Patents

Literature

45results about How to "Precise particle size control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

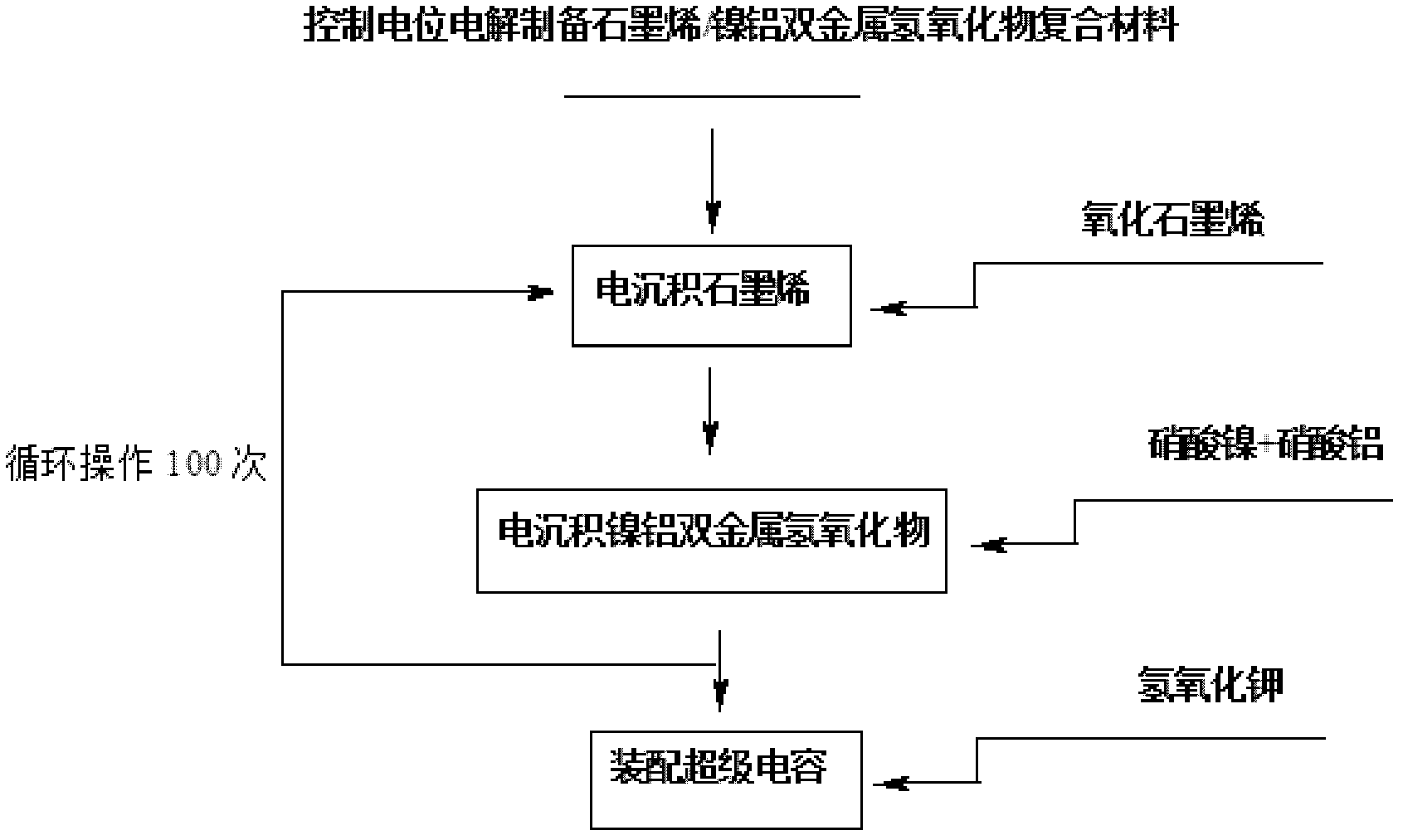

Electrochemical preparation method of graphene/nickel-aluminum bimetal hydroxide composite material for super capacitor

ActiveCN102509640ANo pollutionGood dispersionElectrolytic capacitorsCapacitanceSupporting electrolyte

The invention relates to an electrochemical preparation method of a graphene / nickel-aluminum bimetal hydroxide composite material for a super capacitor, belonging to the technical field of capacitor preparation. The method comprises the following steps of: putting graphite oxide in a beaker; adding deionized water and supporting electrolyte; performing ultrasonic oscillation and constant-potential electrolysis; taking out the electrode; washing the electrode with the deionized water and drying; putting the obtained graphene-modified electrode into a solution containing the precursor of nickel salt and aluminum salt; adding the supporting electrolyte; performing constant-potential electrolysis for 10 seconds; taking out the electrode; and washing the electrode with the deionized water and drying. In the invention, the electrolysis is performed under controlled potential to electrically and alternately deposit the graphene and bimetal hydroxide on the surface of the electrode, therefore, the reduction and deposition of the graphene oxide are finished at the same time, and more importantly, the accurate control on the layer thickness of graphene as well as the size and distribution density of bimetal hydroxide particles is realized; and moreover, the preparation of the material does not produce the 'three wastes' (waste gas, waste water and waste residues).

