Patents

Literature

114results about How to "Precise control of shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

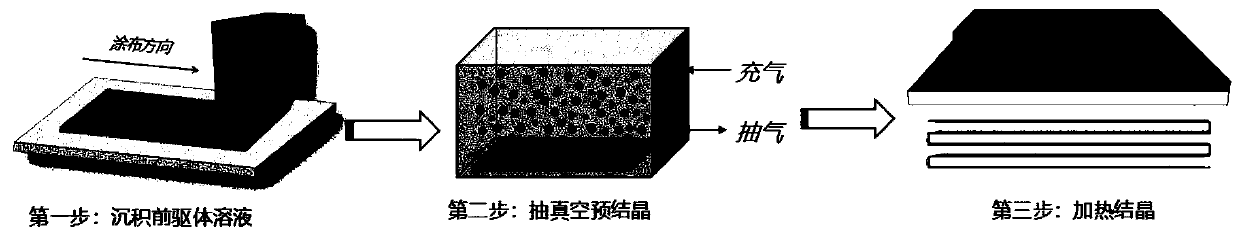

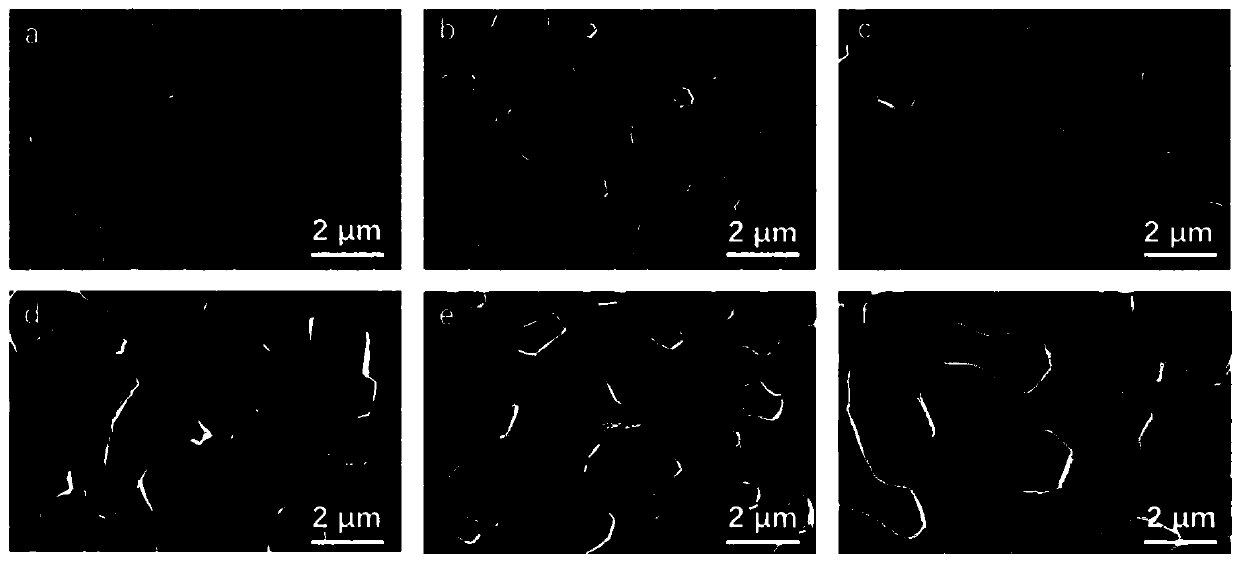

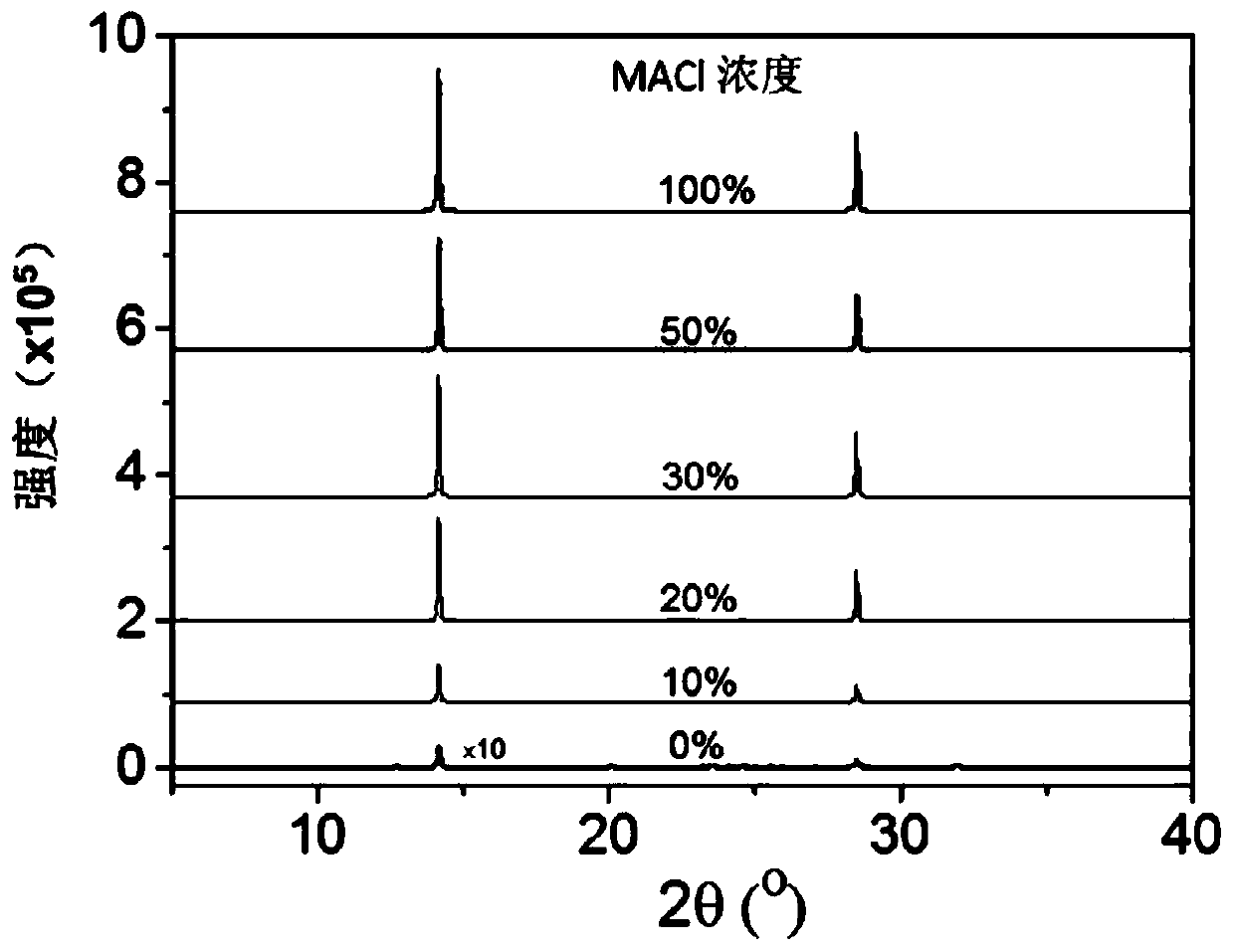

Perovskite polycrystalline film printing preparation method

PendingCN110212098ARegulate and control the crystallization processPromote formationSolid-state devicesSemiconductor/solid-state device manufacturingMaterials preparationCrystallinity

The invention belongs to the field of a material preparation process and discloses a perovskite polycrystalline film printing preparation method. The method is characterized by, to begin with, addingproper amount of additives into a perovskite precursor solution to obtain a mixed solution; then, printing the mixed solution on a substrate under a low temperature condition to form a layer of precursor wet film; vacuumizing the precursor wet film to form an intermediate-phase perovskite film; and finally, carrying out thermal annealing processing to obtain a perovskite polycrystalline film whichis high in degree of crystallinity and good in uniformity. The method realizes effective control of crystal mass and film morphology by adding the additives; and the method is widely applicable and can be expanded to preparation of various perovskite films with different components, such as Cs-based total inorganic perovskite, FA-based perovskite or mixed perovskite containing FA / Cs and Pb / Sn mixed perovskite. The method is simple and feasible, and is helpful to realize the large-scale preparation and industrial production of perovskite batteries and other perovskite devices.

Owner:麦耀华 +1

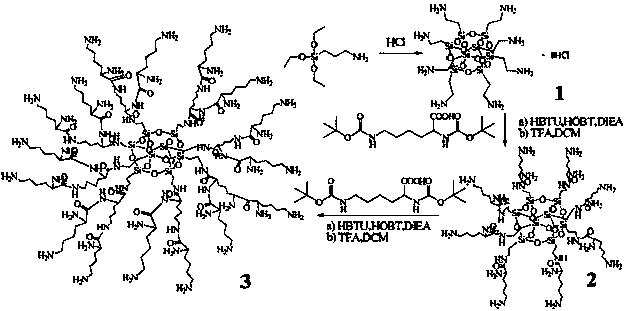

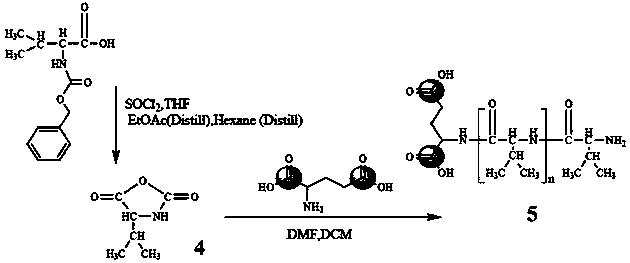

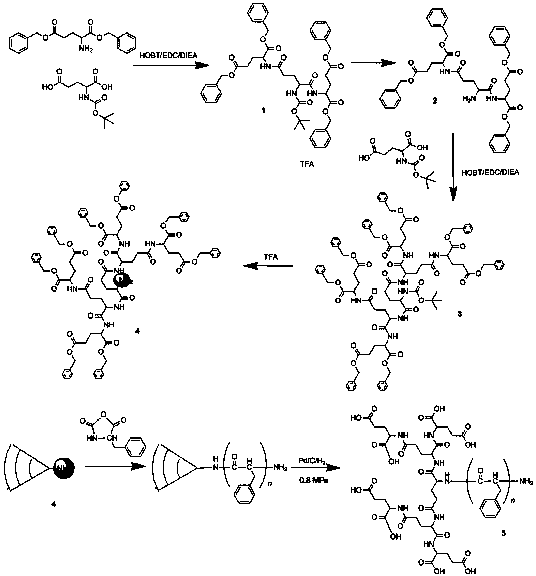

Peptide type tree-shaped macromolecule self-assembly body as well as preparation method and application thereof

InactiveCN103554923AExcellent mechanical strengthExcellent functionalityFlow propertiesOther foreign material introduction processesCovalent bindingPeptide

The invention discloses a peptide type tree-shaped macromolecule self-assembly body, provides a policy of driving peptide type tree-shaped macromolecules to self assemble and constructs a type of new peptide type tree-shaped macromolecule self-assembly bodies. By utilizing the weak interaction, one movable hydrophilic-lyophobic segment is guided into the periphery of a peptide type tree-shaped macromolecule, the hydrophilic-lyophobic segment and the peptide type tree-shaped macromolecule form a two-hydrophily assembly unit without covalent binding in a cosolvent, and the formation of a self-assembly system of the peptide type tree-shaped macromolecule can be further guided. The peptide type tree-shaped macromolecule self-assembly body disclosed by the invention has excellent stability, mechanical strength and functionality, exact molecular structure and abundant surface functional groups, further has the biological characteristics of excellent biocompatibility, a proteoid structure, easiness in endocytosis of cells and the like, and has the wide application prospect in the biological material field.

Owner:SICHUAN UNIV

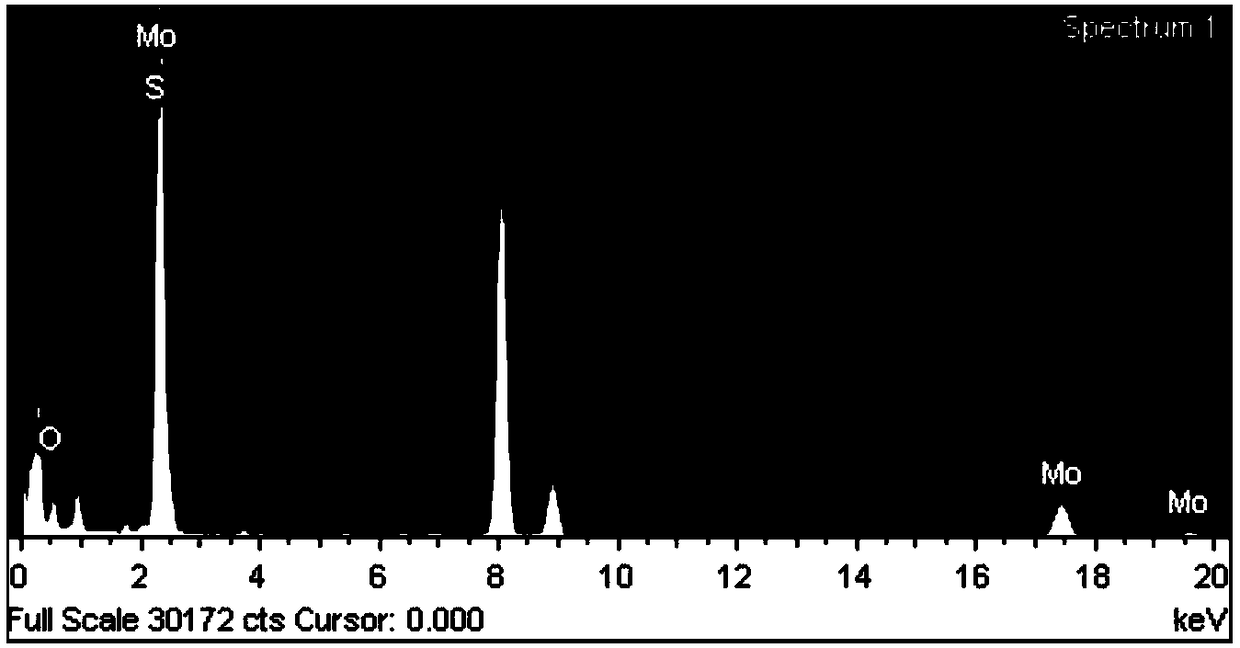

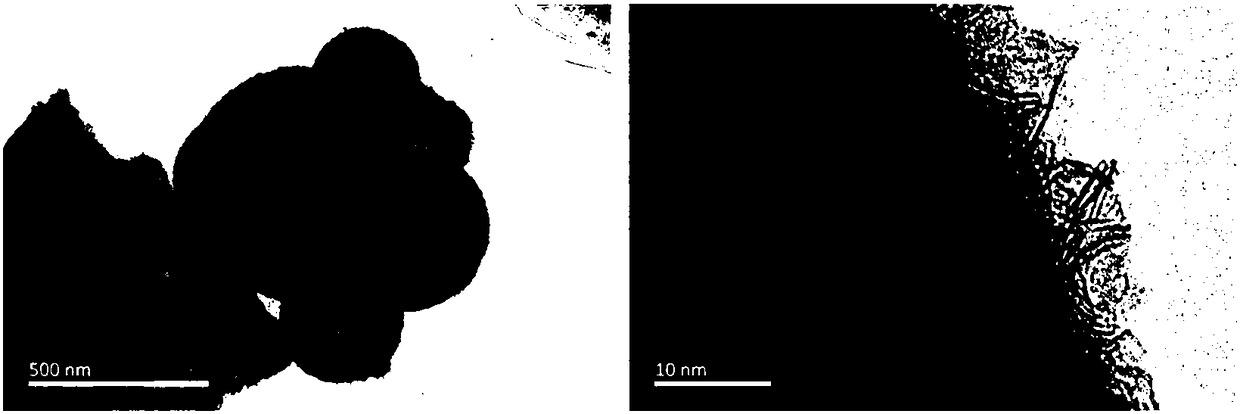

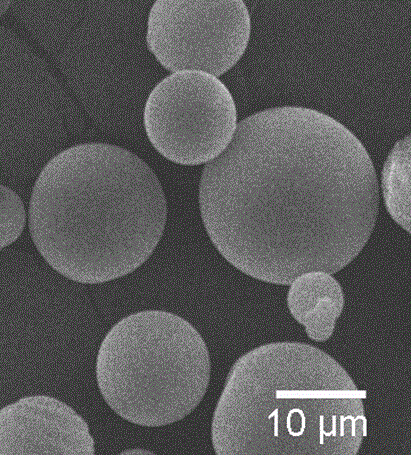

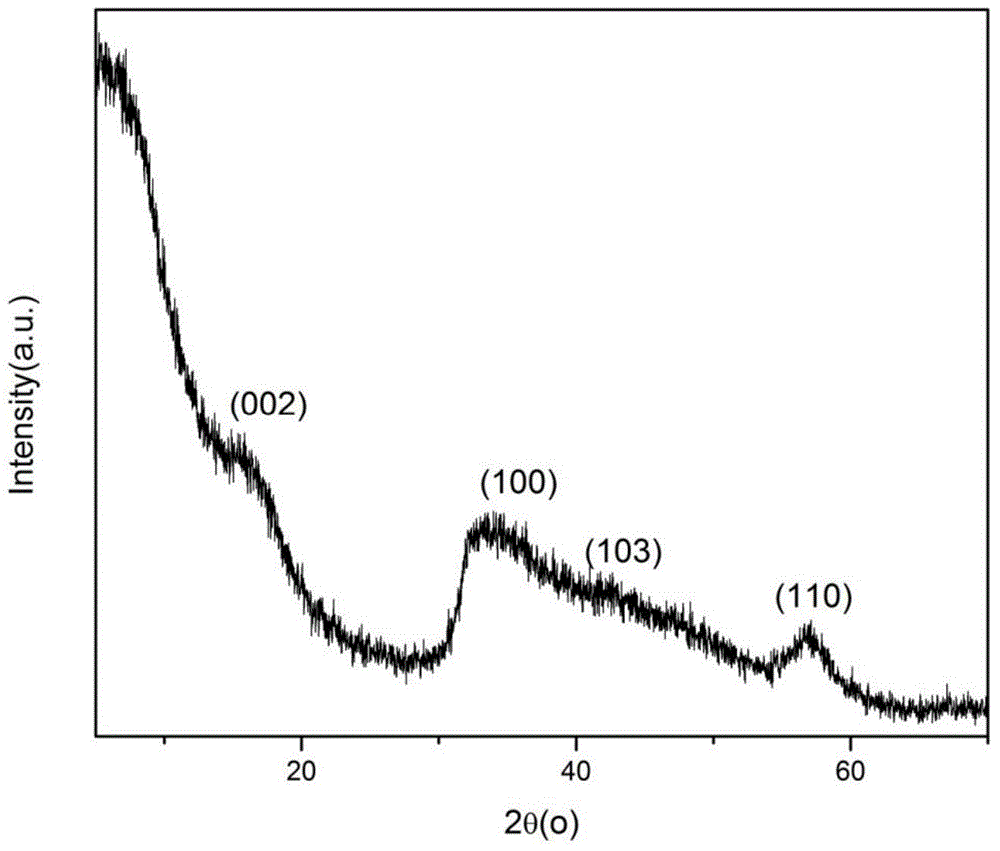

A method of preparing molybdenum disulfide microspheres in a reversed-phase microemulsion system

The invention provides a method of preparing molybdenum disulfide microspheres through sulfurizing and reducing a soluble molybdenum source in a reversed-phase microemulsion system. The method includes a) a step of preparing a reversed-phase microemulsion A through adopting polyethylene glycol octylphenol ether (Triton X-100), n-hexanol, cyclohexane and an aqueous solution of the soluble molybdenum source as a surfactant, a cosurfactant, an oil phase and a water base respectively, b) a step of adding an aqueous solution containing a sulfur source and a reductant into the reversed-phase microemulsion A to obtain a reversed-phase microemulsion B, and c) a step of transferring the reversed-phase microemulsion B to a hydrothermal reactor, performing crystallization thermal treatment at a certain temperature for a certain period of time, separating, washing, and drying the reaction product to obtain the molybdenum disulfide microspheres. The method is simple and mild in reaction conditions. Through characterization by a scanning electron microscope and a transmission electron microscope, the molybdenum disulfide microspheres have the characteristics of being solid or hollow, smooth or wrinkled in surface, and the like.

