

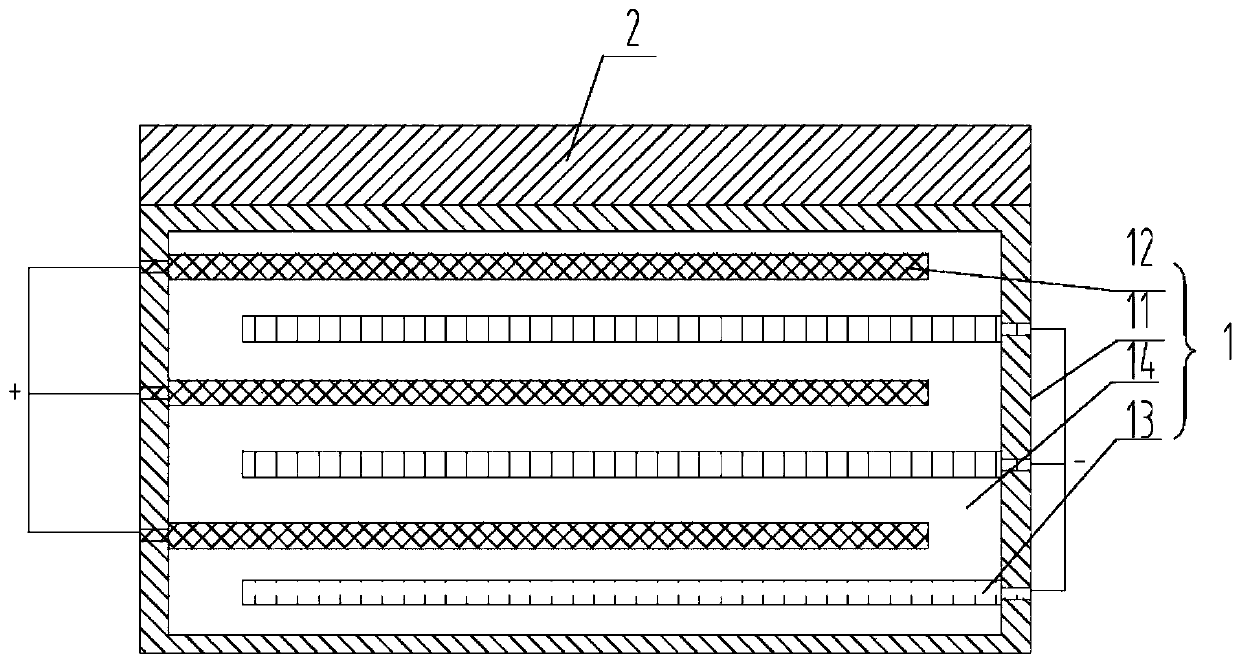

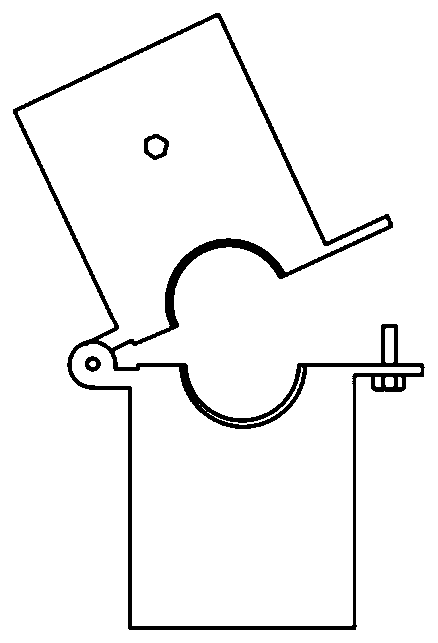

Flexible support body and flexible display device

InactiveCN110085124ARealize free switchingChange bend angleIdentification meansEngineeringComputer terminal

The invention provides a flexible support body and a flexible display device, wherein the flexible support body is used for supporting a flexible screen body and comprises a flexible covering structure, a flaky electrode layer and electrorheological fluid, wherein the flexible covering structure comprises a sealed cavity; the flaky electrode layer comprises a cathode layer and an anode layer arranged in the sealed cavity in a parallel and overlapped way; the electrorheological fluid is filled in the sealing cavity and is positioned in a gap formed on the periphery of the electrode layer. The flexible support body can realize the free switching of a flexible terminal between the flexible state and the non-flexible state; the flexible support body can be fixed at any bending angle; the practicability of the flexible display device is improved.

Owner:BEIJING VISIONOX TECH

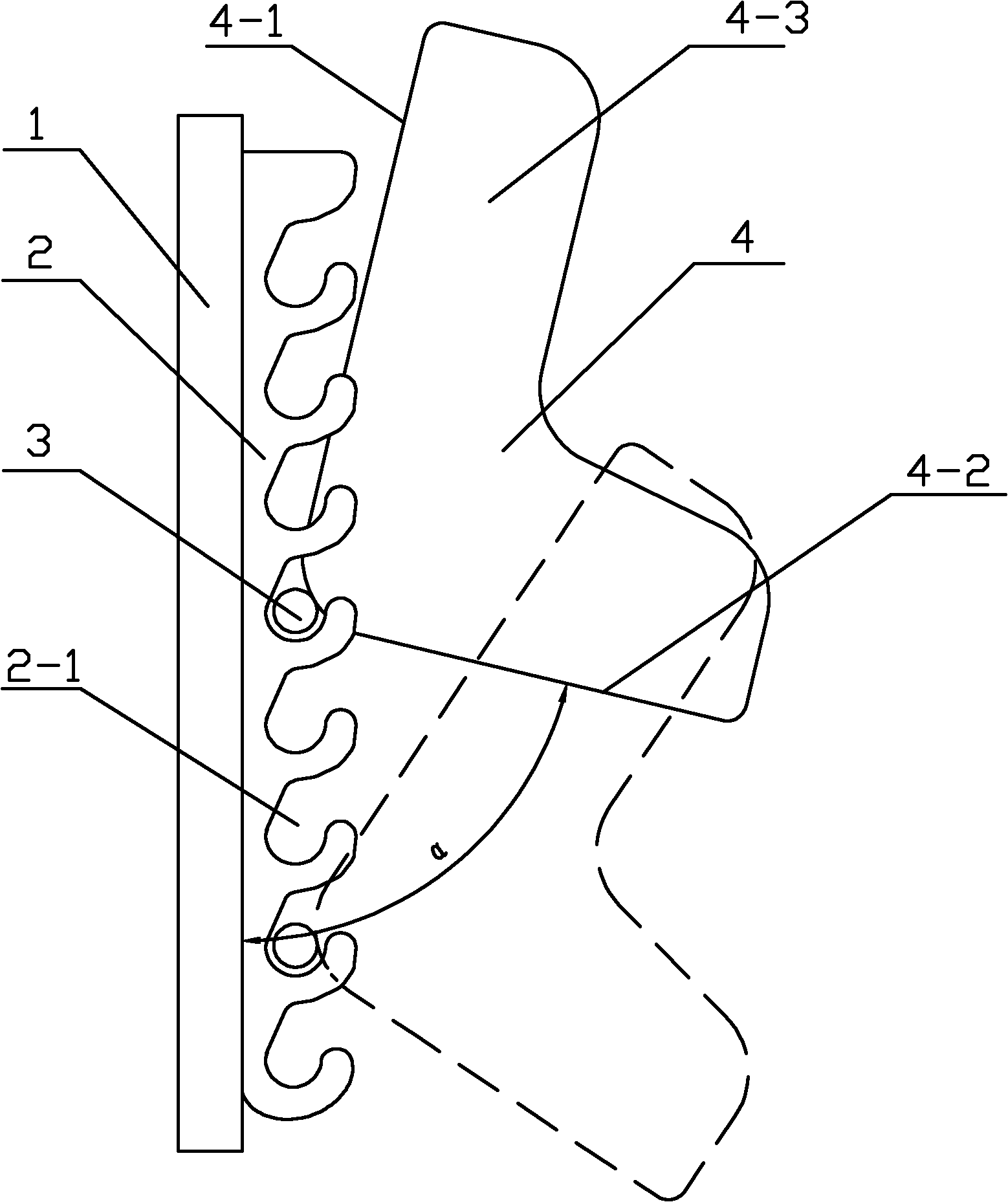

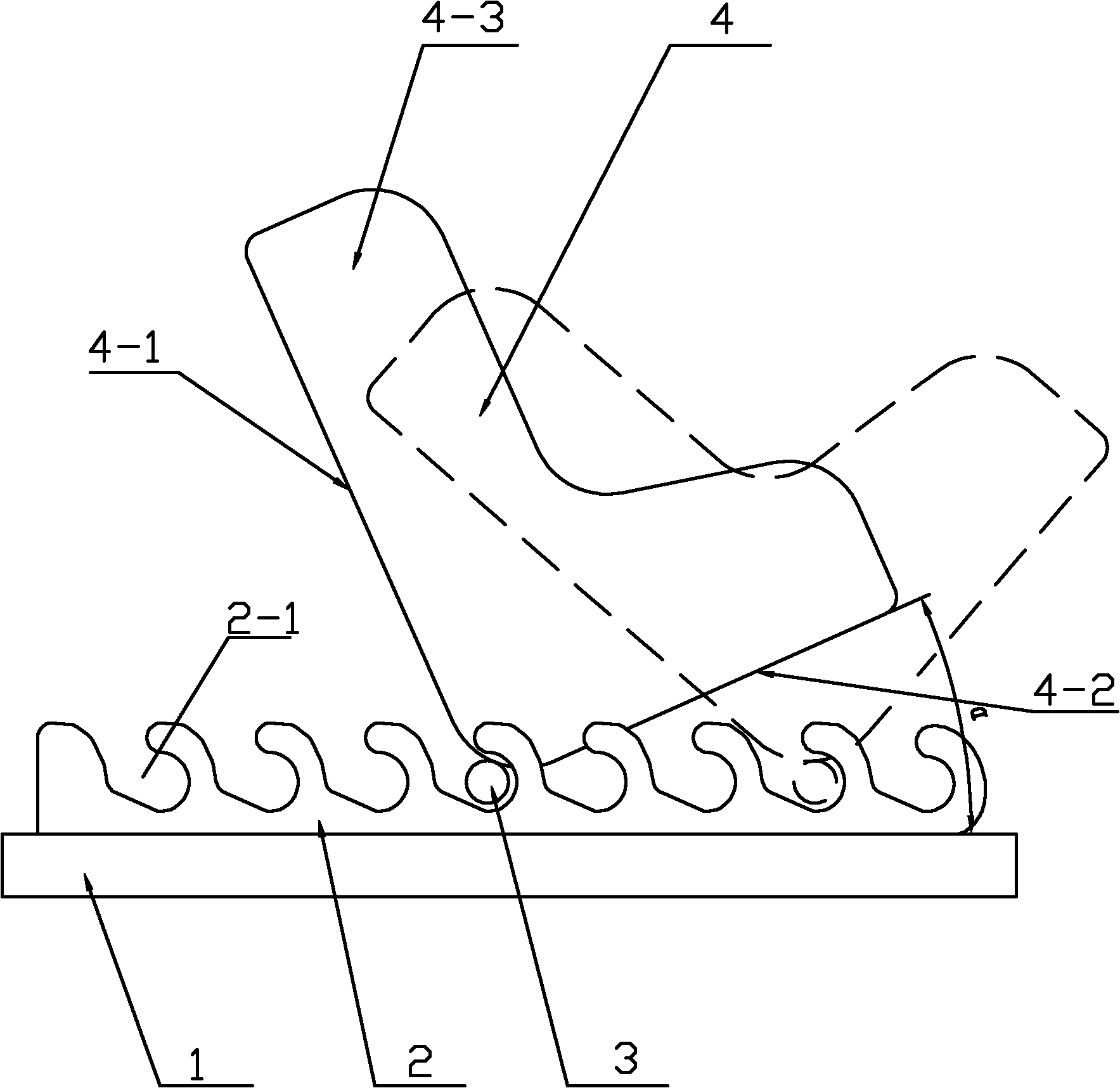

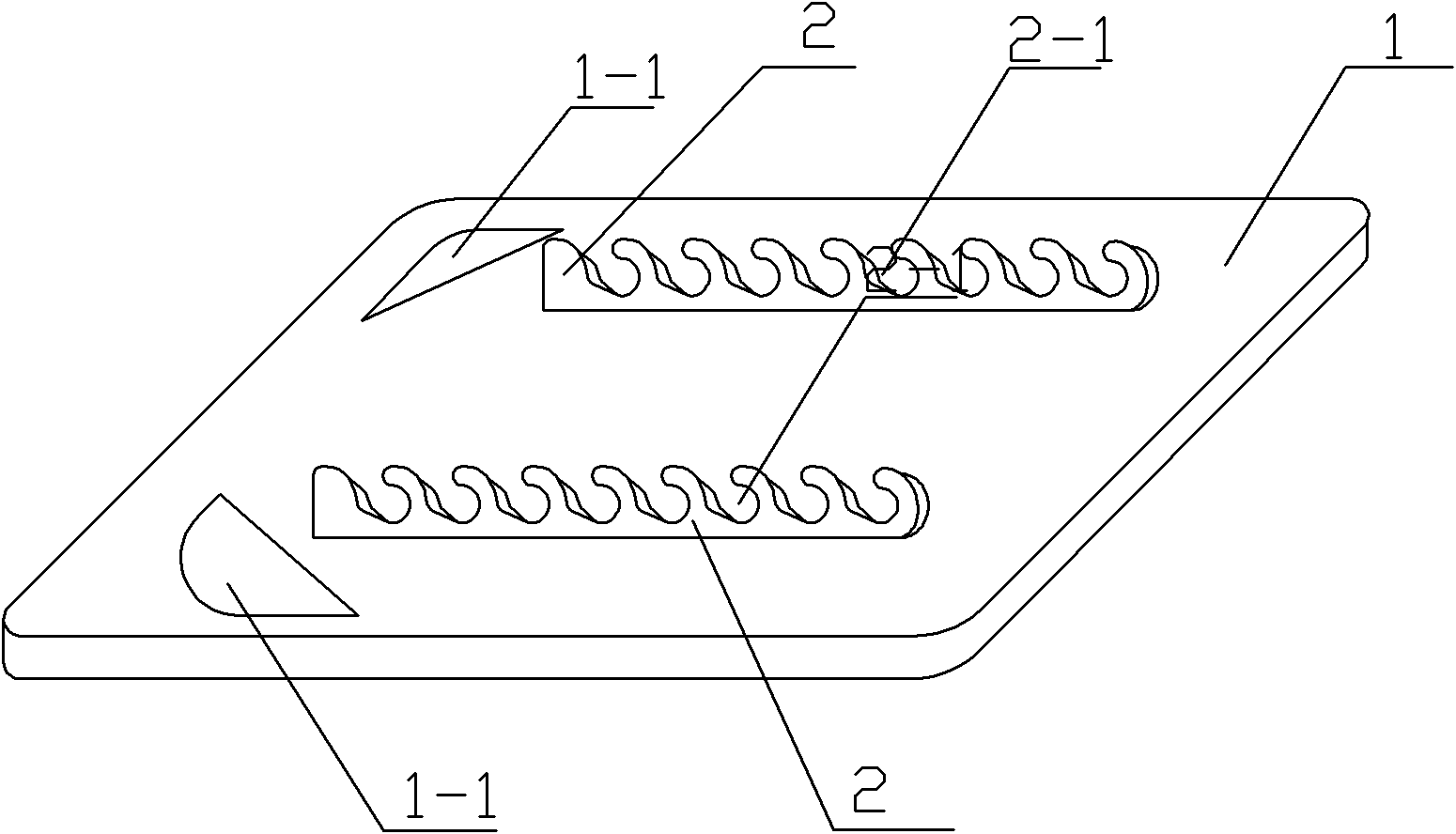

Split adjustable knee joint fixer

InactiveCN101999942AChange bend angleReduce the burden onDiagnosticsInstruments for stereotaxic surgeryPhysical medicine and rehabilitationAnkle

The invention relates to a knee joint fixer, in particular to a split adjustable knee joint fixer, aiming at solving the problems that the labor force is wasted by manually fixing a knee joint of a patient at the specific angle in the knee joint operation, and the operation is influenced because the fixed angle of the knee joint of the patient changes and the limb body of the patient is instable due to the physical draining. The knee joint fixer comprises a base plate, two positioning strips, an adjusting shaft and a fixing boot, wherein each positioning strip is provided with a plurality of clamping grooves and is serrated in the appearance; the end faces on the backs of two positioning strips are arranged on the upper end face of the base plate in parallel and are fixedly connected with the upper end face of the base plate; the adjusting shaft is fixedly connected with the heel part of the fixed boot which is positioned between the two positioning strips; and two ends of the adjusting shaft are respectively clamped in a corresponding clamping groove on one positioning strip. The invention is used for fixing the knee joint and ankles of the patient in the knee joint operation.