Owner:盐城市纺织染整产业园实业开发有限公司

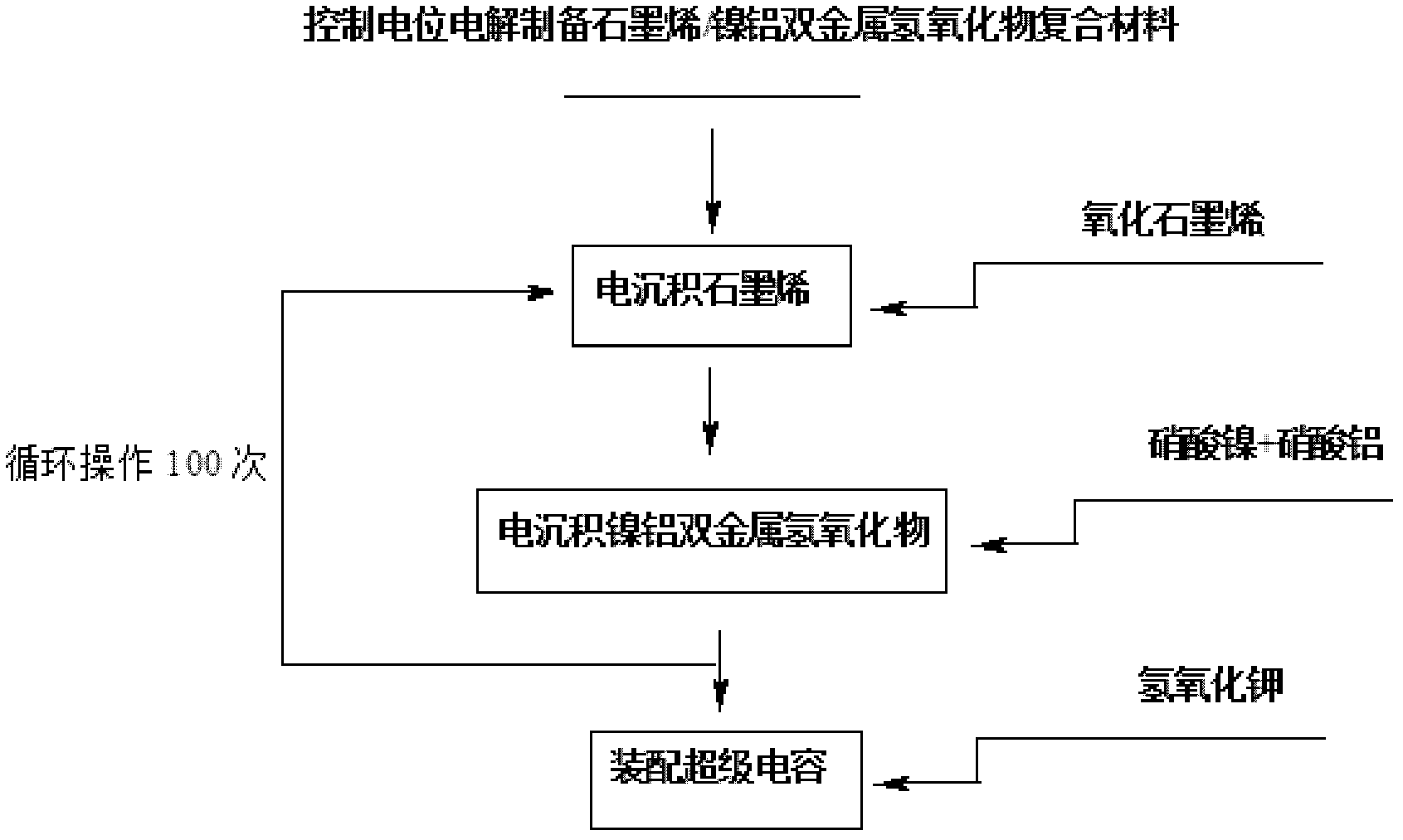

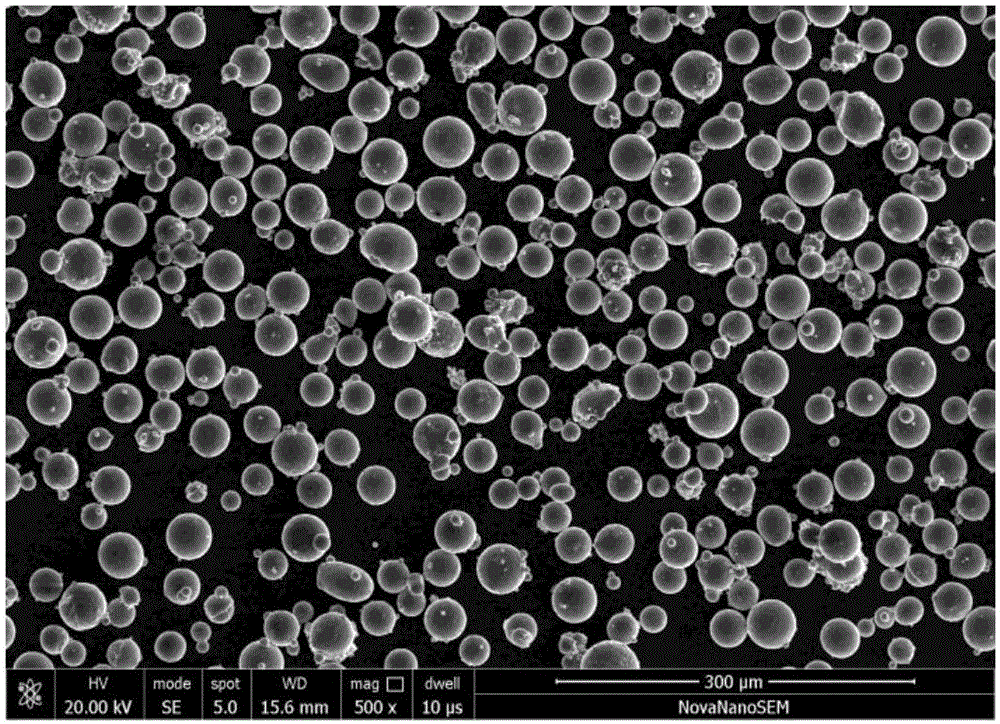

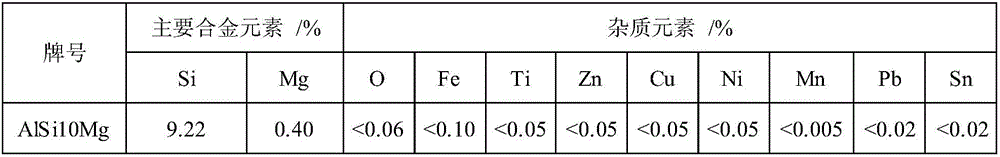

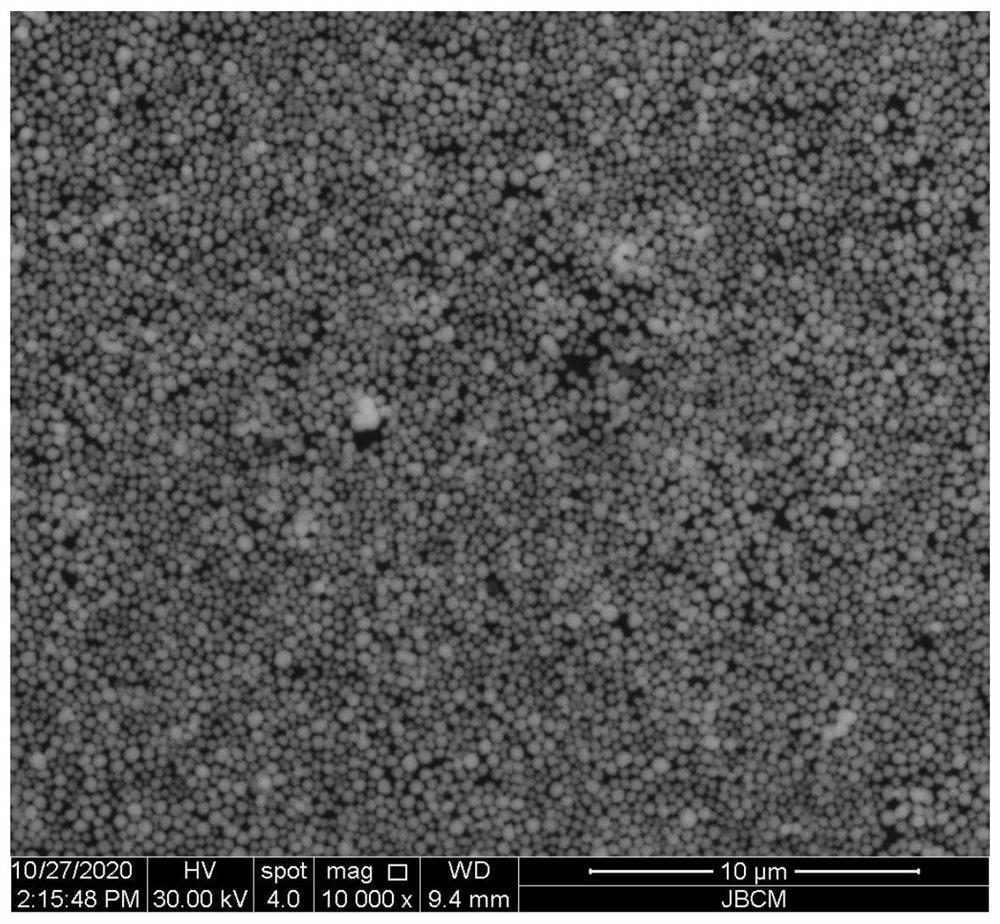

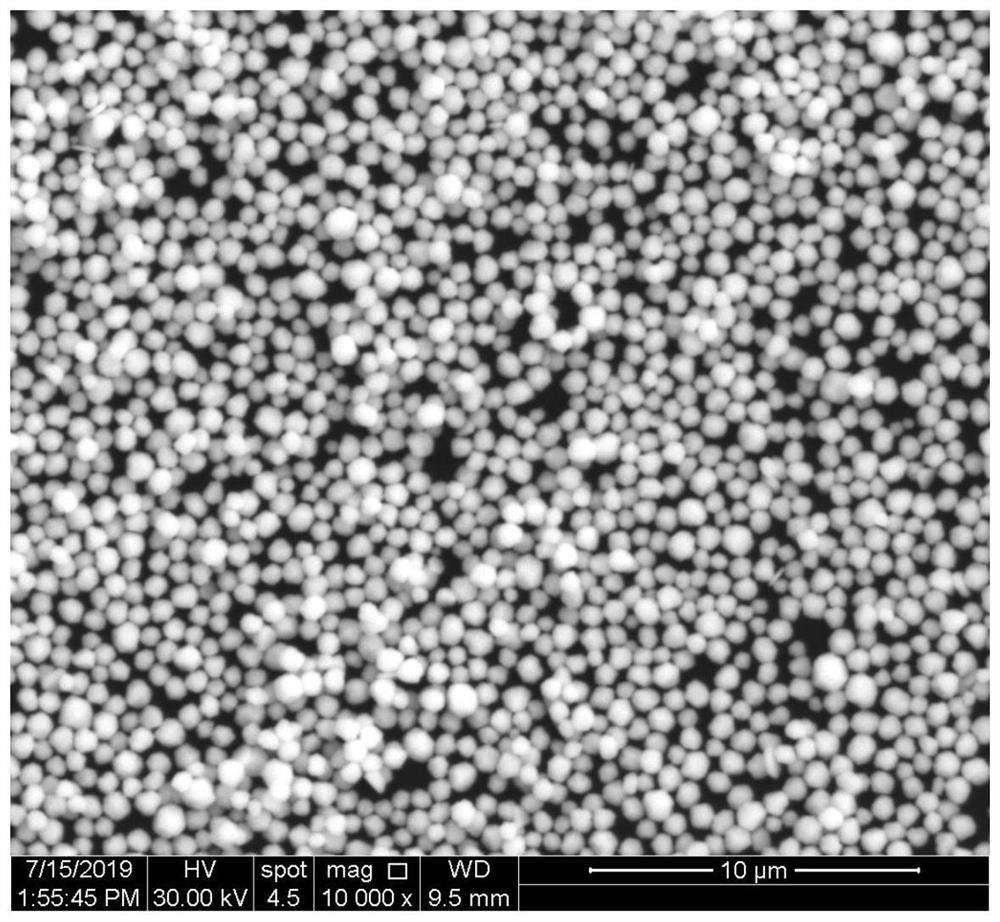

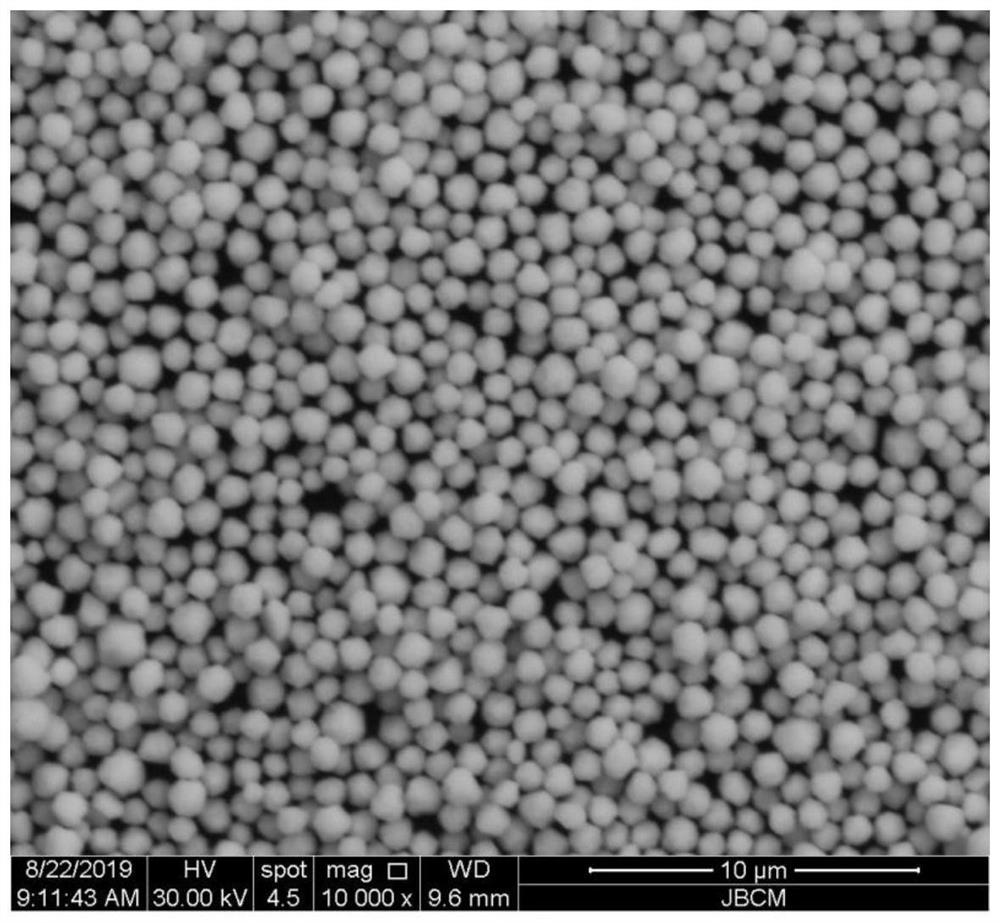

Preparation method for AlSi10Mg aluminum alloy superfine powder for 3D printing

The invention belongs to the technical field of metal and alloy powder preparation, and relates to a preparation method for AlSi10Mg aluminum alloy superfine powder for 3D printing. The preparation method is characterized by comprising the following preparation steps of: performing supersonic-speed gas atomization and ultrasonic-wave vibratory screening. By utilizing homemade equipment, the invention provides the preparation method for AlSi10Mg aluminum alloy superfine powder for 3D printing. Powder prepared by the method has the advantages such as small pollution in a process, high purity, low oxygen content, precise grain size control and low cost, can meet requirements of the 3D printing process, and also can realize replacing imported powder.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

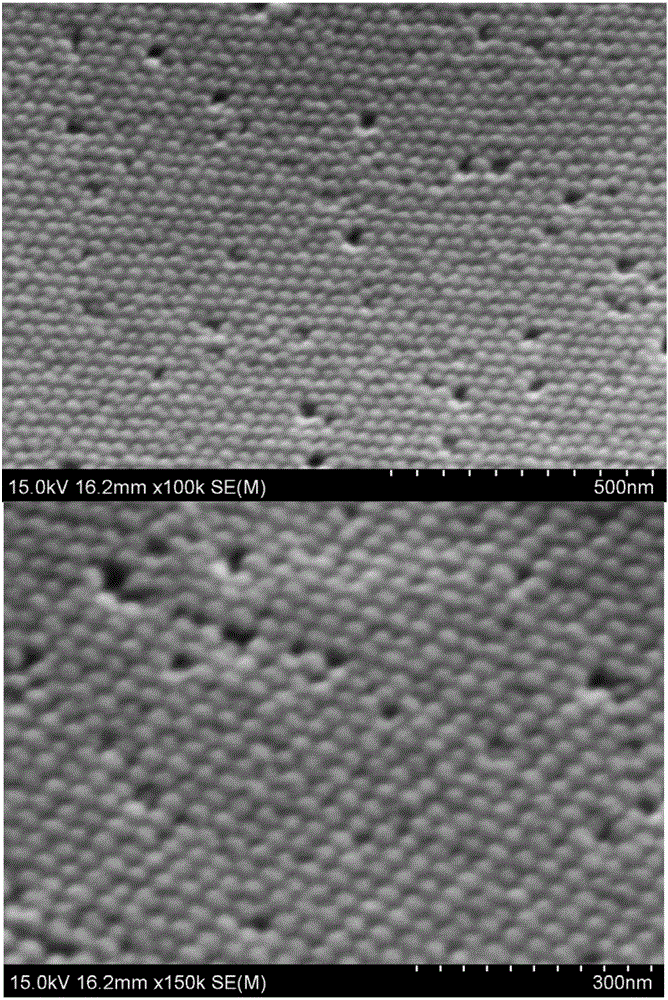

Sphere-like silver powder with particle size capable of being accurately controlled and preparation method thereof

InactiveCN112475311APrecise particle size controlMild reaction conditionsTransportation and packagingMetal-working apparatusDispersitySilver colloid

The invention provides sphere-like silver powder with particle size capable of being accurately controlled and a preparation method thereof. The method comprises the following steps: (1), mixing a nano-silver colloid with a dispersing agent solution to obtain a mixed solution, wherein the silver particles in the nano-silver colloid are approximately spherical; (2) under a stirring condition, dripping a silver salt solution and a reducing agent solution into the mixed solution in the step (1) in a parallel flow mode to react, so as to obtain silver powder slurry; and (3) carrying out solid-liquid separation, washing and drying on the silver powder slurry obtained in the step (2) to obtain the sphere-like silver powder. The silver salt solution and the reducing agent solution are dropwise added into the mixed solution of a dispersing agent and a seed crystal in a parallel flow mode to control the generation speed of elemental silver, so that the elemental silver uniformly grows on the provided nano-silver colloid seed crystal, the sphere-like silver powder with the particle size accurately controllable is obtained, and the reaction conditions are mild, normal temperature and normal pressure are achieved, equipment and process are simple, and the production period is short; it is easy to amplification and industrial application; the prepared silver powder is uniform in morphology,good in dispersity and high in tap density.

Owner:山东建邦胶体材料有限公司

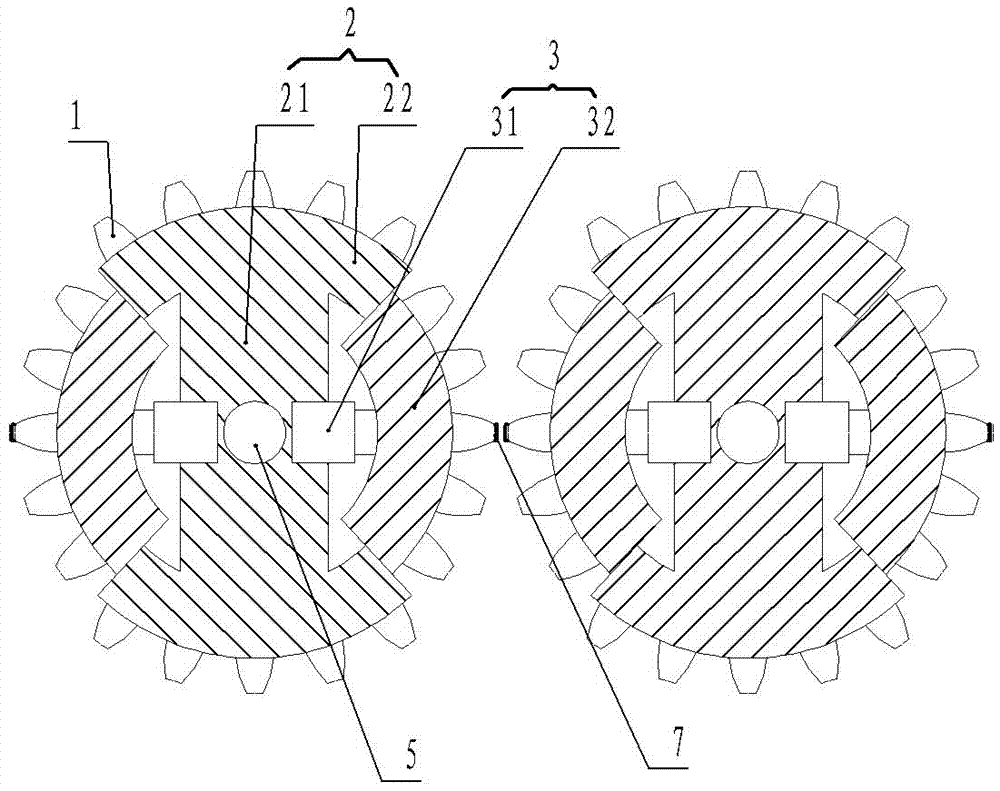

Roll crusher

InactiveCN107233959APrecise particle size controlEasy to operateGrain treatmentsEngineeringPressure sensor

The invention discloses a roller crusher, which belongs to the technical field of mining machinery. The roller crusher includes sawtoothed rollers whose outer walls are driven to rotate by their mandrels. The rollers are two side by side. Both of the two rollers include a radial fixing part and a radial extension part; the tip of the sawtooth located on the outer wall of the radial extension part is provided with a pressure sensor electrically connected to the controller. The invention can solve the problems of inaccurate particle size control and inconvenient operation of existing roller crushers.

Owner:河池市一森机械有限责任公司

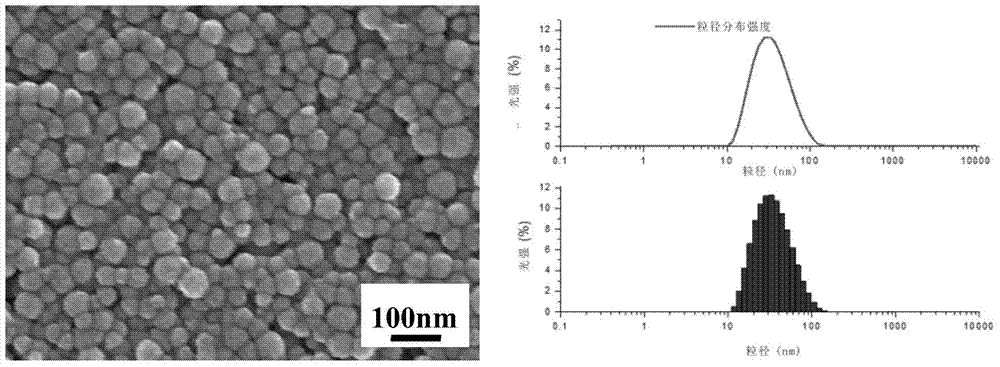

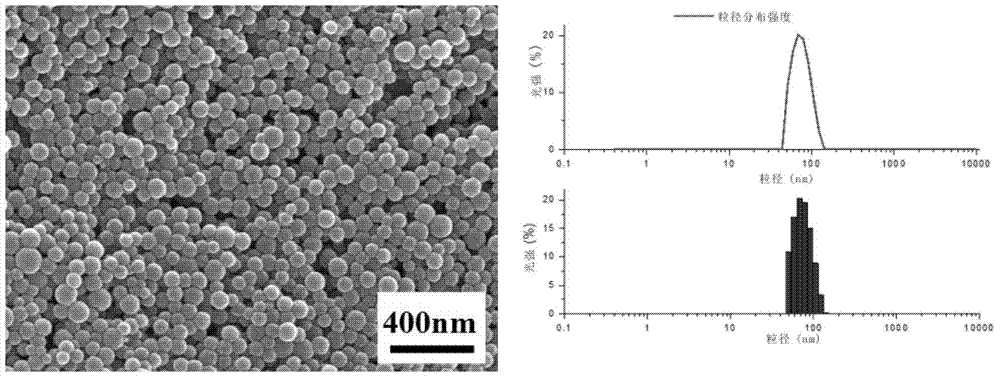

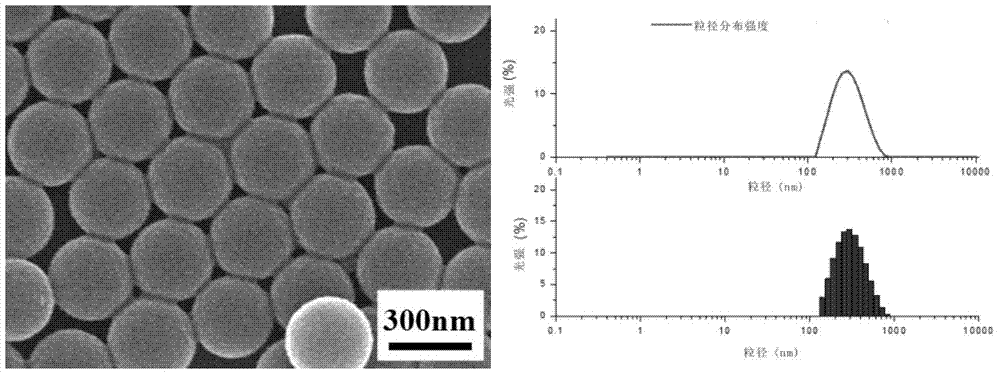

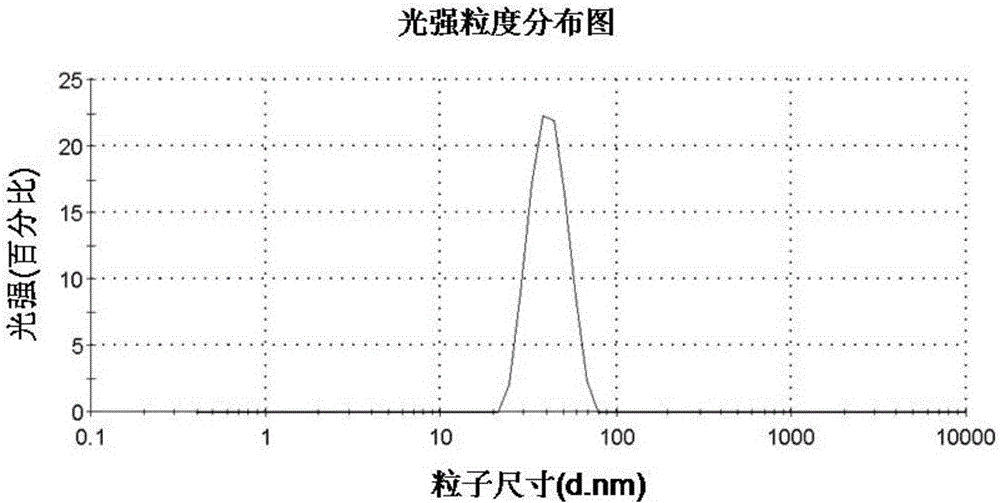

Method for preparing granularity controllable narrow range polymer micro-nano spheres