Owner:PETROCHINA CO LTD +1

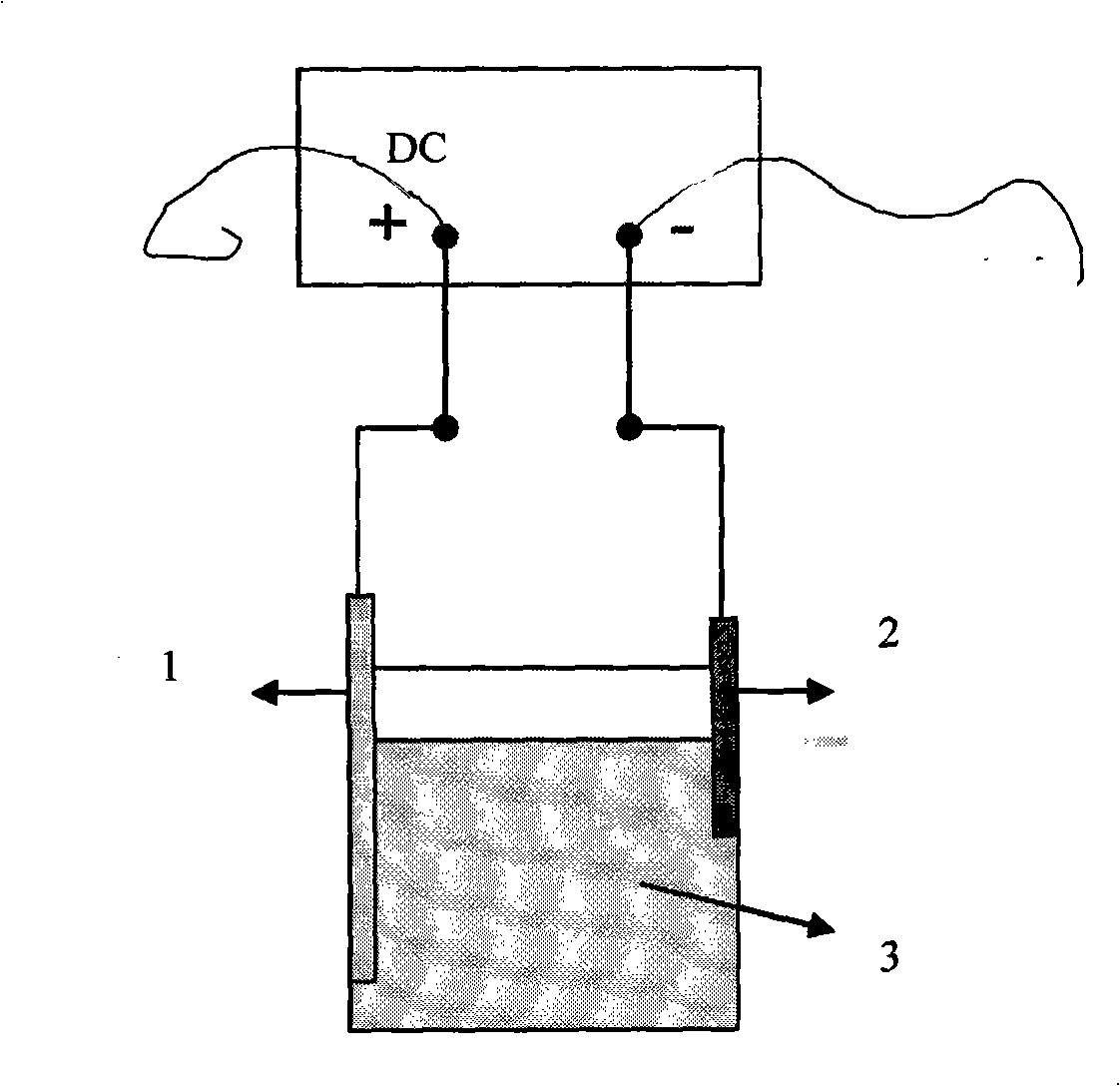

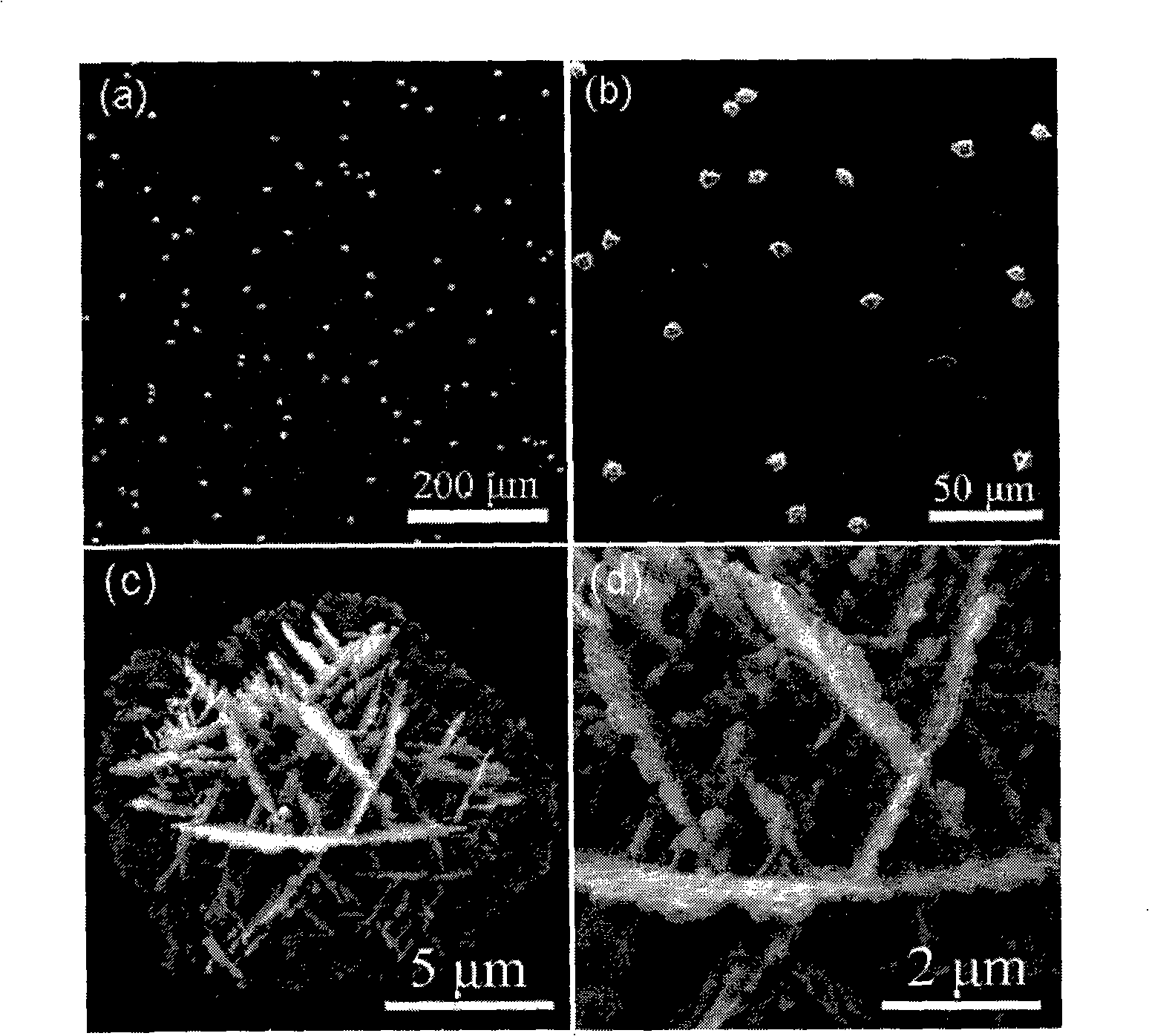

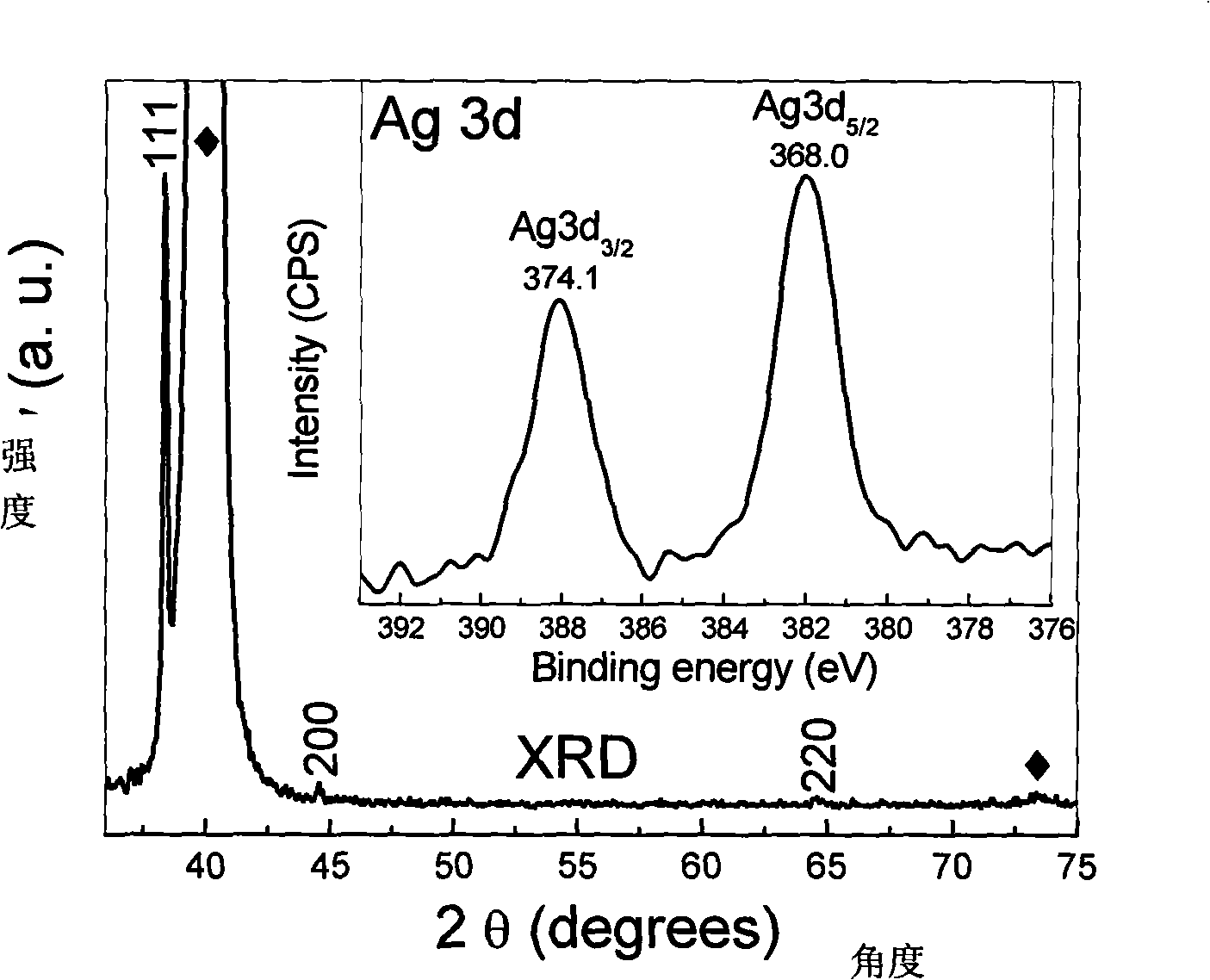

Synthetic method of load type floriform silver nanostructured material

The invention discloses a synthesizing method of a loading flower-shaped nano silver structural material, which is characterized in that a silver plate with high purity is taken as an anode, a platinum film electrode is taken as a cathode, a silver nitrate solution with the concentration of 0.003 to 0.01 mol / L is taken as an electrolytic solution, and the volume of the electrolytic solution is 20 to 100 mL; the range of constant voltage is adjusted to be 50 to 200 mV during electrolytic deposition, and the time of the electrolytic deposition lasts for 2 to 15 minutes; the cathode of the loading nano silver structural material is repeatedly rinsed by deionized water after the reaction, and then dried in nitrogen. The synthesizing method of the loading flower-shaped nano silver structural material realizes the growth anisotropy of crystal, leads the size and the microstructure of the nano metallic structure to be controllable, does not need any addition agent and electrode surface modification, and achieves simple control of appropriate voltage and concentration of the electrolytic solution; the synthesizing method is ultra-simple, and has convenient operation, easy-separated products and high purity and well industrial application prospect.

Owner:NANJING UNIV

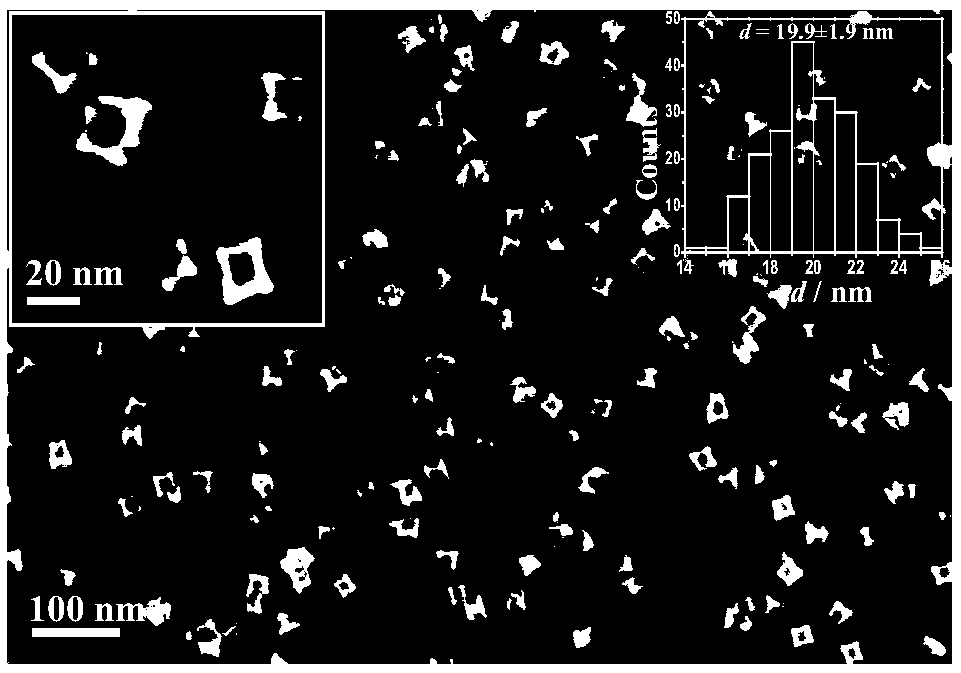

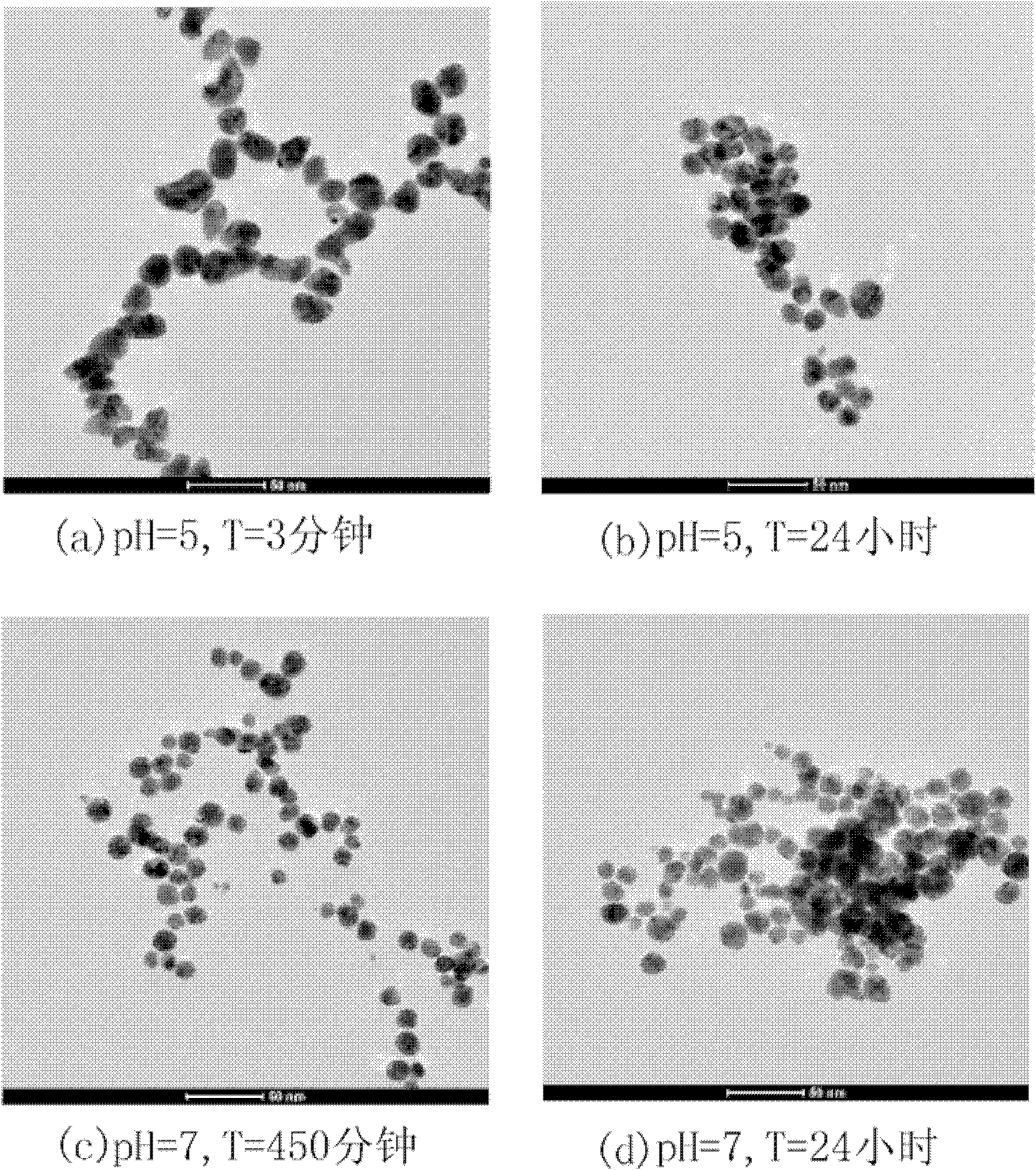

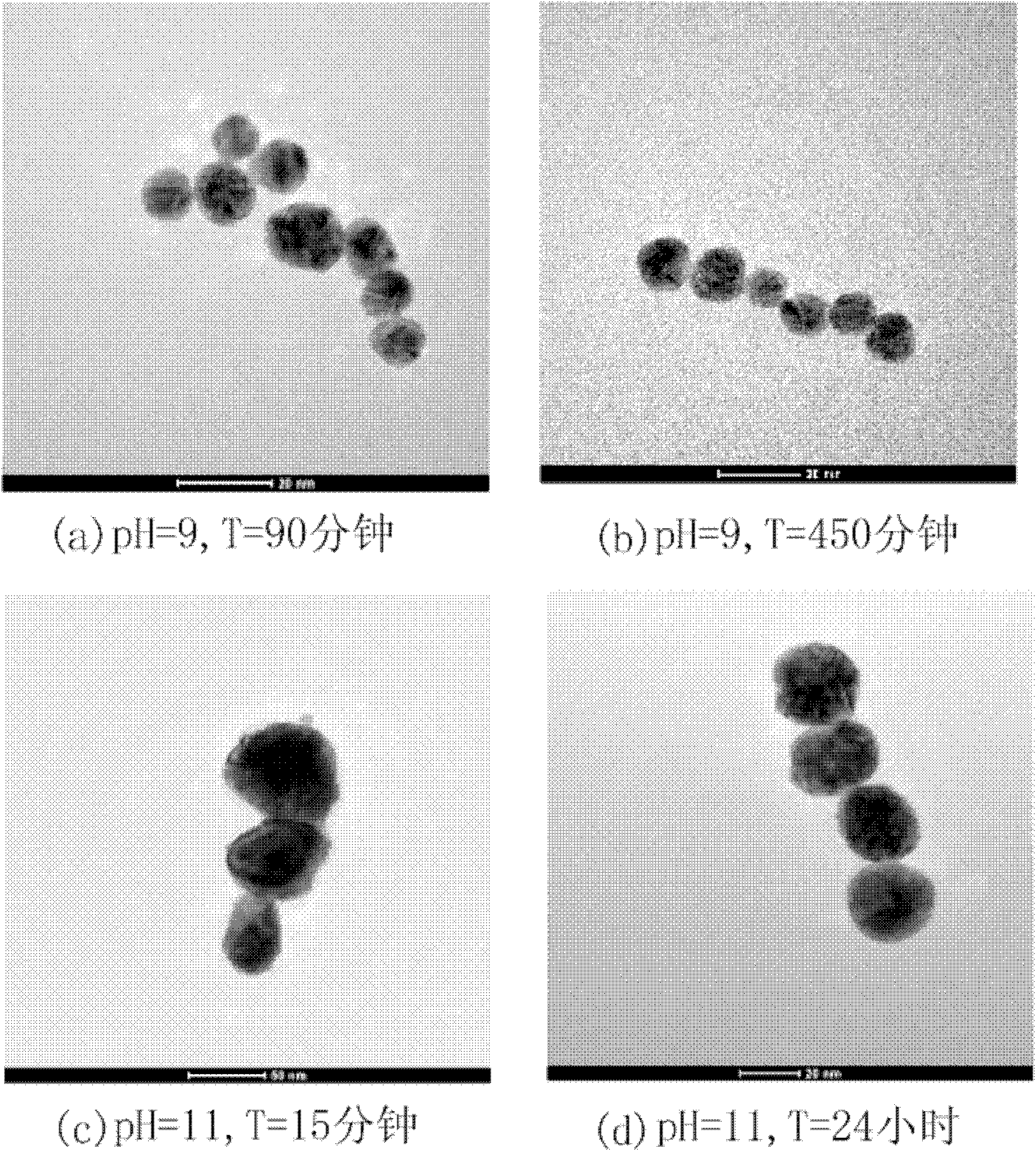

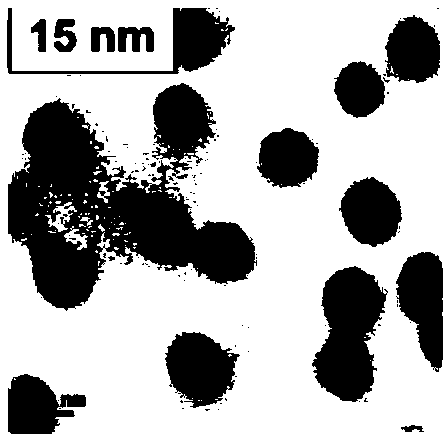

Preparation method of gold nanoparticles

ActiveCN102371356APrecise control of shapeLow costMaterial nanotechnologyTransportation and packagingNanoparticleColloid

The invention relates to a preparation method of gold nanoparticles. The method comprises the following steps of providing gold-ion-contained solution and carboxylic acid solution containing at least two carboxyl used as reducing agent and stabilizer; mixing the gold-ion-contained solution and the carboxylic acid solution to form into mixed solution; reacting the mixed solution at a temperature being 20 DEG C to 60 DEG C, and generating gold nanoparticle colloid solution.