Owner:谷文光

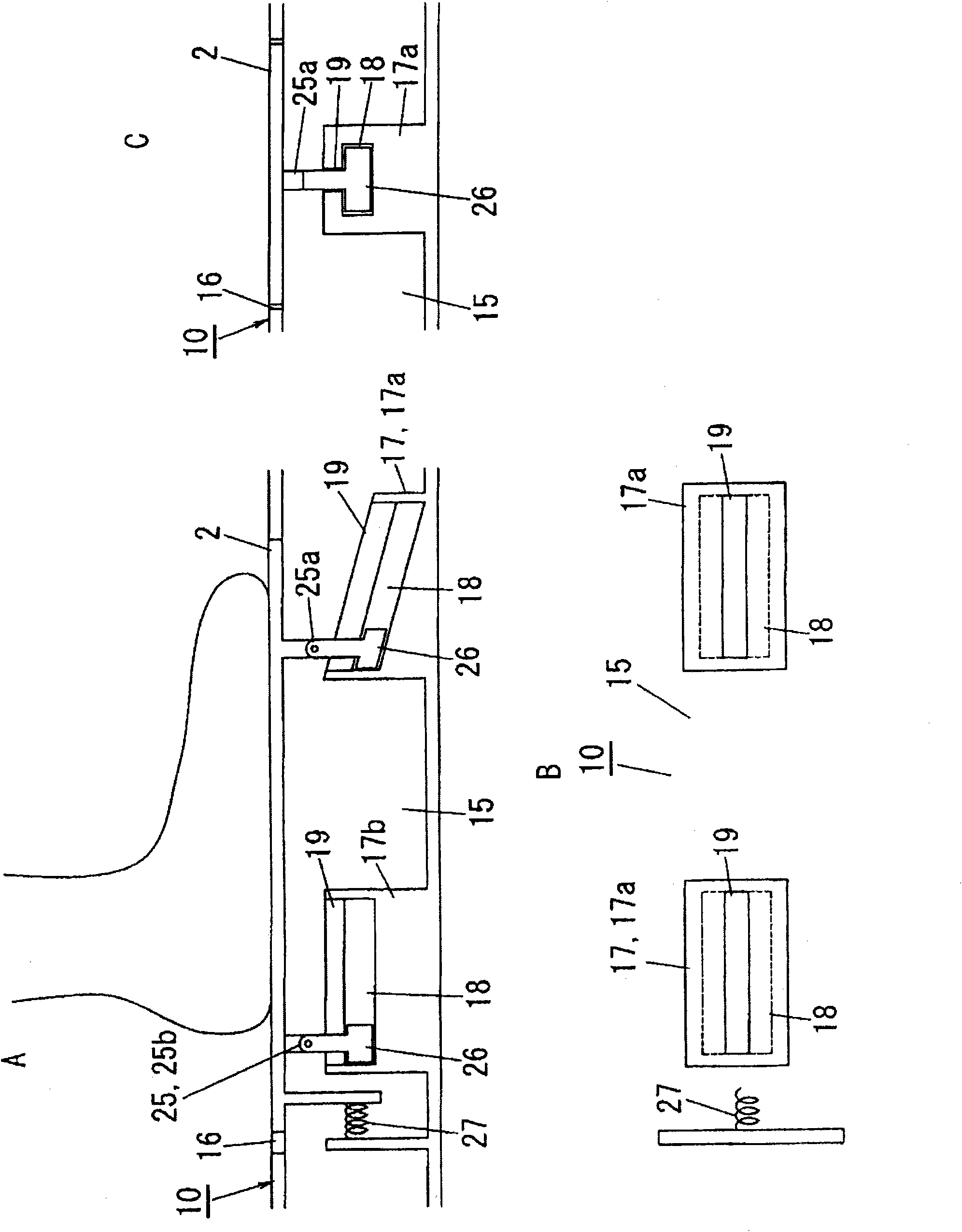

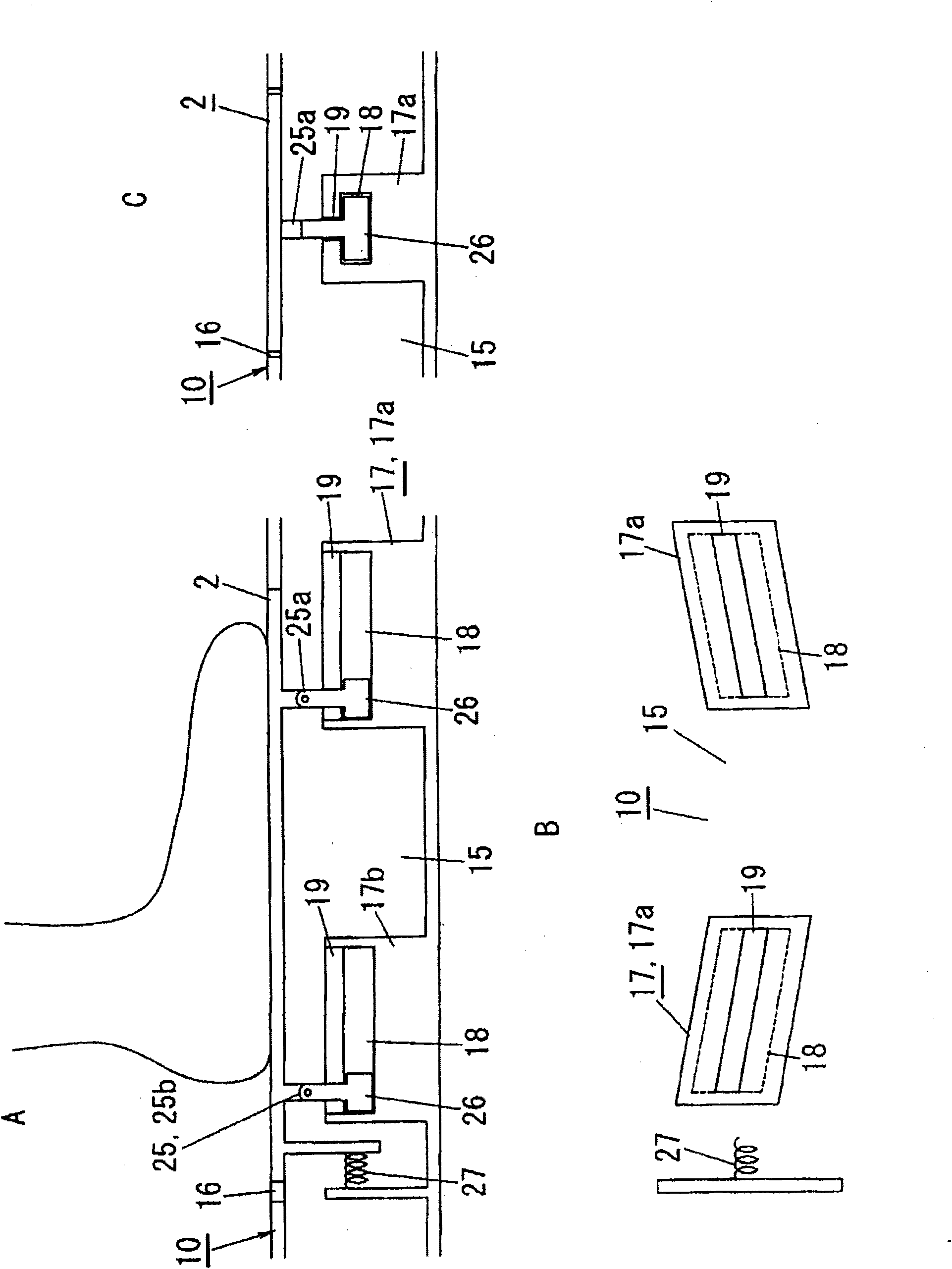

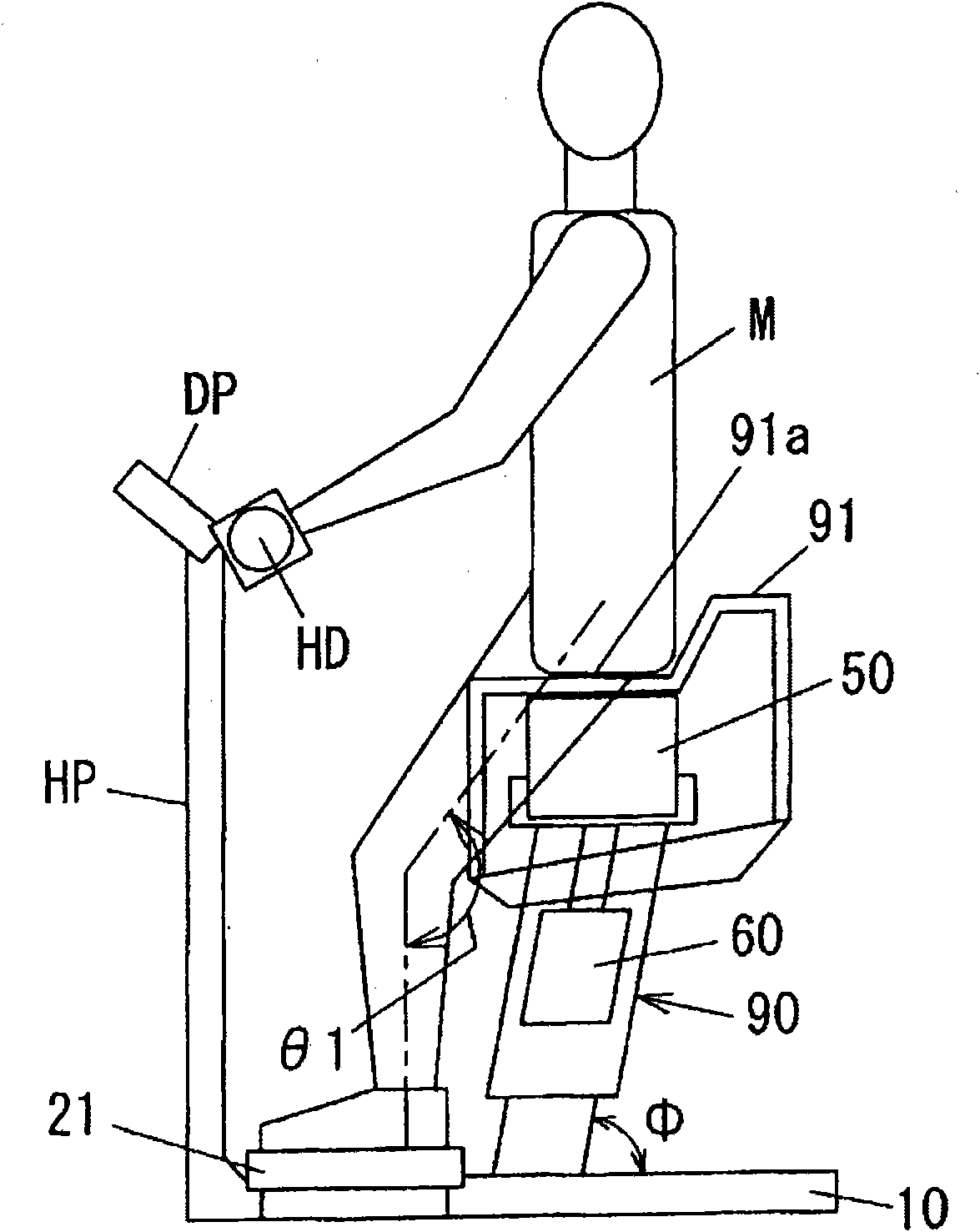

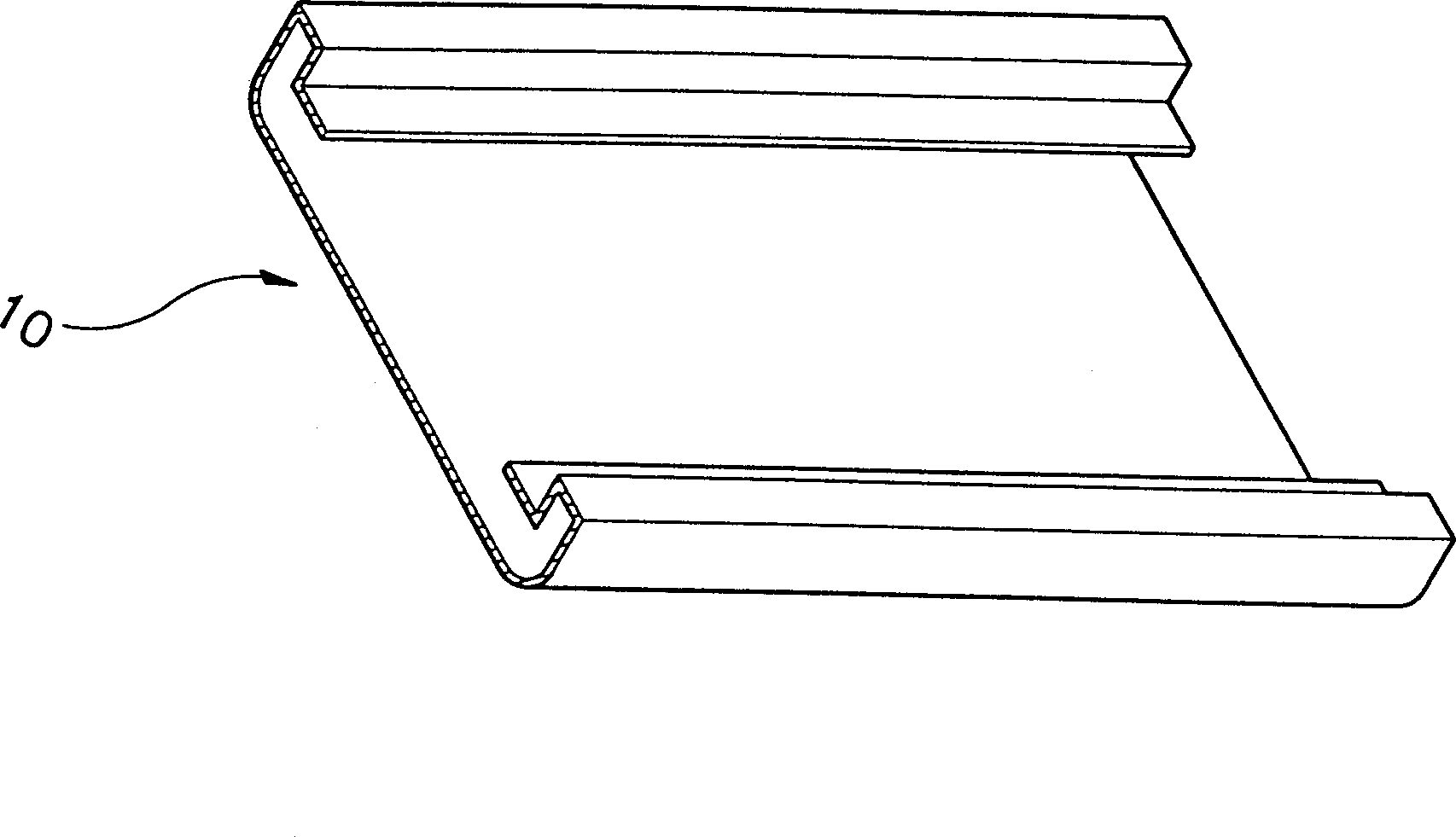

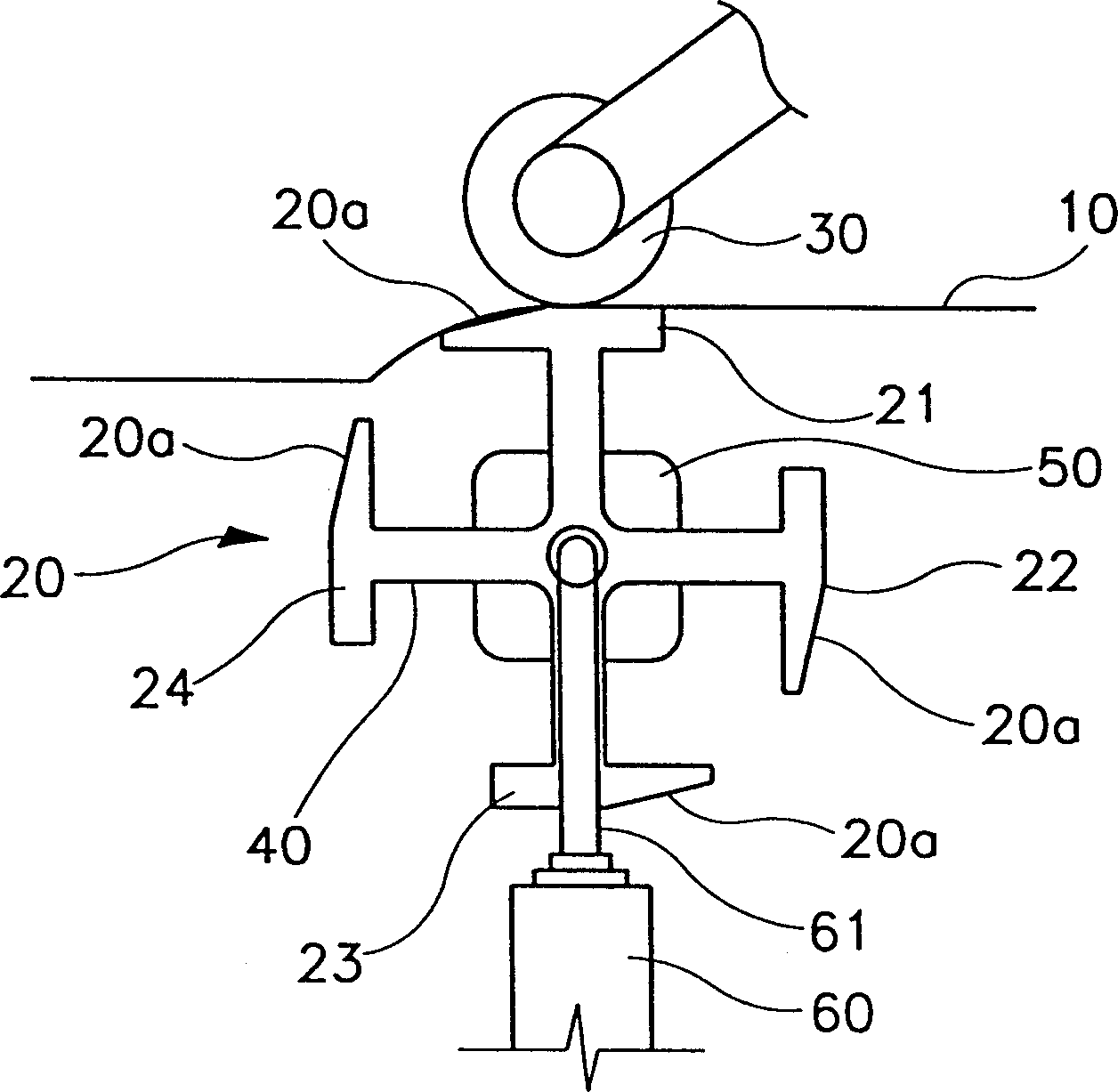

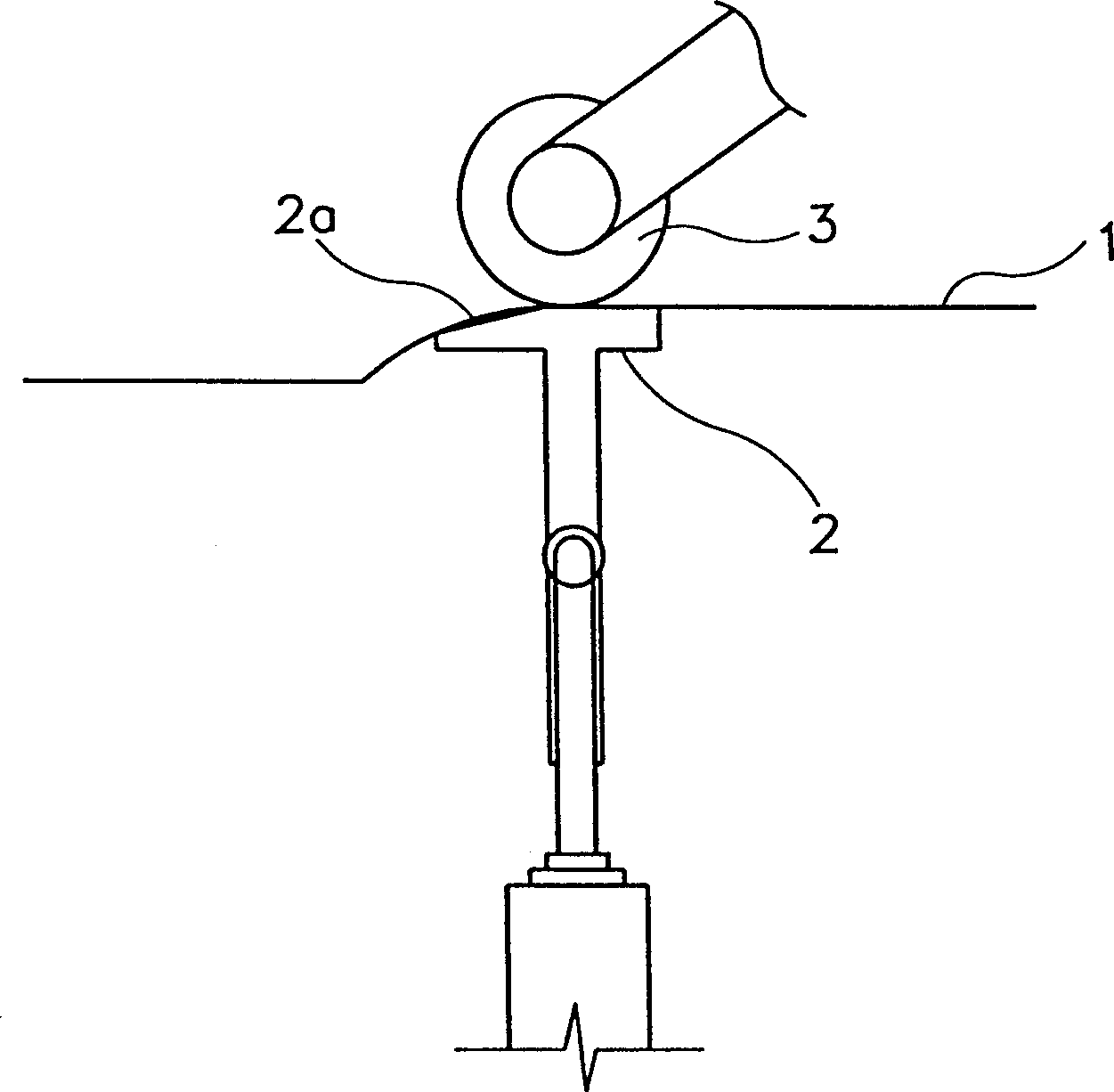

Exercise auxiliary equipment

InactiveCN101835446AChange bend angleSame directionChiropractic devicesMuscle exercising devicesLeft directionFoot supports

An exercise auxiliary equipment which can change the ratio of a load acting on the foot and a load acting on the buttock greatly by changing the direction of the foot. Both foot supporting bases (2) for mounting the right and left feet of a user (M), respectively, and a guide rail portion (17) as a guide portion for restricting the movement course of each foot supporting base (2) are provided on a pedestal (10). The guide rail portion (17) can move the foot supporting bases (2) substantially in the front and back direction freely and respectively, and rotates the foot supporting bases (2) about the axis substantially in the front and back direction, or the right and left direction or the vertical direction.