The invention discloses a method for preparing granularity controllable narrow range polymer micro-nano spheres. The granularity controllable narrow range polymer micro-nano spheres can be efficiently and continuously produced at normal temperature by using industrial grade polydisperse polymer products, recovered polymer materials, homopolymers and copolymers which are wide in source as raw materials by virtue of a two-step production process of mechanical stirring-micro jet flow. In a preparation process, the proportion of a dispersed phase to a continuous phase, the type and use level of surfactants and compounding schemes of types of organic solvents and high pressure chamber of the device are adjusted without high-temperature time-consuming polymerization reaction and cockamamie post-treatment as well as purification of raw materials, so that the grain size and grain size distribution of the micro-nano spheres can be controlled. The diameters are adjustable from 30nm to 3mu m, the polydispersity index is less than 0.2, and the micro-nano spheres are smooth and non-adhesive on the surfaces and can be re-dispersed in a solvent. The obtained polymer micro-nano spheres have a wide application range in the fields of standard metering, food industry, medicines, bioengineering, coating and plastic processing and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

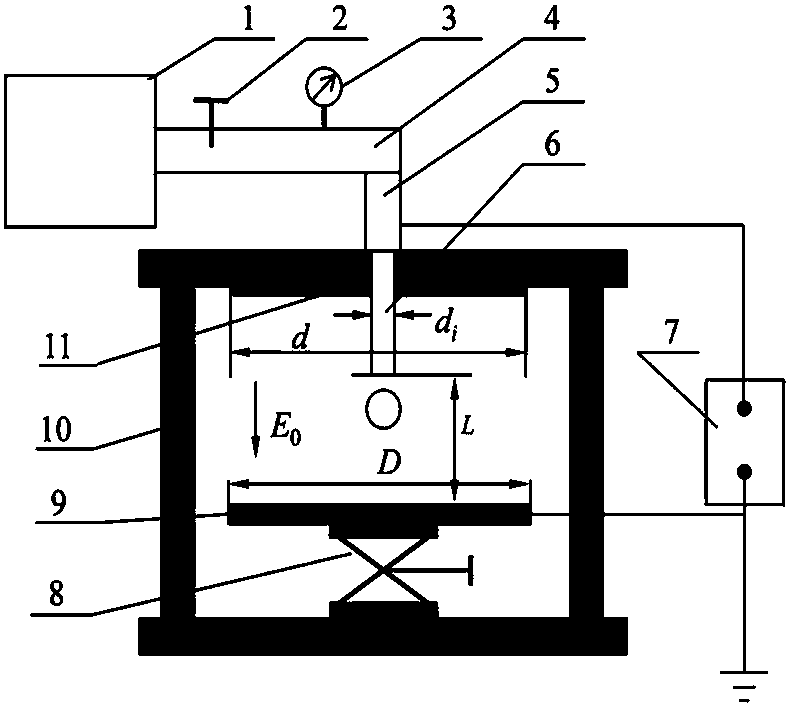

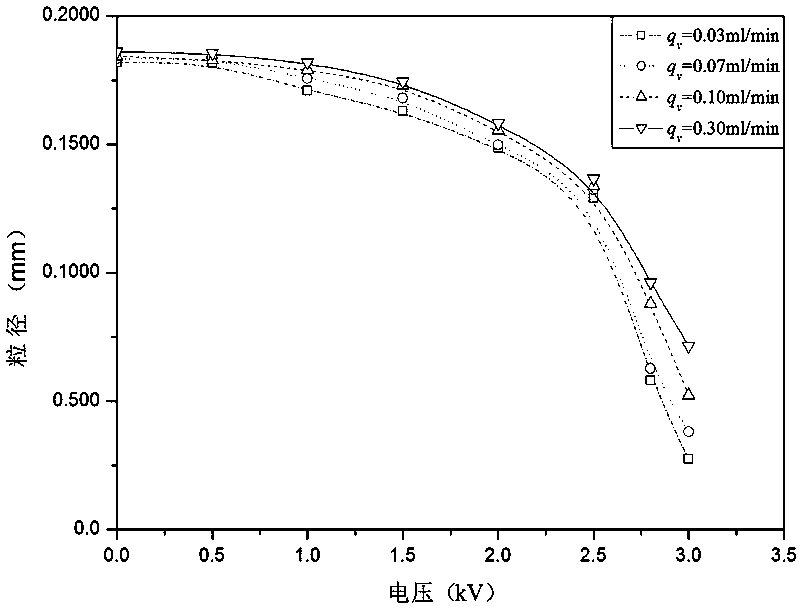

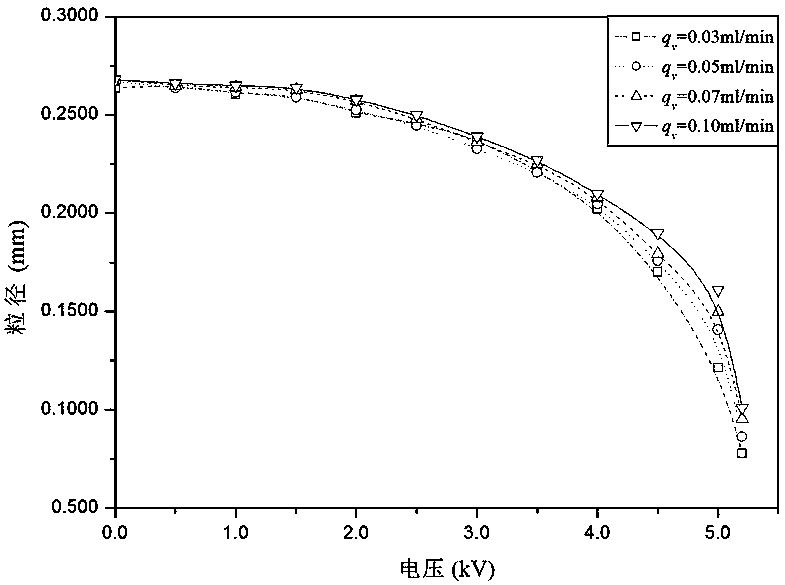

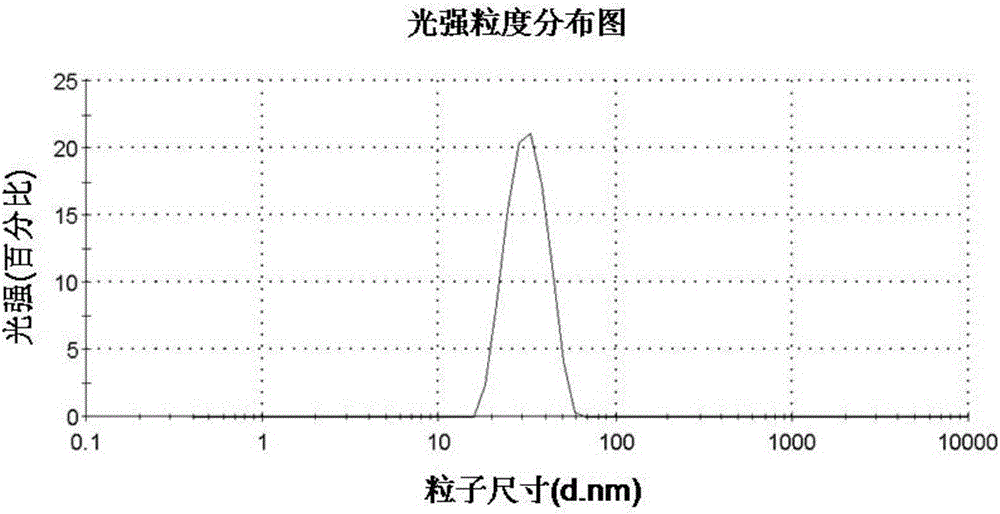

Generating method and device capable of adjusting particle size of atomized single liquid drops

InactiveCN108580074AChange the strength of the space electric fieldChange distanceElectrostatic spraying apparatusEngineeringHigh pressure

The invention discloses a generating method and device capable of adjusting particle size of atomized single liquid drops in the electrostatic atomization field. The device is characterized in that aliquid storage tank is connected to a metal capillary through a guide pipe and is in communication with the metal capillary, and a flow control valve and a flow meter are arranged on the guide pipe; adevice support comprises two square plates which are parallel to each other, and the metal capillary extends into an atomization area from the upper portion of the device support through a through hole in the upper square plate; a capillary support is tightly sleeved outside the upper section of the metal capillary, and the capillary support is connected to a high-voltage electrostatic generatorthrough a wire; and a lifting platform is arranged right below the metal capillary in the atomization area, a metal round copper plate is horizontally placed in the middle of the upper surface of thelifting platform, and the metal round copper plate is connected to the high-voltage electrostatic generator through the wire. According to the generating method and device capable of adjusting particle size of atomized single liquid drops, the action characteristic of the surface tension of the liquid is reduced through static electricity, the liquid drops are crushed into fine liquid drops, the particle size distribution of the atomized liquid drops is controlled through adjusting the voltage, the flow, the size of the polar distance and the specification of the metal capillary, and equal-particle-diameter atomized single liquid drops are generated.

Owner:JIANGSU UNIV

Method for preparing monodisperse large-particle-diameter silica sol through organic-inorganic complex catalysis

The invention relates to a method for preparing monodisperse large-particle-diameter silica sol through organic-inorganic complex catalysis. The method includes the following steps that 1, silica powder is added into an inorganic alkali solution, the mass ratio of the silica powder to water is controlled to be 1:8-15, and a reaction is conducted to obtain a silica sol mother solution with the pH of 9.5-10.5; 2, an organic alkali solution is added into the silica sol mother solution, a reaction is conducted at 70-90 DEG C to increase the particle diameter, and the system pH value in the reaction process is controlled to be 9.5-10.5; 3, after the reaction is finished, unreacted solid impurities in reaction liquid are removed, the product is concentrated to needed concentration, and then the monodisperse large-particle-diameter silica sol is obtained. According to the difference of the relative use quantities and proportions of two kinds of catalysts added in two steps and the difference of the particle diameters, activities and use quantities of the selected silica powder, the monodisperse large-particle-diameter silica sol with the mean particle diameter ranging from 20 nm to 100 nm or so is prepared.

Owner:SHANDONG YINFENG NANOMETER NEW MATERIAL CO LTD

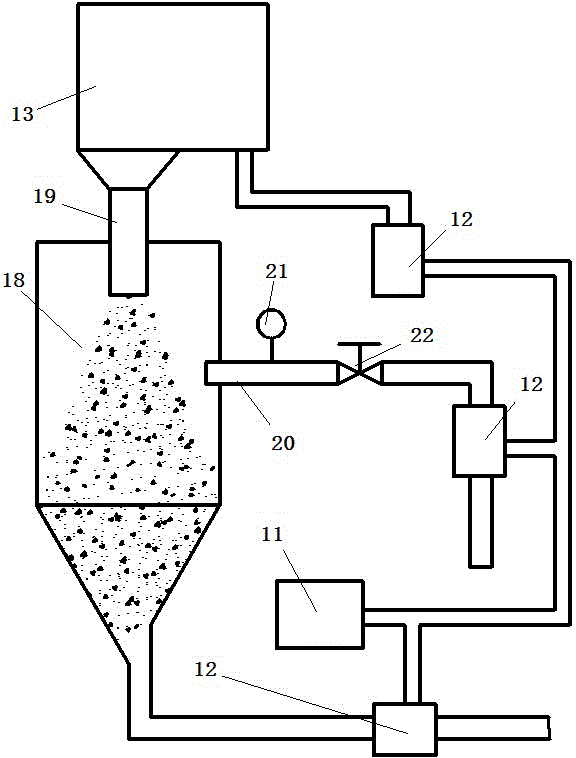

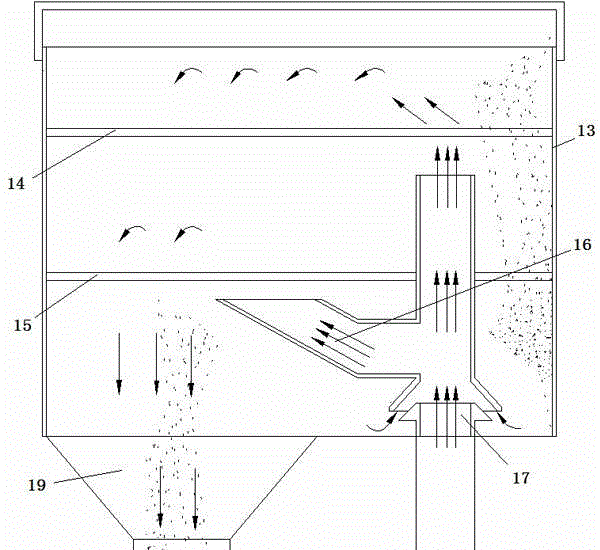

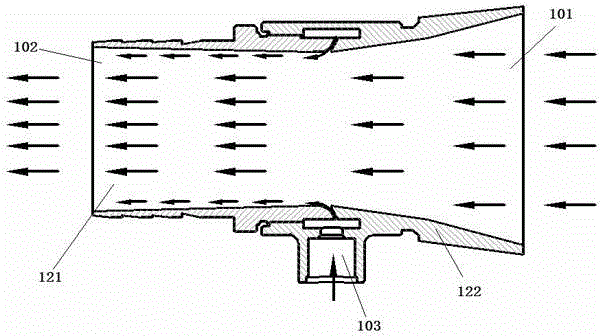

Standard particle generating device

ActiveCN104801491AImprove production efficiencyPrecise particle size controlGas current separationParticle suspension analysisMechanicsPoor quality

The invention relates to the field of calibrating dust concentration and powder particle size, in particular to a standard particle generating device. The standard particle generating device comprises a gas distribution mechanism, a boiling-type particle screening device and a bucket-type particle separating device, wherein the boiling-type particle screening device and the bucket-type particle separating device are sequentially and vertically arranged; the boiling-type particle screening device comprises a shell, at least one layer of screen mesh, and an air blowing mechanism; the screen mesh is arranged in the shell; the air blowing mechanism is connected with the shell, and is used for enabling particles on the screen mesh to be in a fluidized boiling state; the bucket-type particle separating device comprises a separating tank; a negative pressure suction-separation mechanism is connected between the upper end of the separating tank and the lower end of the separating tank; the air blowing mechanism and the negative pressure suction-separation mechanism are both connected with the gas distribution mechanism; the shell of the boiling-type particle screening device is connected with the separating tank through an outlet which is formed in the lower part of the boiling-type particle screening device. According to the standard particle generating device, the problems of low efficiency and poor quality of existing standard particle fabrication are solved.