Owner:TSINGHUA UNIV +1

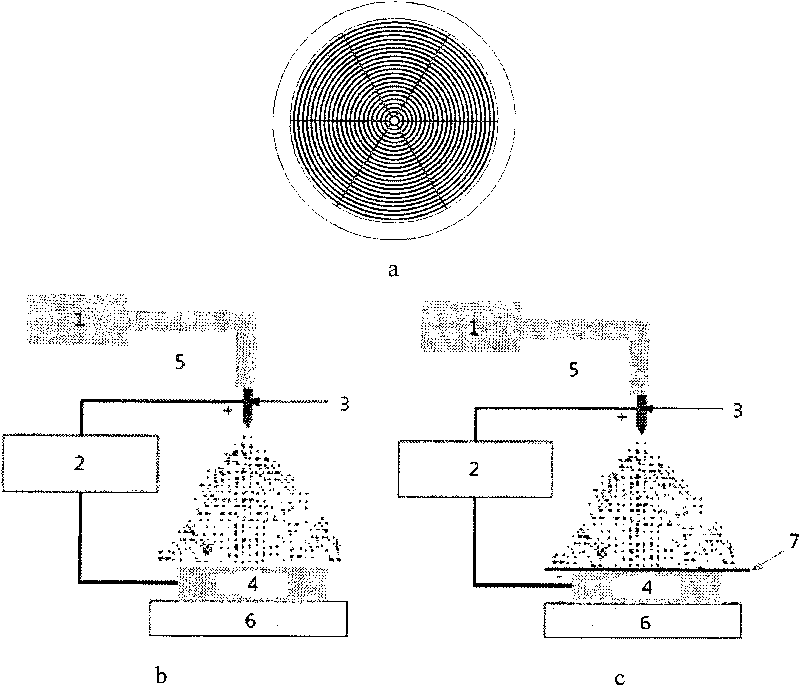

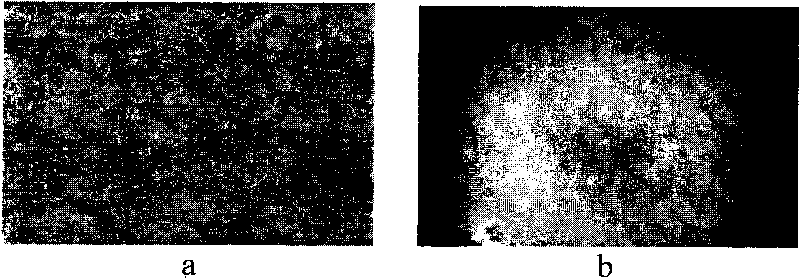

Nano hydroxyapatite coating and preparation method thereof and electrostatic atomization device

InactiveCN101703798AImprove mechanical propertiesImprove biological activityLiquid spraying plantsCoatingsApatiteNano hydroxyapatite

The invention provides a nano hydroxyapatite coating and a preparation method thereof and an electrostatic atomization device, belonging to the technical field of medical biological coating. The coating has the following components in weight percent: 10-30% of silk fibroin and 70-90% of nano hydroxyapatite. The preparation method is as follows: firstly carrying out degumming process and dissolving process to obtain the silk dissolving liquid; preparing into the suspending liquid of silk fibroin-nano hydroxyapatite composite precipitate; washing to neutrality by deionized water to prepare intoprecursor solution; and adopting the electrostatic atomization sedimentation method to lead the precursor solution to be coated on the substrate in atomizing form to prepare into nano hydroxyapatite composite material biological coating. The invention can prepare the silk fibroin / nano hydroxyapatite coating with compact accumulation and no cracks, and the shape thereof can be controlled.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Hollow spherical mesoporous PtAu nanomaterial and preparation method and application thereof

ActiveCN106935871AStructurally precise regulationGood catalytic propertiesCell electrodesPlatinumMethanol fuel

The invention discloses a hollow spherical mesoporous PtAu dual-metal methanol fuel cell catalyst nanomaterial and a preparation method thereof. The hollow spherical nanometer comprises hollow spheres formed by a shell layer; the inner surface of the shell layer is formed by gold while the outer surface of the shell layer is formed by platinum; the shell layer adopts a continuous porous structure; the shell layer is 5-200nm in thickness; the holes are 1-15nm in diameter; the hollow spherical nanometer is 50-2,000nm in grain diameter; and the atomic ratio of gold to platinum in the shell layer is (0.1-9.9) to 1. A dual-metal shell layer is formed on a temperate through a template method via a seed growth method to prepare the core-shell structure; and then the template is removed by adopting a solvent to form the hollow dual-metal shell layer. According to the method disclosed by the invention, the catalyst structure can be realized by controlling preparation conditions in each step, so that accurate regulation and control on appearance and compositions, and simple and easy implementation of the operation are achieved.

Owner:INST OF CHEM CHINESE ACAD OF SCI

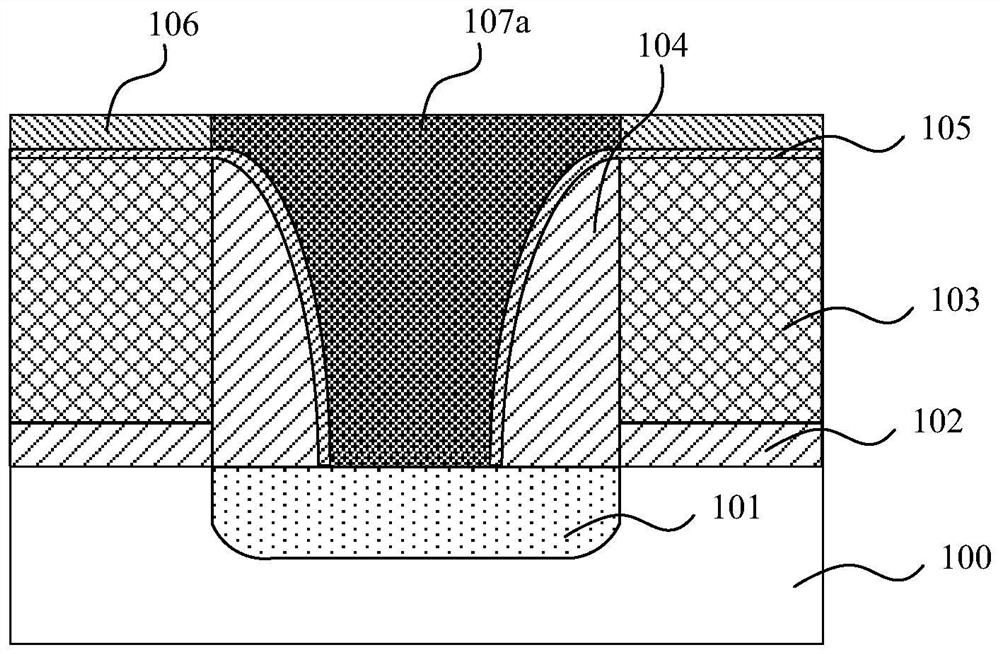

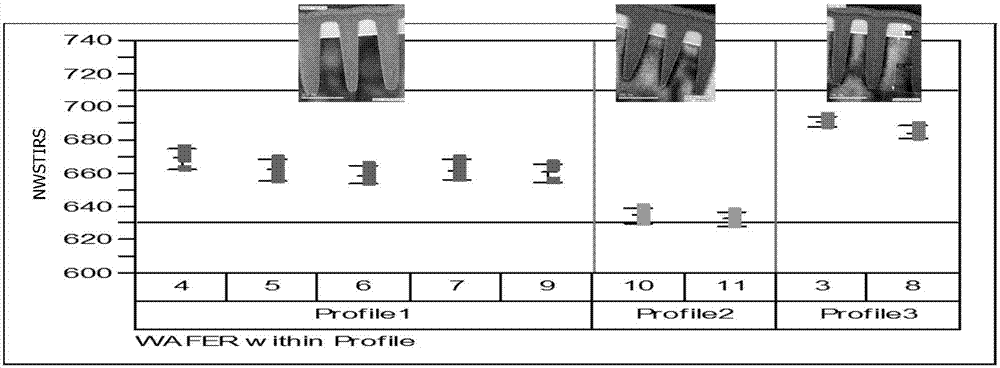

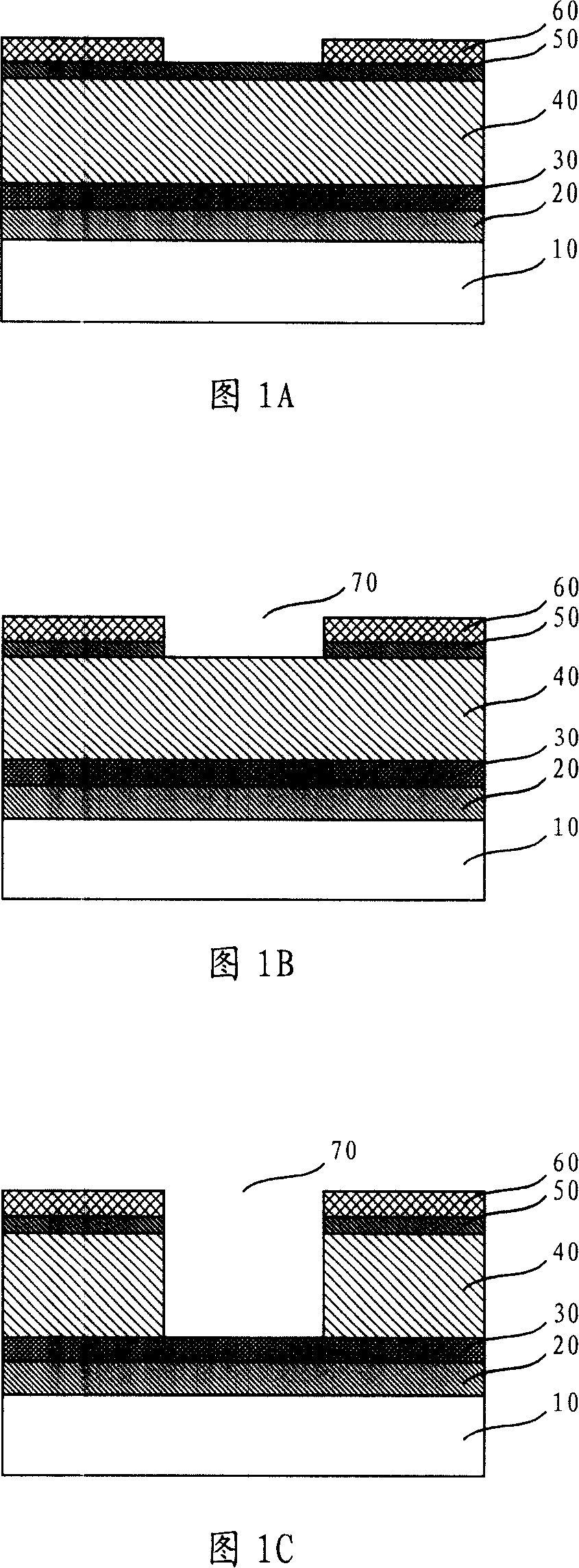

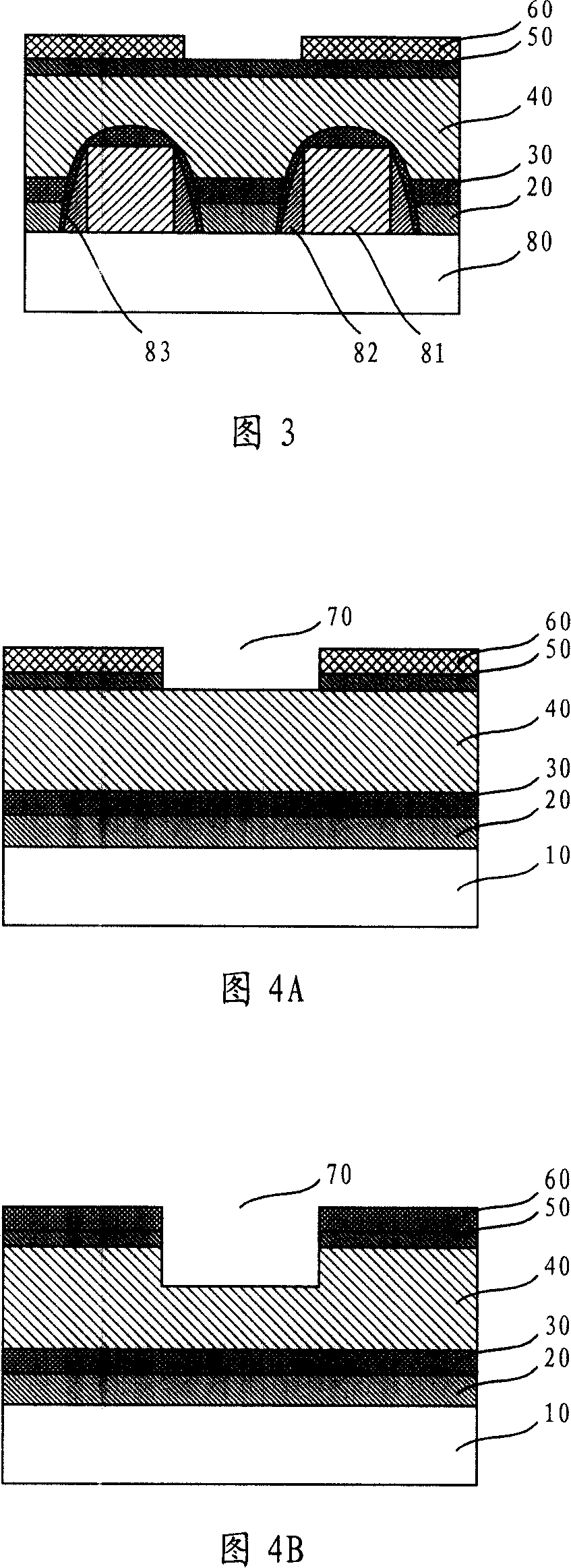

Through-hole etching method

ActiveCN101140882AHigh densityIntegrity guaranteedPhotomechanical apparatusSemiconductor/solid-state device manufacturingEtchingDielectric layer

A pylome etching method is provided, which comprises: forming pylome etching structure, which includes adhesive coating sedimentary in sequence, etch stop layer, dielectric layer and patterned photoresist layer; etching antireflective coating; etching dielectric layer; eliminating photoresist layer; etching the etch stop layer; The etching process of the said dielectric layer includes the first etching process and the second etching process etched respectively by the first etching gas and the second etching gas. The method provided in the invention can improve the tightness of the photoresist layer to effectively control the appearance of the etching pylome, further adjust the both transverse and lognitudinal etching selection ratio and precisely control the shape of the etching pylome to avoid damage to sidewall of the gird and guarantee the normal operation of the device.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

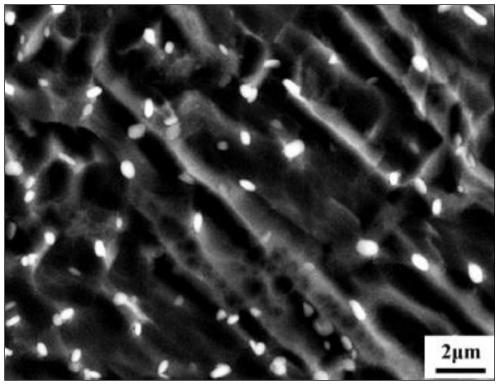

Nano-structure three-dimensional distributed super-amphiphobic metal surface and preparation method thereof

ActiveCN108466015AIncrease the growth areaPrecise control of shapeMetallic material coating processesLaser beam welding apparatusMicrometerNanostructure

The invention discloses a nano-structure three-dimensional distributed super-amphiphobic metal surface and a preparation method thereof and belongs to the technical field of function materials. The super-amphiphobic surface is of a nano grass-shaped structure formed by mutually winding flexible thin nano ribbon-shaped units distributed on the surface of a three-dimensional micrometer array structure which is distributed on a metal substrate. The preparation method comprises the steps that the surface of the metal substrate is subjected to patterning erosion through ultrafast laser to form thethree-dimensional micrometer structure at first, then, the nano grass-shaped structure is formed on the surface of the three-dimensional micrometer structure through chemical bath oxidization, surfacemodification treatment is conducted through (Heptadecafluoro-1,1,2,2-tetradecyl)trimethoxysilane, and the super-hydrophobic super-oleophobic function is achieved. The super-amphiphobic surface has excellent durability, the preparation method of the super-amphiphobic surface is simple, easy to implement, fast, efficient and capable of achieving large-area preparation, the self cleaning performancecan be maintained for a long time under the outdoor environment and other multiple outside environments, and the super-amphiphobic metal surface has wide application prospects in the fields of national defense, industrial production, daily life and the like.

Owner:TSINGHUA UNIV

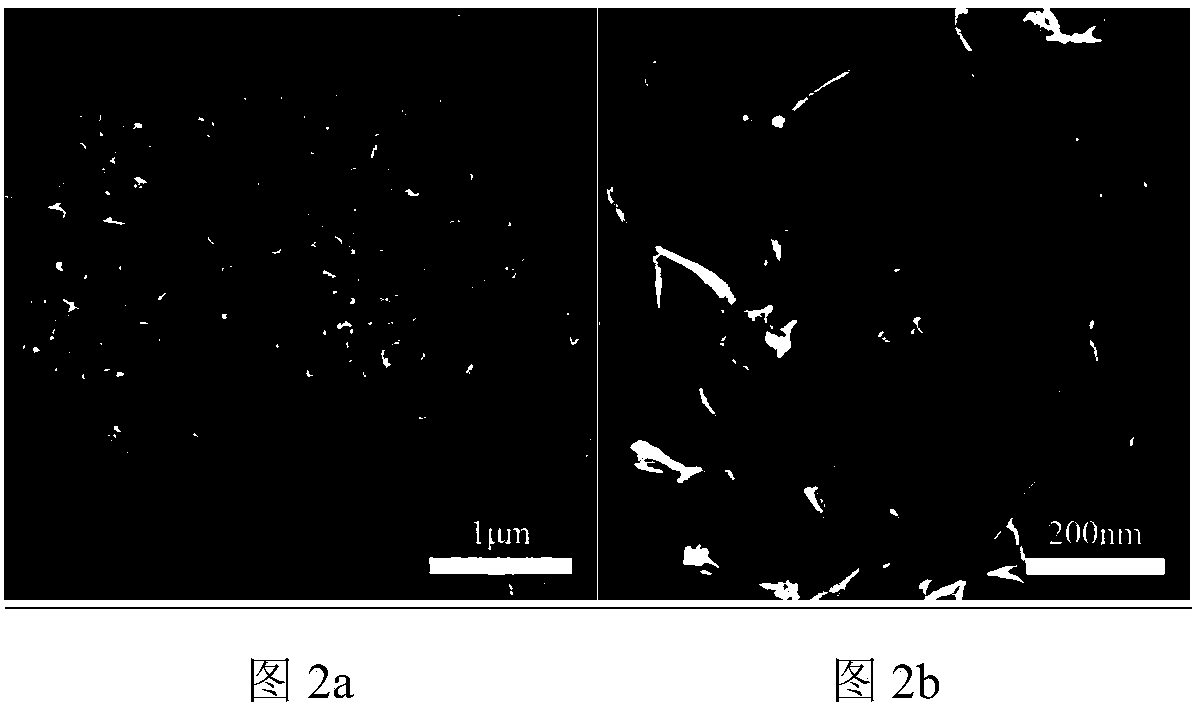

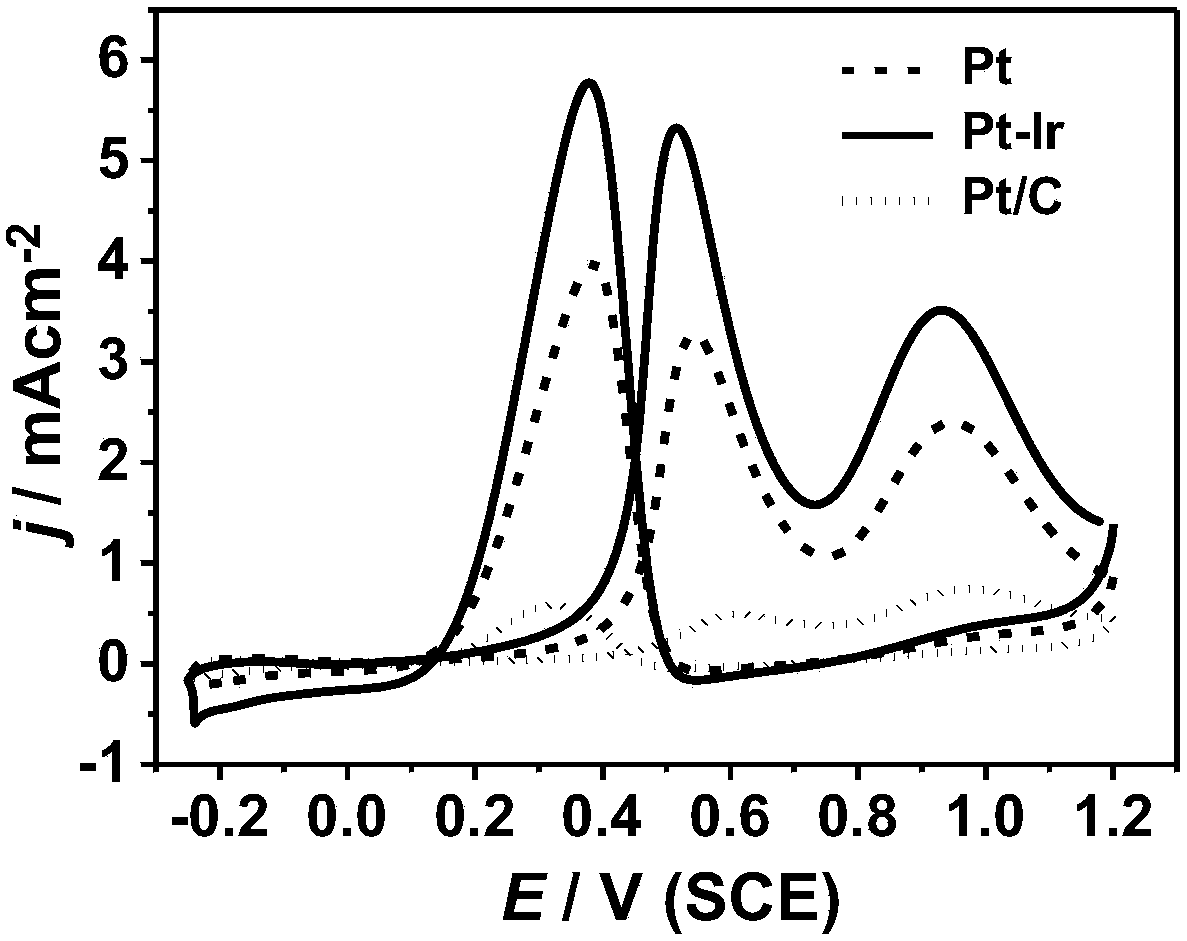

Preparation method of concave cuboid Pt-Ir alloy nanocrystal catalyst

InactiveCN108448129ATunable electrochemical methodEvenly dispersedMaterial nanotechnologyCell electrodesNano catalystMetallurgy

The invention discloses a preparation method of a concave cuboid Pt-Ir alloy nanocrystal catalyst having a high-index crystal surface structure, and belongs to the technical field of preparation of afuel cell catalyst. The Pt-Ir alloy catalyst exists in a green and novel non-aqueous medium, namely a deep-eutectic solvent, and a concave cuboid Pt-Ir alloy nanocrystal with a {hk0} high-index crystal surface-structure surface is prepared by employing an electrochemical cyclic voltammetry method under a condition without any surfactant. The surface of the concave cuboid Pt-Ir alloy nanocrystal catalyst is a high-index crystal surface, the concave cuboid Pt-Ir alloy nanocrystal catalyst is provided with an opening surface structure, a large amount of active sites are provided, the poison capability of an intermediate body resistant to CO and the like is remarkably improved by a dual-functional mechanism of an alloy surface structure, and the concave cuboid Pt-Ir alloy nanocrystal catalysthas excellent electrocatalytic performance on fuel micromolecules such as formic acid, methyl alcohol and ethyl alcohol.