Owner:PANASONIC CORP

Steel-board bending device for refrigerator door

InactiveCN1102081CChange bend angleShaping toolsDomestic cooling apparatusRefrigerator carSheet steel

Owner:SAMSUNG ELECTRONICS CO LTD

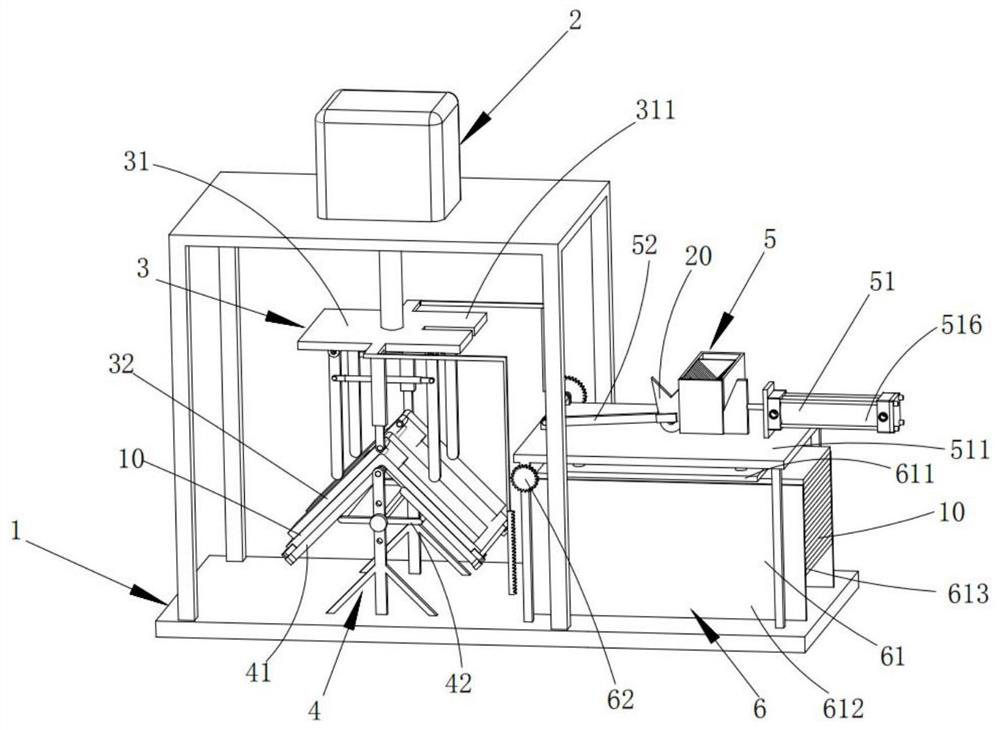

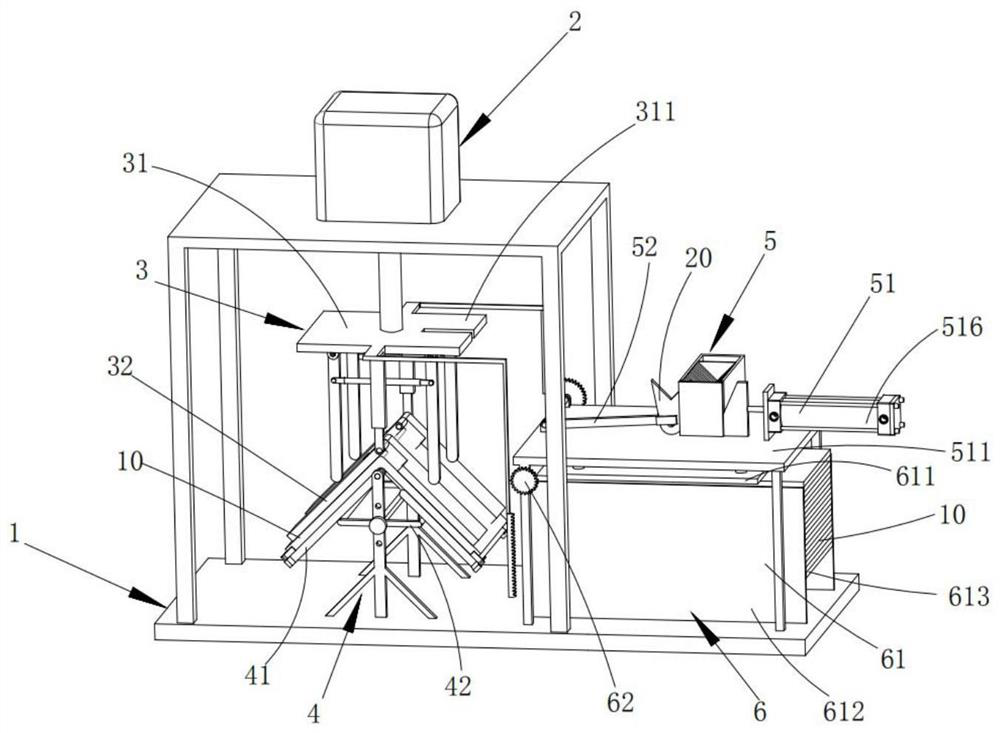

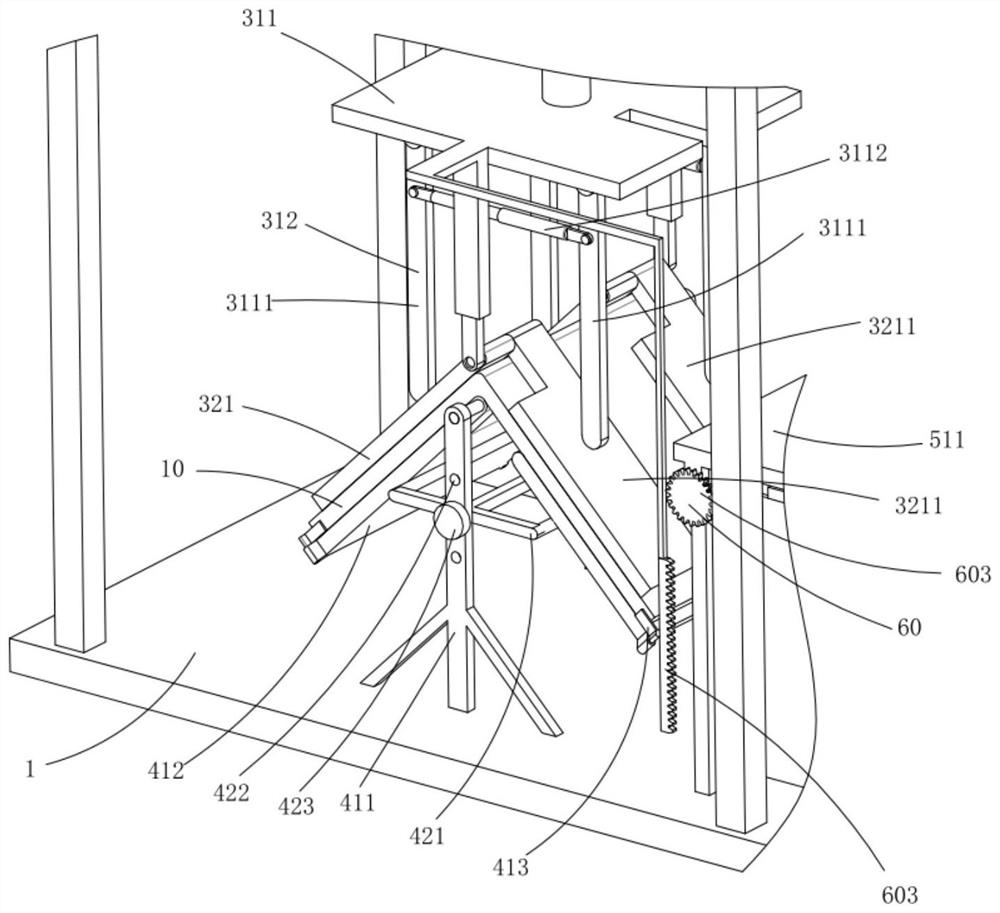

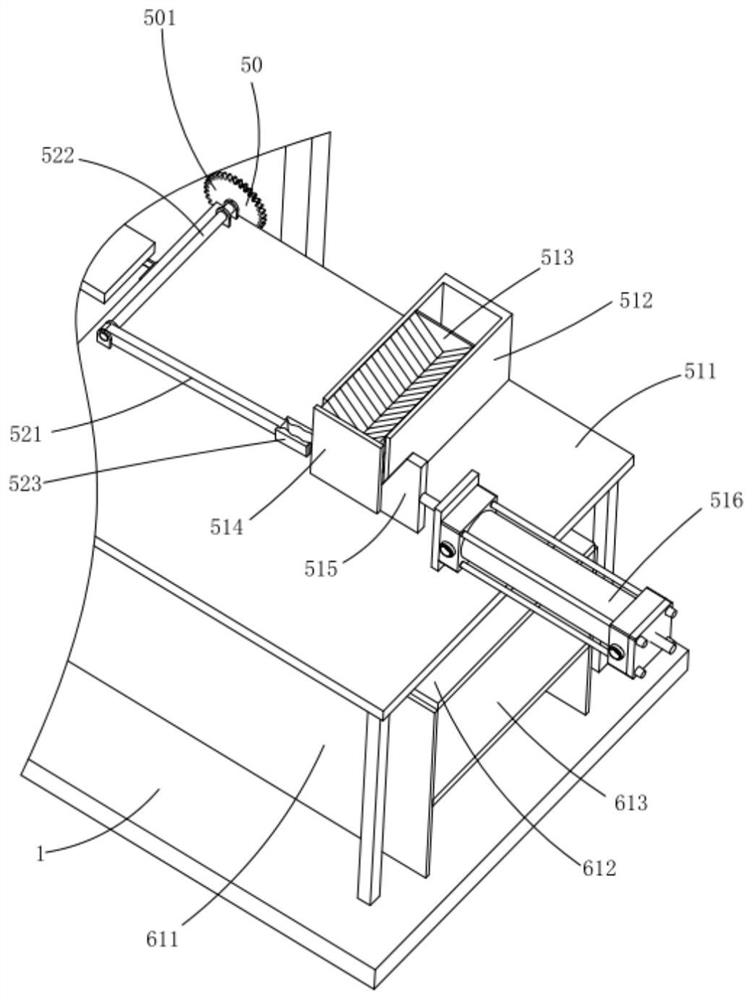

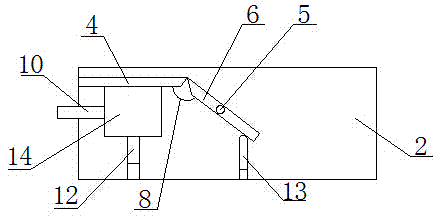

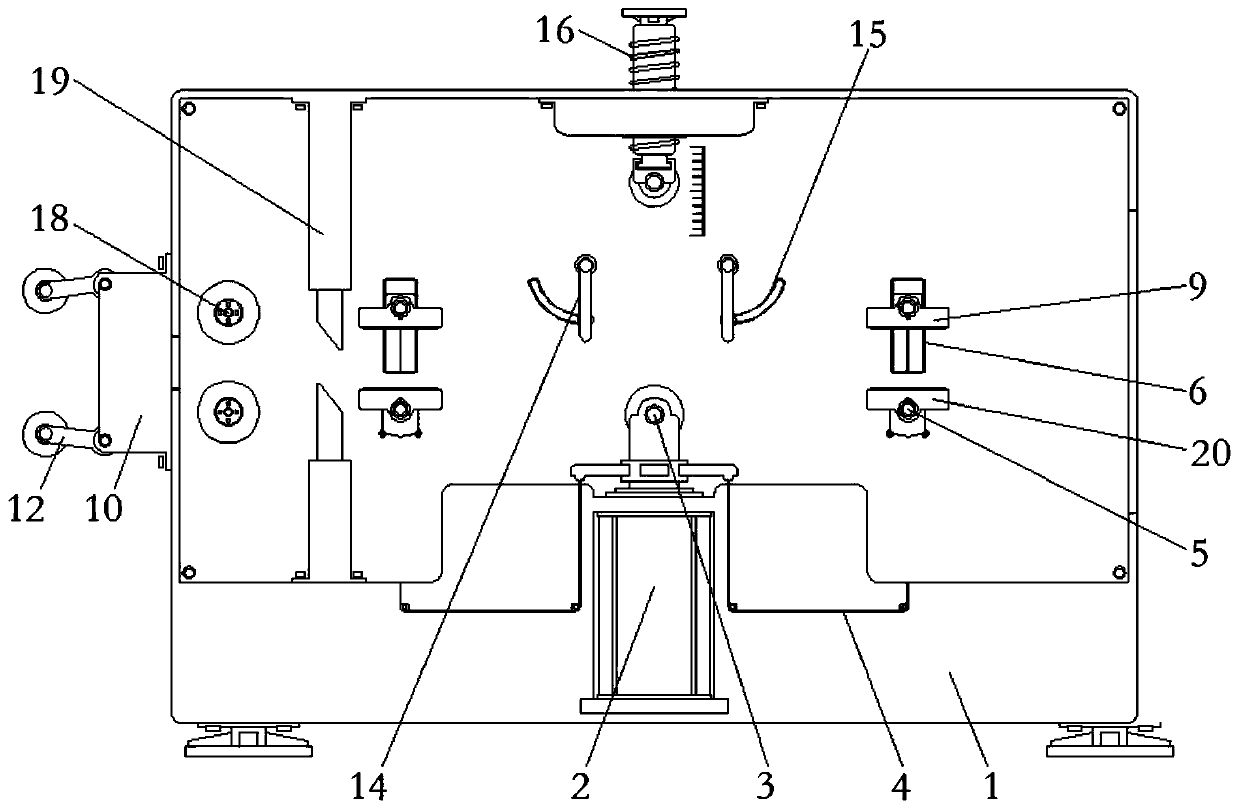

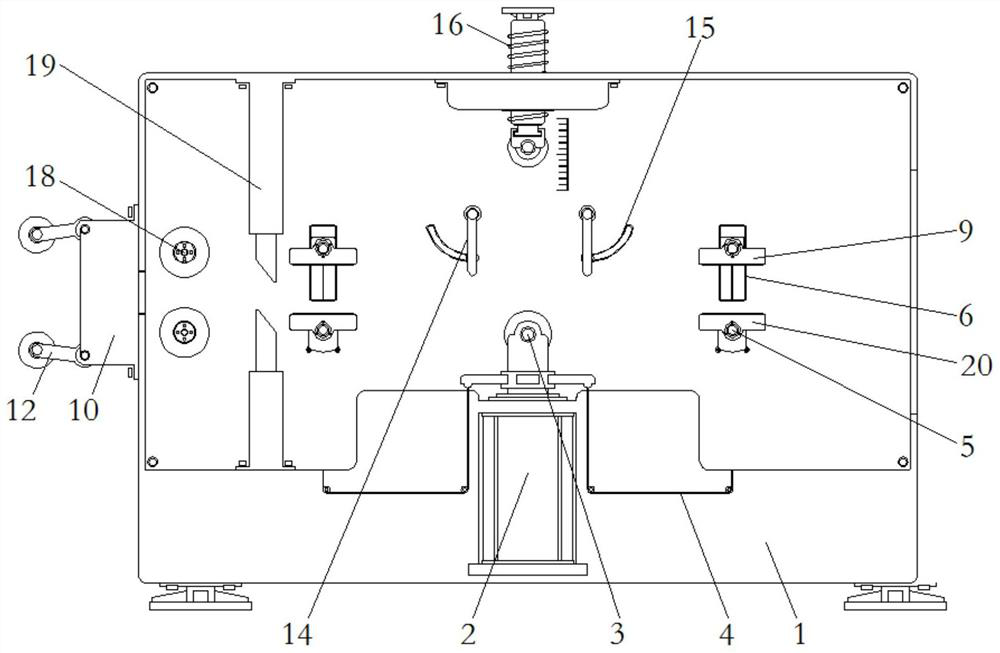

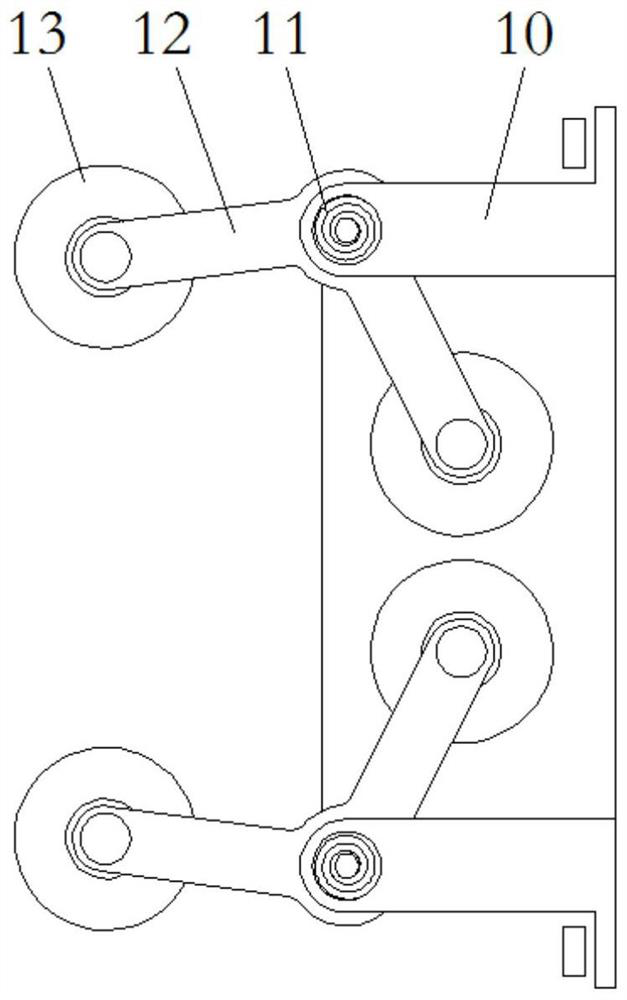

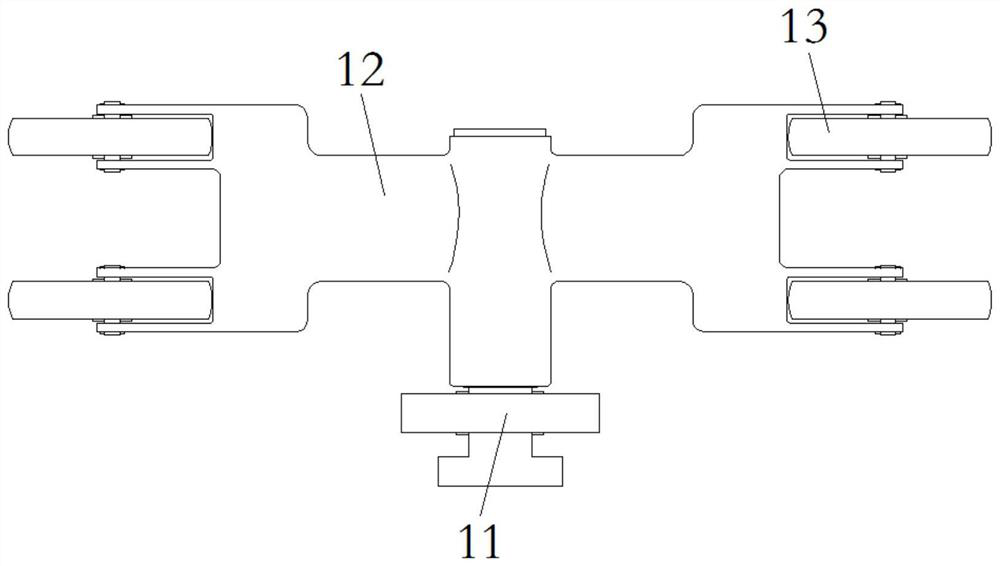

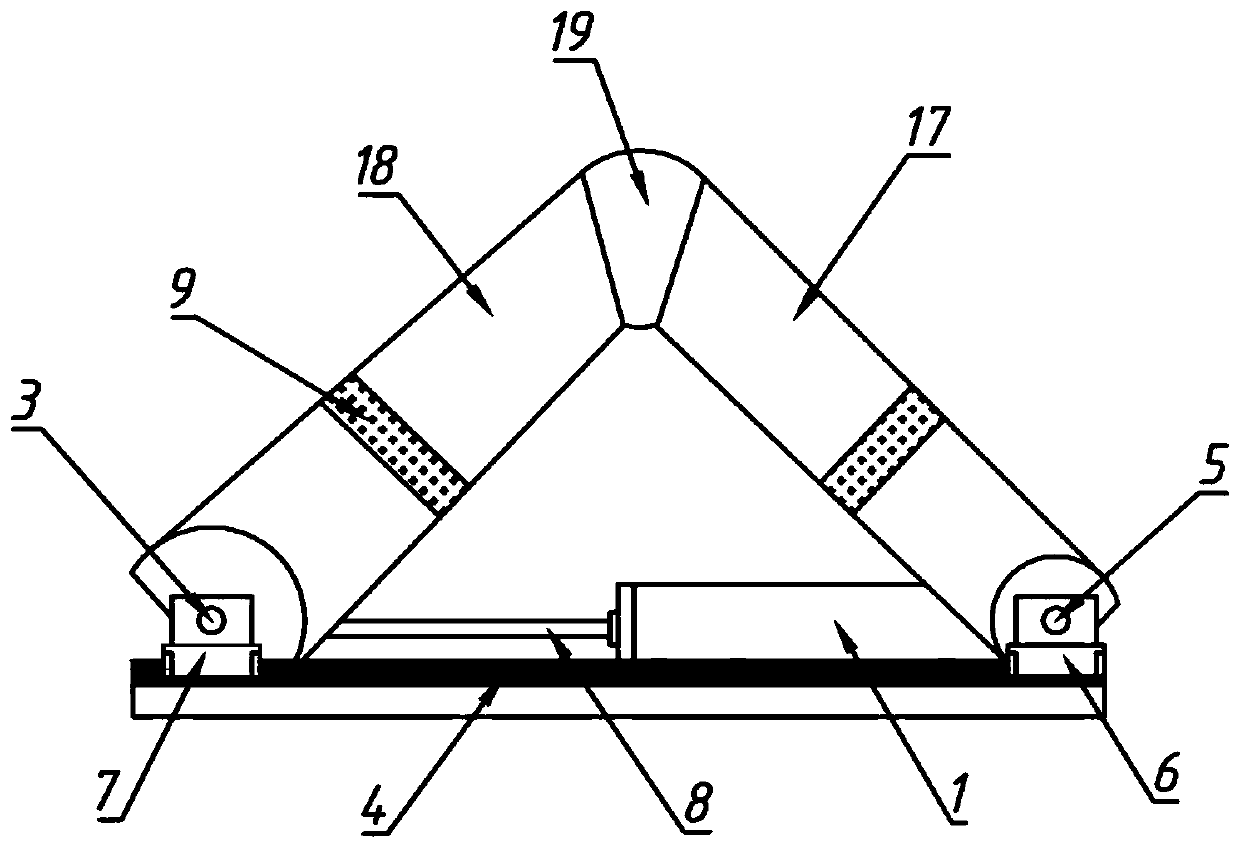

Intelligent carbon contact strip pressing machine with bracket edge folding function and using method thereof