Owner:GL TECH CO LTD

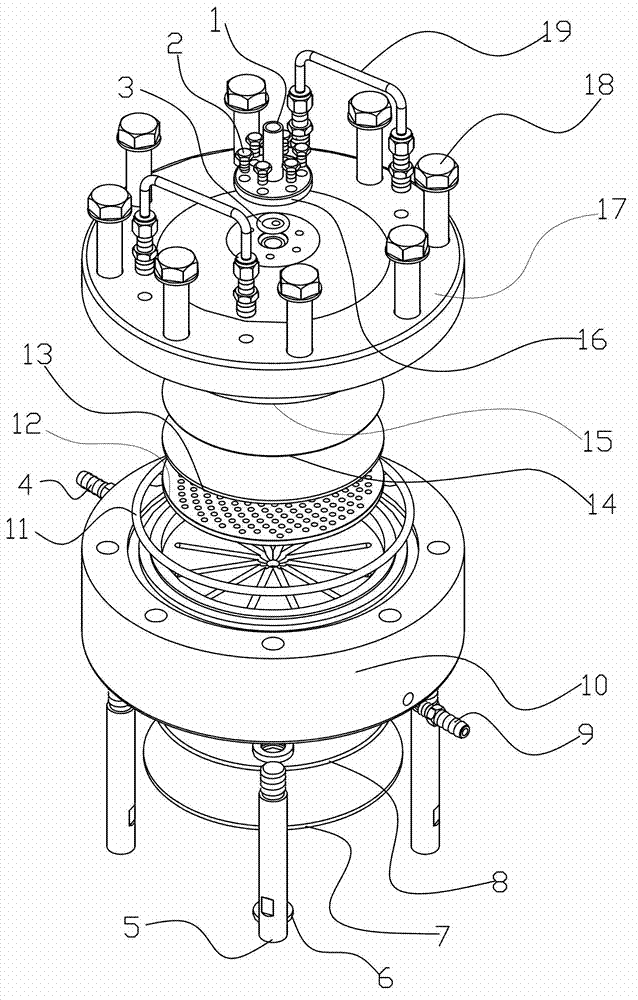

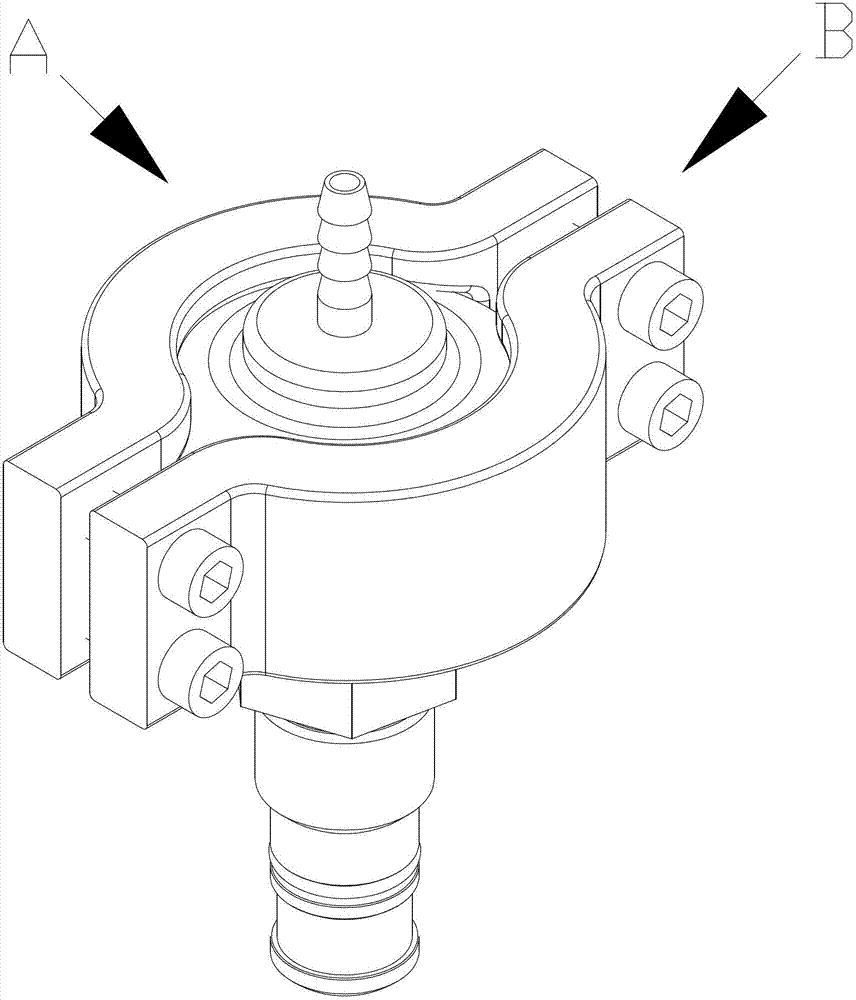

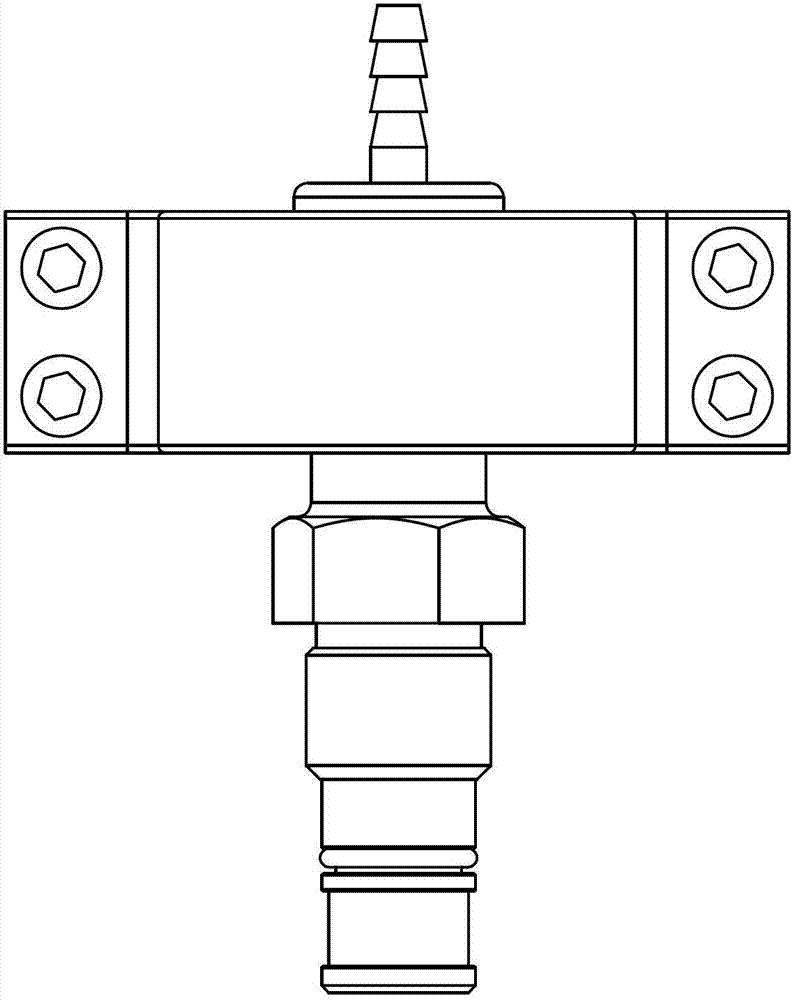

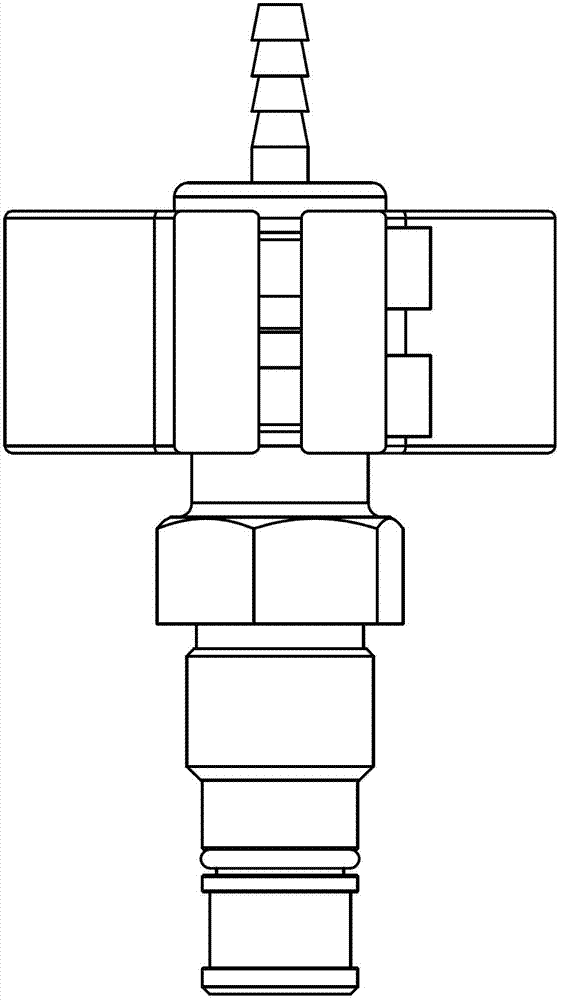

High-pressure extruding and filtering system for preparing liposome

ActiveCN103192516AEfficient exclusionTemperature controlPharmaceutical product form changeWater dischargeFilter system

The invention discloses a high-pressure extruding and filtering system for preparing liposome. The high-pressure extruding and filtering system disclosed by the invention comprises a high-pressure homogenizer and one or a plurality of high-pressure extruders in parallel arrangement, wherein the high-pressure extruder comprises a feeding pipe, a flange fixing bolt, a feeding flange inner sealing gasket, a constant-temperature water discharging opening, a discharging pipe, a constant-temperature tank base plate, a base plate outer sealing gasket, a constant-temperature water feeding opening, a base, an extrusion outer sealing gasket, a supporting plate, a filtering plate, a filtering film, an extrusion inner sealing gasket, a feeding flange, an upper cover and a locking bolt; the feeding pipe is arranged at the upper part of the high-pressure extruder and connected to the discharging opening of the high-pressure homogenizer; and a valve is arranged at the opening of the feeding pipe. The high-pressure extruding and filtering system disclosed by the invention is connected with one or plurality of high-pressure extruders and the high-pressure extruders are freely switched via the valve, so that the liposome is prevented from being inflected by bacterium in the process of replacing the filtering film, the extrusion efficiency is improved, the liposome with large particle diameter is effectively reduced, the precise control of the particle diameter can be realized and the requirement of preparation of liposome medicament can be satisfied.