Owner:XUZHOU NORMAL UNIVERSITY

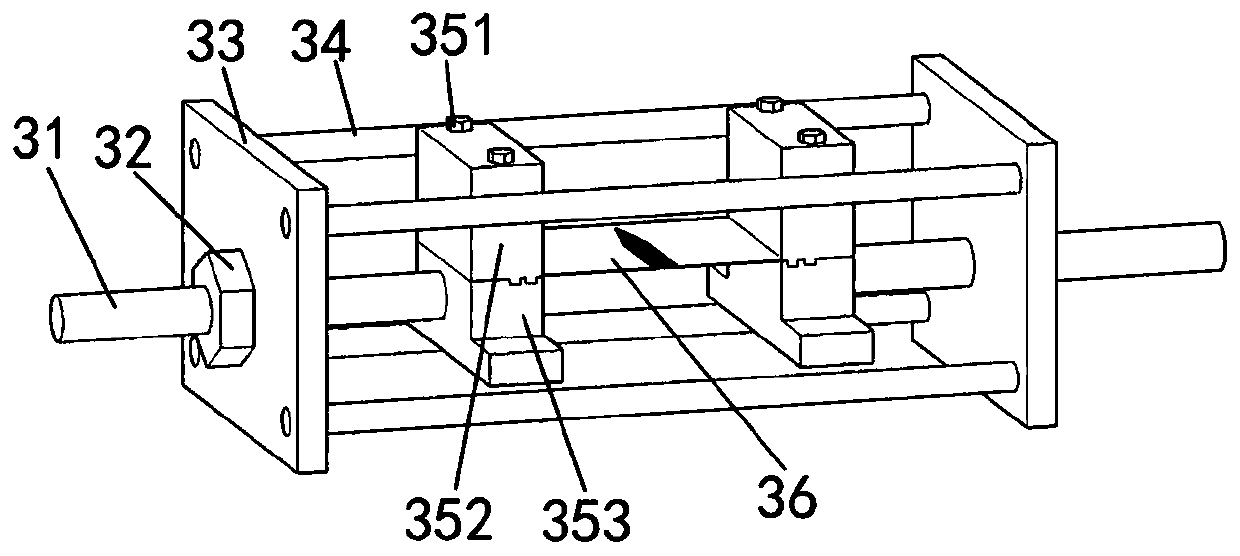

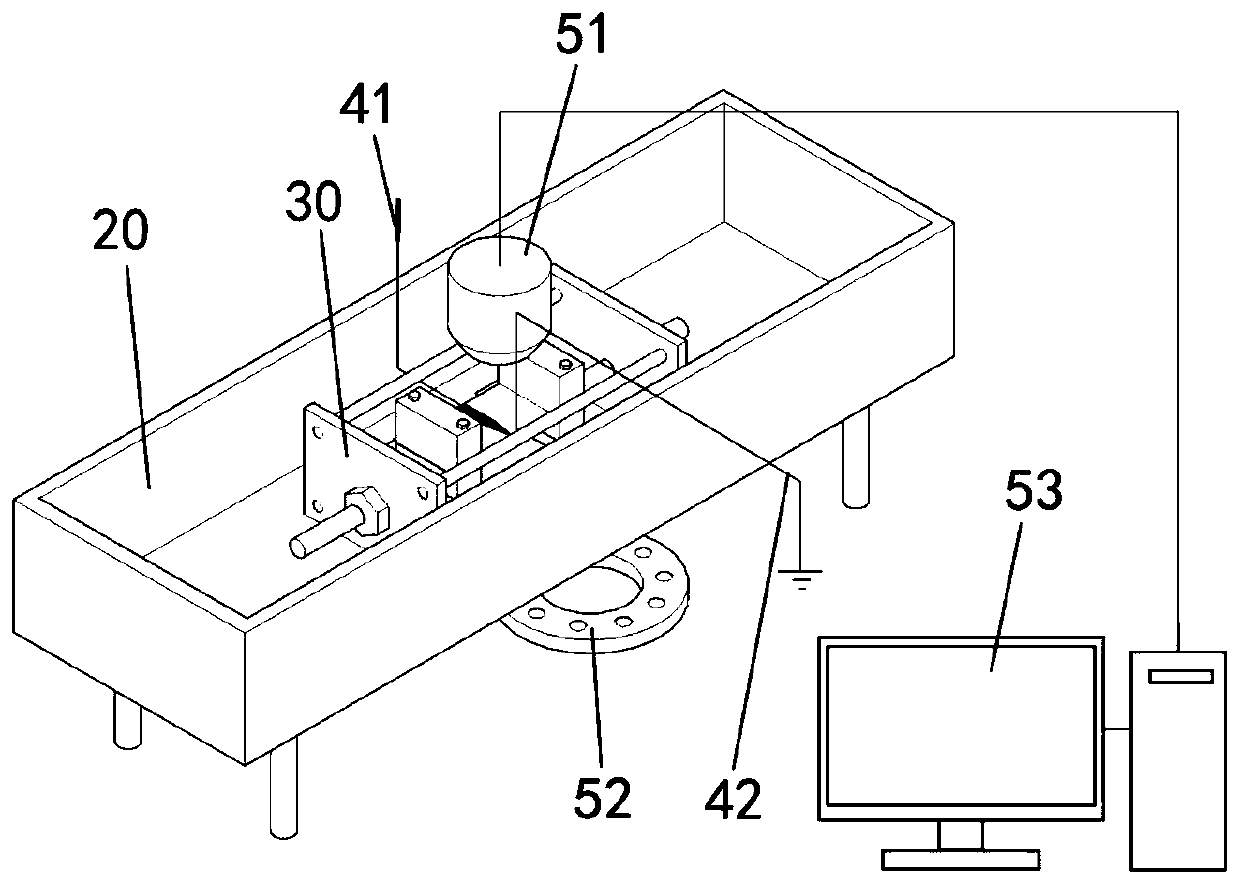

Electric tree test device of silicone rubber material for cable accessory and sample manufacturing method

ActiveCN111308294AConvenient blessingReduce thickness requirementsMeasurement instrument housingTesting using optic methodsElectrically conductiveTest sample

The invention discloses an electric tree test device for a silicone rubber material for cable accessories and a sample manufacturing method. The method includes the steps of adding semi-conductive silicone rubber into xylene, then spraying and curing the surface of a silicone rubber insulation sample, then cutting the silicone rubber insulation sample into a high-voltage electrode with a triangular longitudinal section end part, then adhering the high-voltage electrode to the surface of the silicone rubber insulation sample, and carrying out high-temperature vulcanization to obtain a piezoelectric electrode silicone rubber sample; putting the piezoelectric electrode silicon rubber sample wafer into a mold, injecting glue, and carrying out high-temperature vulcanization to obtain a sample;and cutting at a position 2 mm away from the tip of the high-voltage electrode, and adhering a ground electrode with a flat plate structure to the section. The tip of the high-voltage electrode does not have air gaps and cracks under large mechanical deformation by adopting the test sample provided by the invention. Moreover, an electrical tree in an actual cable accessory is generally developed from semiconduction to insulation, and the semiconductive material as a high-voltage electrode is more similar to the actual working condition of the cable accessory.

Owner:XI AN JIAOTONG UNIV

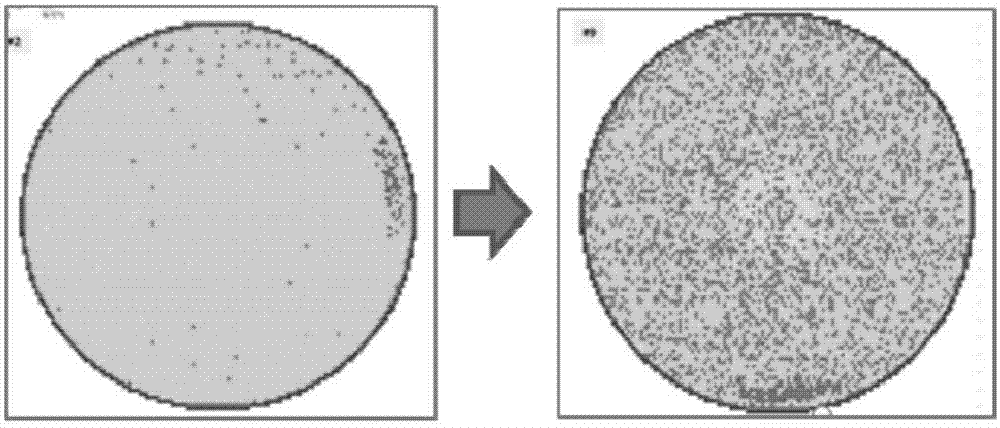

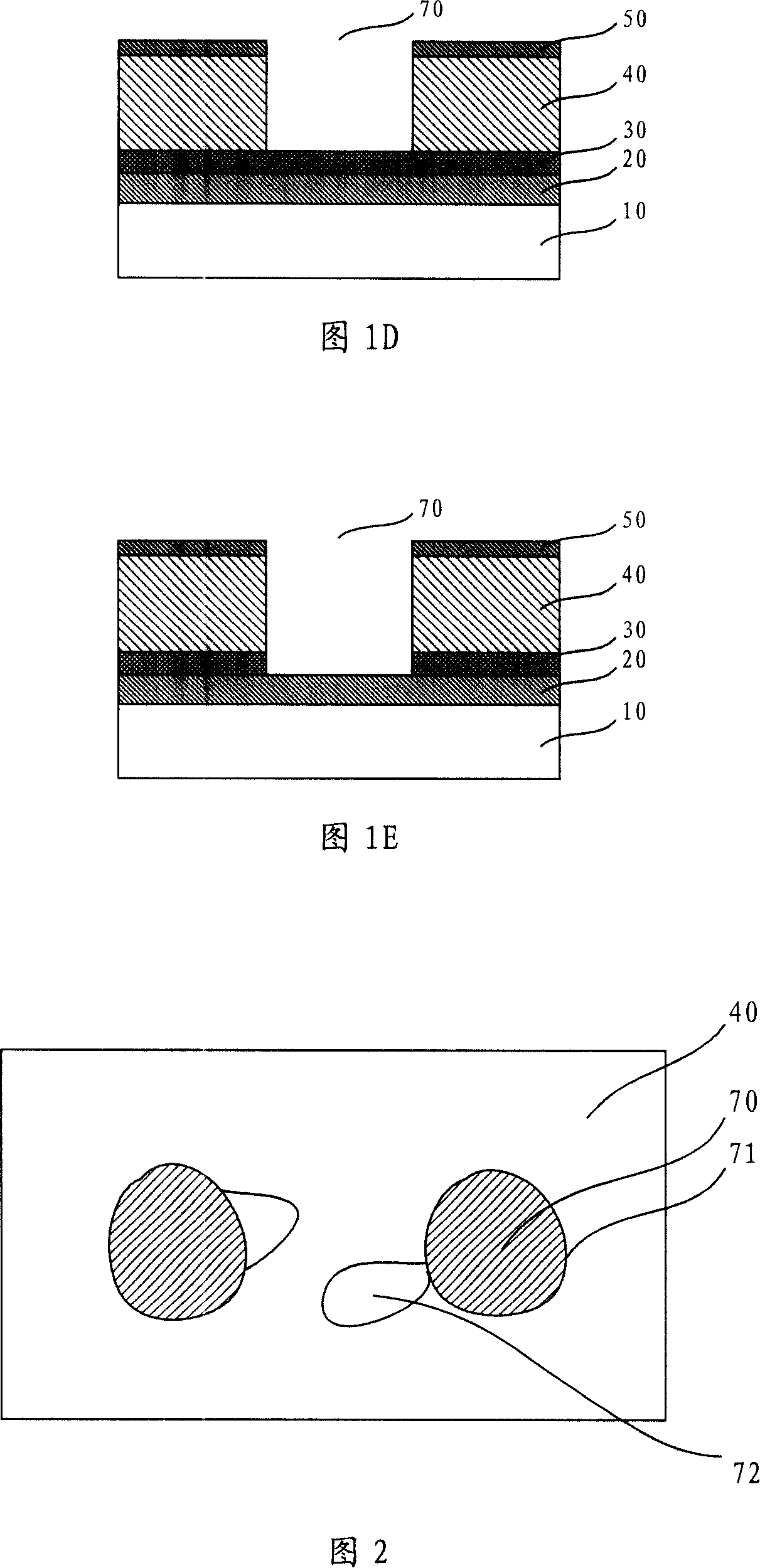

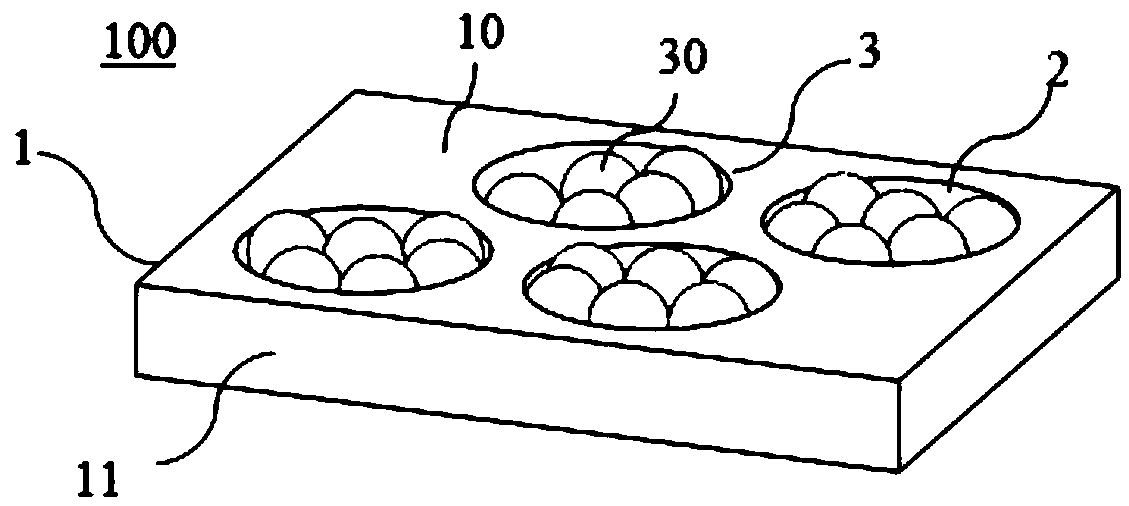

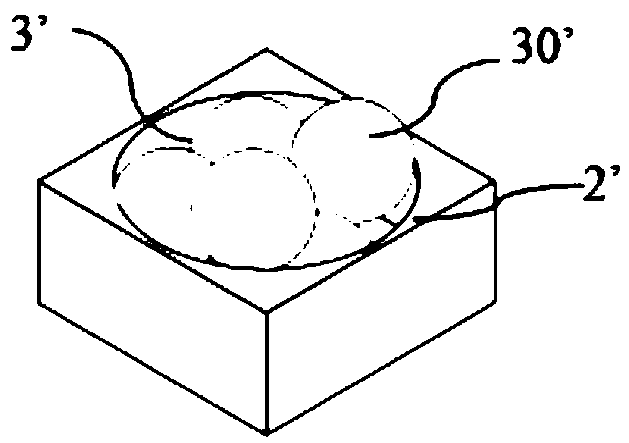

SERS (Surface Enhanced Raman Scattering) unit, and preparation method and application thereof

PendingCN108844943AHigh SERS activityAchieve self-assemblyMaterial nanotechnologyAnodisationRaman scatteringSelf assembled

The invention discloses an SERS (Surface Enhanced Raman Scattering) unit which comprises a substrate having a plurality of nano-recesses scattered on the surface thereof, and a plurality of nano-particle aggregates, each nano-particle aggregate is formed by aggregating a plurality of nano-particles, and each nano-particle aggregate is limited by a corresponding nano-recess. The invention also discloses a preparation method of the SERS unit. The SERS unit can be obtained by impregnating the substrate with nano-recesses into a dispersion containing nano-particles, and then self-assembling the nano-particles. The SERS unit can be directly applied as an SERS chip, has the advantages of high SERS activity, high uniformity, excellent stability, high batch reproducibility and the like, is easy toprepare, can be produced in a large area and on a large scale, and has a broad business prospect.

Owner:苏州英菲尼纳米科技有限公司

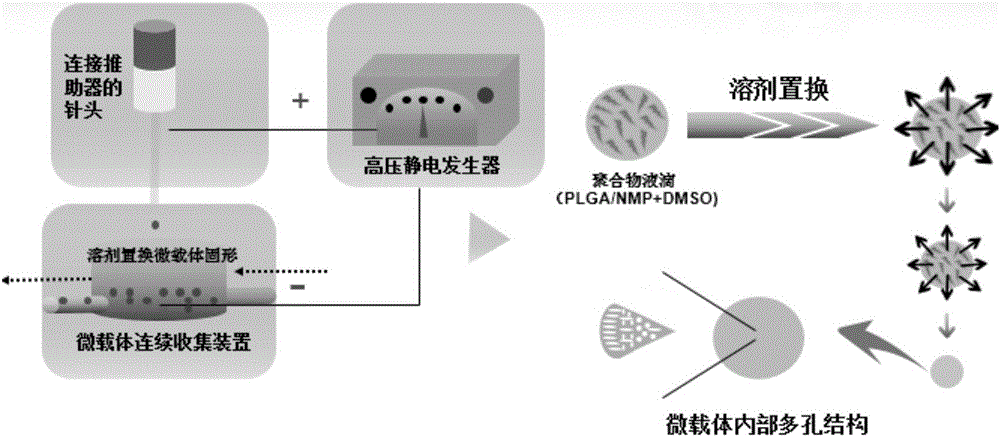

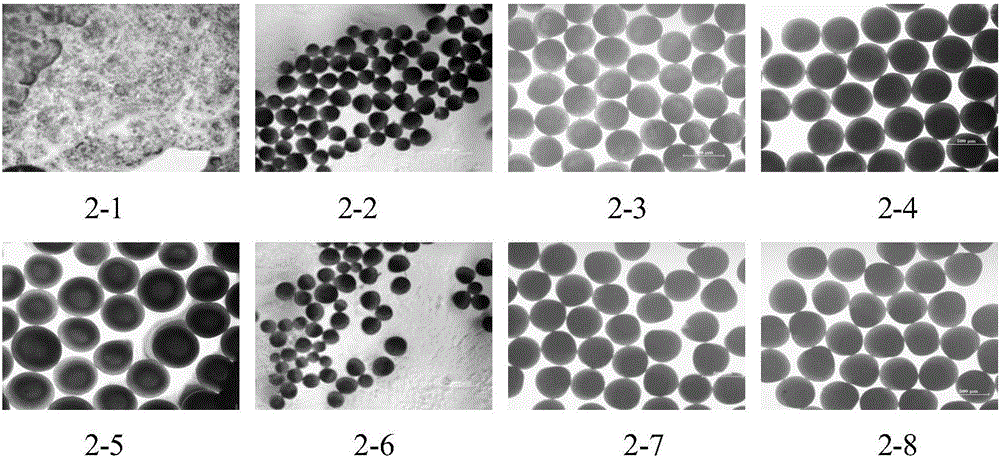

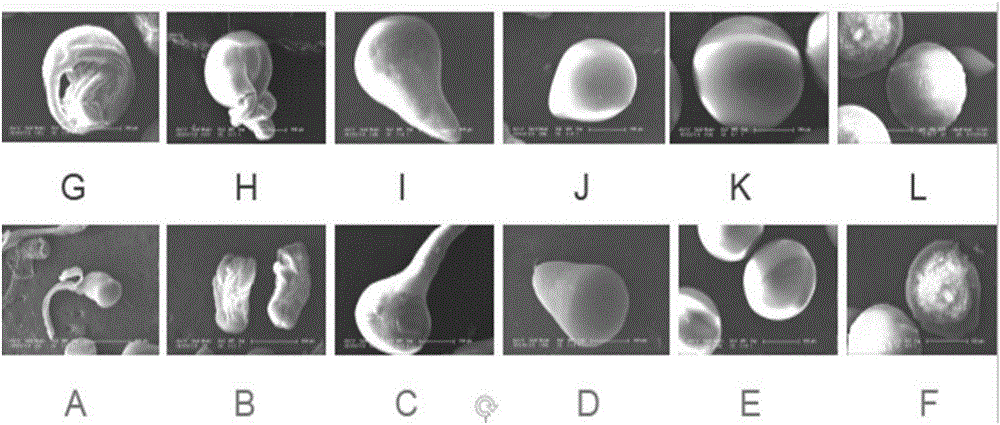

Preparation method of microcarrier

ActiveCN106282088AThe preparation process is easy to controlEasy to makeGeneral culture methodsPolymer sciencePolymer solution

The invention relates to the technical field of cell culture, in particular to a preparation method of a microcarrier. The preparation method of the microcarrier comprises the steps that a high-molecular polymer is dissolved in mixed solvent prepared from DMSO and NMP or pure NMP to obtain a high-molecular polymer solution; the high-molecular polymer solution is put into an electrostatic generator with a needle injection device, the high-molecular polymer solution is charged through high voltage static electricity, a liquid drop is formed at the tail end of a needle and drops into extracting solvent, and organic solvent in the liquid drop is quickly removed through a solvent extracting principle, so that the microcarrier is quickly prepared. According to the preparation method, the time needed by the microcarrier preparation process is shortened, and the advantages of being simple and efficient are achieved; the high-molecular polymer microcarriers with the uniform particle size can be continuously and controllably produced, and the purpose of precisely regulating and controlling the size and morphology of the microcarriers is achieved.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