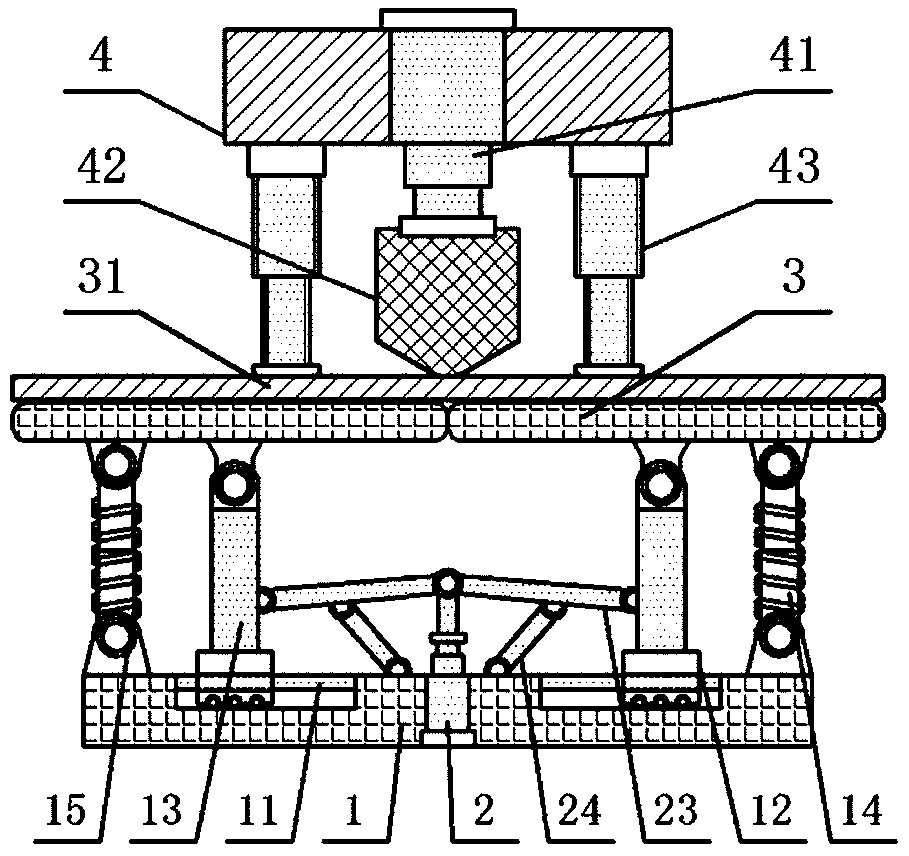

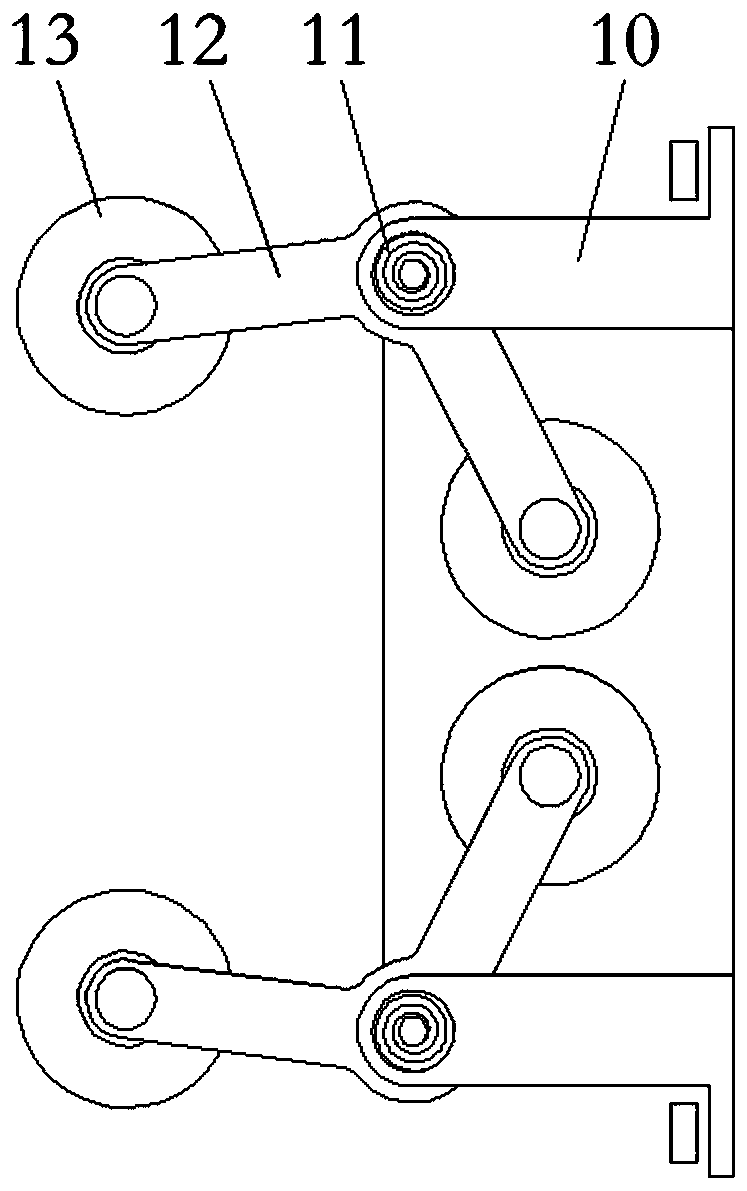

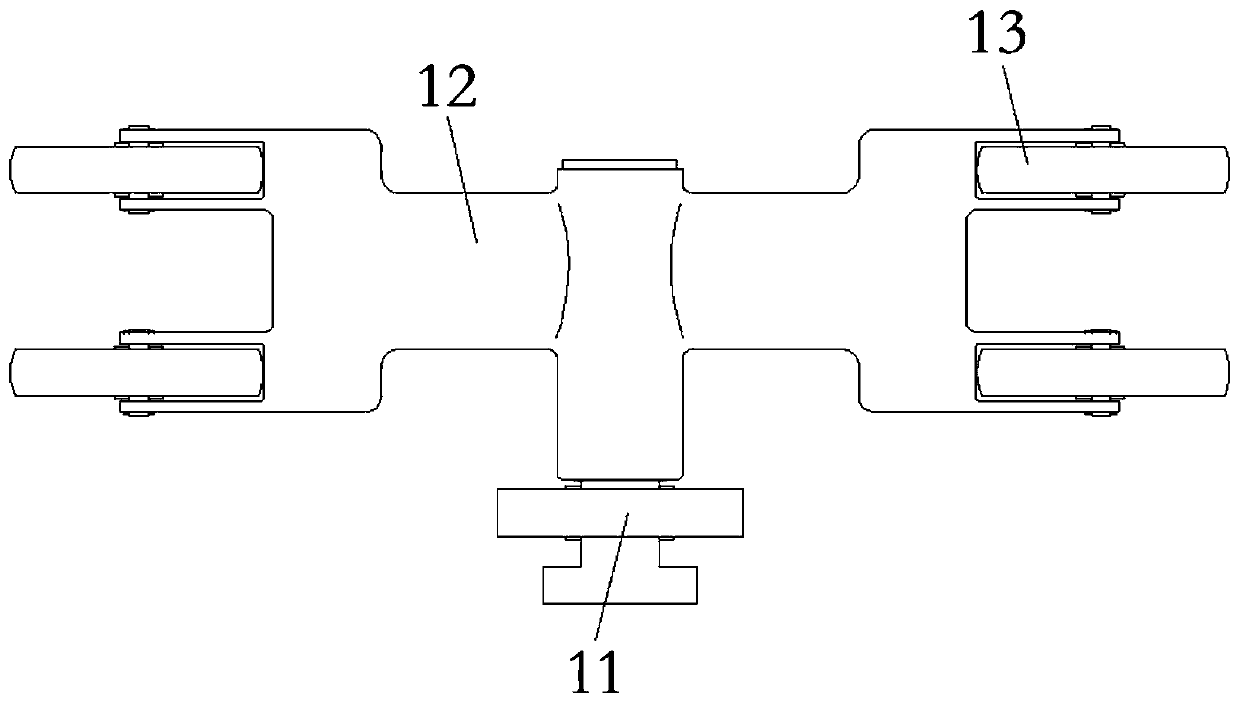

ActiveCN111113973AChange bend angleIncrease diversityPress ramPower current collectorsMachine partsStructural engineering

The invention discloses an intelligent carbon contact strip pressing machine with a bracket edge folding function. The pressing machine comprises a bottom plate, a telescopic cylinder is installed onthe top face of the bottom plate, sliding rods are transversely arranged in rectangular grooves in the top face of the bottom plate, sliding blocks transversely sleeve the sliding rods, and supportingrods are arranged on the top faces of the sliding blocks; a connecting rod mechanism is arranged at the top end of a telescopic rod of the telescopic cylinder and in the middles of the two supportingrods; telescopic pieces are arranged between folding plates and the bottom plate; and a machined part is transversely supported by the top faces of the two folding plates jointly, and a stamping mechanism is arranged on the top face of the machined part. A using method of the intelligent carbon contact strip pressing machine with the bracket edge folding function is further disclosed. According to the pressing machine and the using method, the problems of different required bending angles for different types of carbon contact strips and poor consistency of flanged products are effectively solved; and meanwhile, manual edge folding is avoided, the labor intensity of workers is reduced, and the working efficiency is improved.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

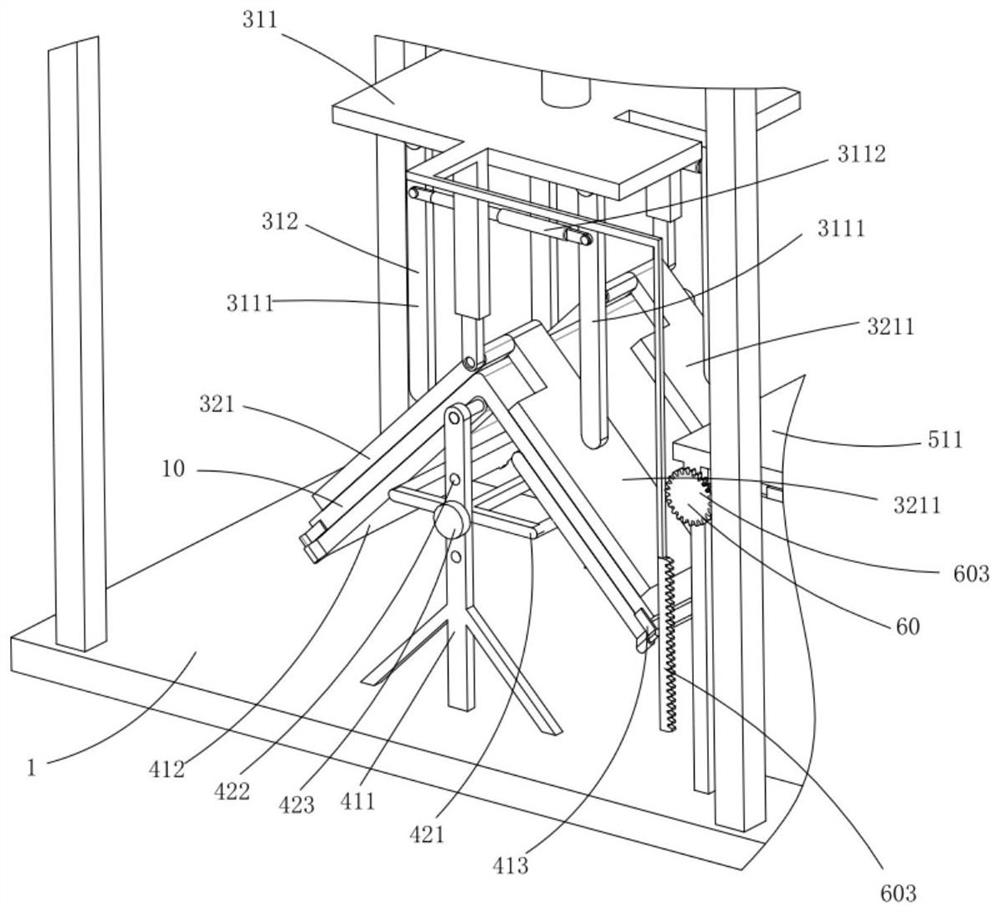

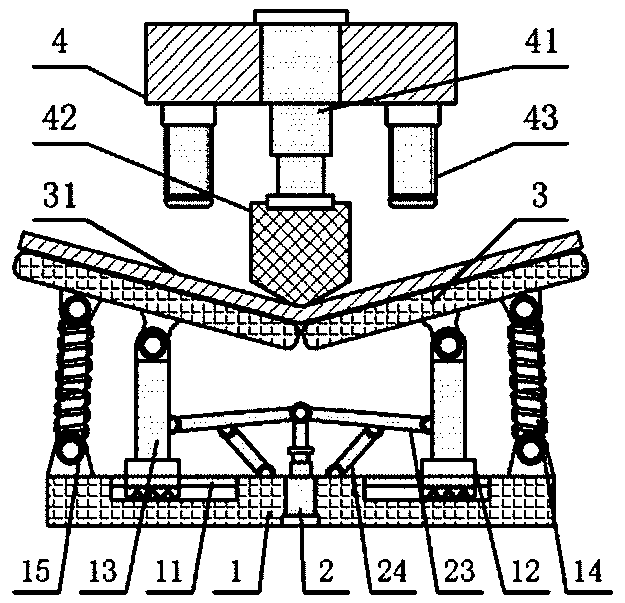

Simple manual multi-angle circular tube bending equipment

The invention relates to bending equipment, in particular to simple manual multi-angle circular tube bending equipment. The equipment does not require electric power but is easy to operate manually, small in size and lightweight. A position adjusting shaft installed on a lifting support frame can be used for adjusting the height, and therefore the bending angle is changed; a molding tool combination can be dismantled, the bending radius of each bent tube is changed, and a manual operation combination is in bolted connection with a support frame combination; the support frame combination is installed on the left side of a lifting combination and is in bolted connection with the lifting combination, the manual operation combination is in shaft connection with the lifting combination and is installed on the left side of the lifting combination, and the molding tool combination is installed at the portion, on the upper side of the lifting combination, of the upper side of the support framecombination and is in bolted connection with the support frame combination. A circular steel tube is installed on the upper portion of the lifting combination, connected with the lifting combinationand disposed at the portion, at the lower portion of the molding tool combination, of the side face of the support frame combination.

Owner:隋秀华

Bending-angle-adjustable hardware punching die structure

PendingCN111672980AChange bend angleImprove securityShaping toolsMetal-working feeding devicesStructural engineeringPunching

The invention discloses a bending-angle-adjustable hardware punching die structure. The bending-angle-adjustable hardware punching die structure comprises an upper die base and a lower die base. The lower end of the upper die base is fixedly provided with a mounting base, the lower end of the mounting base is provided with an upper die in a matched manner, the lower end of the mounting base is provided with dovetail grooves, two sides of the upper end of the upper die are fixedly provided with dovetail-shaped sliding blocks, and the sliding blocks of the upper die are mounted in the dovetail grooves of the mounting base in a matched manner. The upper die is of a C-shaped structure, the front end of a lower arm of the upper die is provided with an adjusting plate, the tip of the front end of the lower arm of the upper die is provided with a through hole, and the lower end of the adjusting plate is fixedly provided with a rotating shaft. By means of the bending-angle-adjustable hardwarepunching die structure, the bending angle of an abrasive tool can be adjusted in a stepless manner, and the adjustment manner is simple and quick, beneficial to reducing the experiment expense and accelerating the experiment progress.