Owner:安拓思纳米技术(苏州)有限公司

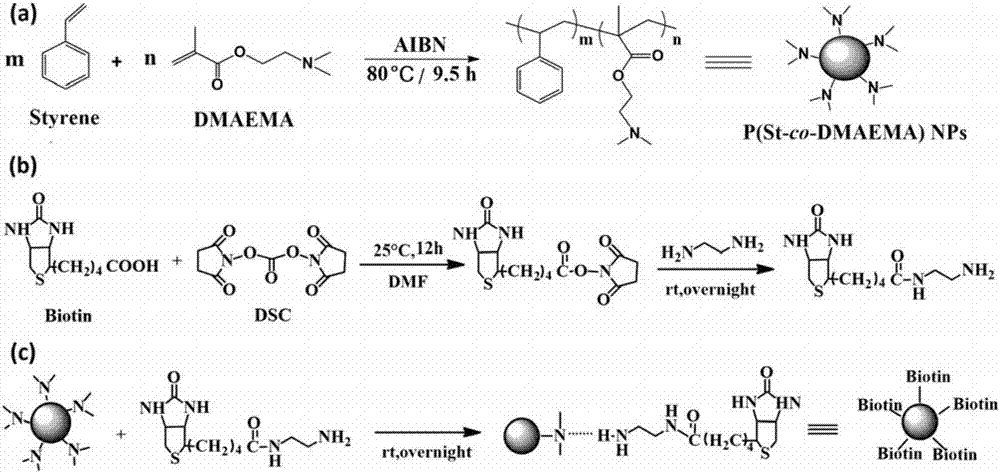

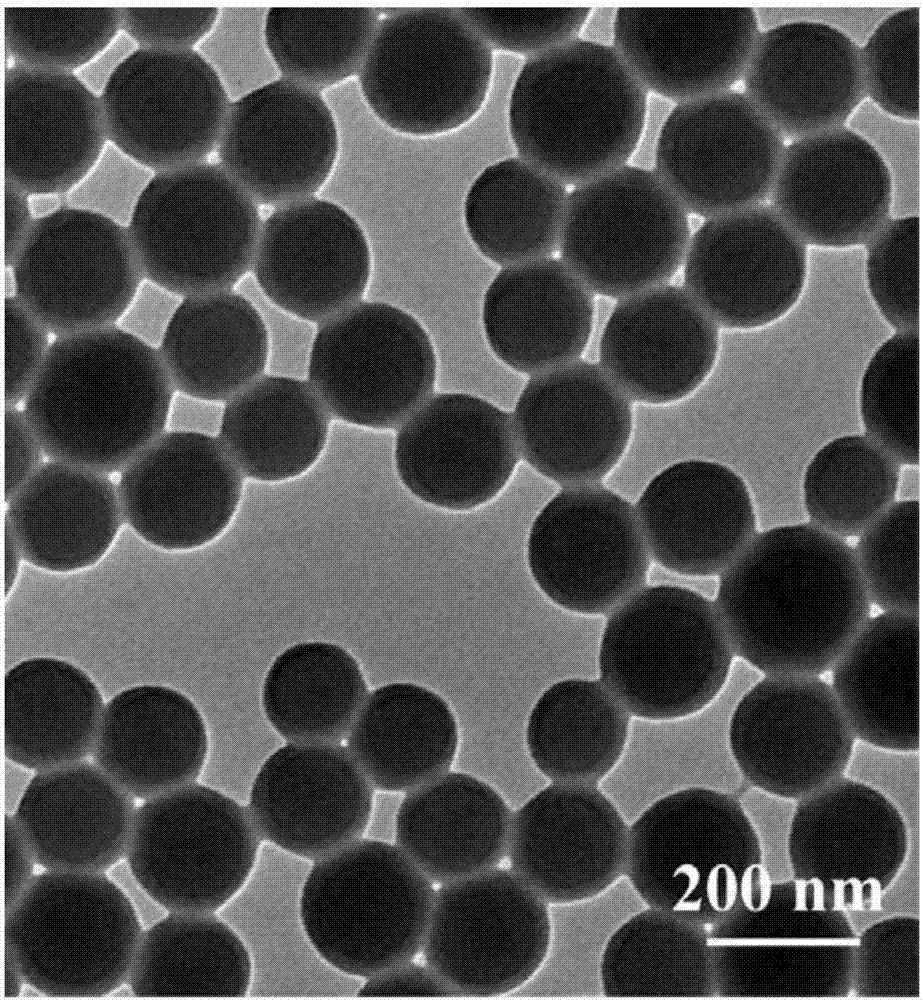

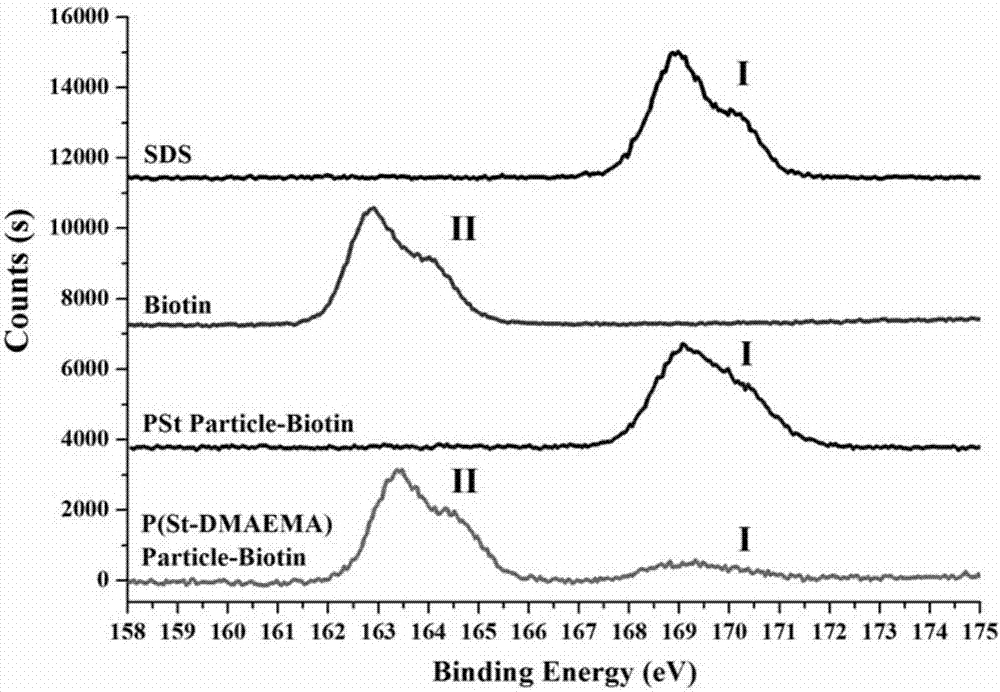

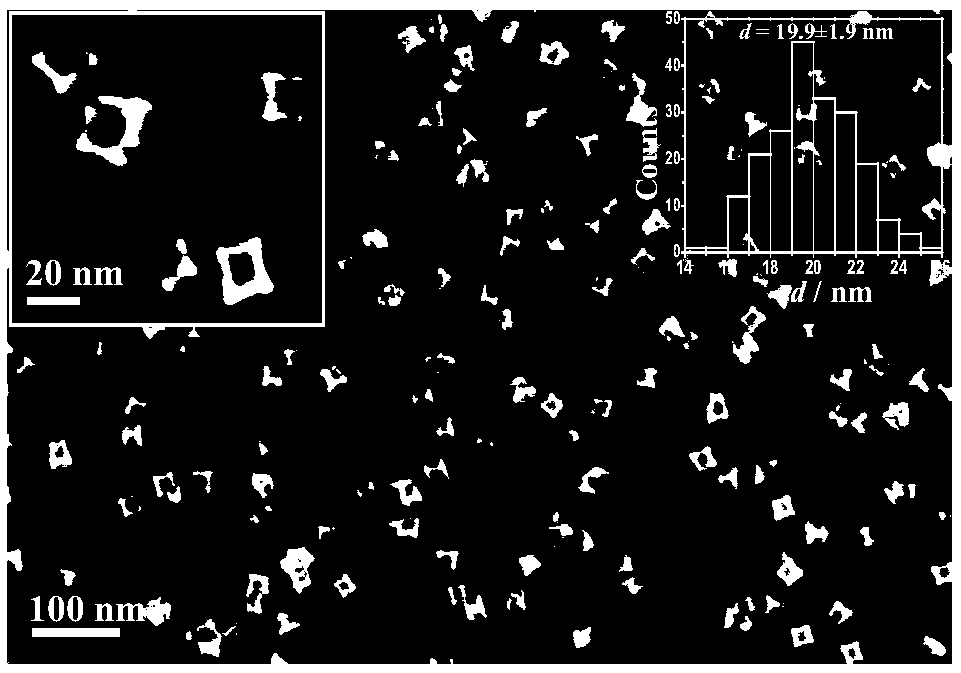

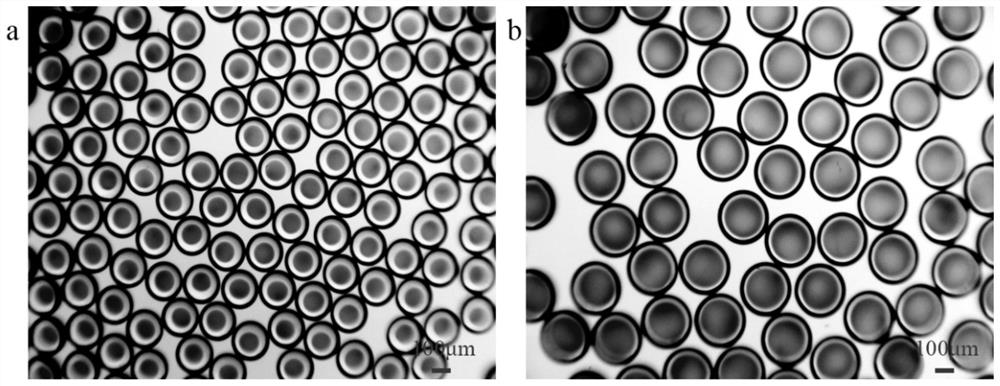

Polymer nanosphere with function of target recognition of cancer cells and preparation method of polymer nanosphere

ActiveCN106924756APrecise particle size controlUniform particle size distributionPharmaceutical non-active ingredientsAntineoplastic agentsCancer cellHydrogen

The invention discloses a polymer nanosphere with a function of target recognition of cancer cells and a preparation method of the polymer nanosphere. The polymer nanosphere comprises polymer nanospheres with surfaces containing amino groups and aminated cancer cell target-mediated molecules, wherein the aminated cancer cell target-mediated molecules are fixedly arranged on the surfaces of the polymer nanospheres containing the amino groups through hydrogen bonds formed by the amino groups in the aminated cancer cell target-mediated molecules and the amino groups in the polymer nanospheres containing the amino groups. The polymer nanosphere prepared by virtue of the preparation method can be used as a drug carrier for coating anti-cancer drugs, and the nanosphere carriers have no cytotoxicity; and the aminated cancer cell target-mediated molecules are fixedly arranged on the surfaces of the nanospheres through the hydrogen bonds, and after the nanospheres are sent into a body in an intravenous injection or oral manner, the nanosphere carriers can be aggregated in a targeted manner adjacent to cancer cells so as to release drugs, so that the drug concentrations of local regions of the cancer cells are increased, and the targeted killing of the cancer cells is realized.

Owner:TSINGHUA UNIV

Passivating metal magnesium particles and passivating method thereof

ActiveCN103695884AEvenly wrappedPrecise active magnesium contentLiquid surface applicatorsMetallic material coating processesGraphiteOrganosilicon

The invention discloses passivating metal magnesium particles and a passivating method thereof. The passivating metal magnesium particles comprise the following components in percentage by weight: less than or equal to 99% and greater than or equal to 92% of Mg, less than or equal to 0.002% of S, less than or equal to 0.01% of Cu, less than or equal to 0.001% of P and less than or equal to 1.2% and greater than or equal to 0.1% of H2O. The passivating method comprises the following steps: (I), preparing a metal magnesium particle passivator, placing metal magnesium particles in the passivator, and then naturally cooling to room temperature; (II), coating a coating on the surface of the magnesium particles: firstly, coating an organic silicon compound on the surface of the metal magnesium particles, coating magnesium oxide on the surface of the metal magnesium particles, then, coating compound rare earth on the on the surface of the metal magnesium particles, and finally coating graphite powder on the surface of the metal magnesium particles; and (III), sieving the metal magnesium particles cooled to room temperature. The metal magnesium particle passivating layer is uniform in coating, and the storage and use safety is ensured.

Owner:JIANGSU ZHENGDA FURNACE CHARGE

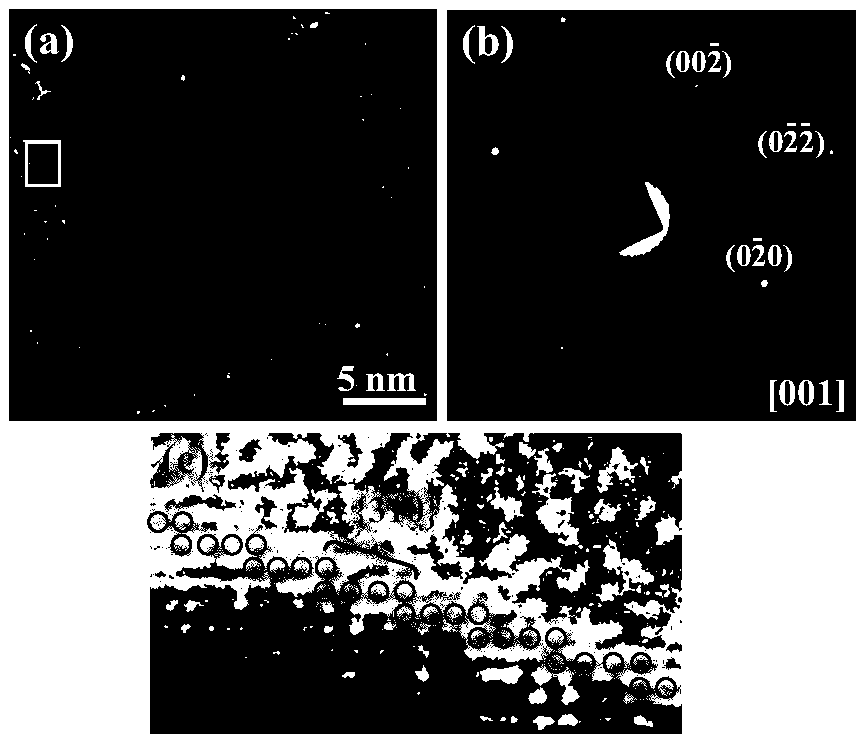

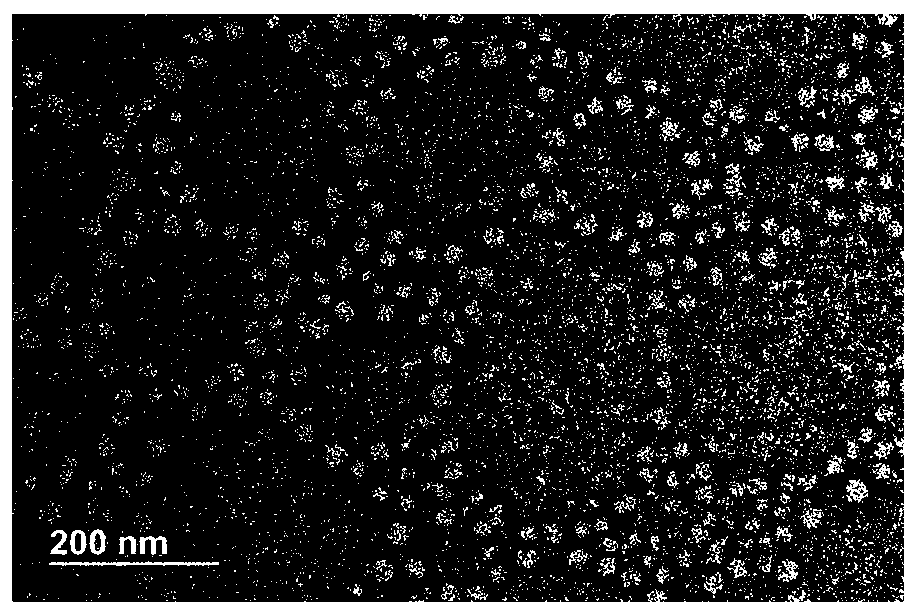

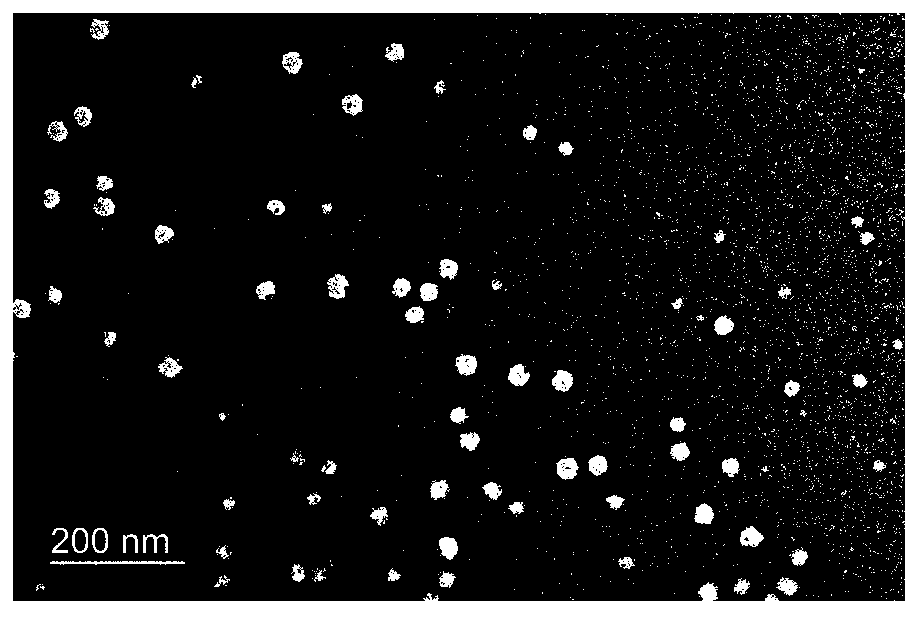

A method for preparing concave cubic platinum-rare earth alloy nanocrystals based on a eutectic solvent

InactiveCN108767267APrecise particle size controlEnhance poisoning abilityMaterial nanotechnologyCell electrodesRare earthAlloy

A method for preparing concave cubic platinum-rare earth alloy nanocrystals based on a eutectic solvent is disclosed, and belongs to the technical field of fuel cell catalyst preparation. The eutecticsolvent which is novel, green and non-aqueous is adopted as a medium to prepare the concave cubic platinum-rare earth alloy nanocrystals with a surface of a {hk0} high-index crystal face structure byelectrochemical cyclic voltammetry without the need of any surfactant. The high-index crystal face has an open type surface structure so that a high number of active sites can be provided and catalyst performance can be significantly improved through a double-function mechanism of an alloyed surface electron structure, and therefore, the nanocrystals have excellent electrocatalytic performance for fuel molecules such as formic acid, methanol and ethanol, and have broad application prospects in the field of fuel cells, the field of electrosynthesis, and the like.

