Preparation method of surface-mineralized chitosan microsphere

A technology of chitosan microspheres and chitosan, applied in coatings, medical science, prostheses, etc., can solve the problem of insignificant effects, inability to obtain components and structures, and the growth of nano-hydroxyapatite cannot reach natural bone. Issues such as the required content of inorganic minerals to achieve the effect of large-scale production, good biological activity and biological function, and good osteogenic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Mix 110 g of liquid paraffin with 3 g of span80, slowly add 50 g of 2 wt% chitosan acetic acid solution after stirring, stir and emulsify for 3 h at 30 °C to form a water-in-oil emulsion.

[0023] Add 0.0428 g of glutaraldehyde dropwise for cross-linking for 3 h to obtain a uniformly mixed emulsion, which is left to settle;

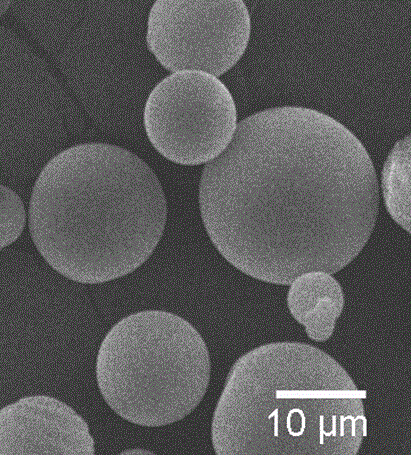

[0024] Add petroleum ether and isopropanol to wash the precipitate, and dry at 50-60°C for 10 h to obtain chitosan microspheres with a particle size of 5-15 μm (see figure 1 ).

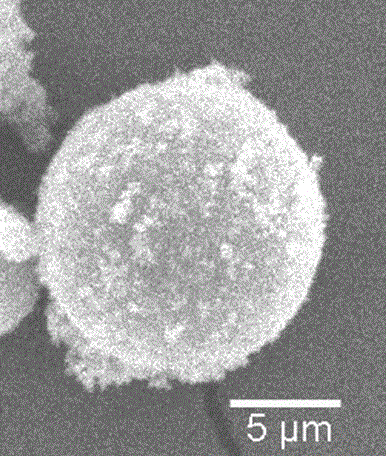

[0025] 0.3 g of chitosan microspheres were fully dispersed in 250 mL of mineralization solution with a pH of 4.5, and the reaction was continuously stirred at 37 °C for 3 h to obtain a uniformly mixed solution. Set aside to settle, wash the precipitate with deionized water and isopropanol successively, and dry to obtain the mineralized chitosan microspheres. The surface of the mineralized chitosan microspheres has an acicular nano-apatite structure (see figure 2 ).

Embodiment 2

[0027] 124.742 g of liquid paraffin and 3.858 g of span80 were mixed, and after stirring, 60 g of 4 wt% chitosan acetic acid solution was slowly added, stirred and emulsified at 37°C for 3 h to form a water-in-oil emulsion.

[0028] 0.214 g of glutaraldehyde was added dropwise for cross-linking for 3 h, and a uniformly mixed emulsion was obtained. Let the precipitate stand still, add petroleum ether and isopropanol to wash the precipitate, and dry at 50-60°C for 12 h.

[0029] 0.4 g of chitosan microspheres were fully dispersed in 250 mL of mineralization solution with a pH of 5, and the reaction was continuously stirred at 70 °C for 12 h to obtain a uniformly mixed solution. Let the precipitate stand, wash the precipitate with deionized water and isopropanol in turn, and dry to obtain mineralized chitosan microspheres.

Embodiment 3

[0031] 124.742 g of liquid paraffin and 3.858 g of span80 were mixed, and after stirring, 50 g of 4 wt% chitosan acetic acid solution was slowly added, and stirred and emulsified at 60°C for 3 h to form a water-in-oil emulsion.

[0032] 0.214 g of vanillin was added dropwise for cross-linking for 3 h, and a uniformly mixed emulsion was obtained. Let the precipitate stand still, add petroleum ether and isopropanol to wash the precipitate, and dry at 50-60°C for 11 h.

[0033] 0.35 g of chitosan microsphere powder was fully dispersed in 250 mL of mineralization solution with a pH of 5.5, and the reaction was continuously stirred at 85 °C for 12 h to obtain a uniformly mixed solution. Let the precipitation stand still, wash the precipitation with deionized water and isopropanol in turn, and dry to obtain the mineralized chitosan microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com