Willow branch willow bending equipment for wicker basket processing

A technology of willow branches and equipment, which is applied in the field of willow handicraft processing, can solve the problems of affecting the appearance, the unsatisfactory fixing effect of willow branches, and the inability to adjust the limit column, etc., and achieves the effect of high applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

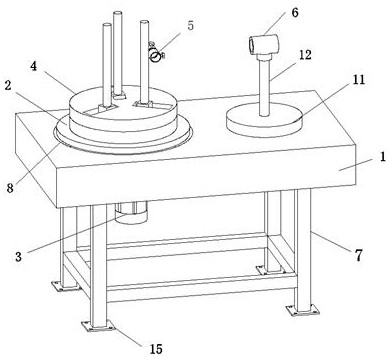

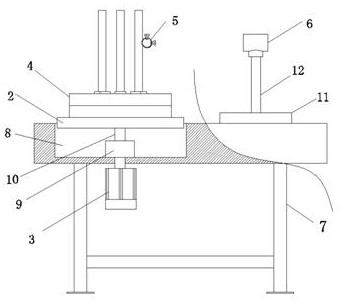

Image

Examples

Embodiment 2

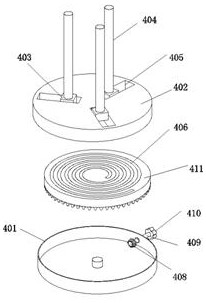

[0044] Embodiment 2 is implemented on the basis of 1, such as Figure 8 and Figure 9 As shown, the willow branch transmission assembly 6 also includes a cleaning pipe 604 and an annular blade 605, the cleaning pipe 604 is fixed to the entrance of the transmission sleeve 601 through a pair of connecting pieces 606, and the inner wall of the cleaning pipe 604 is fixedly equipped with an annular blade 605; A collection tray 13 is placed on the upper surface of the round platform 11 , and a locking groove 14 is opened inside the collection tray 13 , and the collection tray 13 is clipped to the outer wall of the column 12 .

[0045] Embodiment 2 In the working process, willow branches will first enter the inside of the cleaning pipe 604, and the inner wall of the cleaning pipe 604 is fixedly equipped with an annular blade 605, so that the annular blade 605 can remove branches or branch heads on the wicker, reducing the labor force of the staff. Due to the workload, the removed de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com