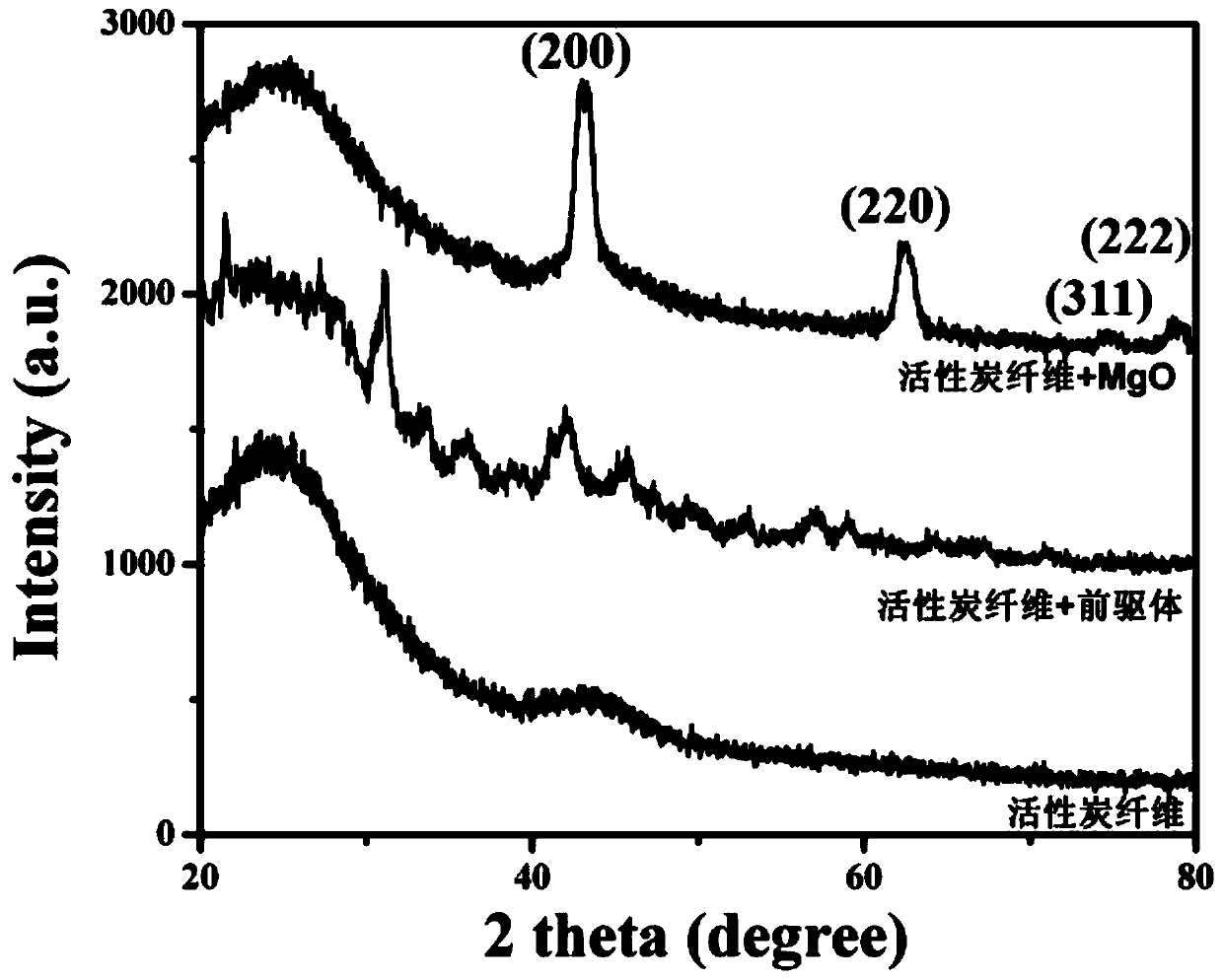

Preparation method of magnesium oxide porous nano-material supported activated carbon fiber felt

PendingCN110652961AHigh Adsorption Properties PerformanceEasy to recycleOther chemical processesWater contaminantsActivated carbonChemical preparation

The invention relates to the technical field of chemical preparation, and concretely relates to a preparation method of a magnesium oxide porous nano-material supported activated carbon fiber felt. The method comprises the following steps: activating an activated carbon fiber felt, loading a magnesium oxide precursor on the activated carbon fiber felt, and preparing the magnesium oxide porous nano-sheet supported activated carbon fiber felt. Compared with a conventional magnesium oxide material for water treatment, the nanomaterial for water treatment, provided by the invention has the high adsorption property of the magnesium oxide porous nanomaterial, and is convenient to recycle; the morphology of the magnesium oxide porous material on the activated carbon fiber felt can be accurately controlled, the modification amount is large and exceeds 40%, and the preparation method has the advantages of low preparation device investment, simple process, and easiness in operation; and the design thought and the preparation method of the water treatment material provide a new design thought and a new preparation method for the practical application of the magnesium oxide porous nanomaterial.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

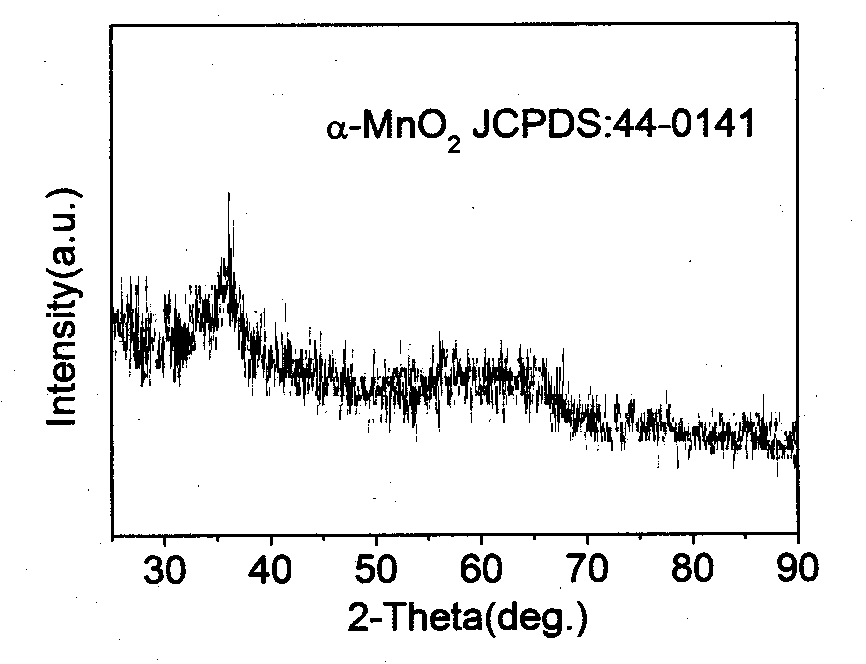

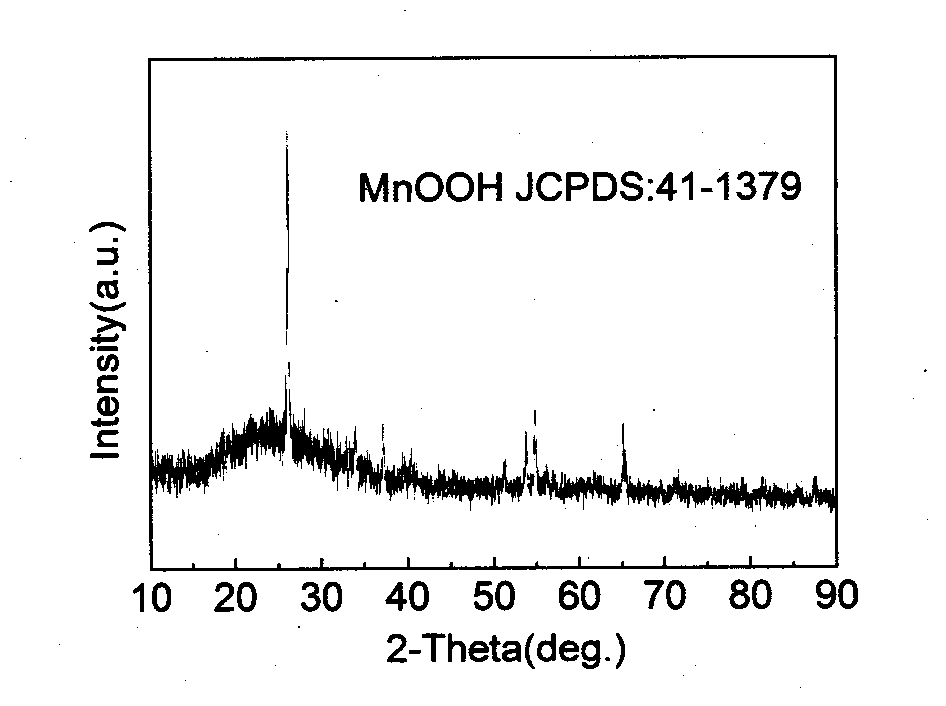

Method for preparing low dimensional manganese oxide nanometer crystal

ActiveCN102745750APrecise control of shapeSimple structureMaterial nanotechnologyManganese oxides/hydroxidesNew energySurface-active agents

The invention discloses a method for preparing a low dimensional manganese oxide nanometer crystal and belongs to the technical field of function materials. According to the method, deionized water, sodium hydroxide and a dilute sulphuric acid are used as solvents, an amorphous manganese dioxide nanoparticle is used as a 'seed' to synthesize the low dimensional manganese oxide nanometer crystal, a surface active agent is not required, the cost is low, and the production is easy to expand. The prepared low dimensional manganese oxide nanometer material crystal is rich in the structure and shape, and the particle size and shape of a synthesized product are uniform. The prepared low dimensional manganese oxide by means of the method can be widely applied to new energy devices of lithium ion batteries, solar cells, supercapacitors and the like, the prepared low dimensional manganese oxide can also be applied to the fields of catalyst carriers, information materials and the like, and the application prospect is wide.

Owner:重庆天渝新材料技术研究院有限公司

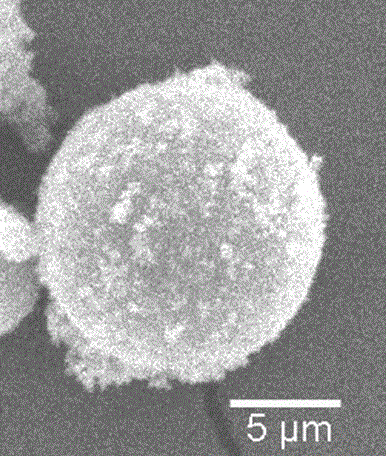

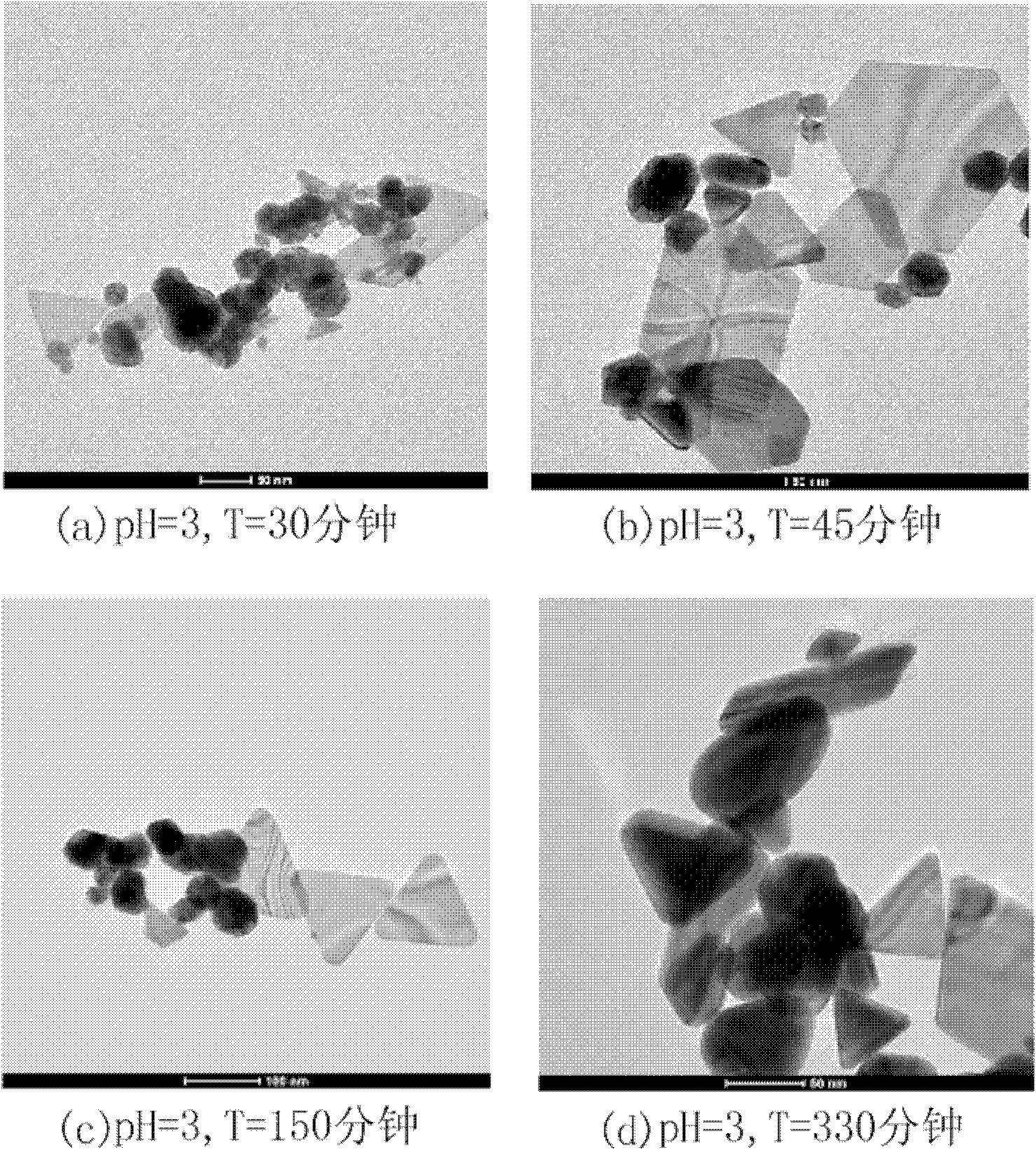

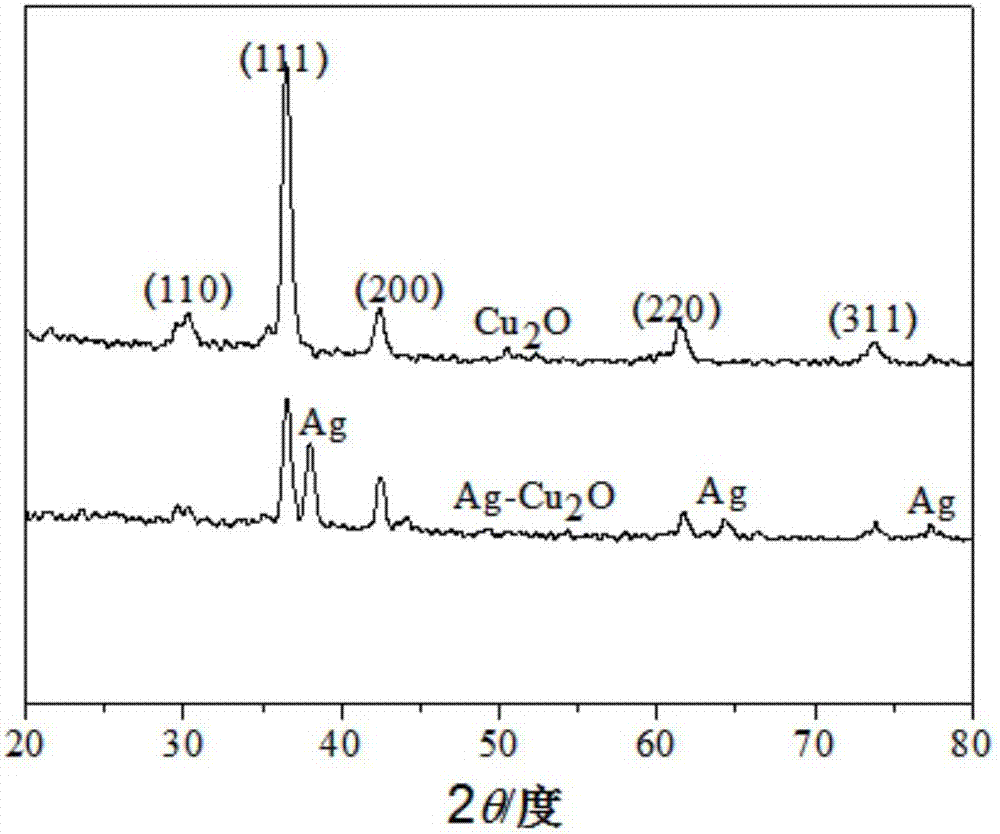

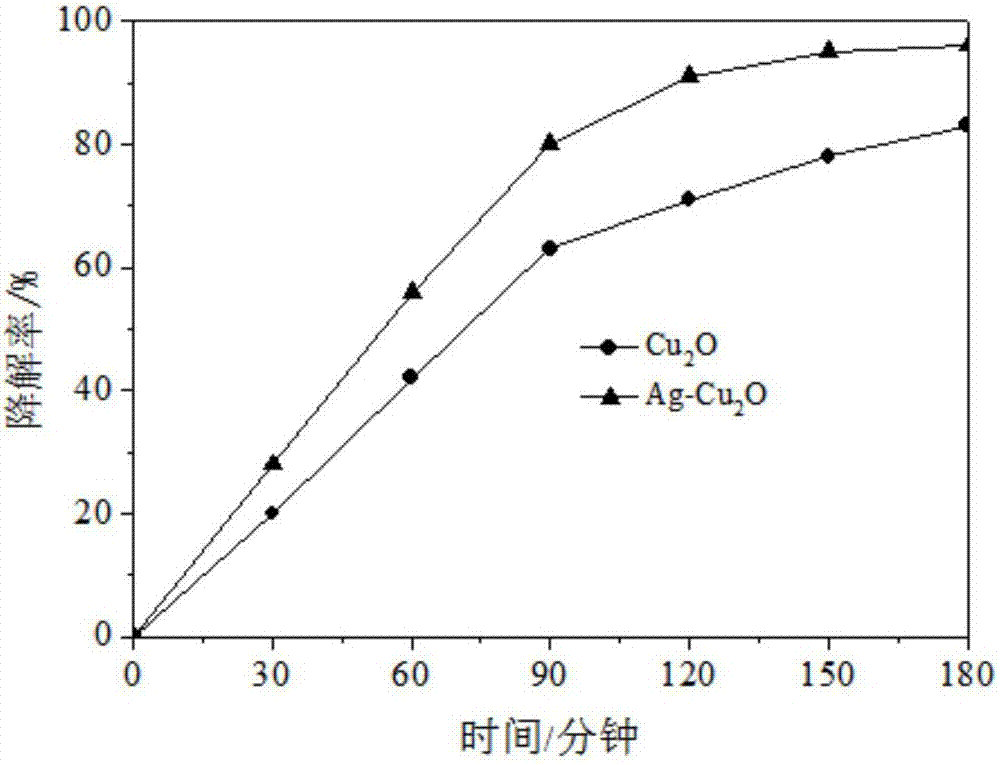

Preparation method of nanometer cuprous oxide photocatalytic material based on silver modification

The invention discloses a preparation method of a nanometer cuprous oxide photocatalytic material based on silver modification. The preparation method is specifically implemented according to the following steps that 1, a Cu2O thin film is prepared; and 2, the Cu2O thin film prepared in the step 1 is immersed in a silver nitrate solution to be reacted, and the Cu2O nanometer photocatalytic material modified by metallic silver is obtained. The nanometer Cu2O thin film containing metallic silver modification and prepared by the preparation method of the nanometer cuprous oxide photocatalytic material based on silver modification is high in stability and reusing rate.