Owner:杭州创融汇科技服务有限公司

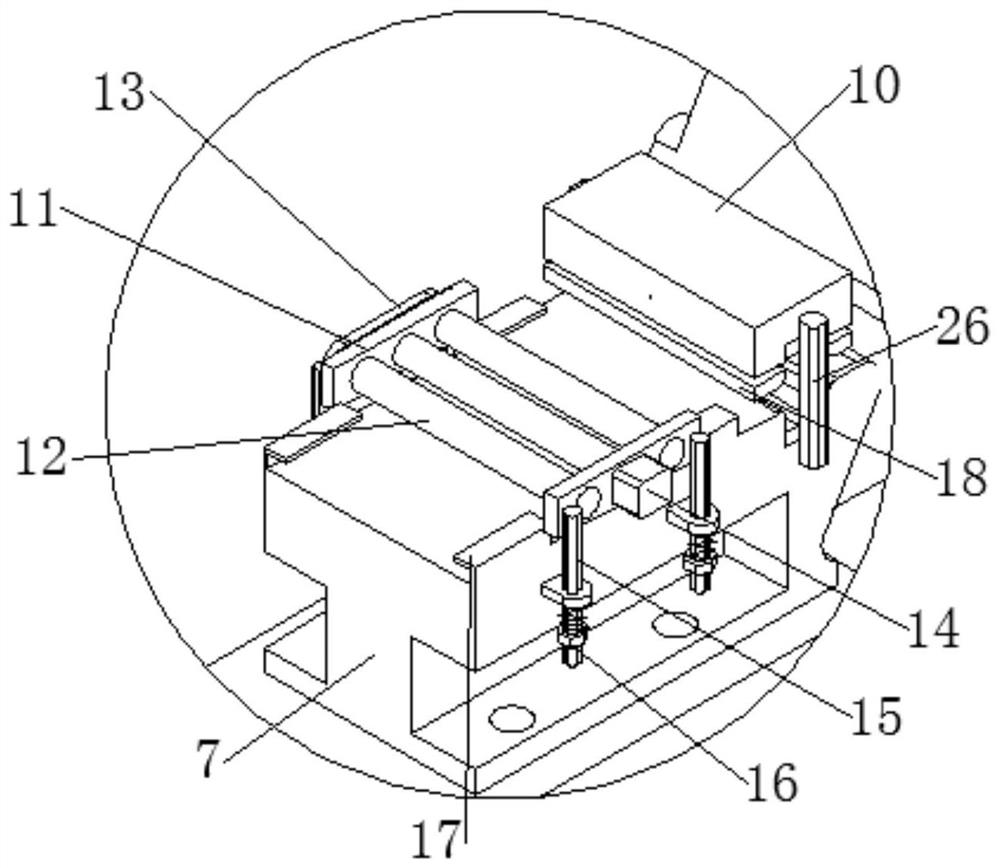

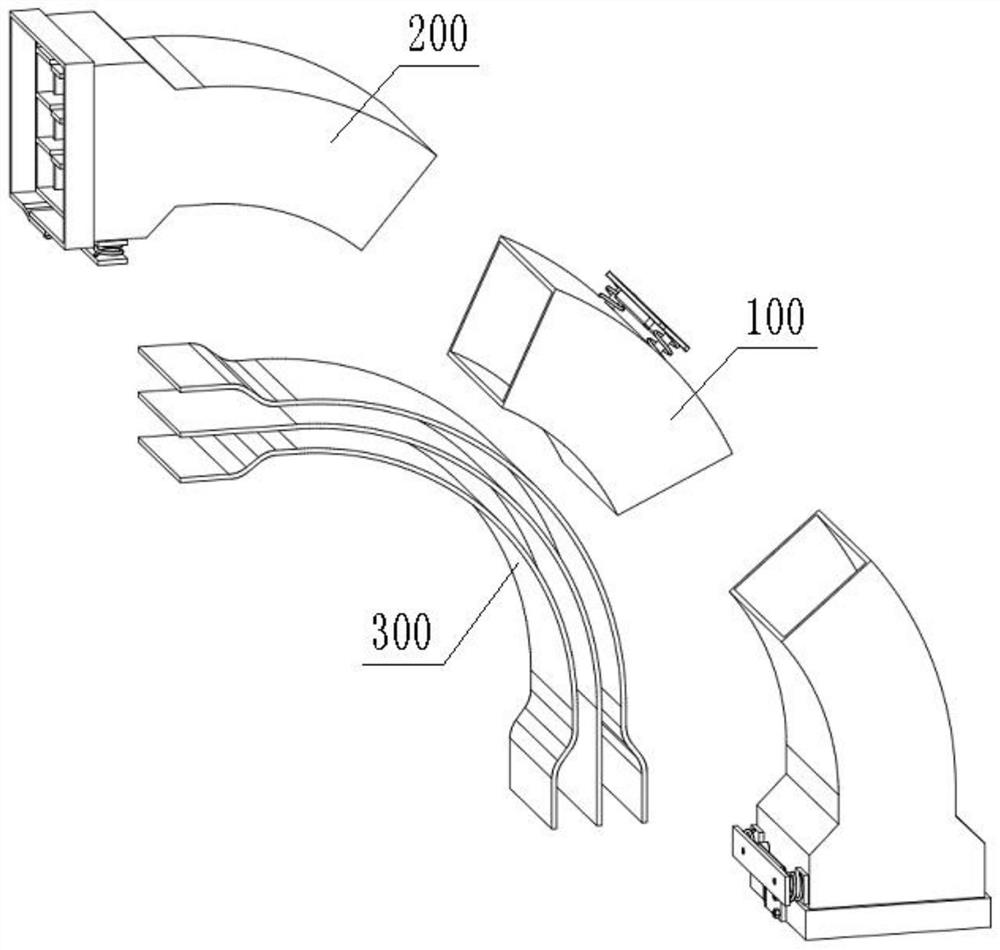

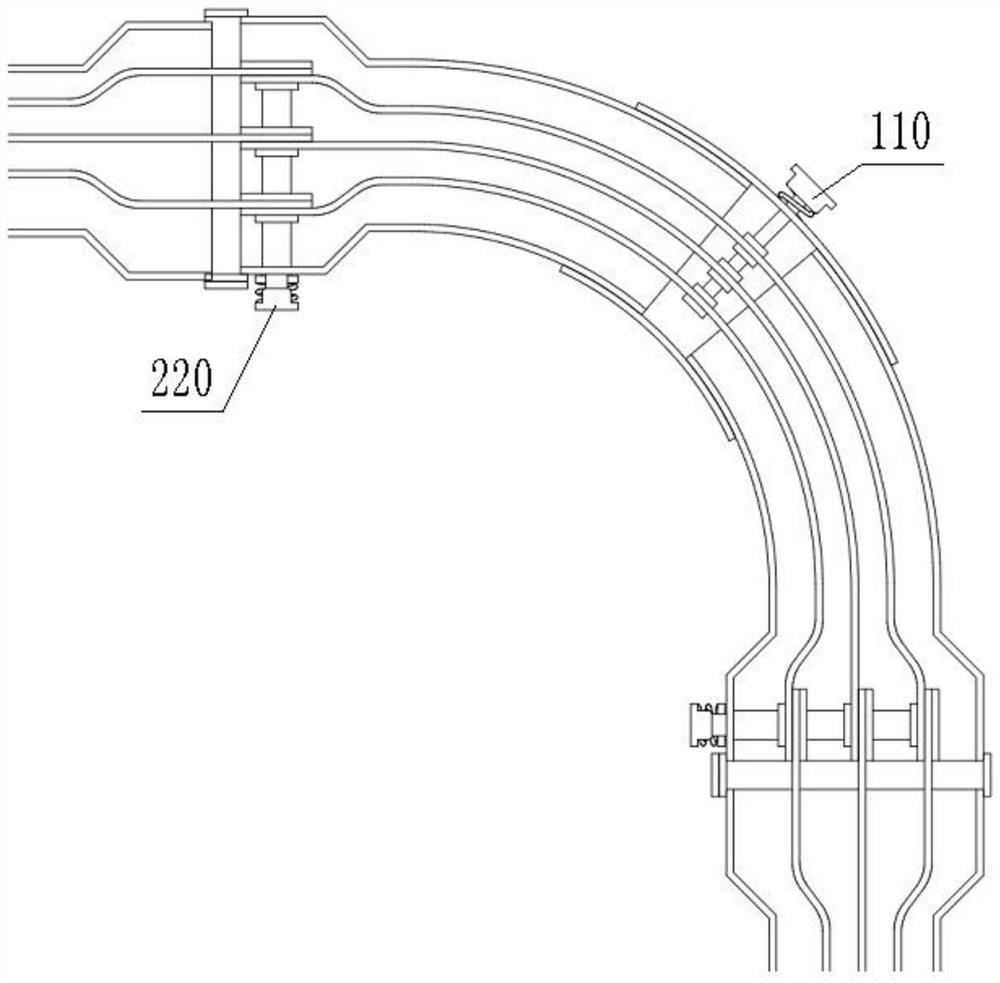

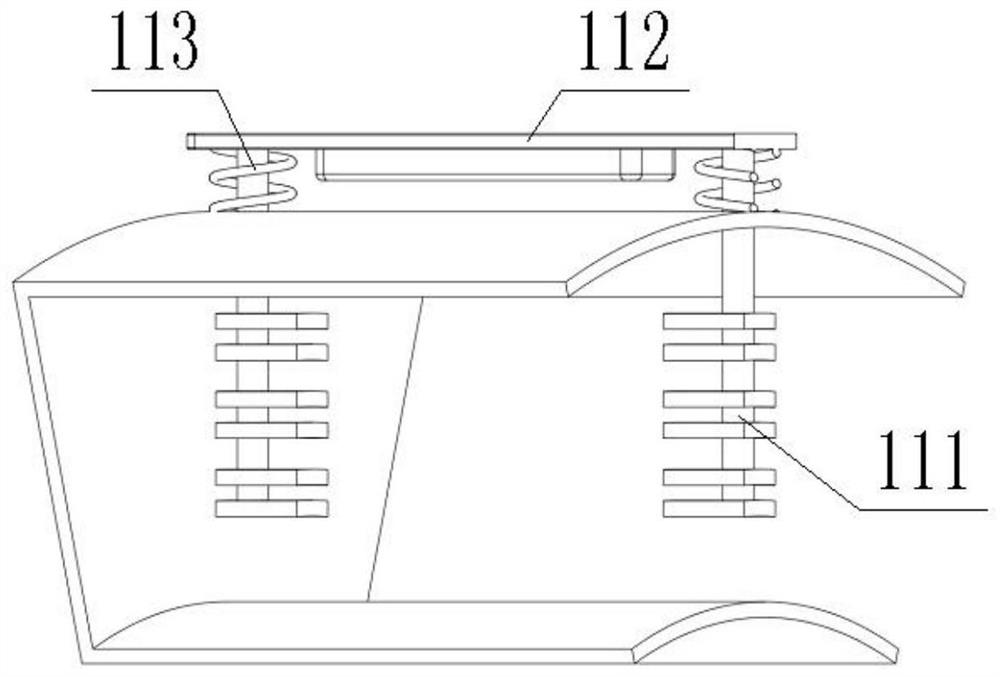

Bus duct corner connecting device

ActiveCN112886510AChange bend angleReduce constraintsTotally enclosed bus-bar installationsPhotovoltaic energy generationStructural engineeringMechanical engineering

The invention discloses a bus duct corner connecting device. The bus duct corner connecting device comprises a connecting groove, an end groove and a first copper bar group. According to the bus duct corner connecting device, connecting grooves and end grooves which are in sliding connection are formed and spliced to form an arc-shaped bus duct with a central angle capable of being changed within 80-100 degrees, and the first copper bar set used for being connected with a circuit is installed in the bus duct. The sleeving depth between the connecting grooves and the end grooves is variable, so that the bending angle of the bus duct corner connecting device can be changed to a certain extent, and the bus duct corner connecting device can be more flexibly applied to various non-right-angle scenes. Compared with an existing right-angle bus duct or non-standard angle bus duct, the bus duct corner connecting device can adjust the angle according to the actual application scene, the restriction is reduced, and the applicability is greatly improved.

Owner:HXXN ELECTRICITY

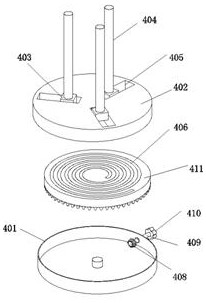

Willow branch willow bending equipment for wicker basket processing

InactiveCN112157752AChange bend angleImprove applicabilityCane mechanical workingWood stock bendingElectric machineDrive shaft

The invention relates to the technical field of wicker artware processing, and in particular relates to wicker branch willow bending equipment for wicker basket processing. The equipment comprises a support table, a rotating disc and a rotating motor, wherein a support frame is fixedly mounted at the bottom end of the support table, a circular groove is formed in the support table, a speed reduceris fixed at the bottom of the circular groove, the input end of the speed reducer is installed with the output end of the rotating motor through a transmission shaft, the output end of the speed reducer is provided with a rotating shaft, the top end of the rotating shaft is fixed with the center of the bottom surface of the rotating disc, a winding assembly is installed at the upper end surface of the rotating disc, a circular truncated cone is also installed on the upper end face of the support table, a stand column is fixed at the top end of the circular truncated cone, and a willow branchconveying assembly is rotationally installed at the top end of the stand column through a bearing seat. According to the equipment, the bending angle of wicker can be changed, the applicability is high, and the wicker does not need to be bent manually; the wicker can be conveyed at different angles, rapid passing of the wicker is facilitated, and the wicker can be prevented from being stuck at aninlet or an outlet of a conveying sleeve.

Owner:阜南县嘉盛柳木工艺品有限公司

Anti-dislocation angle-adjustable bending device for steel plate production

ActiveCN111167904AInhibition biasImprove practicalityMetal-working feeding devicesPositioning devicesButt jointClassical mechanics

The invention discloses an-dislocation angle-adjustable bending device for steel plate production. The anti-dislocation angle-adjustable bending device comprises a base body, a hydraulic rod, a butt joint pressing head and an electric cutter, the hydraulic rod is installed at the middle end of the base body in a penetrating mode, the output end of the hydraulic rod is rotationally connected with the butt joint pressing head, the outer end of the butt joint pressing head is fixedly connected with a traction rope, the traction rope is connected with the inner surface of the base body, a connecting shaft is rotationally connected to the outer surface of the base body, a lower limiting block is fixedly connected to the outer surface of the connecting shaft, a first sliding groove is formed inthe outer surface of the base body, and a reset spring is fixedly connected to the inner surface of the first sliding groove. According to the anti-dislocation angle-adjustable bending device for steel plate production, a butt joint catch wheel is driven by a handheld threaded rod to perform adjustment and control on up and down positions along the upper end of the base body, so that changing theheight position of the butt joint catch wheel is carried out, and the ejection height of a butt joint pressing head is controlled; and therefore, conveniently changing the bending angle of a contact workpiece can be carried out.

Owner:绍兴市卓诚新材料有限公司

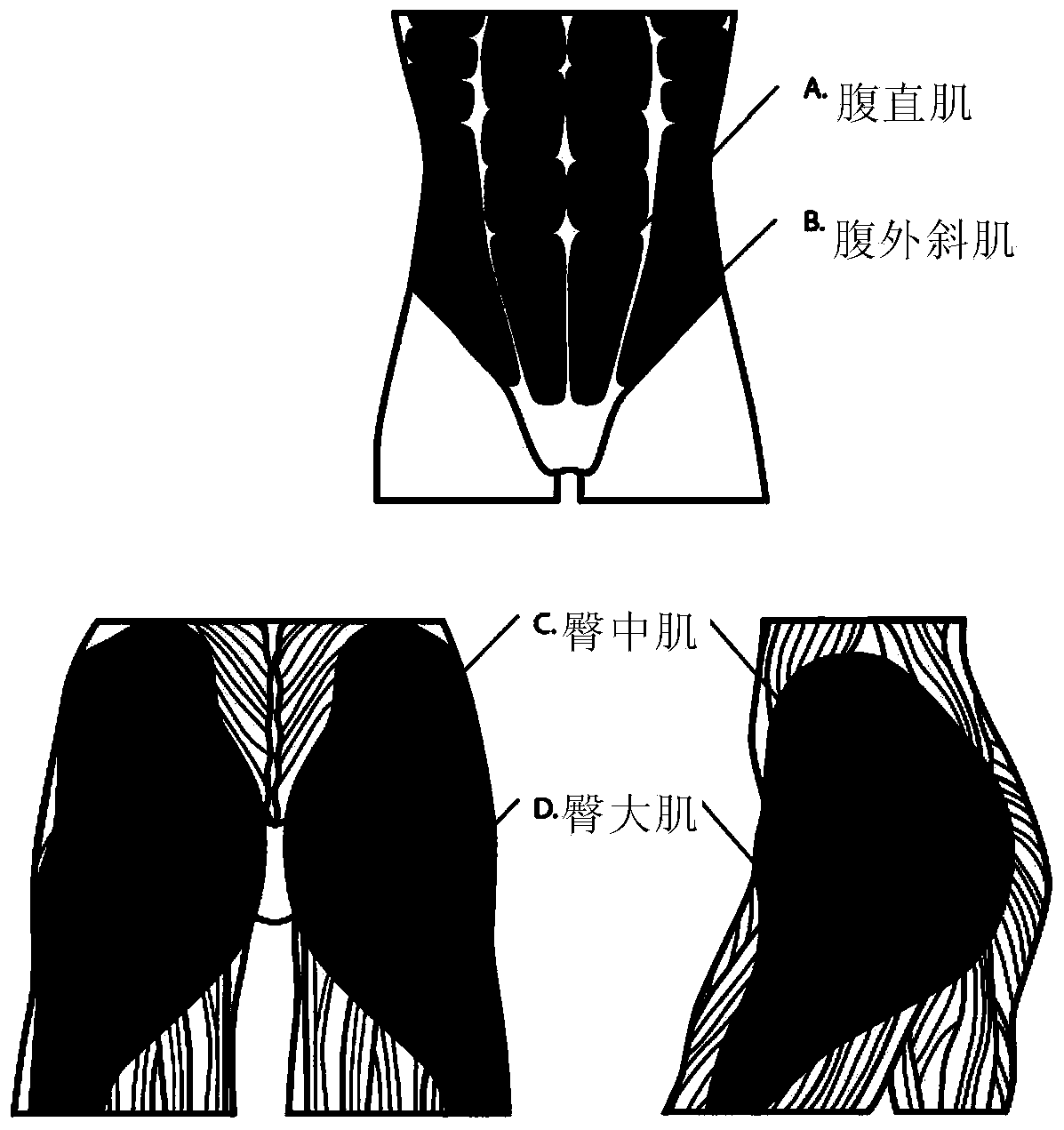

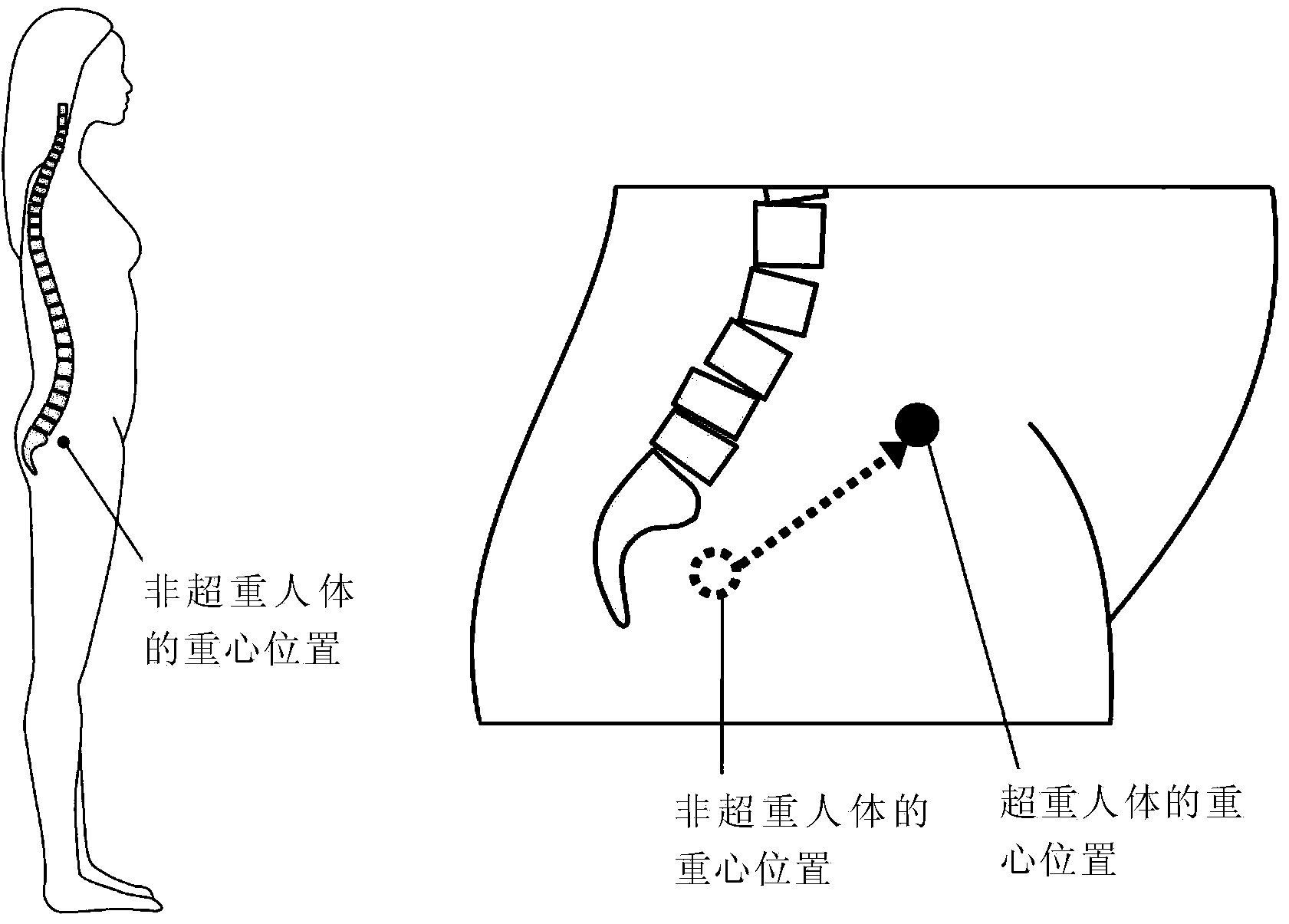

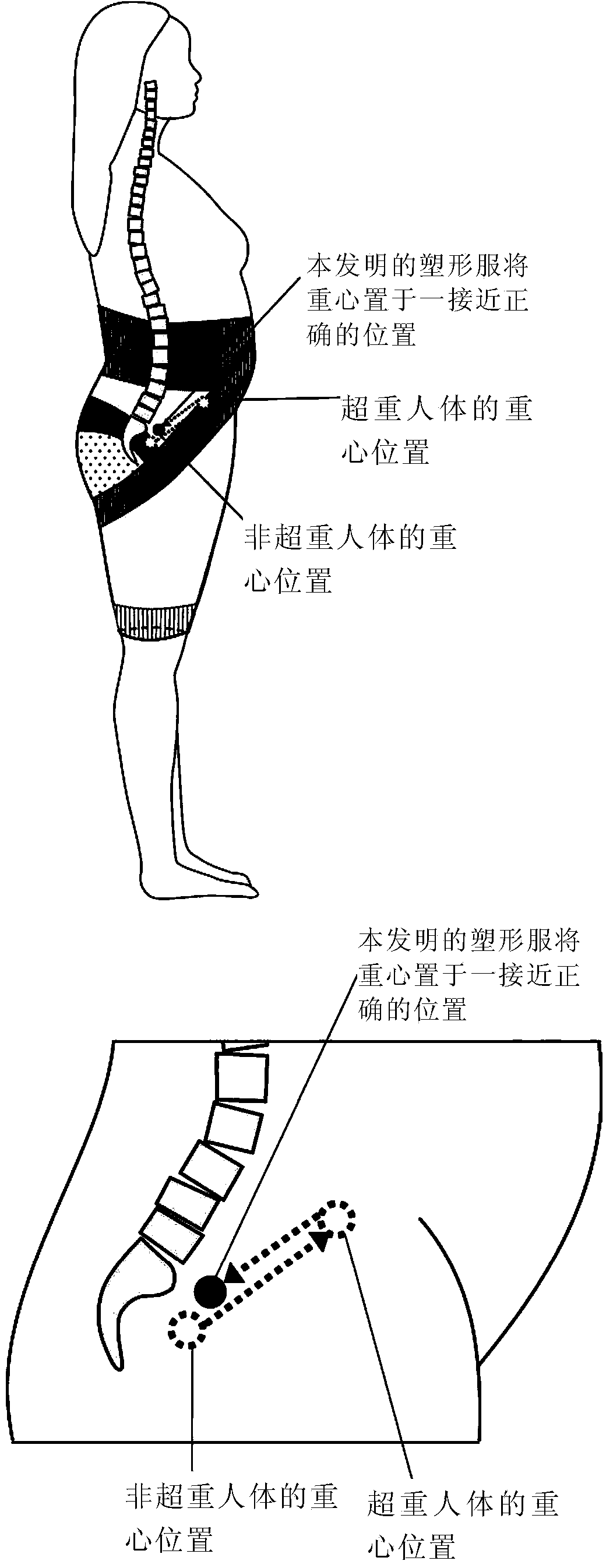

Functional slimming shorts

A kind of functional shorts (1) comprises a thigh section (2), a waist-shaping section (3), an abdomen-shaping section (4), and an adjusting band (7). The majority of the waist-shaping section (3) may be above an umbilicus. The waist-shaping section (3) may exert more force than the adjusting band (7). The waist-shaping section (3), the abdomen-shaping section (4), and the adjusting band (7) assist in correcting one's center of gravity and realigning one's vertical access.