Owner:XUZHOU NORMAL UNIVERSITY

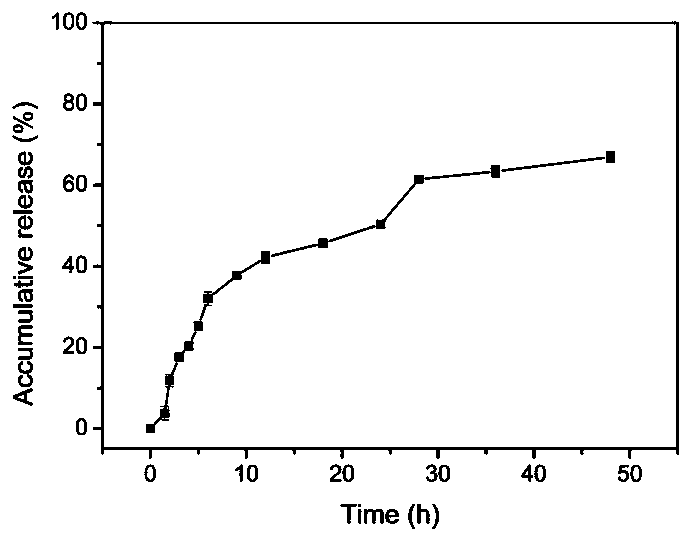

Method for preparing novel polyethylene glycol-poly gamma butyrolactone di-block copolymer nano drug carrying microsphere

InactiveCN110478332AGood biocompatibilityPrecise particle size controlOrganic active ingredientsPharmaceutical non-active ingredientsCarrying capacityMicrosphere

The invention discloses a method for preparing a novel polyethylene glycol-poly gamma butyrolactone (PEG-PBL) di-block copolymer nano drug carrying microsphere. The provided PEG-PBL copolymer copolymer nano drug carrying microsphere has a small particle size, is narrowly distributed, has a high drug carrying capacity, can be slowly released for a long time, and can reduce the drug delivery frequency. In addition, according to results of biological evaluation, it is proved that the polyethylene glycol-poly gamma butyrolactone di-block copolymer nano drug carrying microsphere has excellent biocompatibility and anticancer activity. The provided novel polyethylene glycol-poly gamma butyrolactone di-block copolymer nano drug carrying microsphere has a simple preparation method, is easily produced on a large scale, and has broad application prospects in the field of drug slow release.

Owner:QINGDAO UNIV OF SCI & TECH

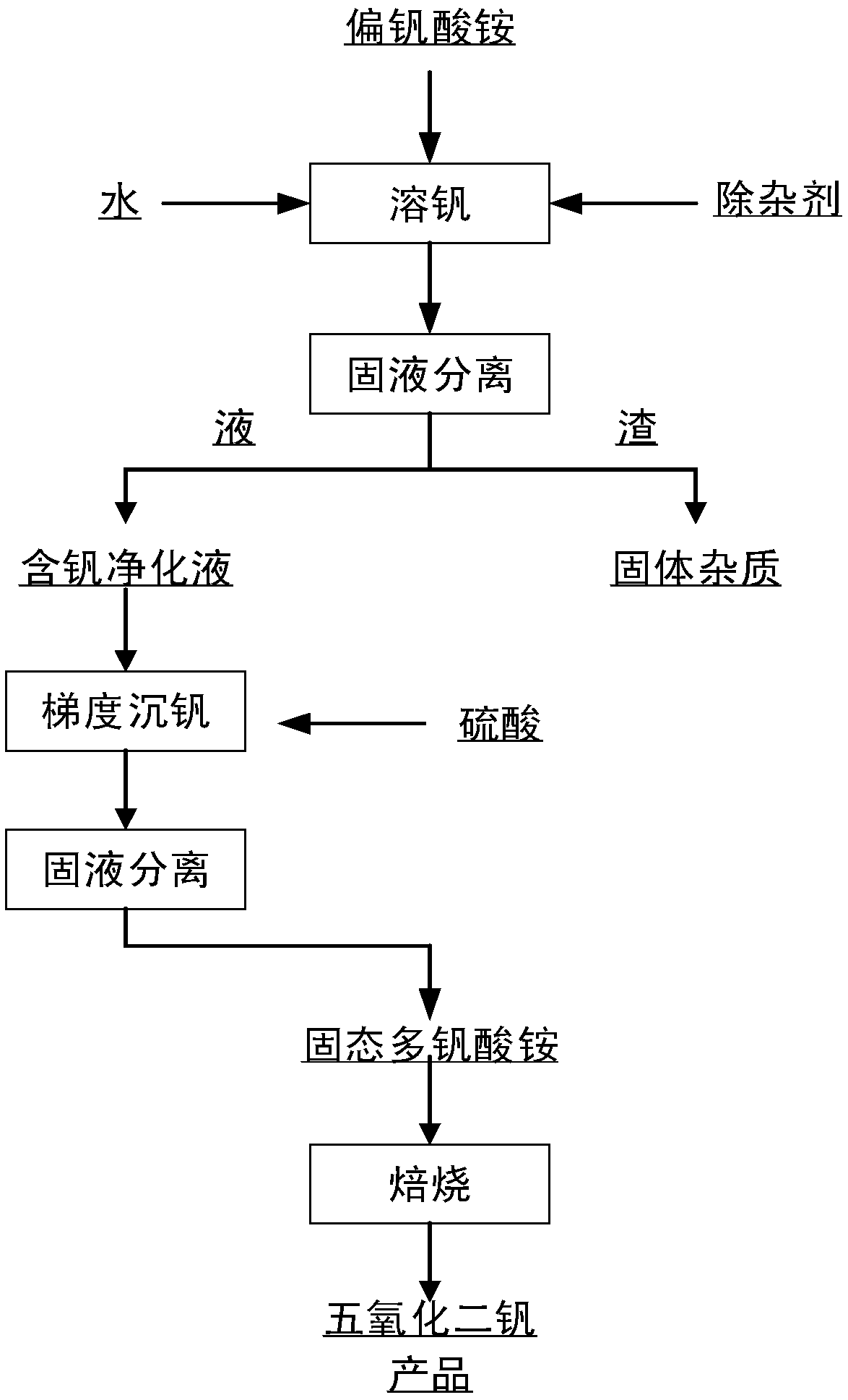

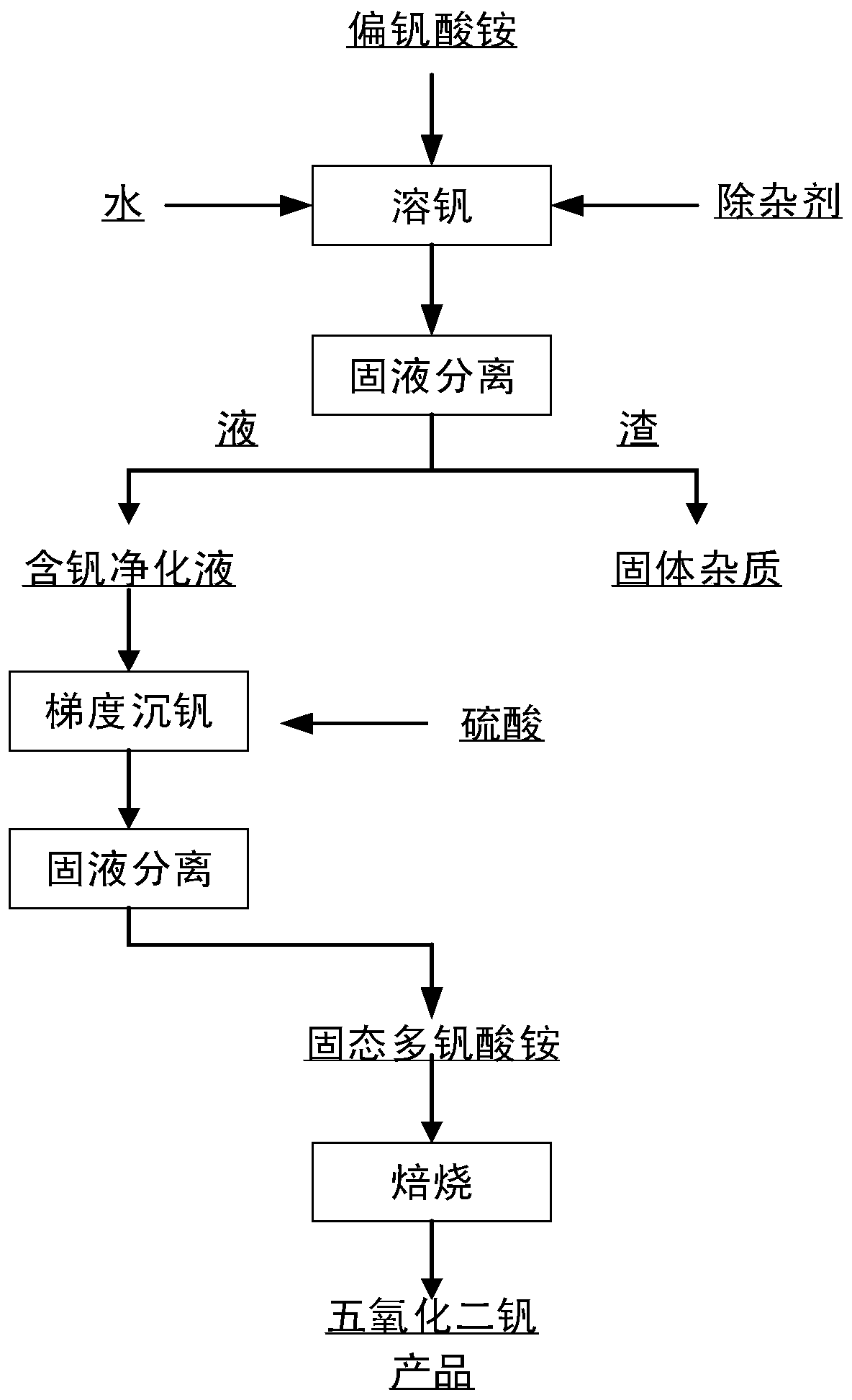

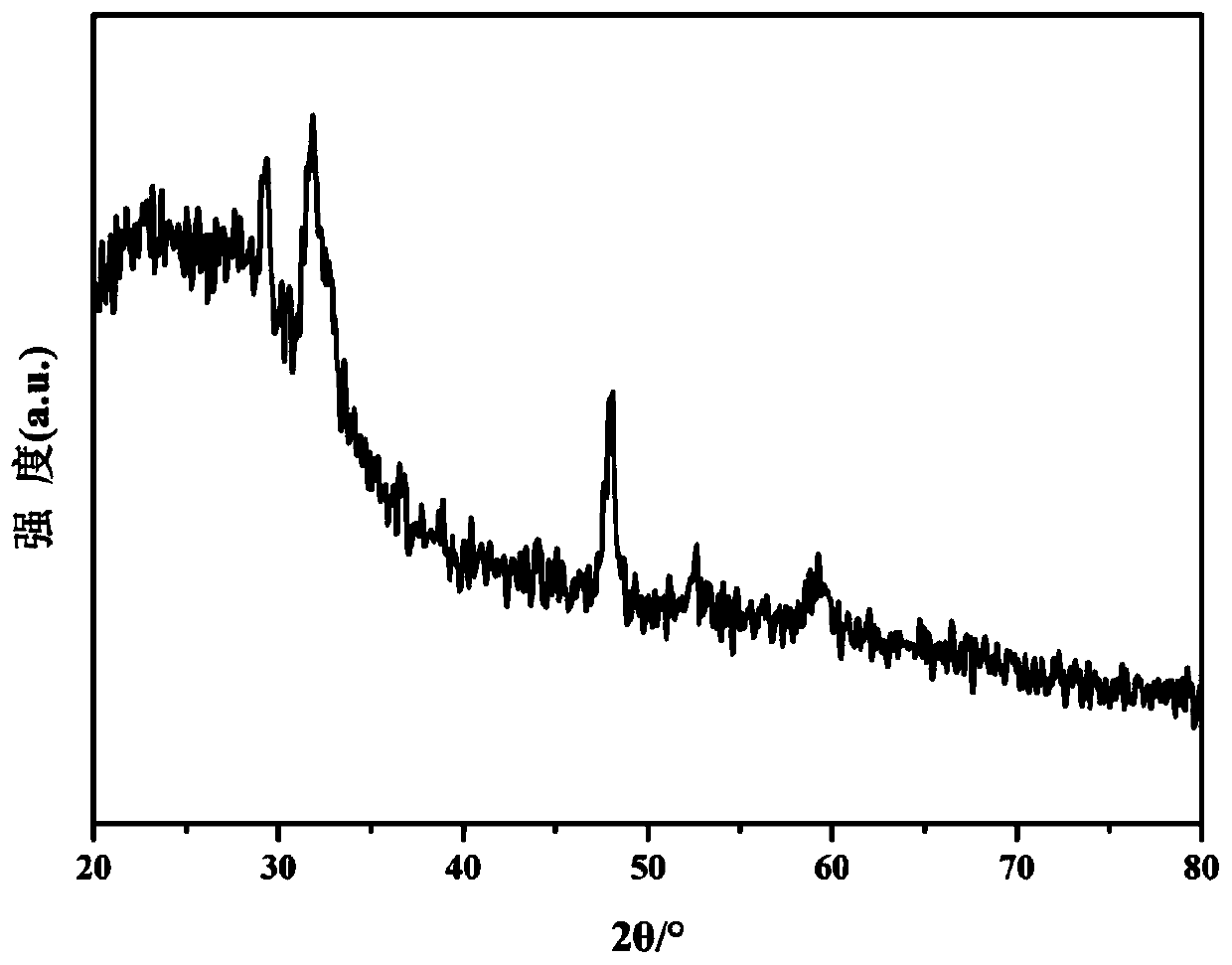

Method for preparing large-particle high-purity vanadium pentoxide

The invention relates to a method for preparing large-particle high-purity vanadium pentoxide. The method comprises the following steps: after dissolving ammonium metavanadate, adding an impurity removing agent; regulating the pH (Potential of Hydrogen) of a solution to 6.5 to 8.2 and carrying out vanadium dissolving; after the vanadium dissolving is finished, carrying out solid-liquid separationto obtain a vanadium-contained purification solution; heating the vanadium-contained purification solution; then regulating the pH to 6 to 5.8, 5.7 to 5.4, 4.8 to 4.0 and 2.4 to 1.9 in sequence at four phases and carrying out gradient vanadium deposition; after vanadium deposition is finished, carrying out the solid-liquid separation to obtain a vanadium deposition mother solution and solid-phaseammonium polyorthovanadate; carrying out calcination and deamination on the ammonium polyorthovanadate to obtain a vanadium pentoxide product with the purity of greater than or equal to 99.95 weight percent and the granularity of greater than or equal to 150mum. According to the method provided by the invention, a vanadium dissolving and gradient vanadium deposition method is adopted and impurityelements are greatly removed; meanwhile, the granularity of the vanadium pentoxide is accurately controlled, so that the content of particles with the size in a range of 180 to 230mum is greater thanor equal to 60 percent; the requirements of customers are met and the method has a good application prospect.

