Split adjustable knee joint fixer

An adjustable knee joint technology, used in stereotaxic surgical instruments, medical science, surgery, etc., can solve problems affecting surgical operations, patient limb instability, waste of manpower, etc., to improve surgical efficiency, eliminate limb instability, The effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

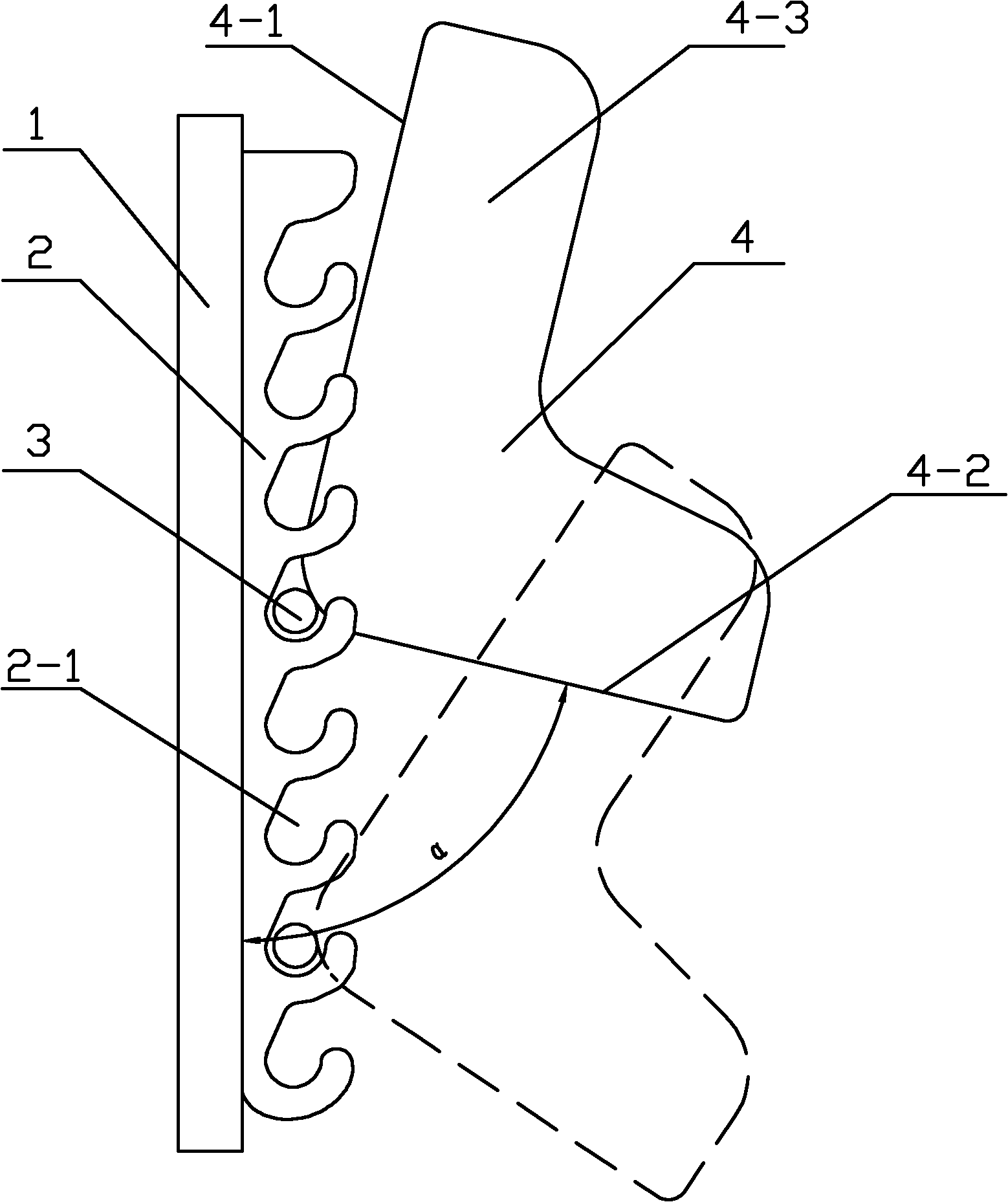

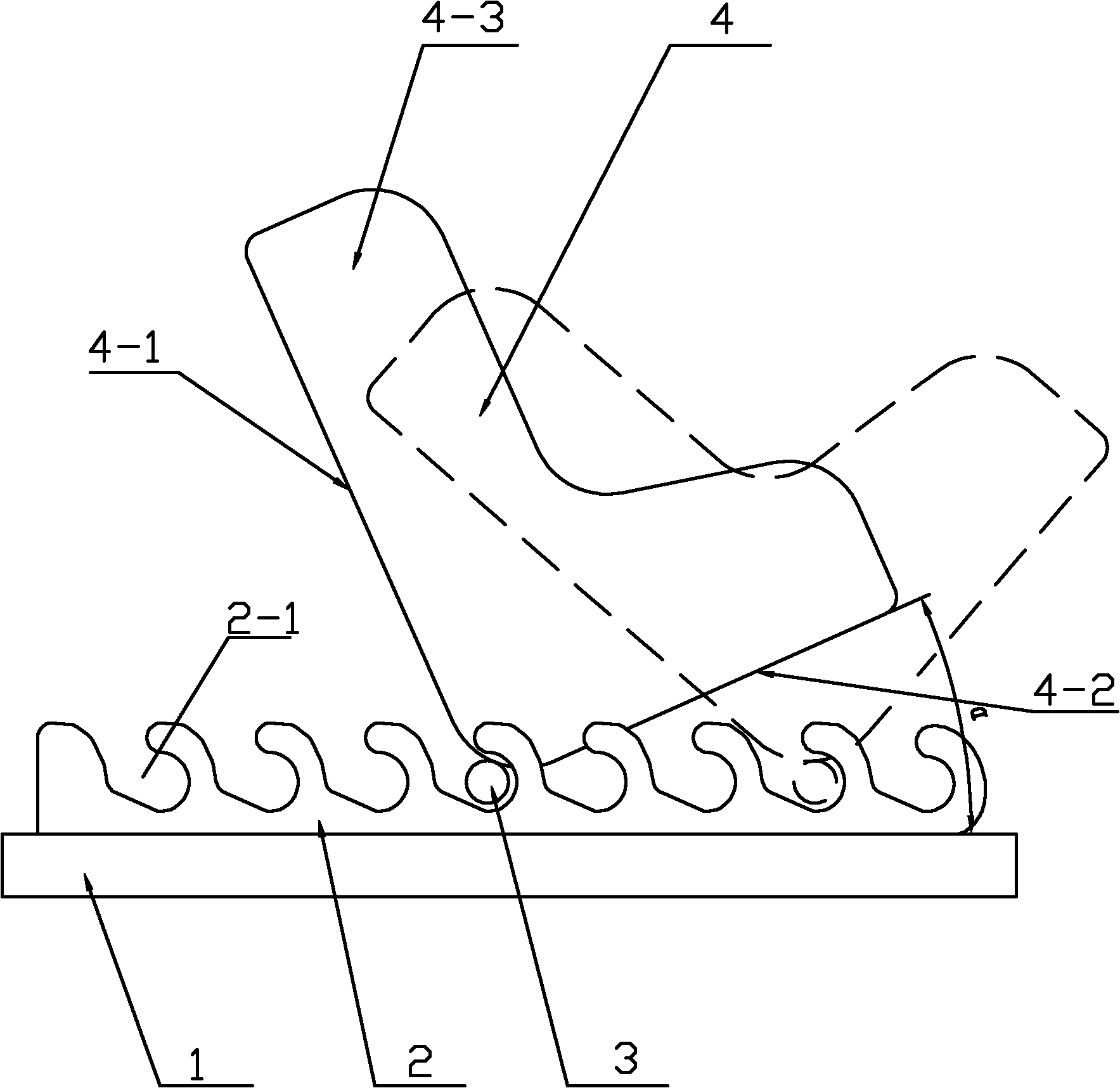

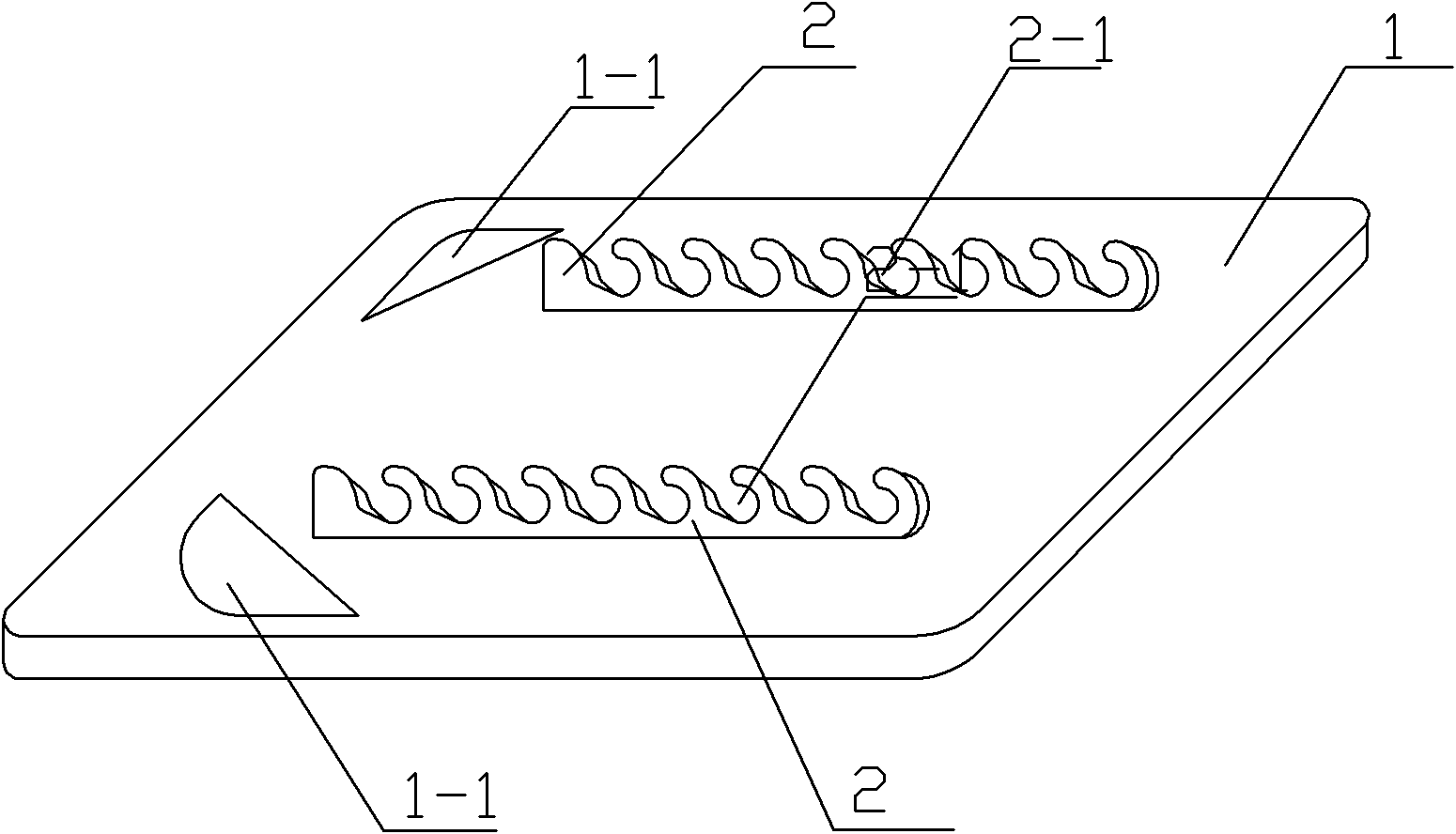

[0007] Specific implementation mode one: as Figure 1-5 As shown, a split-type adjustable knee fixator described in this embodiment includes a base plate 1, two positioning bars 2, an adjustment shaft 3 and a fixing shoe 4, and each positioning bar 2 is provided with several card slots 2- 1. The shape of each positioning bar 2 is jagged, and the back end faces of the two positioning bars 2 are arranged side by side and parallel on the upper end face of the bottom plate 1 and fixedly connected with the upper end face of the bottom plate 1. The adjustment shaft 3 and the heel of the fixed