Owner:S·马佐里克

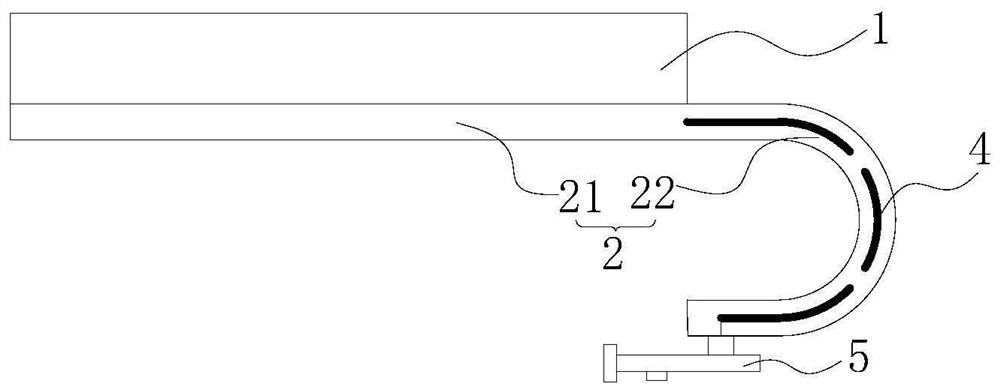

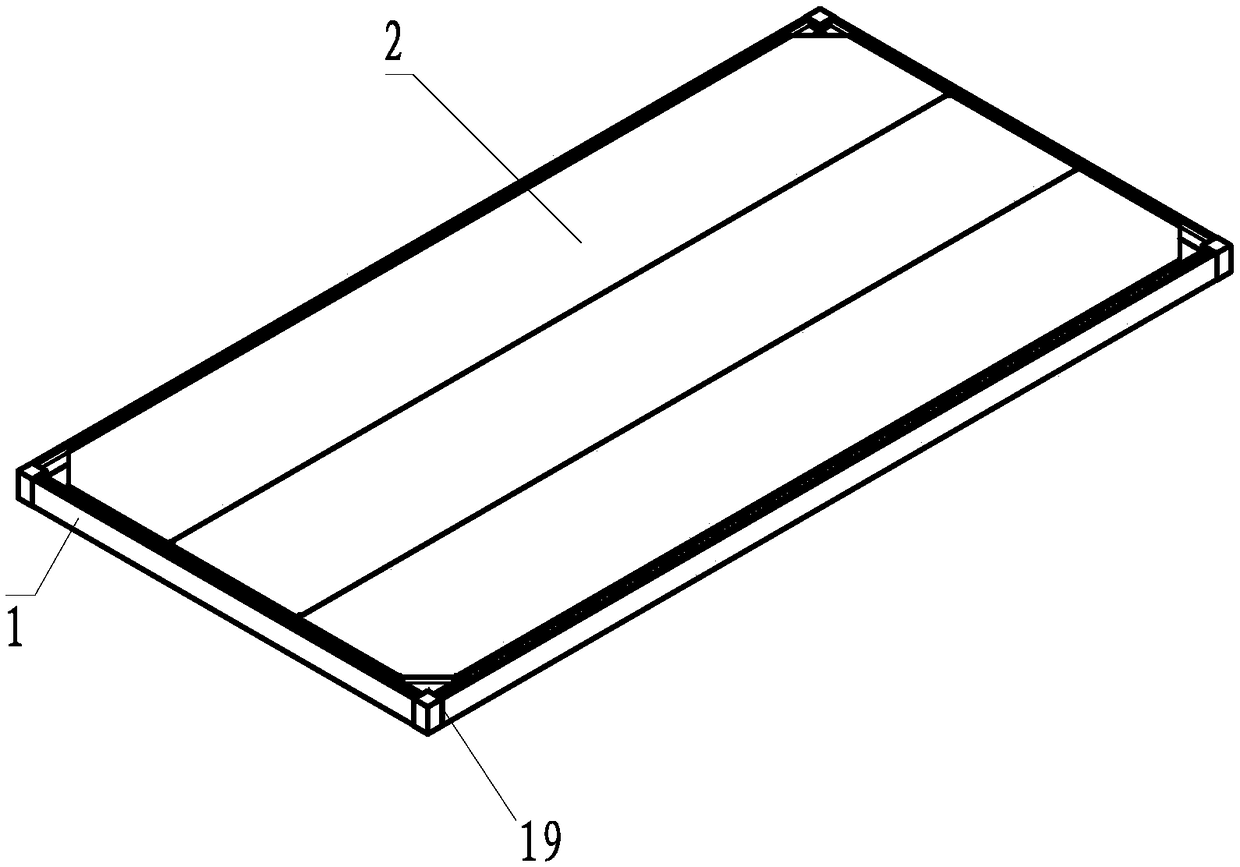

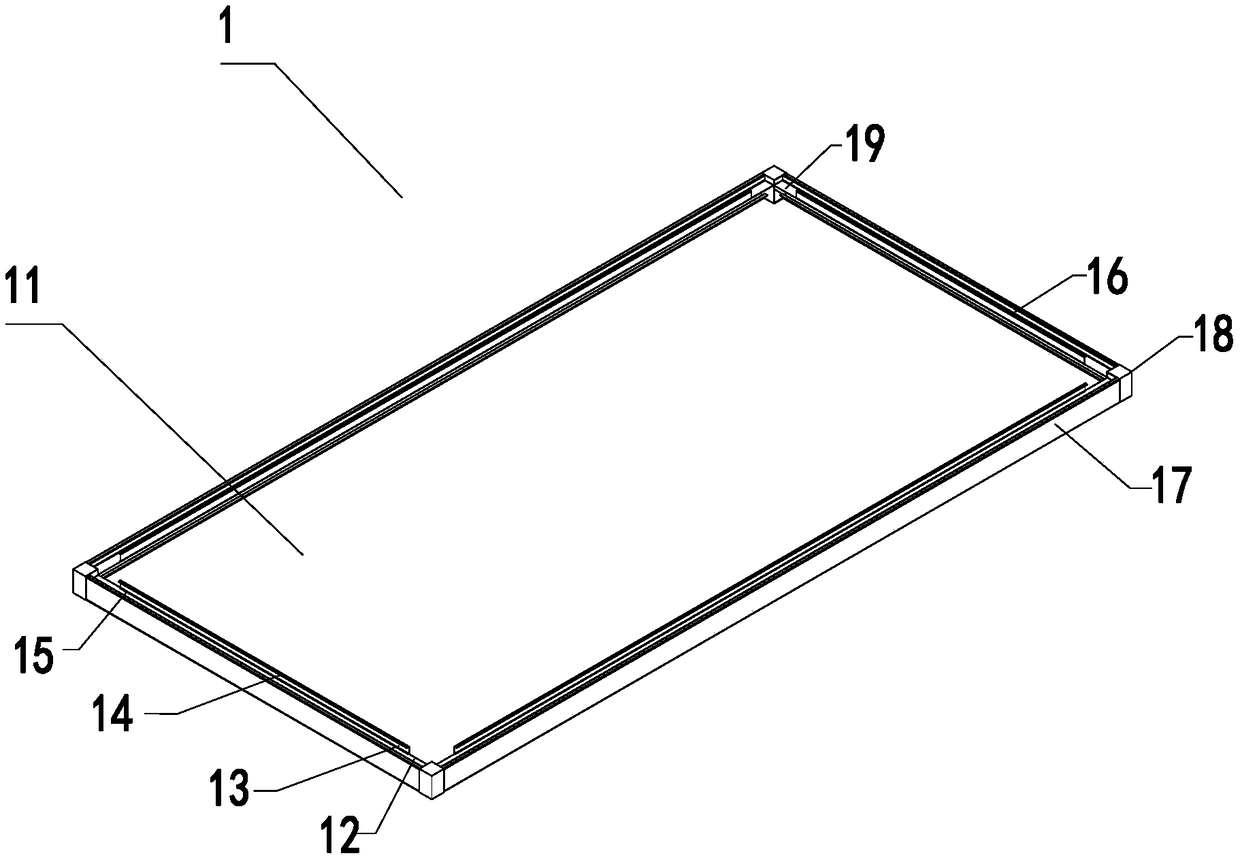

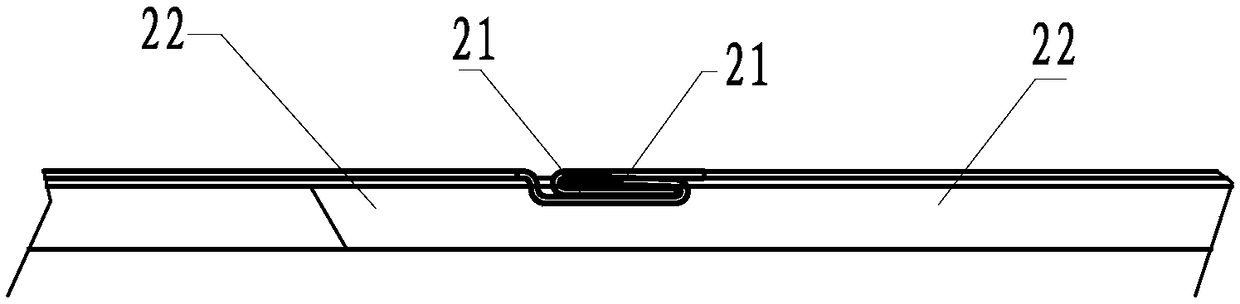

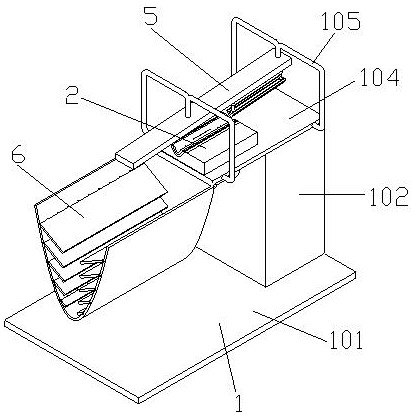

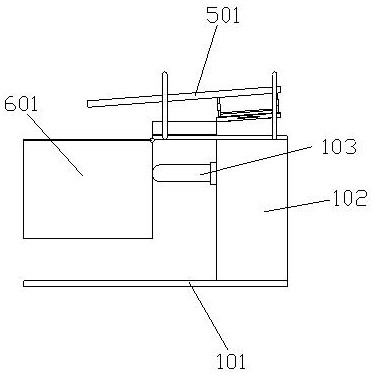

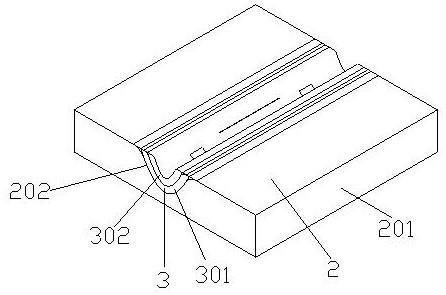

A processing method for the top structure of a residential container

ActiveCN107090990BNovel structureRealize automated productionSpecial buildingRoof toolsEngineeringMechanical engineering

The invention provides a processing method of the top structure of a house-type container. The method includes the following steps that 1, a rectangular frame is manufactured, wherein the rectangular frame has a containing space, a circle of fence is arranged on the periphery of the frame, the side, facing the containing space, of the fence extends horizontally inwards to form a platform, the free end of the platform extends vertically upwards to form a surrounding edge, the free end of the surrounding edge extends horizontally in the direction away from the containing space to form a skirt edge, and a containing groove is formed between the surrounding edge and the side face, facing the containing space, of the fence; 2, a top plate is placed in the containing space, wherein locking edges are arranged around the top plate, and when the top plate is placed in the containing space, one part of each locking edge covers the upper surface of the skirt edge, and the other part of each locking edge hangs down along the free end of the skirt edge; 3, an edge locking machine is placed on the surrounding edge, a squeezing mechanism of the edge locking machine is placed in the containing groove, and when the edge locking machine moves, the squeezing mechanism makes contact with and squeezes the hanging parts of the locking edges to make the hanging parts bent in the direction close to the lower surface of the skirt edge.

Owner:XIAMEN ZHENGLIMING METALLURGICAL MACHINERY

Transmission belt fatigue test tool, fatigue testing machine and fatigue testing method

The invention relates to a driving belt fatigue testing tool, a fatigue testing machine, and a fatigue testing method, and the tool, machine and method are used for the fatigue testing of a driving belt. The tool comprises a supporting frame, a belt pulley, and a tension pulley. The supporting frame comprises an installation part, and the tension pulley and / or the belt pulley are / is connected to the installation part in an adjustable manner. The axis of the belt pulley and the axis of the tension pulley are parallel to each other, and the bending angle of a to-be-tested driving belt wound around the belt pulley and / or the tension pulley can be adjusted. Through the adjustment of the belt pulley and / or the tension pulley, the tool can change the bending angle of the to-be-tested driving belt wound around the belt pulley and / or the tension pulley, and can meet the demands of the testing of fatigue characteristics and service life of the driving belt in different bending force states.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

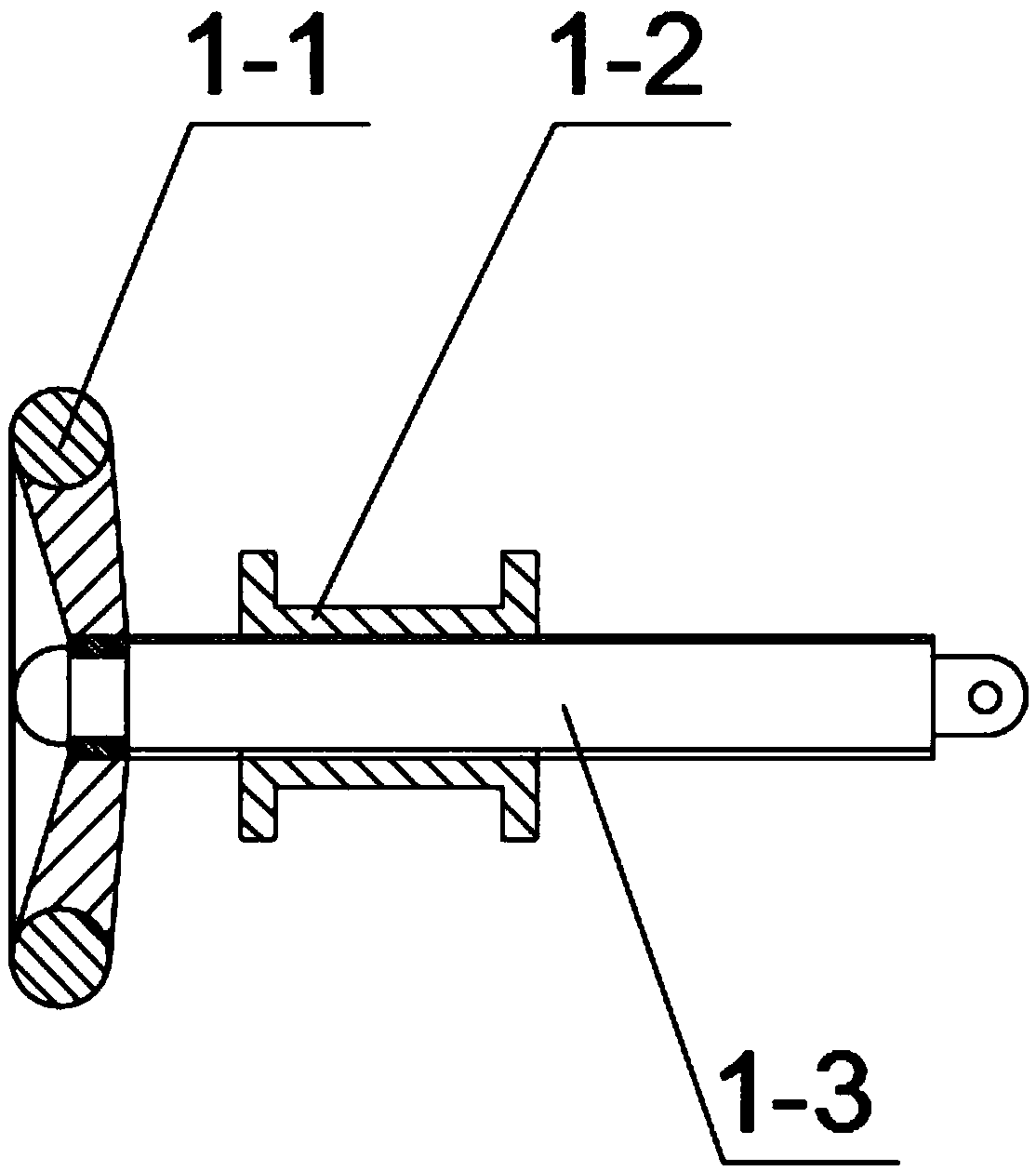

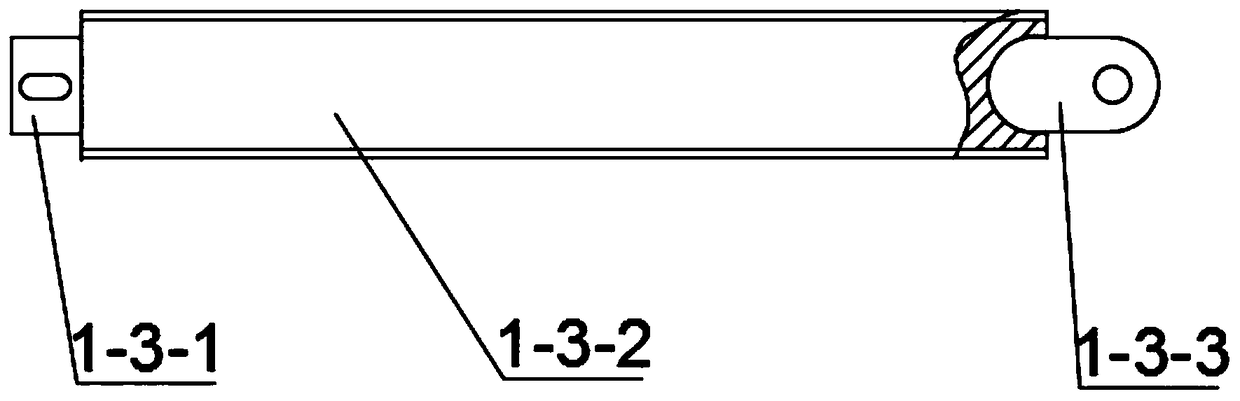

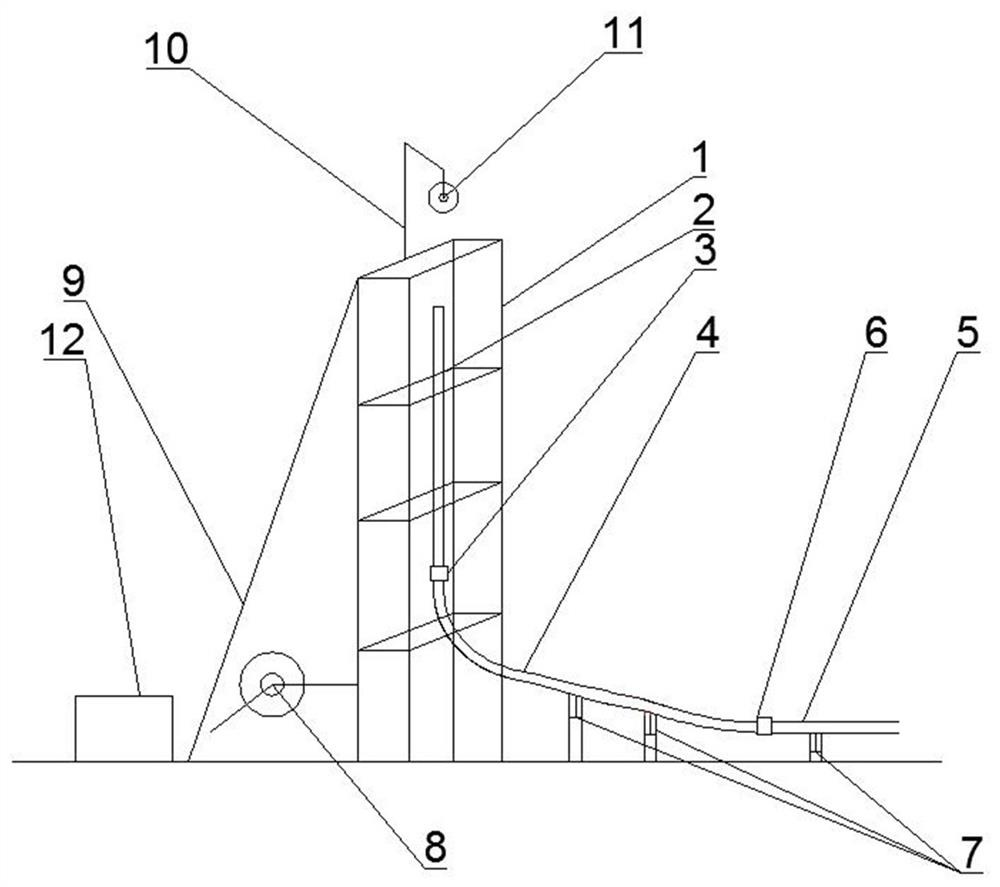

Visualized test device for trafficability of operation tool string in inclined shaft

The invention provides a visualized test device for trafficability of a rope operation tool string, relates to the technical field of oil exploitation test devices, and can simulate trafficability tests of various tool string combinations under the conditions of different oil pipe sizes, different well deviation and azimuth angles and different shaft environments. Test data is provided for optimization and combination of the rope operation tool string in an on-site inclined well section. The visualized test device for trafficability of the rope operation tool string comprises a fixing frame (1), a vertical transparent pipe (2), a connector I (3), a transparent hose (4), a horizontal transparent pipe (5), a second connector II (6), adjusting oil cylinders (7), a middle pulley (8), a guy rope (9), a top pulley support (10), a top pulley (11) and a winch (12). The visualized test device for trafficability of the rope operation tool string is simple in structure and low in manufacturing cost, various oil pipe sizes can be replaced, well deviation and azimuth angles can be adjusted at any time, various wellbore environments can be simulated, test means are provided for newly-developed rope operation tools, and a basis is provided for on-site operation tool selection.