Owner:HEBEI IRON AND STEEL

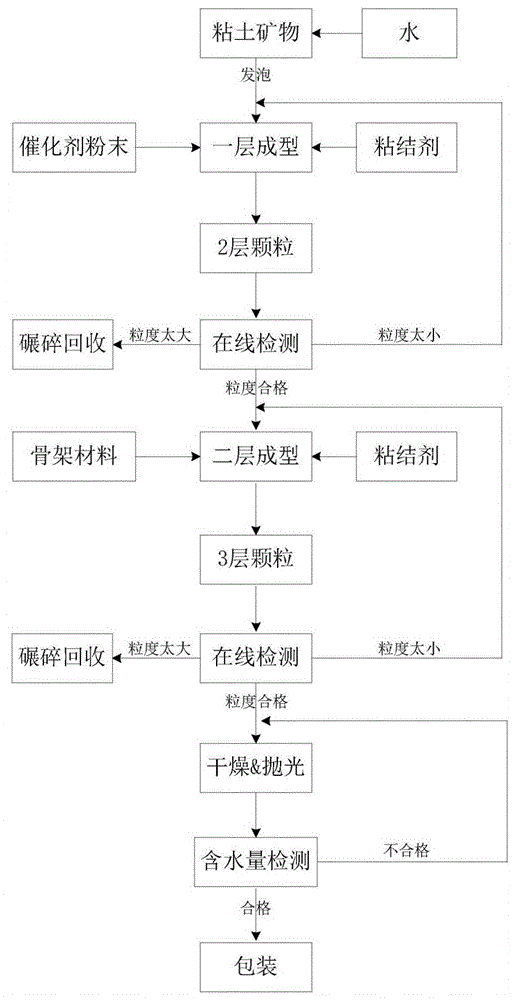

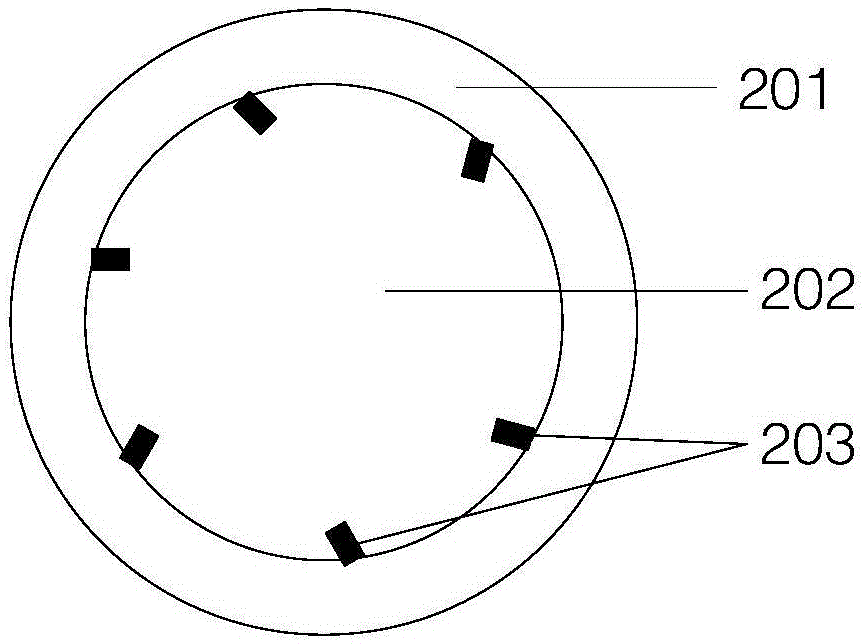

Catalyst particles for air purifiers and method for forming same by means of layer-by-layer cladding

ActiveCN105107490AImprove purification efficiencyLarge specific surface areaCatalyst protectionDispersed particle separationActivated carbonClay minerals

The invention provides catalyst particles for air purifiers and a method for forming the same by means of layer-by-layer cladding. The method includes acquiring core-shell structures by means of layer-by-layer cladding in particle forming procedures; manufacturing cores from selective clay mineral materials; cladding catalysts on the outsides of the cores; cladding safe and harmless inorganic porous materials such as activated carbon on the outermost layers of the cores by the aid of non-perishable inorganic adhesive in cladding procedures to obtain the spherical catalyst particles. The safe and harmless inorganic porous materials are used as framework materials. The spherical catalyst particles have uniform particle sizes, are high in catalytic activity and are non-perishable and non-mildew when stored at the room temperature for a long time The catalyst particles and the method have the advantages that the material adding speeds are automatically controlled, so that the uniformity of particle structures can be guaranteed; the spherical catalyst particles prepared by the aid of the method are high in catalytic efficiency, are non-perishable, have the uniform particle sizes and are safe and healthful.

Owner:UCHEER PURIFICATION & POLLUTION CONTROL TECH ZHEJIANG CO LTD

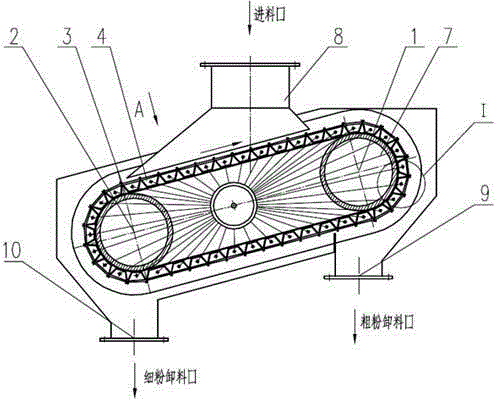

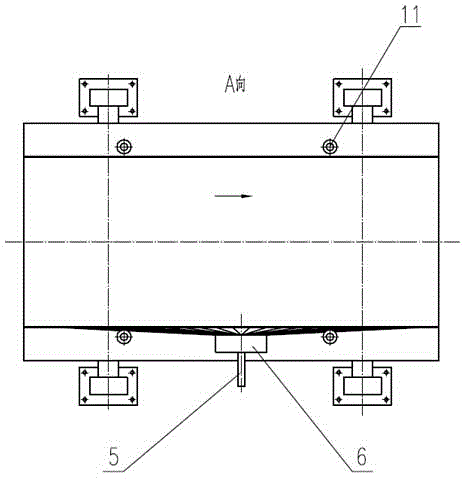

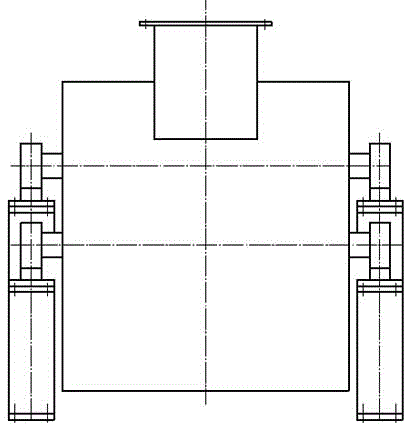

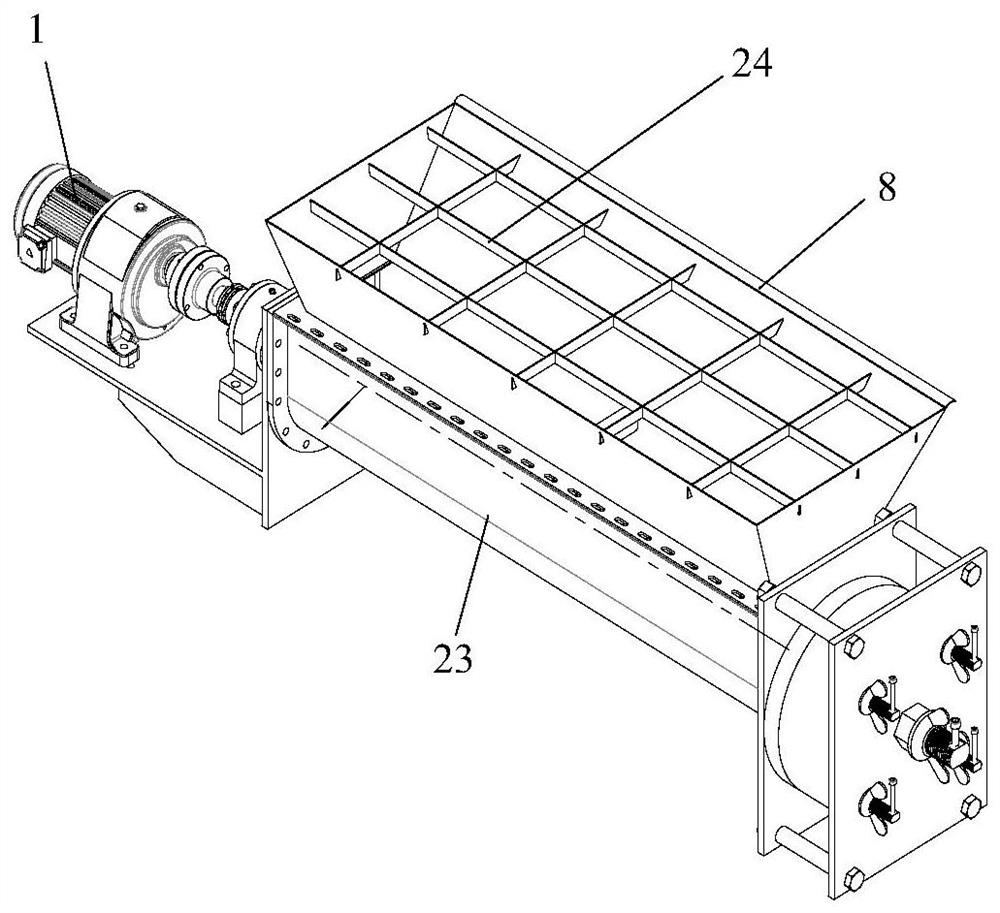

Chain plate type powder sorting machine

ActiveCN104353611ASorting accuracy dropsReduce energy consumptionGas current separationDrive wheelEngineering

The invention discloses a chain plate type powder sorting machine and belongs to the technical field of mine equipment. The chain plate type powder sorting machine comprises a driving wheel, a driven wheel and a transmission chain, wherein the transmission chain is assembled on the driving wheel and the driven wheel and is arranged in an inclined way; a plurality of sorting gas chambers are formed in the surface of the transmission chain and are connected with a gas distribution device through gas pipes; the gas distribution device is connected with a gas source; a feeding hole is formed above the working surface of the transmission chain ; a coarse powder discharging hole is formed below the low end of the inclination surface of the transmission chain; a fine powder discharging hole is formed below the high end of the inclination surface of the transmission chain. According to the chain plate type powder sorting machine, fine powder with any particle size can be sorted by adjusting the pressure of gas and the inclination angles of the sorting gas chambers, so that the stepless sorting of materials on the same machine is realized. Compared with a powder sorting machine, the chain plate type powder sorting machine has the advantages that not all materials need to be blown, and fine powder collecting equipment is not needed, so that the energy consumption is greatly reduced.

Owner:CHENGDU LEEJUN TECH CO LTD

A method for preparing large particle high-purity vanadium pentoxide

ActiveCN108975402BMeet purity requirementsAchieve high removalVanadium oxidesPhysical chemistryAmmonium metavanadate

The invention relates to a method for preparing large-particle high-purity vanadium pentoxide. The method comprises the following steps: after dissolving ammonium metavanadate, adding an impurity removing agent; regulating the pH (Potential of Hydrogen) of a solution to 6.5 to 8.2 and carrying out vanadium dissolving; after the vanadium dissolving is finished, carrying out solid-liquid separationto obtain a vanadium-contained purification solution; heating the vanadium-contained purification solution; then regulating the pH to 6 to 5.8, 5.7 to 5.4, 4.8 to 4.0 and 2.4 to 1.9 in sequence at four phases and carrying out gradient vanadium deposition; after vanadium deposition is finished, carrying out the solid-liquid separation to obtain a vanadium deposition mother solution and solid-phaseammonium polyorthovanadate; carrying out calcination and deamination on the ammonium polyorthovanadate to obtain a vanadium pentoxide product with the purity of greater than or equal to 99.95 weight percent and the granularity of greater than or equal to 150mum. According to the method provided by the invention, a vanadium dissolving and gradient vanadium deposition method is adopted and impurityelements are greatly removed; meanwhile, the granularity of the vanadium pentoxide is accurately controlled, so that the content of particles with the size in a range of 180 to 230mum is greater thanor equal to 60 percent; the requirements of customers are met and the method has a good application prospect.

Owner:HEBEI IRON AND STEEL

Flower-like CuS submicron spheres and ionic liquid microemulsion thermal synthesis method thereof

ActiveCN110550650ARegular shapeHigh crystallinityWater/sewage treatment by irradiationWater treatment compoundsIonPhotocatalysis

The invention discloses flower-like CuS submicron spheres and an ionic liquid microemulsion thermal synthesis method thereof. The synthesis method mainly comprises the following steps: (1) adding a sulfur source into an ionic liquid, and heating, stirring and dissolving to obtain a mixture A; (2) uniformly mixing and stirring bivalent copper salt, a surfactant, a cosurfactant and vegetable oil toobtain a mixture B; (3) uniformly mixing and stirring the mixture A and the mixture B to obtain a microemulsion C; (4) transferring the microemulsion C into a hydrothermal reaction kettle with a polytetrafluoroethylene lining, sealing, placing at the temperature of 60-160 DEG C, carrying out a reaction for 2-24 h, and naturally cooling at room temperature to obtain a black solution; and (5) separating, washing and drying the black solution to obtain the final product black powder. The CuS particles prepared through ionic liquid microemulsion assisted thermal synthesis are of a flower-like submicron sphere structure, and are large in specific surface area, regular in morphology, uniform in size, high in crystallinity and high and stable in photocatalysis efficiency.