shoe 4 The fixed shoe 4 is located between the two positioning bars 2, and the two ends of the adjustment shaft 3 are respectively clamped in the corresponding slots 2-1 on a positioning bar 2. This embodiment ensures that during the knee joint operation, when the posture of the patient's thigh remains unchanged, by changing the adjustment shaft 3, that is, the adjustment shaft 3 is in the slot...

specific Embodiment approach 2

[0008] Specific implementation mode two: as Figure 1-5 As shown, the fixed boot 4 of a split-type adjustable knee joint fixer described in this embodiment includes a curved vertical plate 4-1, a sole support plate 4-2 and two L-shaped side plates 4-3, two L-shaped side plates 4-3 The side plates 4-3 are vertically arranged side by side on the upper surface of the sole support plate 4-2, and the lower ends of the two L-shaped side plates 4-3 are fixedly connected to the front edge and the rear end edge of the sole support plate 4-2 respectively. , the lower end of the curved surface vertical plate 4-1 is affixed to the side edge of the sole support plate 4-2, and the two side edges of the curved surface vertical plate 4-1 are respectively connected to the side ends of the two L-shaped side plates 4-3 The edges are fixed, and the curved surface contour of the curved surface vertical plate 4-1 is consistent with the outer contour of the calf of the human body. This embodiment e...

specific Embodiment approach 3

[0009] Specific implementation mode three: as Figure 1-5 As shown, two semicircular through holes 1-1 are opened at one end of the bottom plate 1 of the one-piece adjustable knee joint fixer described in this embodiment. This embodiment guarantees the operation process of the knee joint. The base plate 1 can be fixed on the operating table with a surgical towel or gauze to ensure that the patient’s limbs remain stable during the operation, the fixed angle of the patient’s knee joint remains unchanged, and the base plate 1 will not be affected by the patient The leg slides freely due to the strength it implements, which in turn affects the operation. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com