Owner:中国石油天然气股份有限公司西南油气田分公司工程技术研究院

Bending mechanism for stainless steel product production

ActiveCN114769373AGuaranteed yield and pass rateImproved Angle AdjustabilityShaping toolsMetal-working feeding devicesSteel platesStructural engineering

Owner:TAIZHOU JUNYU STAINLESS STEEL MATERIAL CO LTD

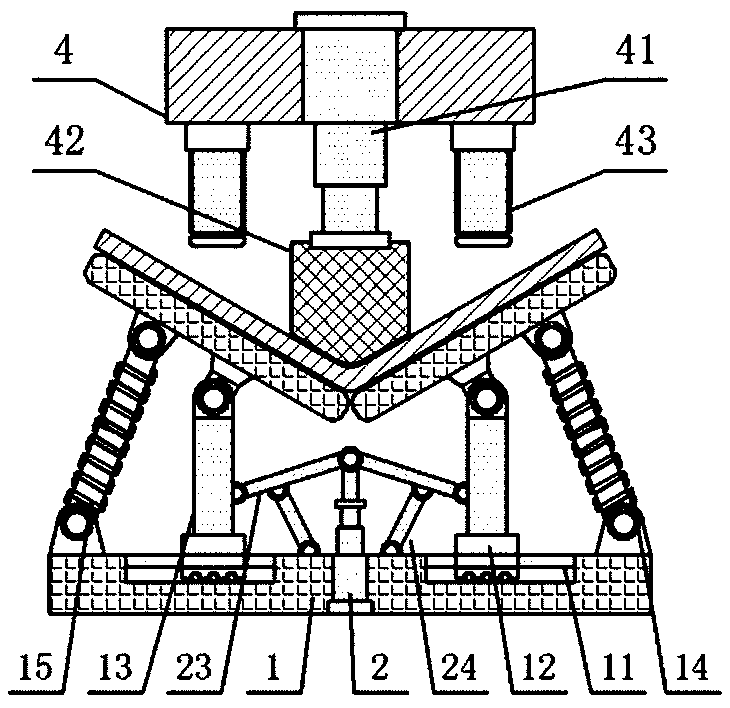

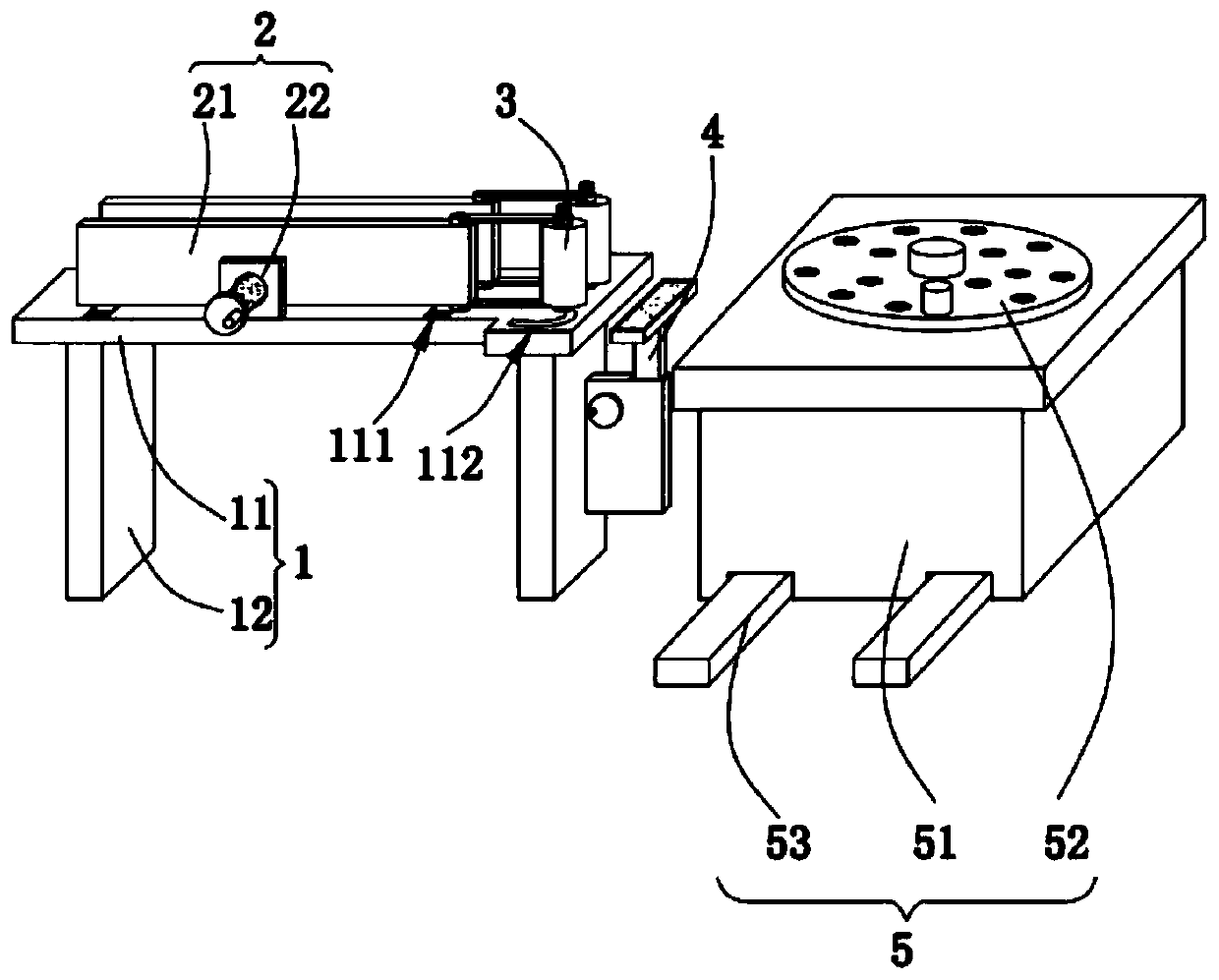

A kind of bending method of thin-walled ring profile

ActiveCN108637042BSmooth movementReduce laborMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention relates to the technical field of structural component bending, in particular to a thin-wall ring sectional material bending method. A bending machine adopted by the method comprises a supporting mechanism, a clamping mechanism, conveying mechanisms, a lifting mechanism and a machining mechanism. Sectional materials can be limited and clamped through clamping plates and can be placedon an object placing mechanism, so that the sectional materials are not required to be handheld so as to be bent and machined through manual work, and the labor capacity of a worker is reduced effectively; a space between the clamping plates can be regulated according to the widths of the sectional materials, and the object placing mechanism can make stretching motion when the space between the clamping plates is changed, so that the clamping mechanism is wider in application scope; the motion of the sectional materials is more fluent through balls distributed on the inner walls of the clamping plates; and the conveying mechanisms are rotationally connected with the clamping mechanism, so that a space between the two conveying mechanisms can be regulated according to the widths of the sectional materials, and automatic conveying is achieved.

Owner:NANTONG GUANGYI ELECTROMECHANICAL CO LTD

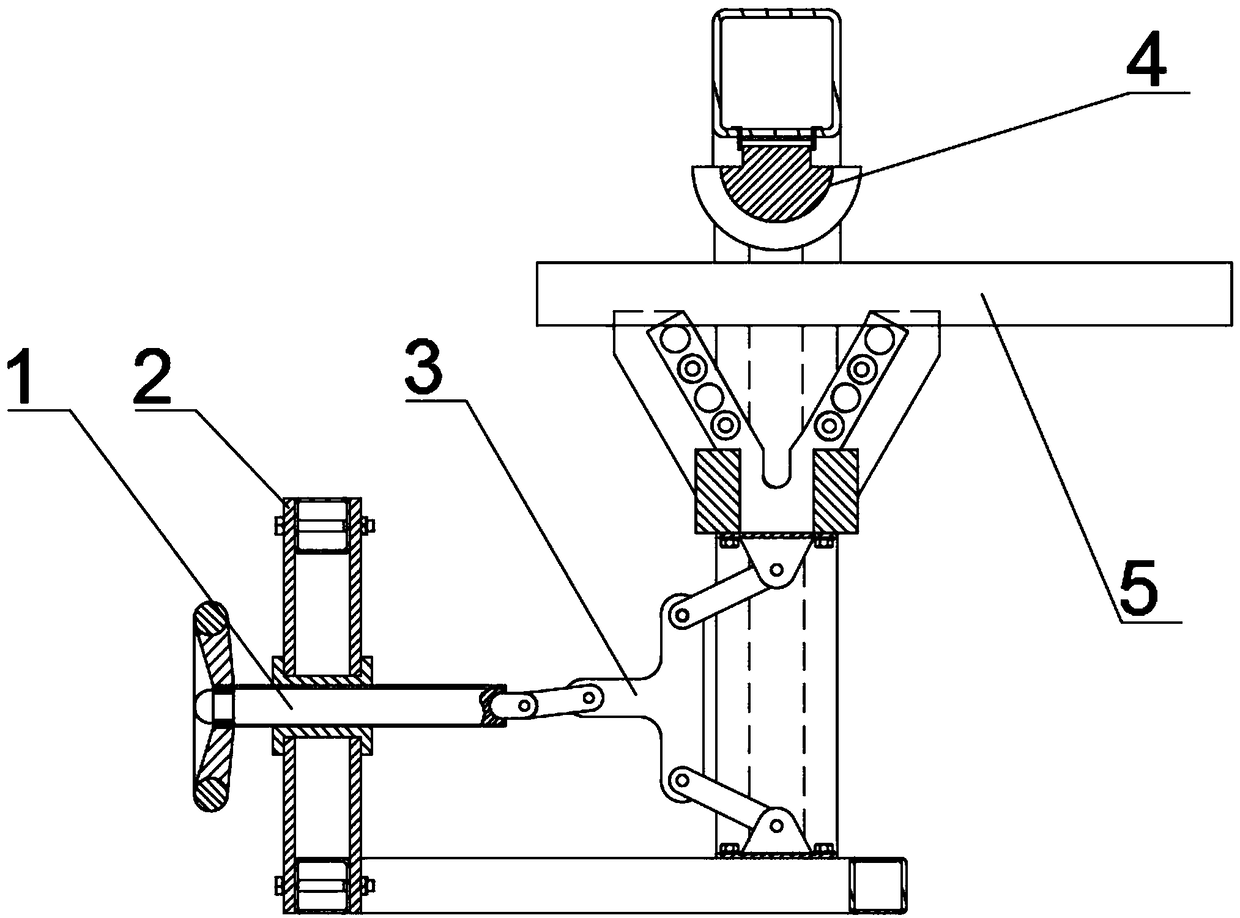

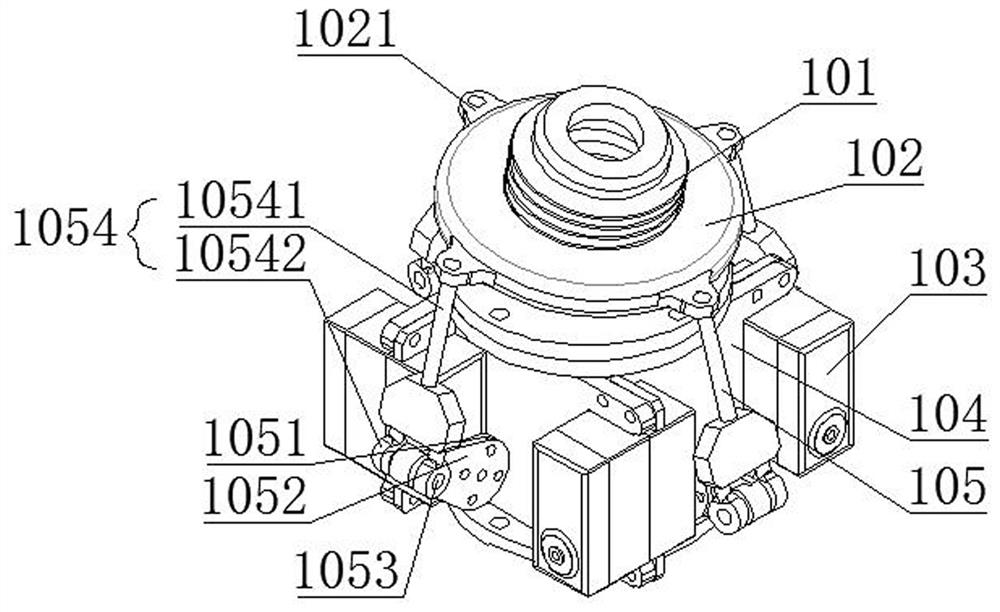

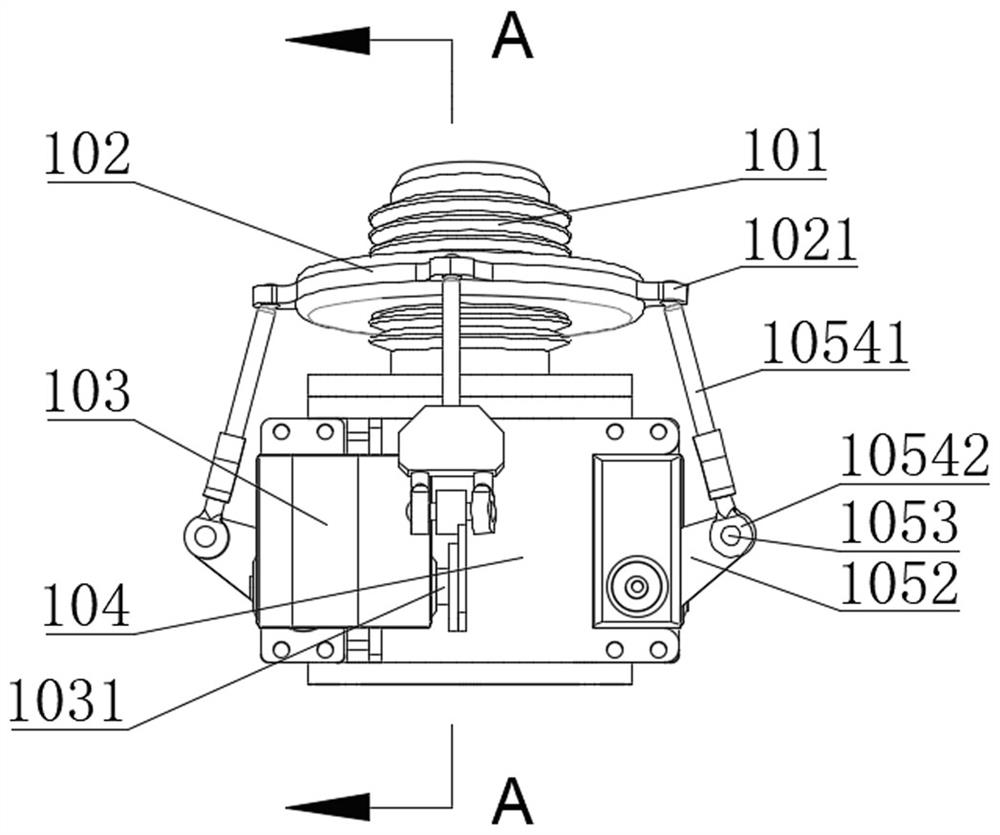

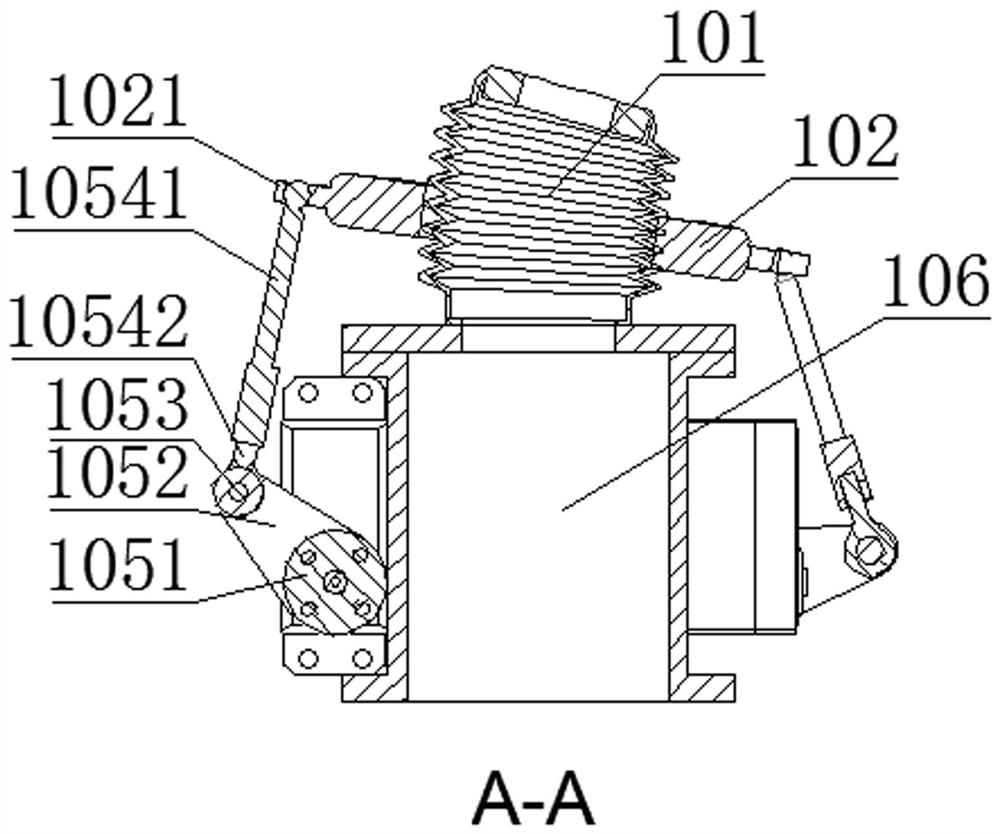

A nozzle orientation vector control structure

The invention provides a nozzle orientation vector control structure, which includes a corrugated nozzle, an amplitude modulation ring and several steering gears; The connection positions are different, and each crank connection mechanism adjusts the height of different connection positions of the amplitude modulation ring, so that the inclination angle of the amplitude modulation ring is variable, and the amplitude modulation ring is clamped outside the corrugated nozzle. In the nozzle azimuth vector control structure, the steering gear drives the connecting crank of the rudder disc to rotate, and the connecting crank of the rudder disc drives the connecting rod to rotate, and then changes the height position of the connecting ear of the amplitude modulation ring connected to the connecting rod. According to the inclination angle of the AM ring, the four steering gears raise or lower the connecting ear of the AM ring according to different height requirements, and the inclination angle of the AM ring changes accordingly. After the inclination angle of the amplitude modulation ring is changed, the bending angle of the corrugated nozzle is also changed, thereby changing the jetting angle of the gas.