Owner:XIAN UNIV OF TECH

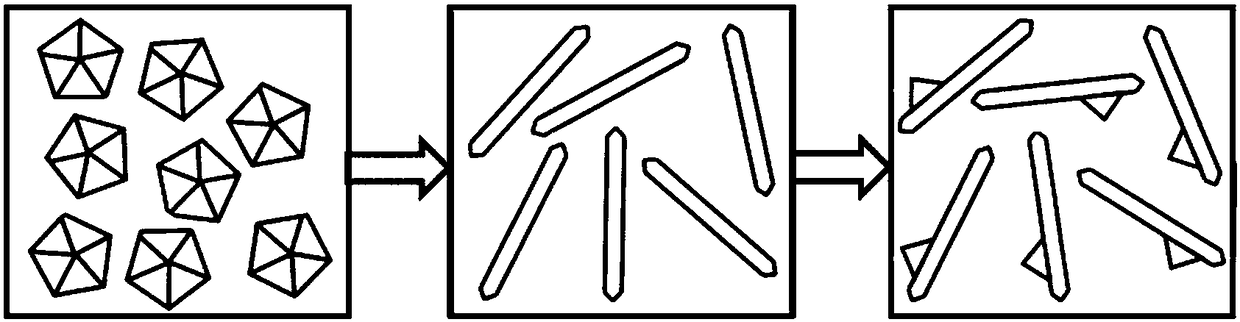

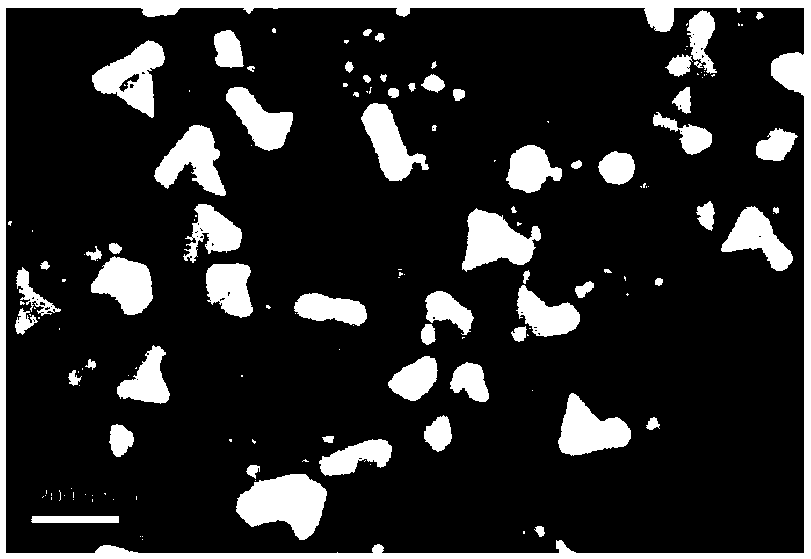

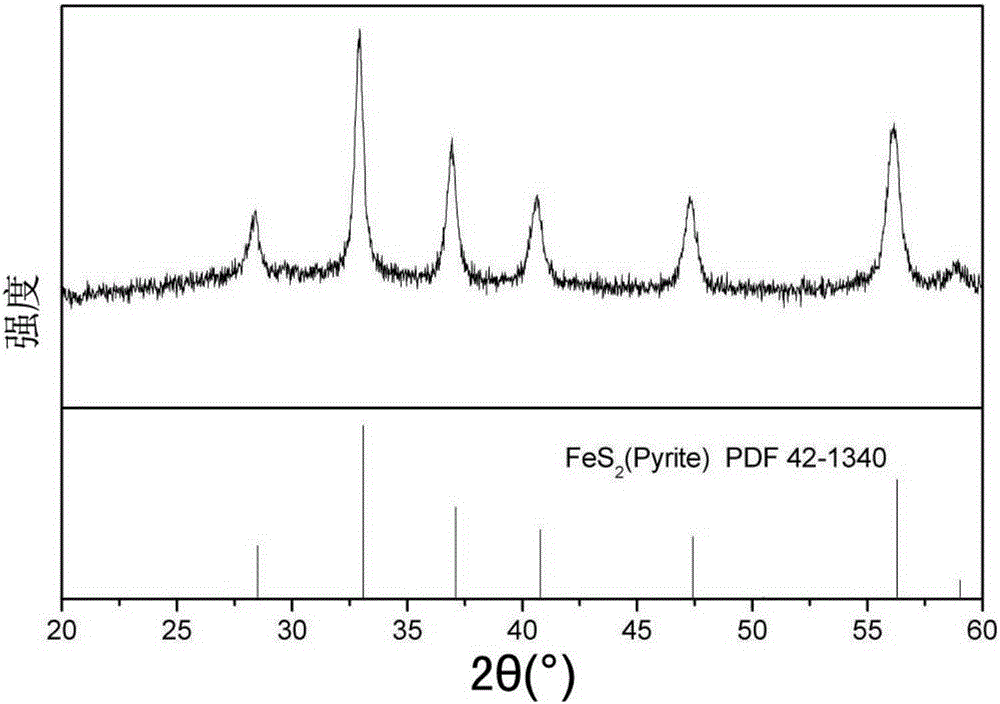

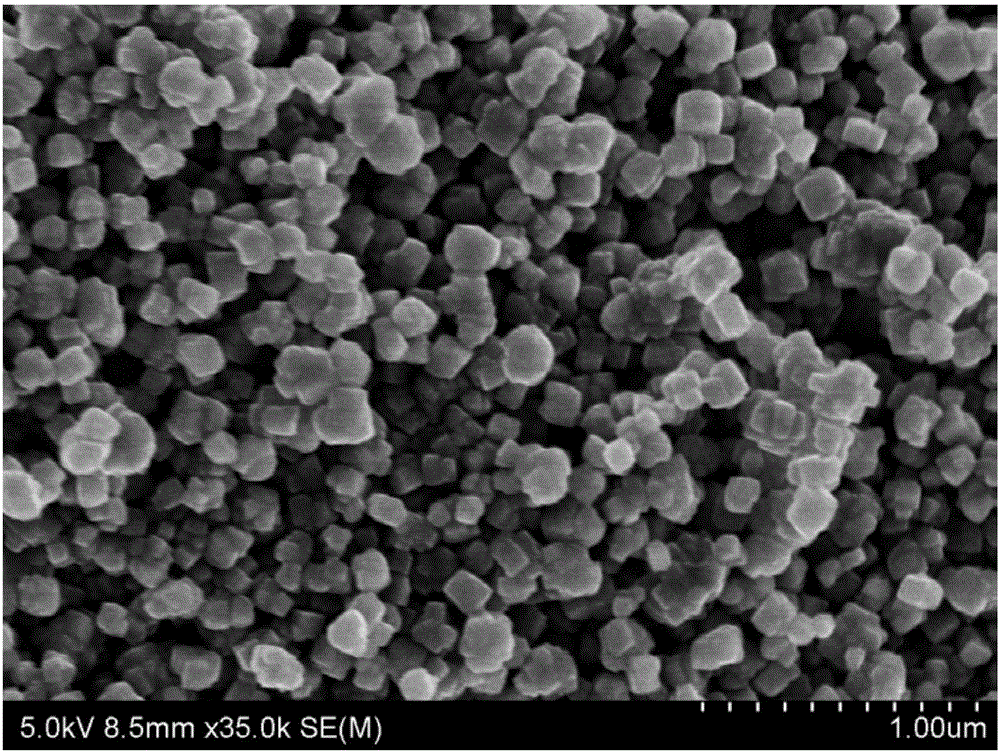

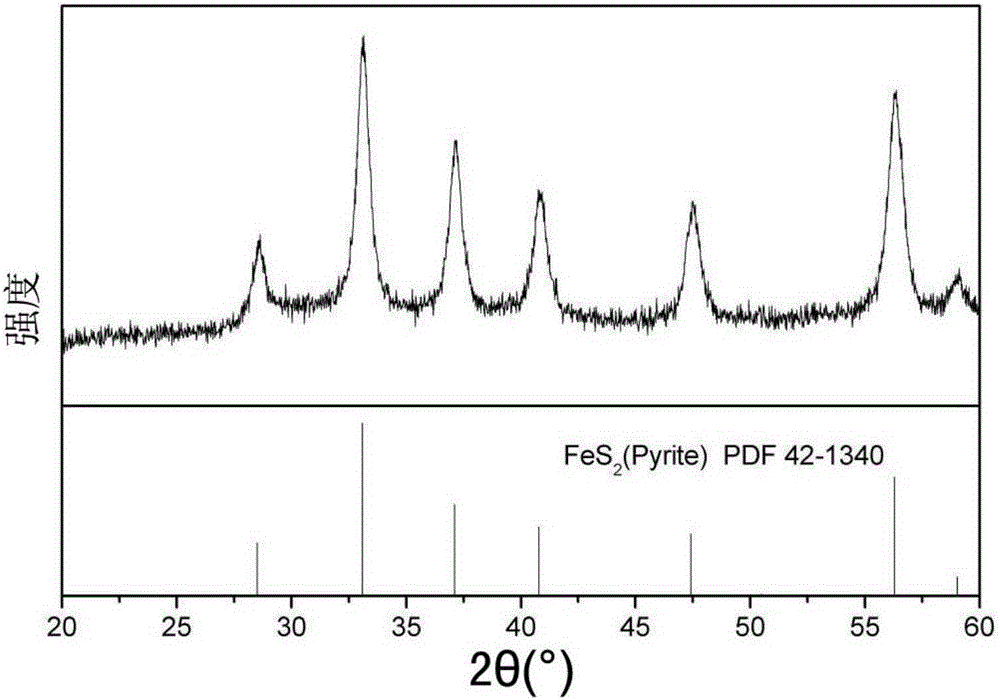

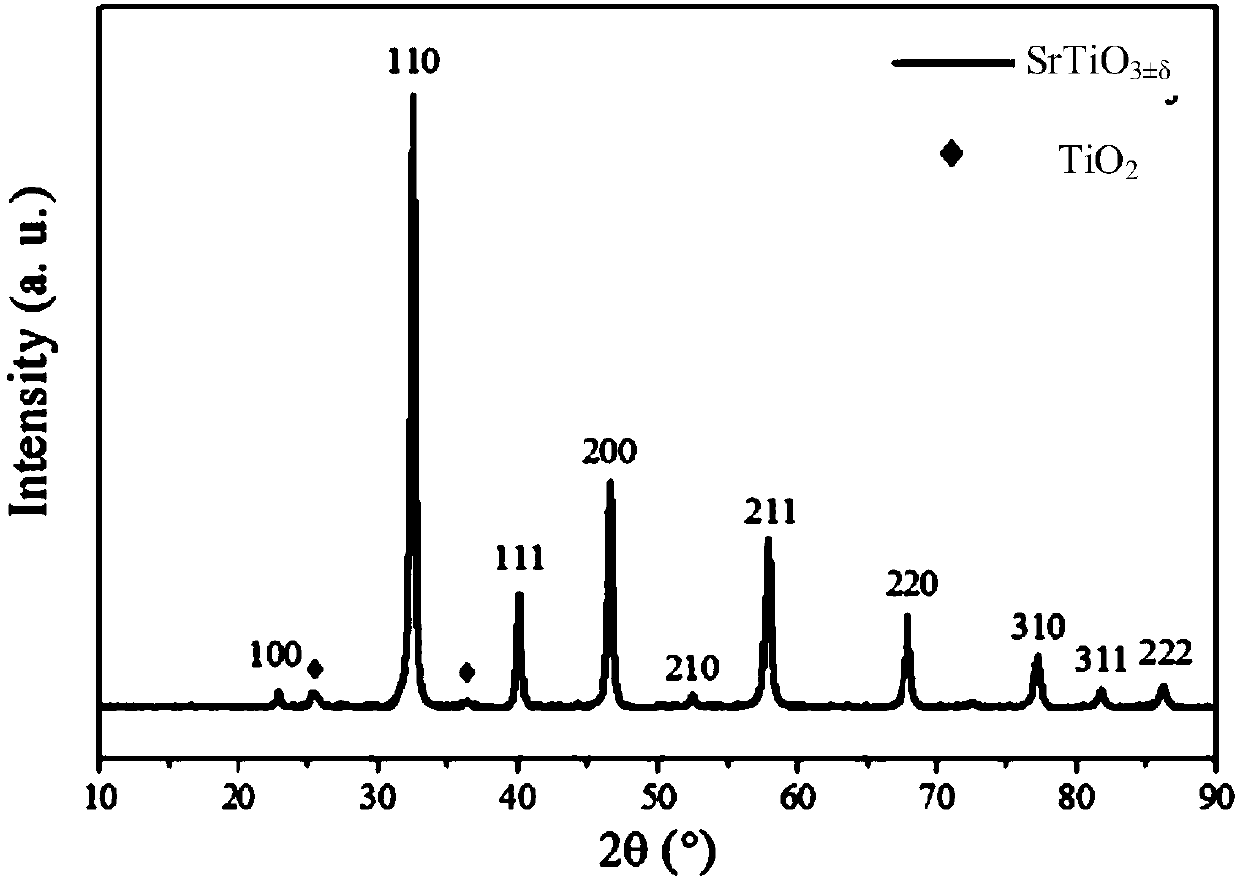

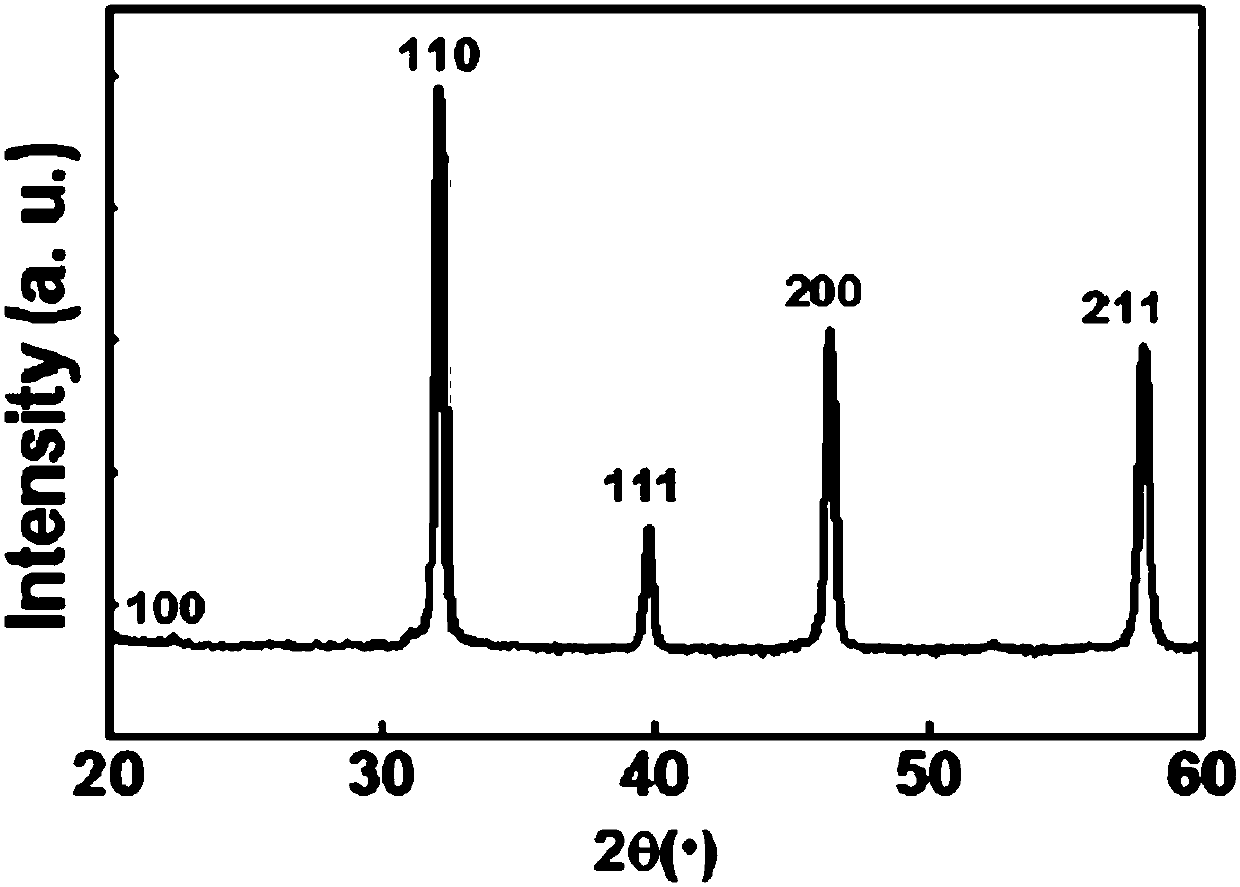

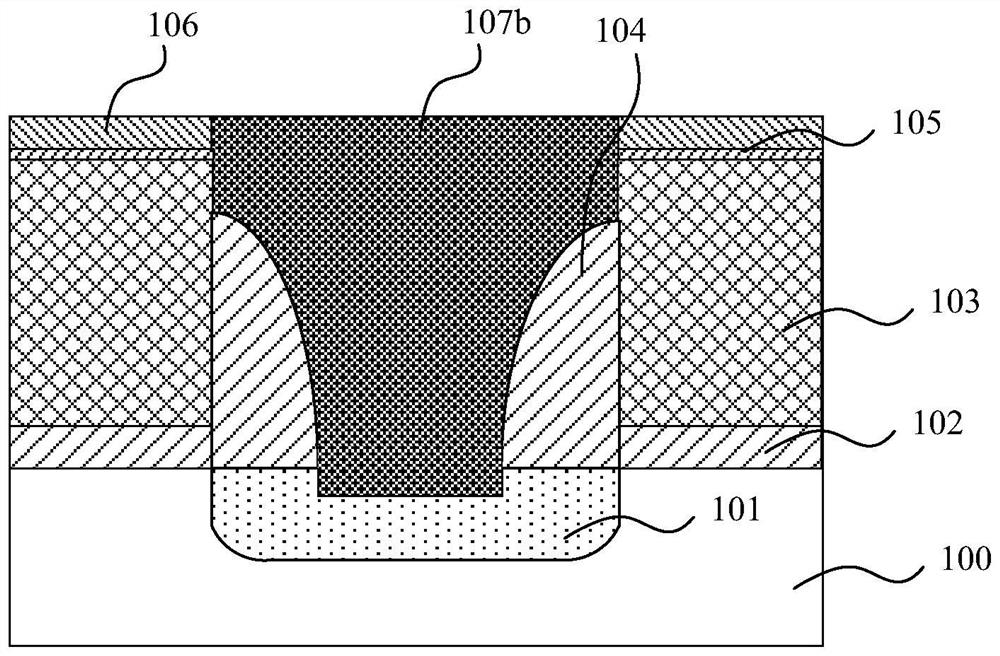

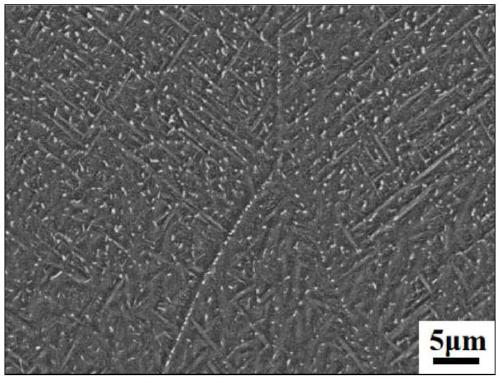

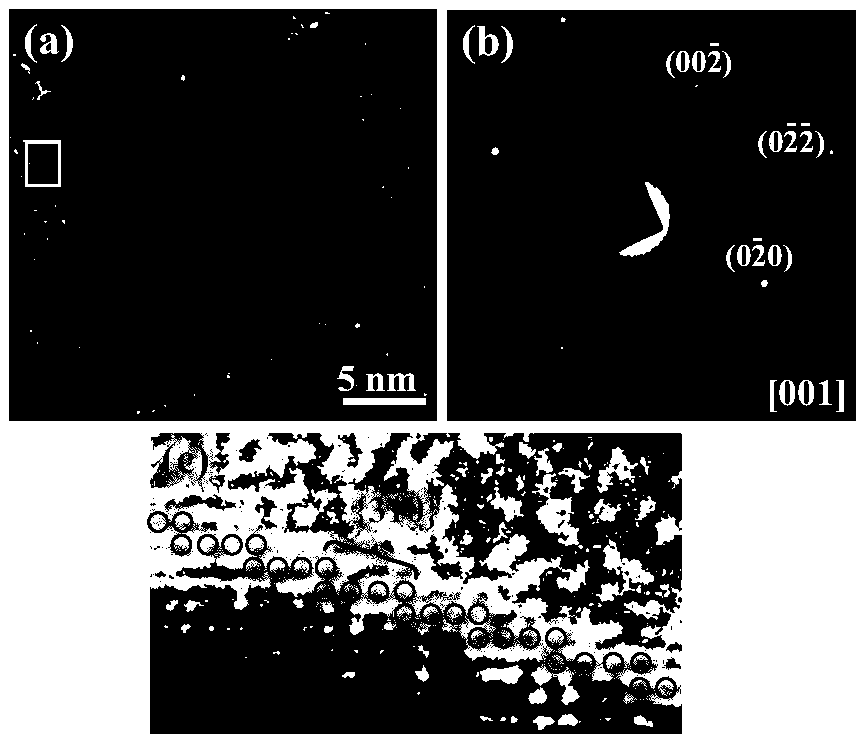

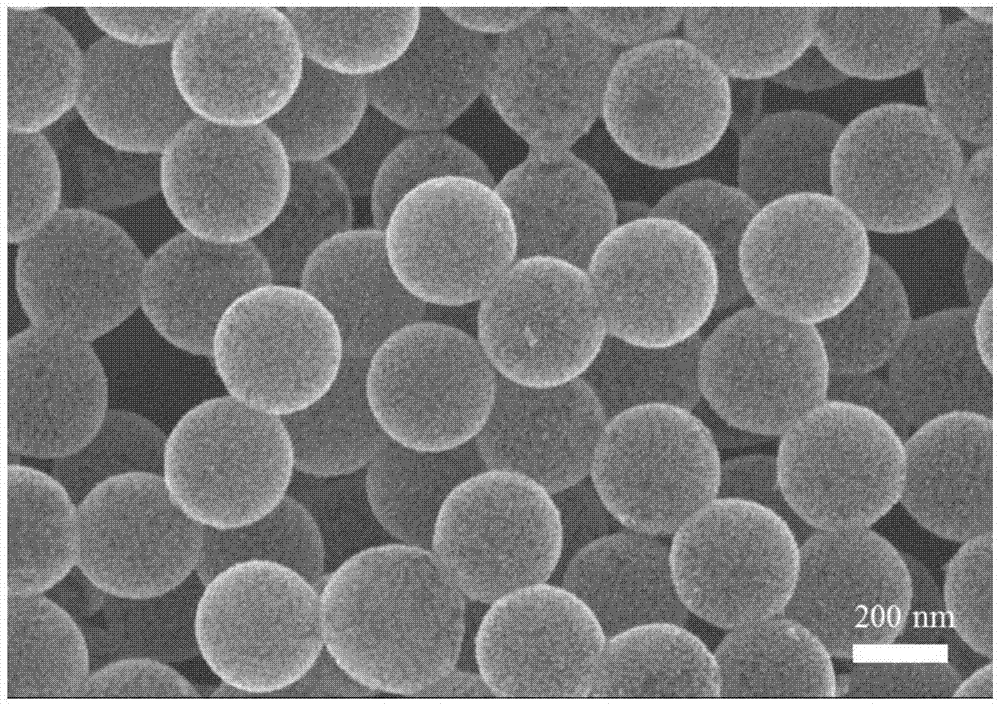

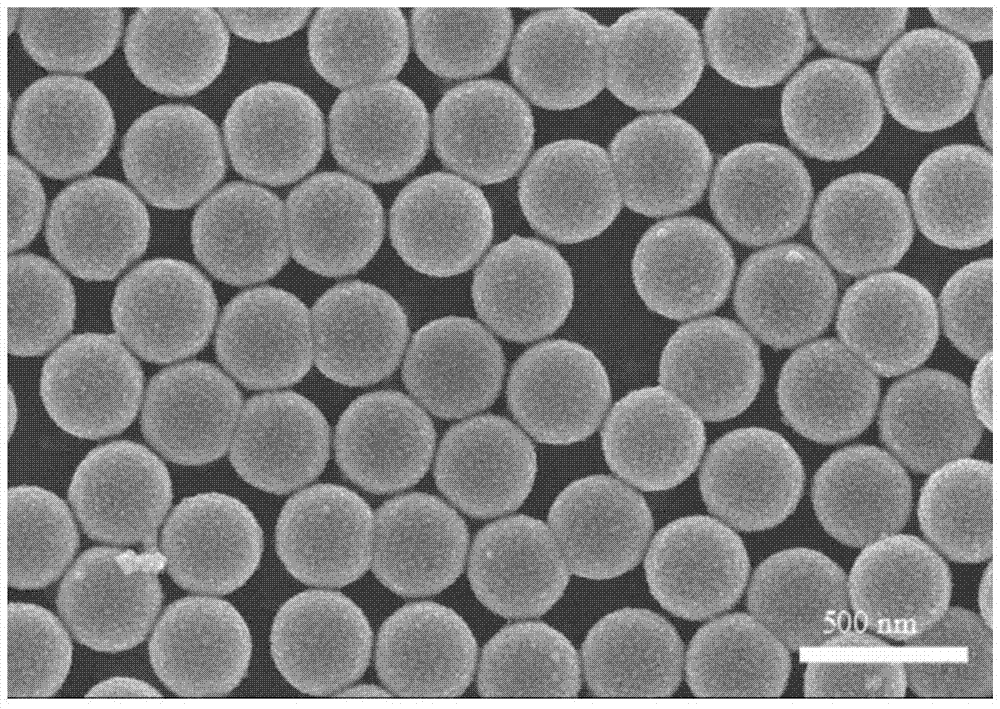

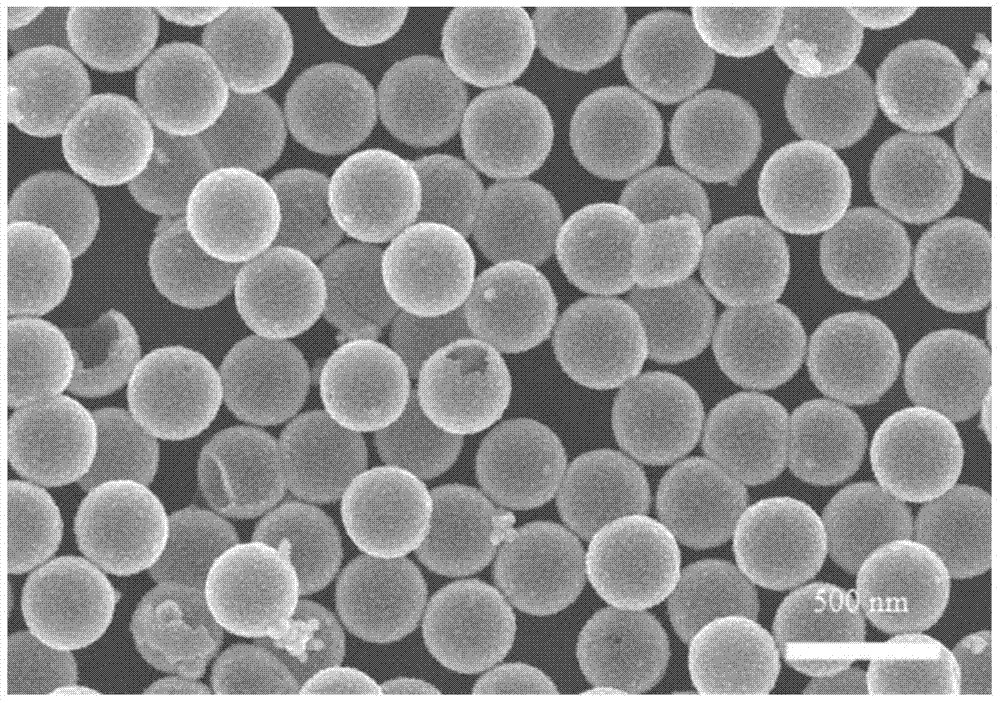

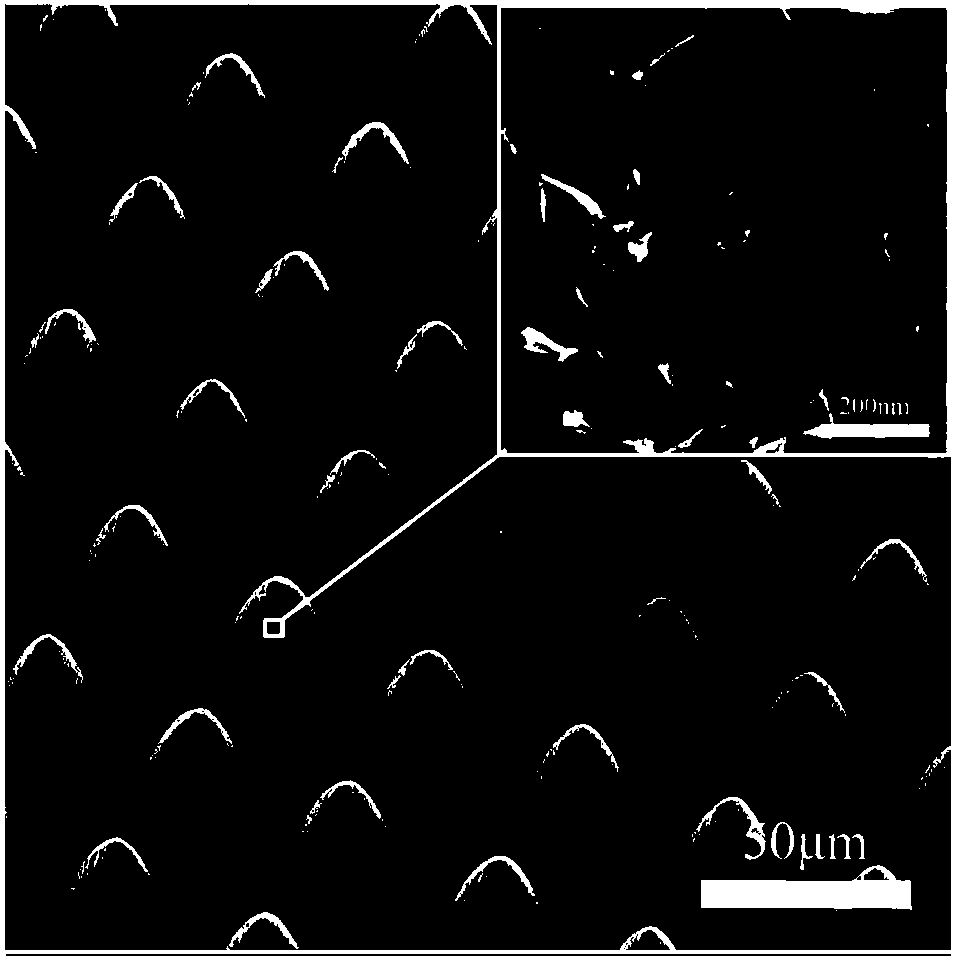

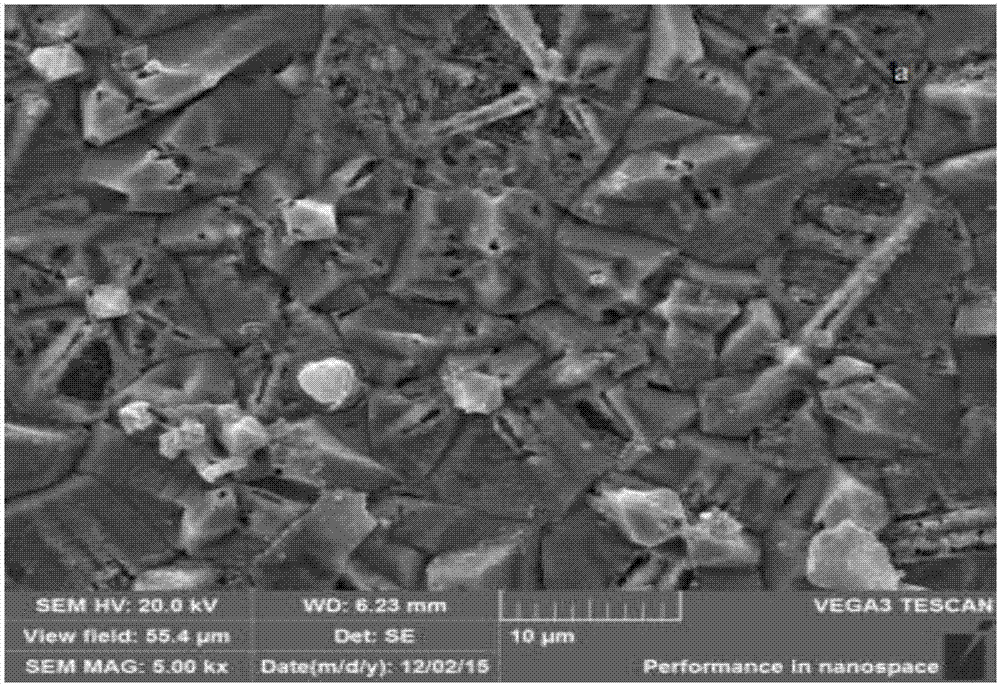

Synthetic method of AyB1-y[Co(CN)6]0.67PBA and AxB1.8-xCo1.2O4

ActiveCN106674532AImprove scalabilityEasy to manufactureCobalt oxides/hydroxidesSolid solutionCopolymer

The invention provides a ''copolymer-eutectic morphology'' strategy for accurately regulating and controlling the morphology of an AyB1-y[Co(CN)6]0.67PBA metal organic coordination polymer. In a PVP solution, by preparing a solid solution of two hexacyano-cobaltates (A-Co and B-CoPBA), AyB1-y[Co(CN)6]0.67PBA with a specific morphology can be prepared. In addition, through simple heat treatment, a doped porous transition metal oxide AxB1.8-xCo1.2O4 with a specific morphology can be synthesized. By the morphology controllable synthesis strategy and through simple conversion of a transition metal precursor, MnyFe1-y[Co(CN)6]0.67 and ZnyFe1-y[Co(CN)6]0.67PBA with specific morphology can be easily synthesized. In comparison with other methods in literature, the morphology synthesis strategy has the characteristic of accurate regulation and control of nano-materials' morphology and composition and has strong expansibility.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

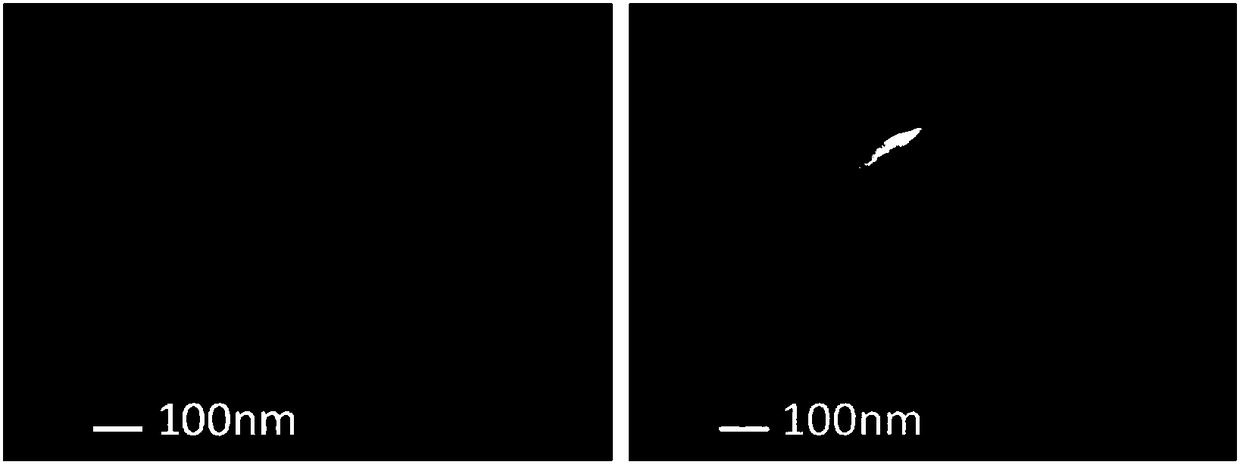

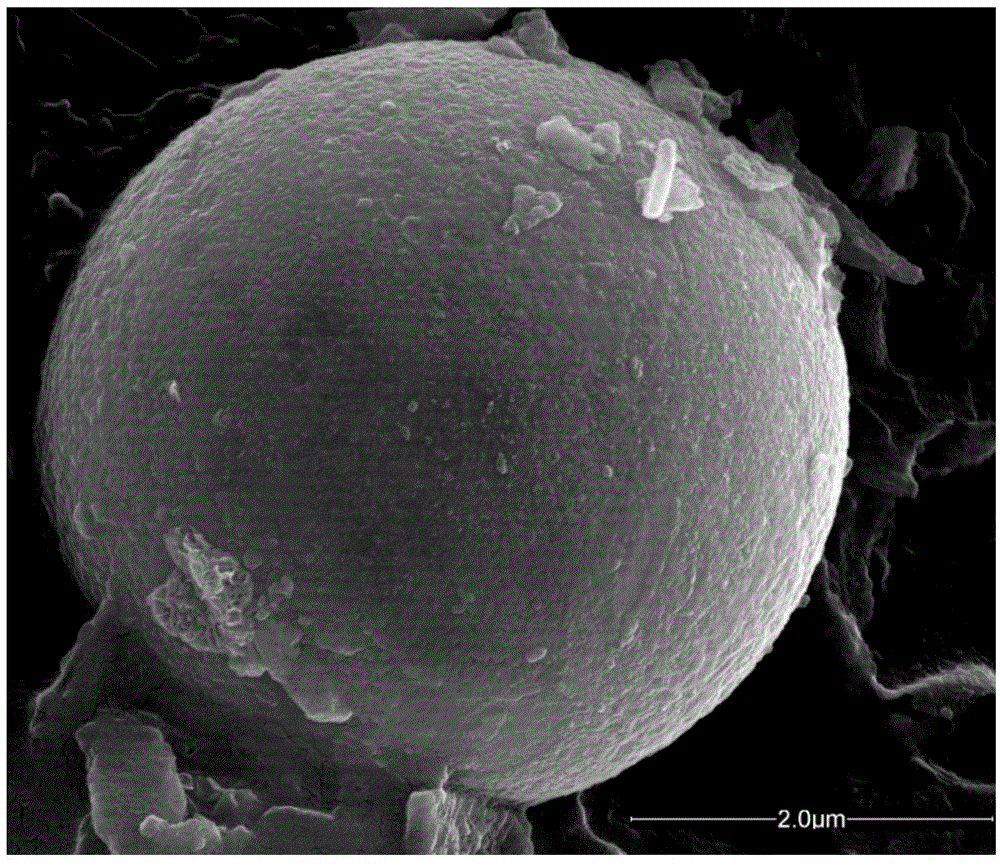

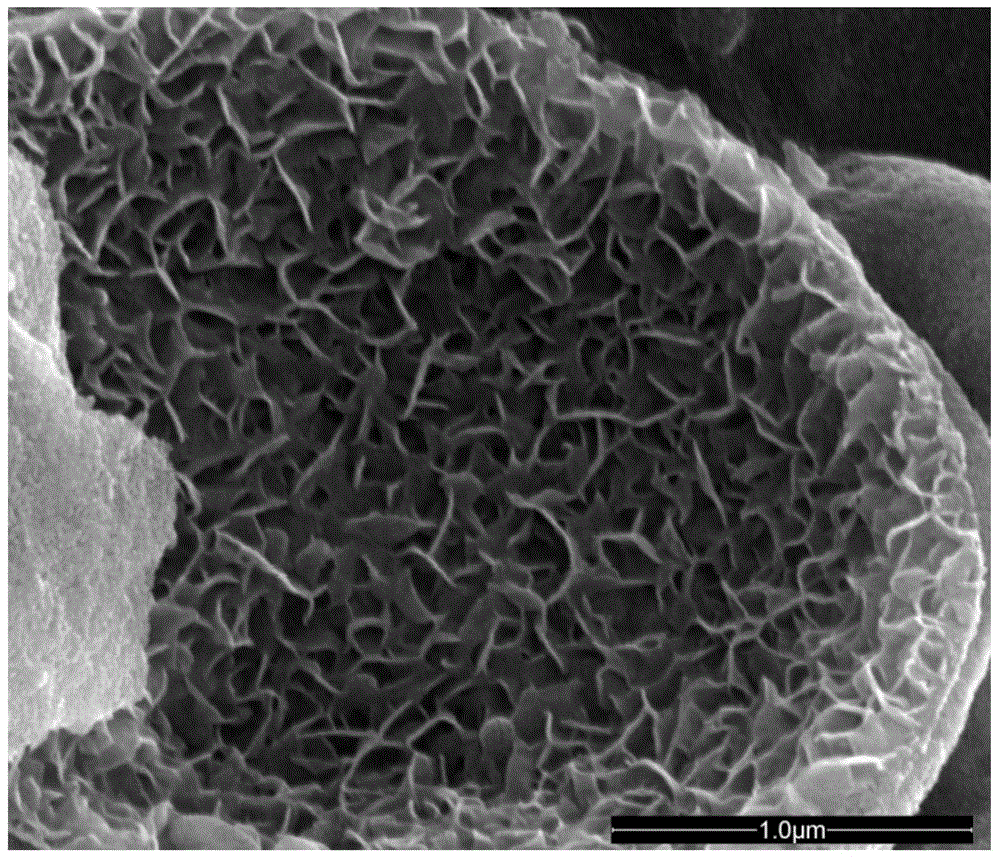

Method for preparation of hollow molybdenum disulfide microspheres in inverse microemulsion

InactiveCN108083337APrecise size controlPrecise control of shapeMolybdenum sulfidesMicrospherePolyethylene glycol

The invention provides a method for preparation of hollow molybdenum disulfide microspheres in an inverse microemulsion. The method mainly includes the steps of: (1) mixing polyethylene glycol octylphenyl ether (Triton X-100), alcohol and cyclohexane evenly to obtain a mixture A, and dividing the mixture A equally into three parts for standby use; in an inert atmosphere, dissolving MoCl5 in one part of the mixture A to obtain a solution B; adding an aqueous solution of a sulfur source and an aqueous solution of a reducing agent respectively into one part of A and performing mixing to obtain amicroemulsion C and a microemulsion D; and then mixing the B, C and D to obtain an inverse microemulsion E; and (2) placing the inverse microemulsion E in a high-pressure reaction kettle, conducting sealing, then conducting reaction at 120-250DEG C for 3-72, performing cooling, and then conducting separation, washing and drying to obtain a black powder sample, and conducting scanning electron microscope and transmission electron microscope characterization to obtain hollow molybdenum disulfide microspheres with a particle size of 100-500nm. The method provided by the invention has the advantages of simple preparation process, abundant raw materials and low cost.