Owner:气味王国(山东)科技有限公司

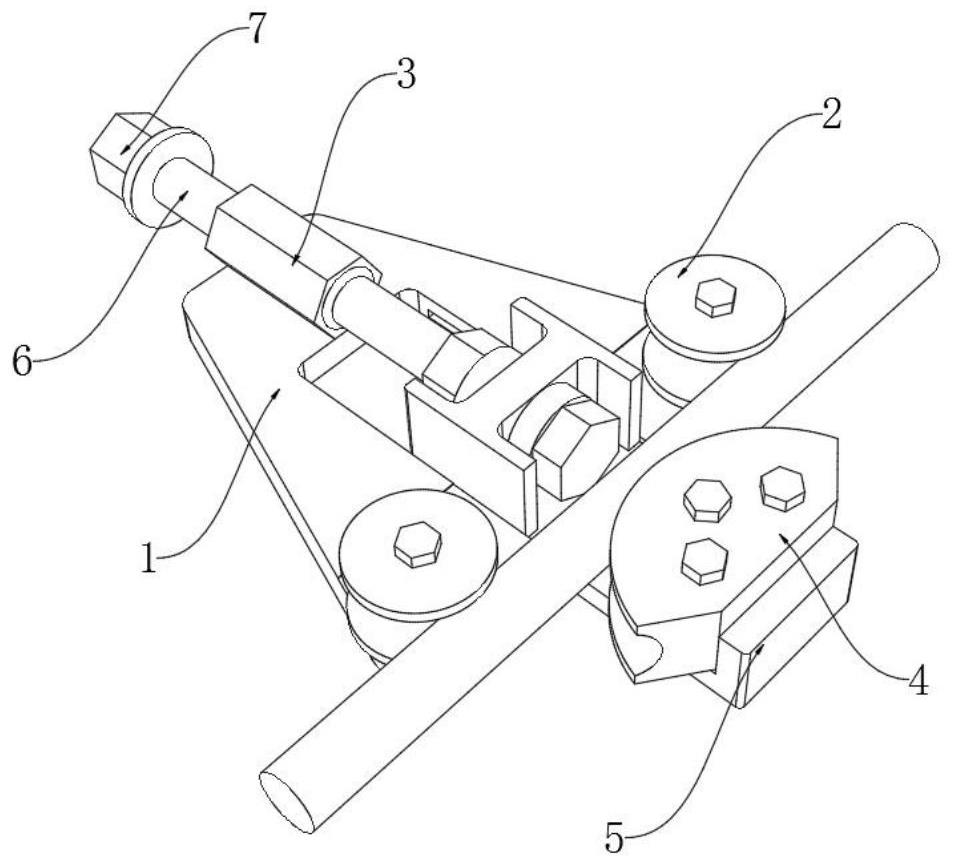

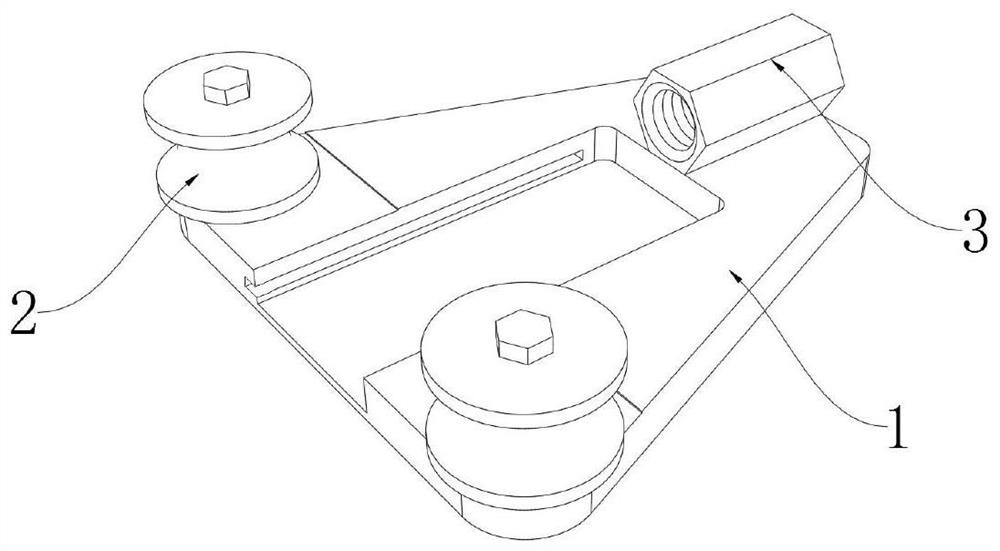

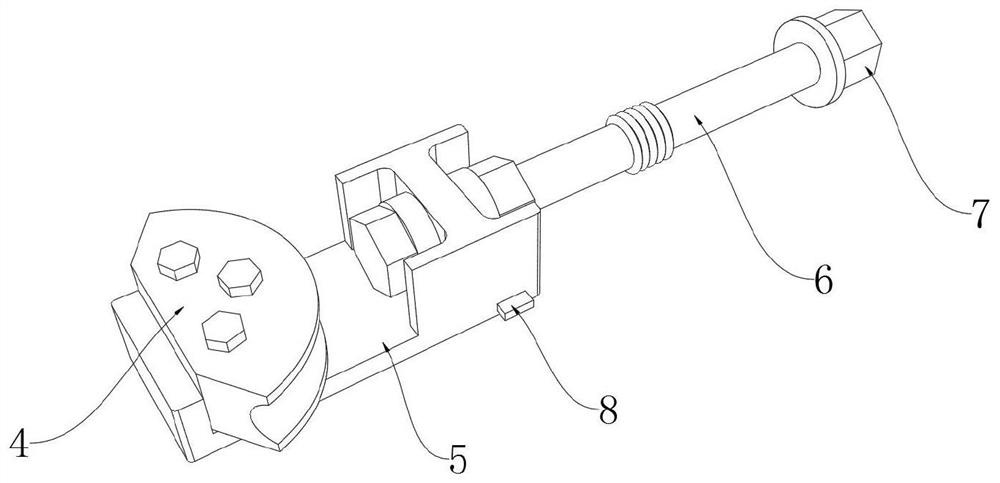

Steel wire rope bending tool

The invention provides a steel wire rope bending tool which comprises a fixing flat plate, an auxiliary rotating wheel, a fixing block, an arc-shaped positioning plate, a connecting plate, a connecting rod, a rotating nut and a thrust bearing. Bending operation of the steel wire rope can be simplified, strand loosening of the steel wire rope is avoided, and the strength requirement is met. The bending angle of the steel wire rope can be changed by replacing the arc-shaped positioning plates in different shapes and adjusting the distance between the two auxiliary rotating wheels, and the connecting plate can be prevented from being separated from the fixed flat plate during moving through cooperation of the fixed flat plate, the connecting plate and the sliding block.

Owner:BEIJING NORTH VEHICLE GROUP CORP

An anti-misalignment angle adjustable bending device for steel plate production

ActiveCN111167904BInhibition biasImprove practicalityMetal-working feeding devicesPositioning devicesClassical mechanicsStructural engineering

The invention discloses a misalignment-proof angle-adjustable bending device for steel plate production, which includes a base body, a hydraulic rod, a butt joint pressure head and an electric cutter. A hydraulic rod is installed through the middle end of the base body, and the hydraulic pressure The output end of the rod is rotatably connected with a butt press head, the outer end of the butt press head is fixedly connected with a traction rope, and the traction rope is connected with the inner surface of the base body, the outer surface of the base body is rotatably connected with a connecting shaft, and connected The outer surface of the shaft is fixedly connected with a lower limit block, the outer surface of the base body is provided with a first chute, and the inner surface of the first chute is fixedly connected with a return spring. The anti-misalignment angle-adjustable bending device for steel-shaped plate production uses a hand-held threaded rod to drive the docking retaining wheel to adjust and control the upper and lower positions along the upper end of the base body, thereby changing the height and position of the docking retaining wheel so that the butt joint pressure The ejection height of the head is controlled, so that the bending angle at which it contacts the workpiece can be easily changed.

Owner:绍兴市卓诚新材料有限公司

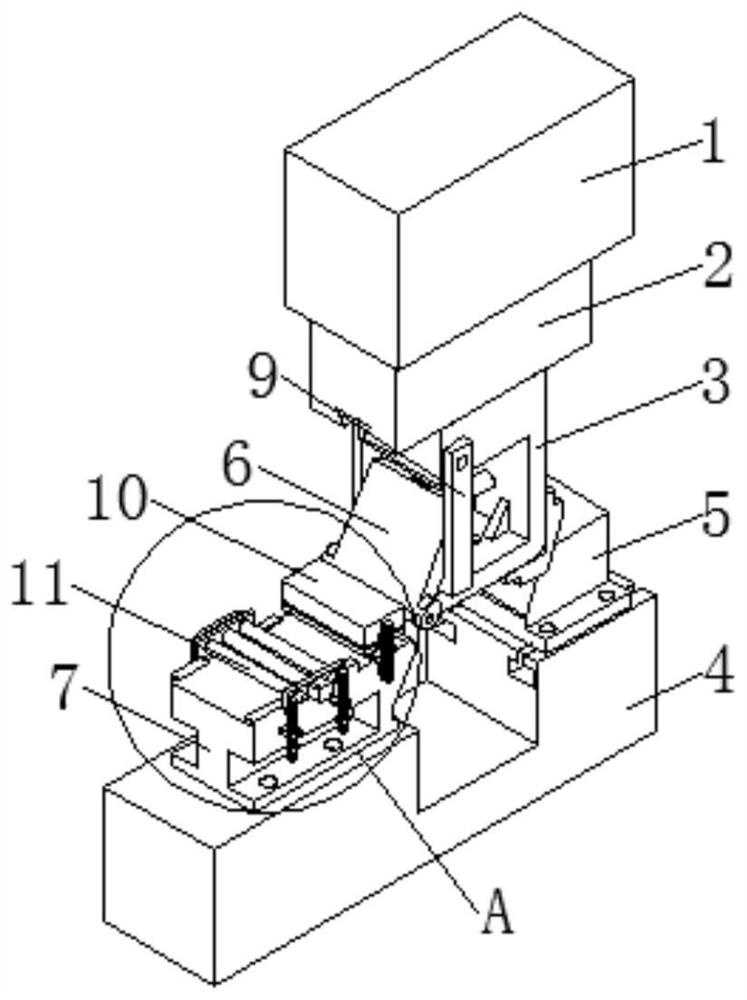

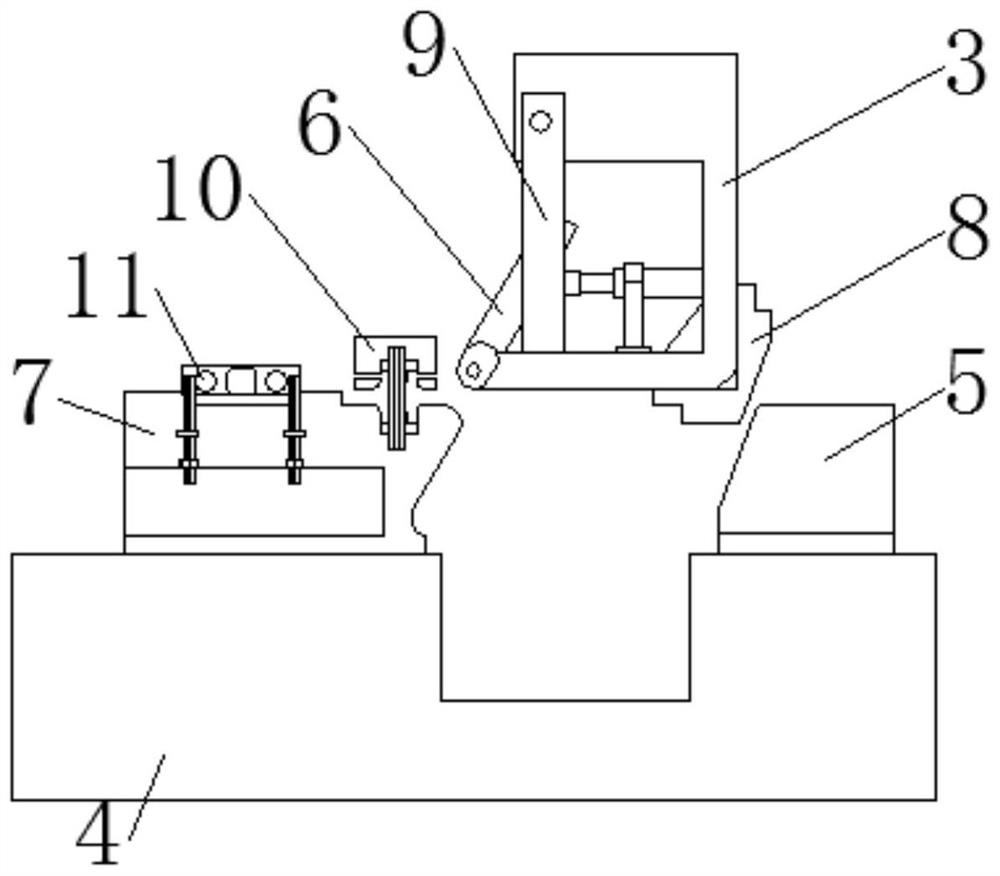

Clothing arching testing device and clothing arching testing method

ActiveCN111007003AReproduce deformationImproving the Efficiency of Arching ExperimentsUsing mechanical meansMaterial analysisImaging processingImage manipulation

The invention discloses a clothing arching testing device and a clothing arching testing method. At present, a common fabric arching test method is a steel ball jacking test sample method, and although the method measures arching residual deformation, arching deformation generated in the actual wearing process of clothes cannot be completely simulated. The device comprises a flexion and extensiondriving module, a rack and a leg simulation mechanism, the flexion and extension driving module comprises a single-side flexion and extension assembly, an air cylinder and a driving rod. The leg simulation mechanism comprises a flexible sleeve, a shank supporting rod, a thigh supporting rod, an inflatable air bag and a hook-and-loop fastener. The flexible sleeve is sleeved on the shank supportingrod and the thigh supporting rod and consists of a shank sleeve, a thigh sleeve and a connecting sleeve which are connected in sequence; knee movement can be simulated, and the arching condition of the fabric when the fabric is subjected to various external forces can be reproduced. According to the method for evaluating the arching performance of the fabric, a plurality of indexes capable of reflecting the arching degree are obtained through an image processing technology, and the arching grade can be predicted according to the established linear model.

Owner:ZHEJIANG SCI-TECH UNIV

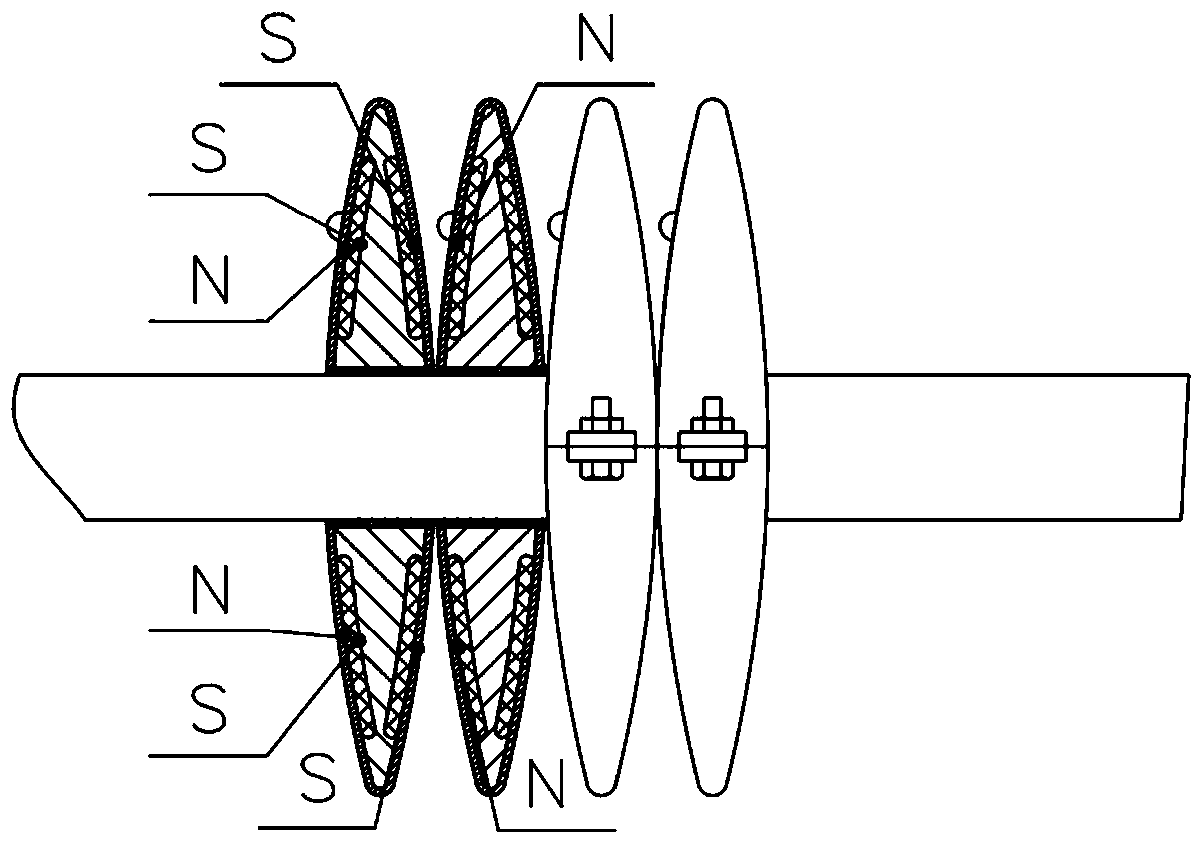

An electromagnetic type ultra-thin-wall pipe multi-diameter segmental bending forming device

The invention discloses an electromagnetic ultra-thin-wall pipe multi-bending-diameter sectional bending forming device. The device comprises a plurality of basic unit bodies which are arranged on a pipe in a sleeving mode and are the same in structure, each basic unit body is mainly composed of a base body, limiting protrusions and electromagnets, the base body is divided into two sub base bodieshalf-and-half, semicircular holes are formed in the middles of the contact end surfaces of the two sub base bodies correspondingly, the semicircular holes are in butt joint to form a through hole forallowing the pipe to penetrate therethrough to be installed, the electromagnets are arranged in the two sides of each of the two sub base bodies, the magnetic pole polarity directions of the electromagnets are in the axial direction of the pipe, and the limiting protrusions are arranged on the surfaces of the two sides of each of the two sub base bodies. According to the device, the acting forcedistribution is more uniform compared with that of a traditional pipe bending mechanism, the bending processing quality of the pipe is improved, the device is suitable for processing of the ultra-thin-wall pipes and pipe bending operation at the assembling field, the processing plane can be changed, all the unit bodies can be located at different planes according to requirements, and the spatial arbitrary curve bending processing of the pipes can be realized at the assembling field.

Owner:ZHEJIANG UNIV

Display screens and display devices

ActiveCN111627331BChange bend angleReduce the magnitude of the tensile stressPrinted circuit detailsIdentification meansDisplay deviceElectrical connection

The invention provides a display screen and a display device. The display screen includes a display panel and a flexible substrate. The display panel includes a plurality of pads arranged adjacently. The flexible substrate includes a display part and a bending part. The first surface of the bending part There are a plurality of protrusions, and at least one metal trace is provided on the surface of each protrusion, and each metal trace is electrically connected to the corresponding pad; on the one hand, when the bending part is bent, the metal trace is attached to the The raised surface has a three-dimensional structure, thereby changing the bending angle of the metal traces, thereby reducing the tensile stress on the metal traces, and ensuring the stability of the connection between the display panel and the PCB board; on the other hand, it can increase the The length of the trace is such that when the metal trace is bent, the increased length can effectively compensate for the increased length required due to stretching.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com