Owner:PETROCHINA CO LTD +1

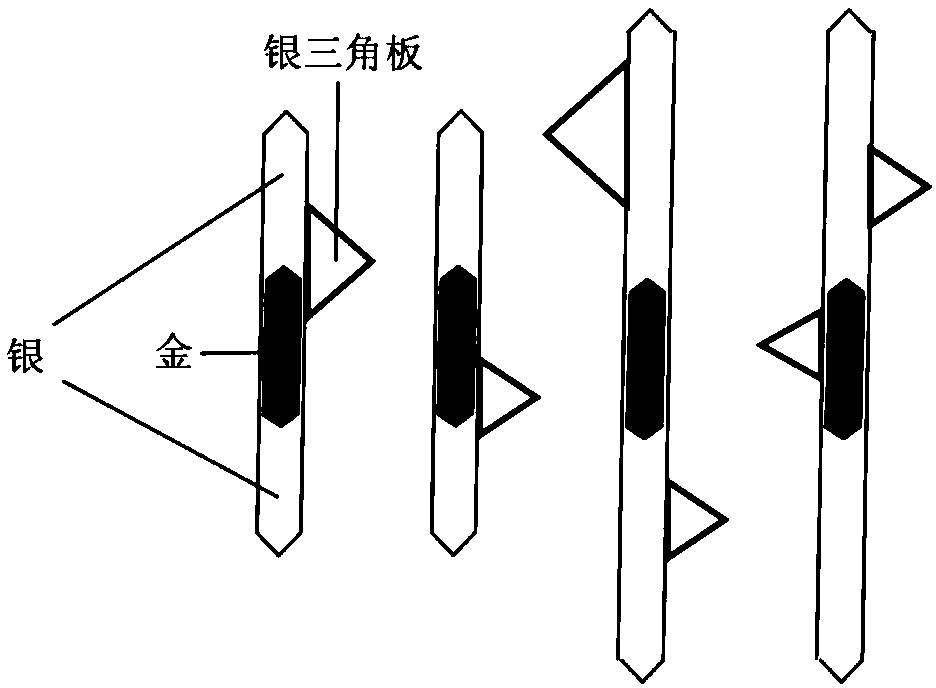

Large-scale controllable preparation method of surface plasmon nanonail structure

InactiveCN108356278AImprove consistencyHigh Q valueMaterial nanotechnologyTransportation and packagingIsoetes triquetraWavelength

The invention provides a large-scale controllable preparation method of a surface plasmon nanonail photoelectric structure. The size of the nanometer material can be controlled at sub-wavelength. Thenanometer material has good localized surface plasmon resonance effect, and the optical, electrical and mechanical properties of the nanometer material all can be regulated and controlled. The surfaceplasmon nanonail is composed of two parts including a silver nanorod or a silver-gold-silver alloy nanorod and an approximate equilateral triangular nano-silver sheet growing on the nanorod. The length of the nanorod is controlled within 20-30 nanometers, the diameter of the nanorod is controlled within 10-200 nanometers, the side length of the triangular nano-silver sheet is controlled within 20nannometers to 2 microns, and the size of the triangular sheet is less than or equal to the length of the nanorod. The plasmon nanonail photoelectric structure has the characteristics of the tunablespectrum, the narrow-band resonance enhancement effect, high Q value and the like. Accordingly, the silver nanonail has extensive application prospects.

Owner:SOUTHEAST UNIV

Controllable preparation method of multielement sulfide semiconductor nano-material

InactiveCN105152228APrecise control of shapePrecise size controlMaterial nanotechnologyTin compoundsSource typeReaction temperature

The invention relates to a controllable preparation method of a multielement sulfide semiconductor nano-material. The controllable preparation method comprises 1, weighing a metal salt and a high boiling point organic solvent, and carrying out mixing stirring dissolution to obtain a metal salt solution, 2, weighing a solid sulfur source and dissolving the solid sulfur source in the high boiling point organic solvent to obtain a sulfur solution or directly utilizing a liquid sulfur source as a sulfur solution, 3, respectively heating the metal salt solution and the sulfur solution, injecting the sulfur solution into the metal salt solution, heating the mixed solution to a reaction temperature, and carrying out a reaction process, and 4, cooling the reaction liquid, carrying out washing, carrying out centrifugation until the supernatant liquid is clear and transparent, putting the obtained black solids into a drying oven and carrying out drying to obtain the multielement sulfide semiconductor nano-material. Through control of reaction time, a reaction temperature, reaction raw material types and sulfur source types, accurate regulation and control of material morphology, size, phase structure and optical properties are realized. The controllable preparation method of the multielement sulfide semiconductor nano-material has the advantages of low price, simple processes, safety, environmental friendliness and industrial production easiness.

Owner:NANJING UNIV OF TECH

Micro-filtration membrane and method for modifying same

ActiveCN109433017AIncrease release rateEnhanced Grading and Screening CapabilitiesUltrafiltrationFiltration membraneWater soluble

The invention relates to a micro-filtration membrane and a method for modifying the same, and belongs to the technical field of membrane modification. By the aid of the micro-filtration membrane and the method, the problem of difficulty in releasing enriched cells by micro-filtration membranes in the prior art can be solved. The micro-filtration membrane is modified by temperature-sensitive water-soluble polymer solution. The method for modifying the micro-filtration membrane includes (1), preparing the temperature-sensitive water-soluble polymer solution with the volume percent concentrationof 0.1%-6%; (2), coating the temperature-sensitive water-soluble polymer solution on the micro-filtration membrane to modify the micro-filtration membrane and drying the micro-filtration membrane coated with the temperature-sensitive water-soluble polymer solution to obtain a modified micro-filtration membrane. The micro-filtration membrane and the method have the advantages that membrane filtration technologies can be widely applied to the field of medical treatment, and accurate detection results can be obtained.

Owner:BEIJING MECHANICAL EQUIP INST

Preparation method for nanometer composite metal oxide

ActiveCN108046217AEmission reductionReduce manufacturing costRare earth metal oxides/hydroxidesMaterial nanotechnologyPowder mixtureDecomposition

The invention discloses a preparation method for a nanometer composite metal oxide. The preparation method comprises the following steps: with a nanometer metal oxide, which is one of the main metal components of the composite metal oxide, as a nanometer template, evenly dispersing the nanometer template in aqueous solutions of water-soluble salts of other metal components in the composite metal oxide so as to obtain mixed dispersion liquid, wherein the main metal component refers to a metal component with a molar content accounting for more than 30% of the molar content of all metal components; drying the mixed dispersion liquid through spray drying or vacuum freeze drying so as to obtain a powder mixture; and subjecting the powder mixture to heat treatment to allow oxides formed by the decomposition of the water-soluble salts to be compounded with the nanometer metal oxide so as to form the nanometer composite metal oxide. The preparation method of the invention significantly reducescost and operation difficulties, avoids the large-scale use of organic compounds, and prevents the problems of impure composition and difficultly-controllable microstructure caused by nonuniform mixing and the introduction of ball milling impurities.

Owner:深圳市大擎科技有限公司

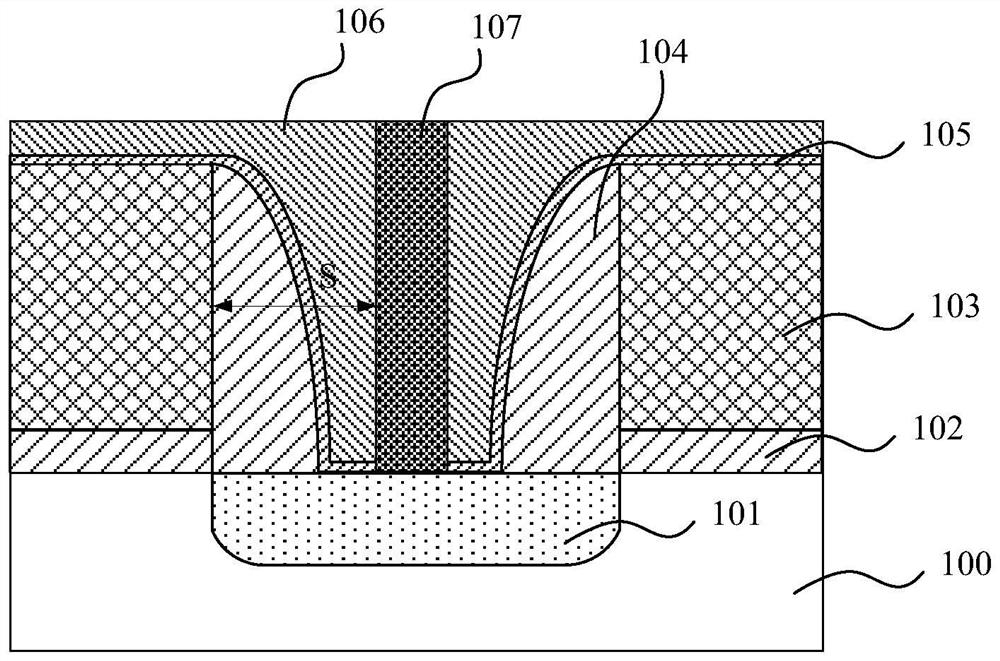

Manufacturing method of self-aligned contact hole and manufacturing method of semiconductor device

ActiveCN111739839AIncreased process windowReduce chip areaSemiconductor/solid-state device detailsSolid-state devicesPhysicsComposite material

The invention provides a manufacturing method of a self-aligned contact hole and a manufacturing method of a semiconductor device. The method comprises the following steps of filling a sacrificial material layer in a trench between adjacent gate stack structure, removing the sacrificial material layer outside the region where the contact hole is to be formed, forming an opening in the sacrificialmaterial layer, filling the opening with an insulating dielectric layer, removing the sacrificial material layer through a selective etching process, so as to avoid etching loss to the insulating dielectric layer around the sacrificial material layer, the side wall and the bottom etching stop layer or the liner oxide layer in the process of removing the sacrificial material layer. The morphology of the formed self-aligned contact hole can be accurately controlled, further reduction of the distance between the contact hole and the gate is facilitated, and the size of the chip is reduced.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

Regional control method for additive manufacturing of in-situ self-generated TiC reinforced titanium-based composite material

ActiveCN111451502APrecise control of shapePrecise content controlAdditive manufacturing apparatusIncreasing energy efficiencyTitanium matrix compositesPowder mixture

The invention discloses a regional control method for additive manufacturing of an in-situ self-generated TiC reinforced titanium-based composite material. The method comprises the following steps: I,ball-milling and drying after uniformly mixing titanium powder with nano carbon powder or uniformly mixing titanium alloy powder with nano carbon powder, spraying aerosol to uniformly mix, and dryingto obtain C / Ti composite powder; II, preparing a series of C / Ti composite powder with different nano carbon mass contents; III, separately selecting a powder mixture of one or more of one series of C / Ti composite powder with different nano carbon mass contents as a raw material, and adopting a high energy beam additive manufacturing method to prepare the in-situ self-generated TiC reinforced titanium-based composite material. Nano carbon mass content in the raw material is controlled on line by selecting the powder mixture of one or more of one series of C / Ti composite powder with different nano carbon mass contents, and different-area TiC dimension, morphology and content of the titanium-based composite material are precisely controlled, so that regional control on the in-situ self-generated TiC reinforced titanium-based composite material is realized.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

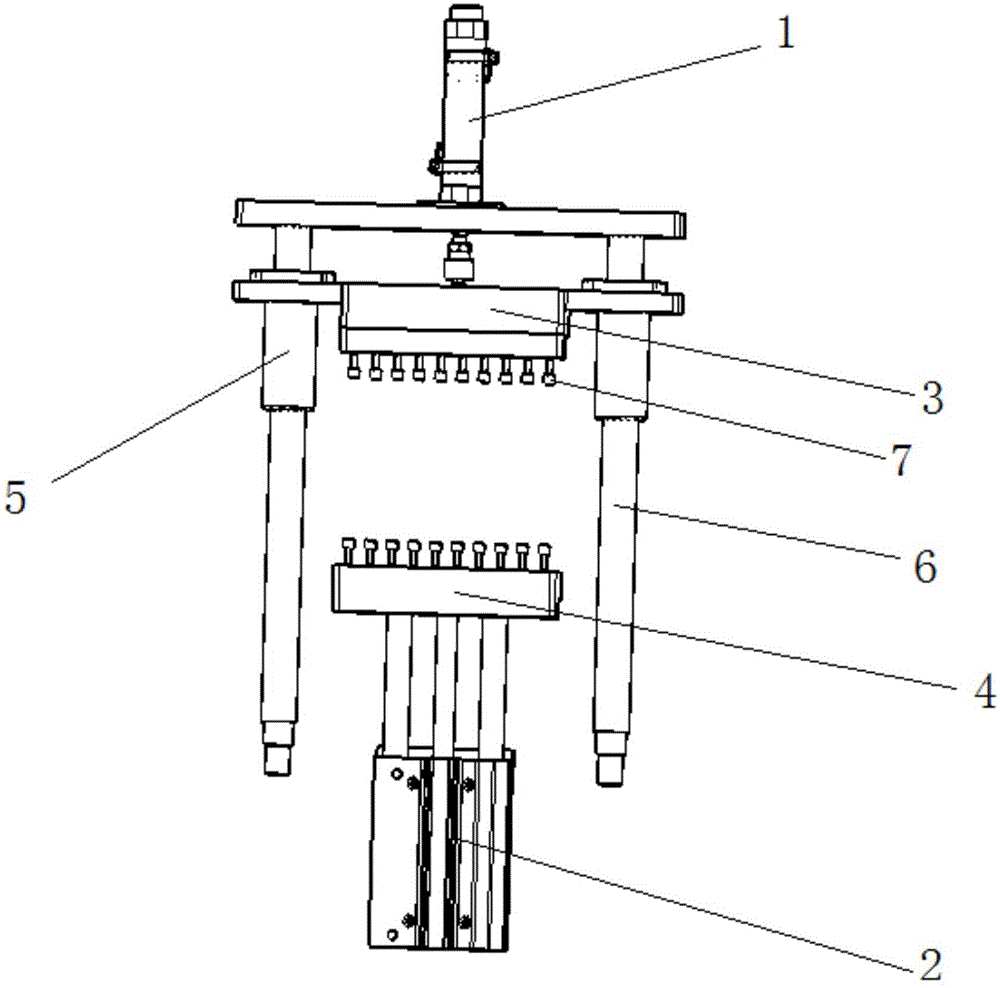

Workpiece crimping forming device

InactiveCN105033440AFirm and reliable workpiece clampingHigh crimping accuracyNon-electric welding apparatusFastenerEngineering

The invention discloses a workpiece crimping forming device. The workpiece crimping forming device is characterized by comprising a first air cylinder, a second air cylinder, an upper crimping mechanism, a lower crimping mechanism and a workpiece fixing device; the upper crimping mechanism is connected with sliding cylinders, and sliding rails are sleeved with the sliding cylinders; the upper crimping mechanism is connected with the first air cylinder, and the lower crimping mechanism is connected with the second air cylinder; the upper crimping mechanism is provided with a first crimping platform and a plurality of crimping pieces, and the lower crimping mechanism is provided with a second crimping platform and a plurality of crimping pieces; the workpiece fixing device comprises a supporting frame, a fastener transmission device and a fastener; a controller is connected with the first air cylinder, the second air cylinder and the fastener transmission device. According to the workpiece crimping forming device, by the arrangement of the workpiece fixing device, a workpiece can be firmly and reliably clamped, crimping heads can not generate displacement in the crimping process, and high crimping precision is guaranteed. The workpiece crimping forming device can not damage a zinc coating on the outer surface of the workpiece.

Owner:SUZHOU TINGYIHUA AUTOMATION EQUIP CO LTD

Preparation method of surface-mineralized chitosan microsphere

InactiveCN106046399AHigh specific surface areaPrecisely Regulated ComponentsTissue regenerationCoatingsEmulsionHydroxyapatite crystal

The invention relates to a preparation method of a surface-mineralized chitosan microsphere and belongs to the field of medical materials. The preparation method comprises the following steps: (1) preparing a chitosan microsphere by utilizing an emulsion-crosslinking method; (2) configuring a mineralized solution; (3) putting prepared chitosan microsphere powder into the configured mineralized solution to enable mineralization reaction for a certain time at a certain temperature, standing and precipitating, washing and drying to obtain a chitosan microsphere surface-mineralized composite material. A large number of uniformly-dispersed lamellar nano hydroxyapatite crystals are generated on the surface of the chitosan microsphere in situ through a mineralization method. According to the preparation method provided by the invention, under mild conditions, the accurate control of the components, the structure and the content of the nano hydroxyapatite crystals on the surface of the polymer microsphere are realized, so that a bone-like apatite surface with high surface activity and good osteogenetic activity is prepared; the preparation method is stable in process and low in cost and can realize large-scale production. The preparation method provided by the invention has a wide application value in clinical aspect of bone tissue engineering.

Owner:TAIYUAN UNIV OF TECH

Method for accurately controlling overall morphology and performance of shallow trench isolation

ActiveCN108010869APrecise control of shapePrecise controlSemiconductor/solid-state device manufacturingEtchingLine width

The present invention provides a method for accurately controlling overall morphology and the performance of shallow trench isolation. An optical line width measurement instrument is used to detect and quantify three-dimensional topography parameters and especially three-dimensional lumbar topography parameters of shallow groove etching under different light transmittances, thus a light transmittance interval suitable for an etching menu is defined according to the three-dimensional topography parameters and especially three-dimensional lumbar topography parameters of the shallow groove etching so as to accurately control the overall topography and performance of the shallow trench isolation. According to the method, the defects of a low precision and a long period of groove morphology after slicing monitor etching can be overcome, the disadvantage that a scanning electron microscope can only measure a line width and can not measure the topography of a shallow groove can be overcome, the defect that the accurate feedback of the actual information of the shallow groove topography can not be achieved can be overcome, and the shallow trench isolation development efficiency and productyield can be improved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

A method for preparing concave cubic platinum-rare earth alloy nanocrystals based on a eutectic solvent

InactiveCN108767267APrecise particle size controlEnhance poisoning abilityMaterial nanotechnologyCell electrodesRare earthAlloy

A method for preparing concave cubic platinum-rare earth alloy nanocrystals based on a eutectic solvent is disclosed, and belongs to the technical field of fuel cell catalyst preparation. The eutecticsolvent which is novel, green and non-aqueous is adopted as a medium to prepare the concave cubic platinum-rare earth alloy nanocrystals with a surface of a {hk0} high-index crystal face structure byelectrochemical cyclic voltammetry without the need of any surfactant. The high-index crystal face has an open type surface structure so that a high number of active sites can be provided and catalyst performance can be significantly improved through a double-function mechanism of an alloyed surface electron structure, and therefore, the nanocrystals have excellent electrocatalytic performance for fuel molecules such as formic acid, methanol and ethanol, and have broad application prospects in the field of fuel cells, the field of electrosynthesis, and the like.

Owner:XUZHOU NORMAL UNIVERSITY

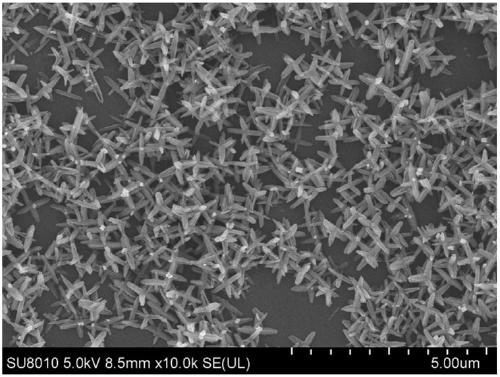

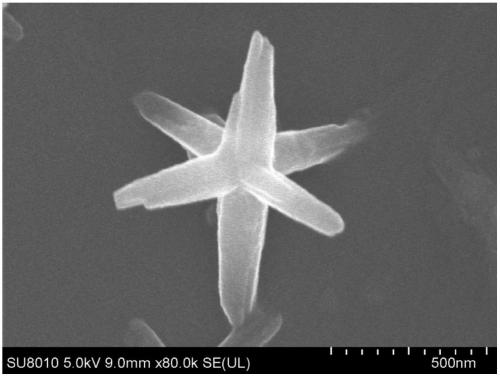

Method of synthesizing and preparing zeolitic imidazolate framework material ZIF-8 nanometer six-foot body by using seed growth

The invention relates to a method of synthesizing and preparing a zeolitic imidazolate framework material ZIF-8 nanometer six-foot body by using seed growth. The method comprises the following steps of (1) mixing and dissolving zinc salt, an imidazole ligand, a surfactant and water at room temperature, performing thermal insulation for 2-4 h at room temperature, performing washing to obtain ZIF-8cube seeds, and then dispersing the ZIF-8 cube seeds into water to obtain a seed dispersion liquid; and (2) stirring, mixing and dissolving the zinc salt, the imidazole ligand, the surfactant, the seed dispersion liquid and a solvent at room temperature, performing thermal insulation for 1-12 h at room temperature, and performing washing to obtain a ZIF-8 nanometer six-foot body product. Accordingto the method provided by the invention, the ZIF-8 nanometer six-foot body is prepared by using a seed growth method, the seeds which are synthesized in advance instead of a precursor are selected asa starting point of crystal growth. Compared with a one-step synthesis method, the method can avoid a complex and difficultly controlled initial nucleation step and accurately controls the growth stage from angles of thermodynamics and dynamics.

Owner:SHANDONG UNIV

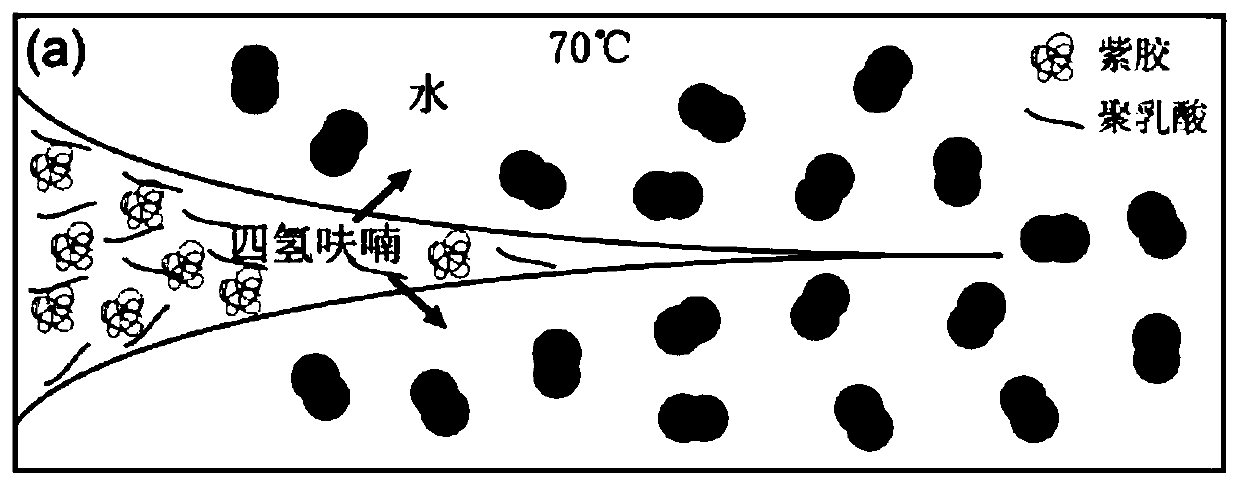

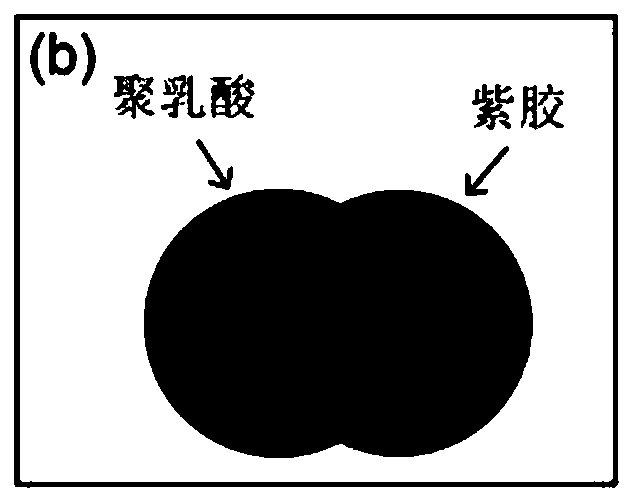

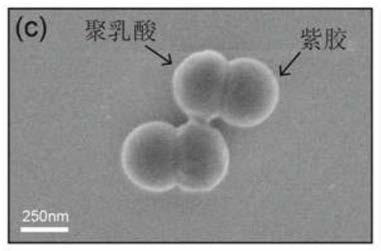

Janus particles with compatibility and preparation method thereof

ActiveCN110229368AGood biocompatibilityPromote degradationTransportation and packagingMixingActive agentSurface-active agents

The invention discloses Janus particles with compatibility and a preparation method thereof. According to the preparation method, biocompatible materials are adopted, and lac and polylactic acid materials are dissolved in a common good solvent; then, the mixed solution is rapidly injected into an aqueous solution containing a surfactant at a certain temperature; and based on the coprecipitation and phase separation mechanism, lac-polylactic acid Janus nanoparticles with lac at one end and polylactic acid at the other end are obtained. By adjusting the concentration of lac and polylactic acid in the good solvent, size of the Janus nanoparticles can be regulated. By adjusting the ratio of lac to polylactic acid in the good solvent, proportions of lac hemispheres and polylactic acid hemispheres can be regulated. Through interaction of positive and negative charges, the surface of the lac hemispheres is modified with polylysine having biocompatibility, thus enhancing hydrophilicity of thelac hemispheres. The Janus nanoparticles with compatibility have amphipathy, and can greatly stabilize an oil-in-water emulsion when being used as a particle surfactant.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthetic method of AyB1-y[Co(CN)6]0.67PBA and AxB1.8-xCo1.2O4 Synthetic method of AyB1-y[Co(CN)6]0.67PBA and AxB1.8-xCo1.2O4](https://images-eureka.patsnap.com/patent_img/e1b3a116-95b0-44dd-99bf-9e1f9fe7bd36/HDA0000888886070000011.png)

![Synthetic method of AyB1-y[Co(CN)6]0.67PBA and AxB1.8-xCo1.2O4 Synthetic method of AyB1-y[Co(CN)6]0.67PBA and AxB1.8-xCo1.2O4](https://images-eureka.patsnap.com/patent_img/e1b3a116-95b0-44dd-99bf-9e1f9fe7bd36/HDA0000888886070000012.png)

![Synthetic method of AyB1-y[Co(CN)6]0.67PBA and AxB1.8-xCo1.2O4 Synthetic method of AyB1-y[Co(CN)6]0.67PBA and AxB1.8-xCo1.2O4](https://images-eureka.patsnap.com/patent_img/e1b3a116-95b0-44dd-99bf-9e1f9fe7bd36/HDA0000888886070000013.png)