Owner:SOUTH CHINA UNIV OF TECH

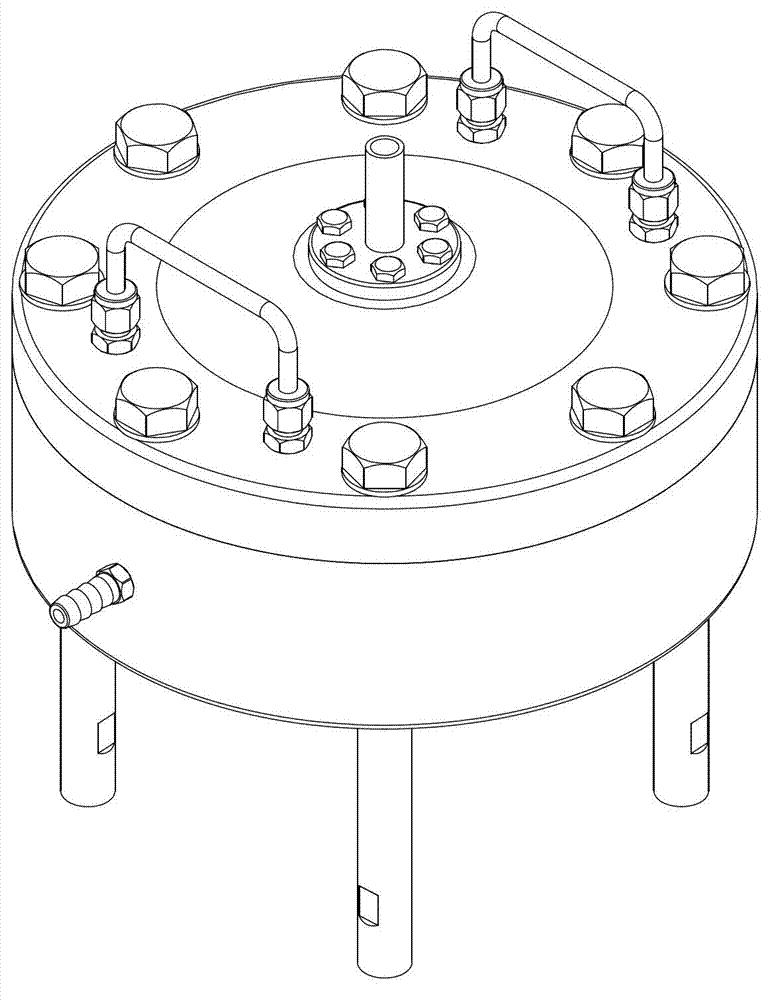

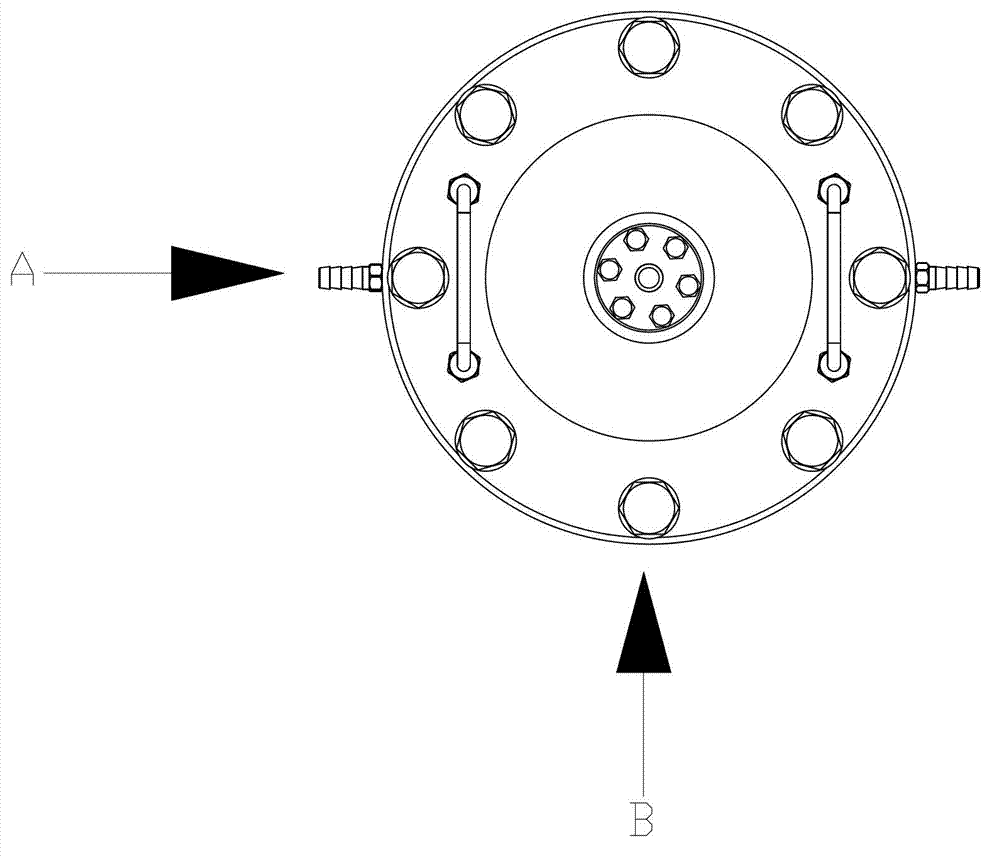

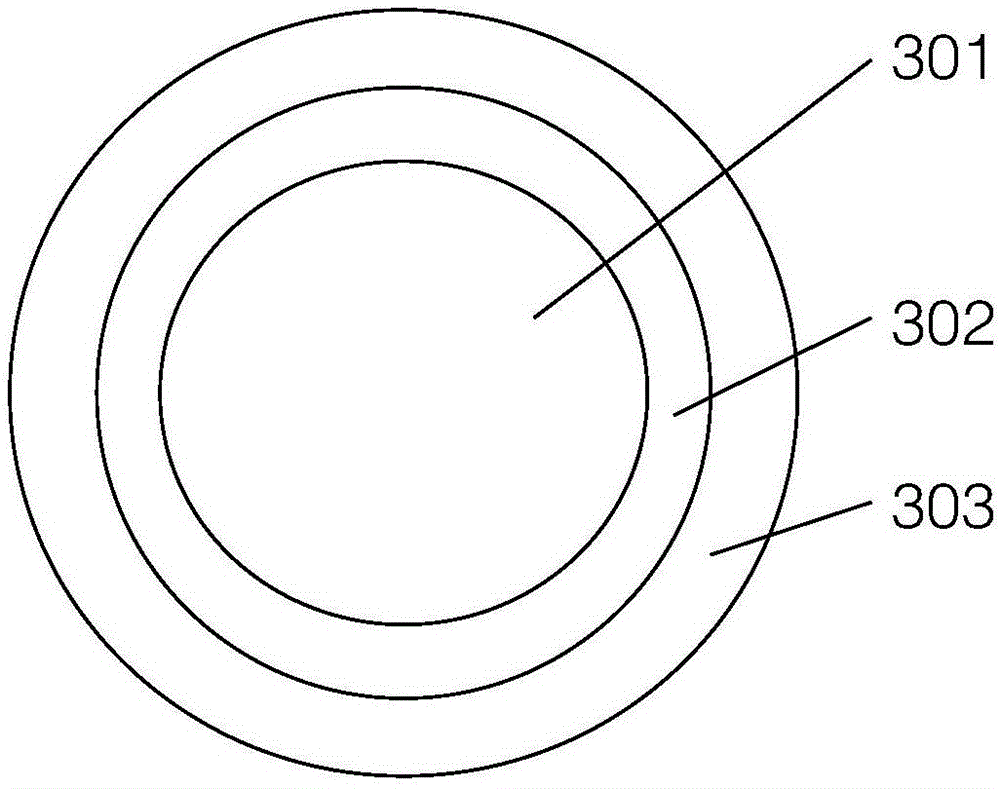

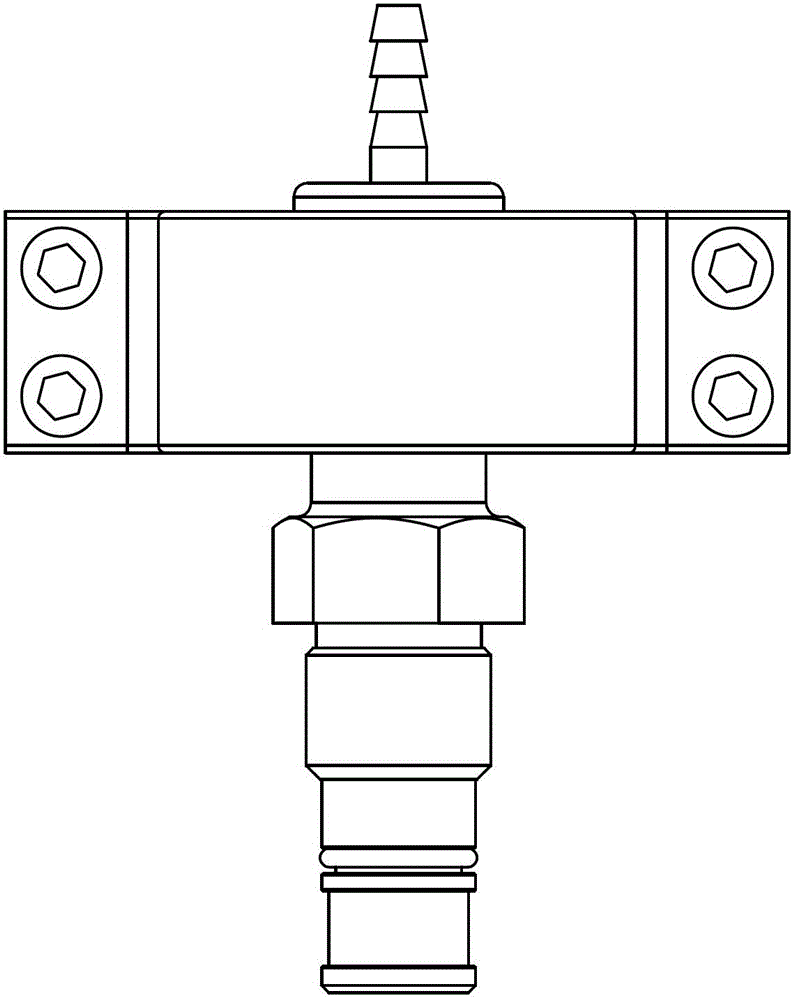

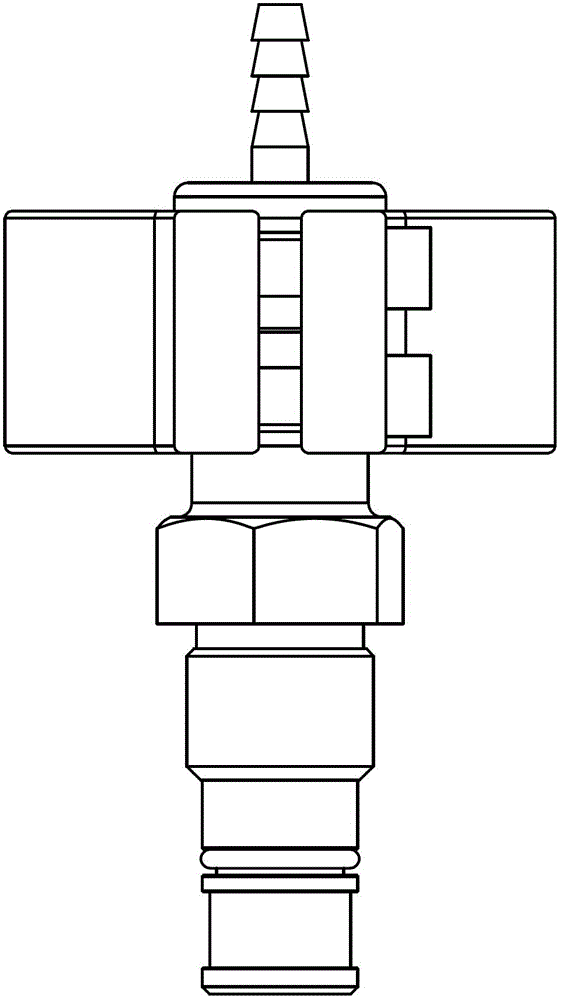

Lipidosome extruding and filtering device

ActiveCN103203127AEfficient exclusionRealize NanoizationSemi-permeable membranesStationary filtering element filtersEngineeringPartial discharge

The invention provides a lipidosome extruding and filtering device which comprises a material discharge pipe, an upper cover, an extruding outer seal gasket, a support plate, a filtering plate, a filtering membrane, an extruding inner seal gasket, a connector, a hoop and a hoop locking bolt; the center of the connector is provided with a material charge through hole; the center of the upper cover is provided a material discharge through hole of which the opening at the upper end is connected with the material discharge pipe; the bottom surface of the upper cover is provided with an annular seal groove and an internally sinking cylindrical groove; the support plate, the filtering plate, the filtering membrane and the extruding inner seal gasket are sequentially arranged in the cylindrical groove from inward to outward; the extruding outer seal gasket is arranged in the annular seal groove; the upper cover and the connector are fixed together through the hoop and the hoop locking bolt. According to the invention, nanocrystallized equipment and homogenized equipment are designed integrally; material particle size can be controlled accurately through replacing different filtering membranes; cross contamination is prevented; and the lipidosome extruding and filtering device is convenient to use, and can be widely applied to the nano medicament field.

Owner:安拓思纳米技术(苏州)有限公司

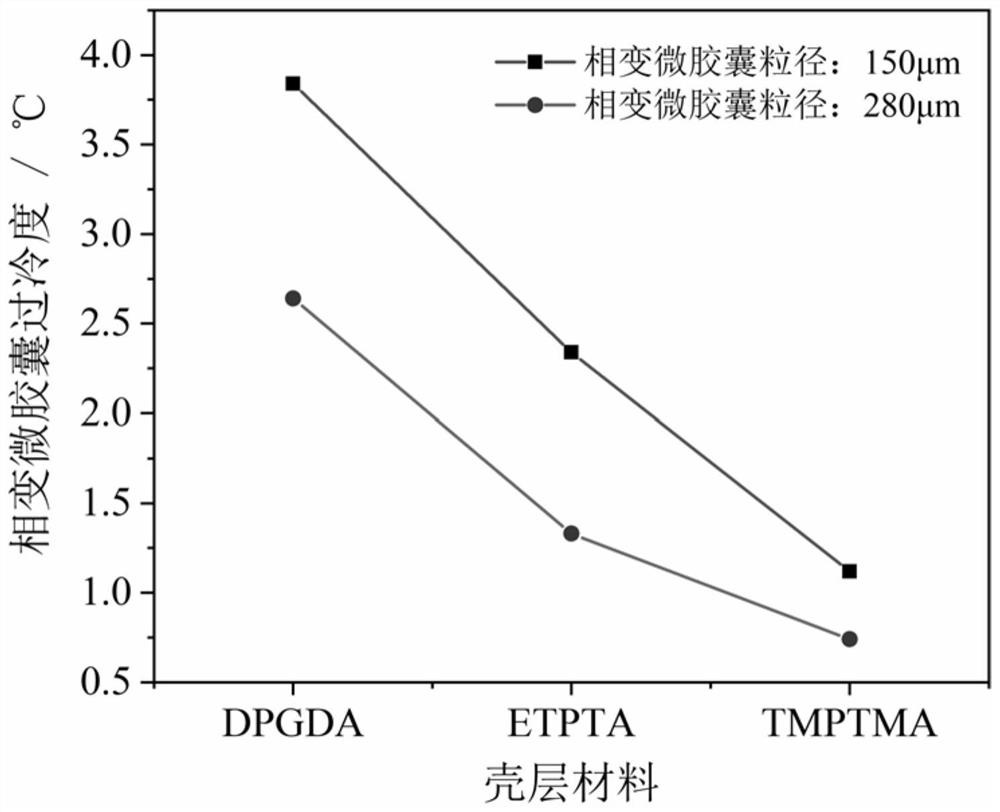

Method for reducing supercooling degree of alkane phase change microcapsule by using different shell materials, microcapsule prepared by method and application of microcapsule

ActiveCN113648943ASubcooling controlReduce subcoolingMicroballoon preparationMicrocapsule preparationAlkanePolymer science

The invention belongs to the technical field of functional material preparation, and discloses a method for reducing the supercooling degree of an alkane phase change microcapsule by using different shell materials, the microcapsule prepared by the method and application of the microcapsule. The method comprises the following steps: preparing an intermediate phase, a continuous phase and a collection phase, respectively feeding a dispersed phase, the intermediate phase and the continuous phase into a micro-fluidic chip through an injection pump, and respectively introducing the dispersed phase, the intermediate phase and the continuous phase into the micro-fluidic chip from a small sharp-nose glass capillary tube, a first closed liquid storage tank and a second closed liquid storage tank; enabling the dispersed phase to flow out of the small sharp-nose glass capillary tube, to be wrapped by the intermediate phase and then flow into the small sharp-nose glass capillary tube under the flowing of the continuous phase, radiating an initiator in the intermediate phase by an ultraviolet lamp to initiate a polymerization reaction of a shell material, forming a thin film layer to wrap the phase change material, and obtaining the phase change microcapsule after drying. Precision control over particle size control and supercooling degree reduction of the phase change microcapsules is achieved, and the method is suitable for industrial production of the phase change microcapsules.

Owner:GUANGDONG UNIV OF TECH

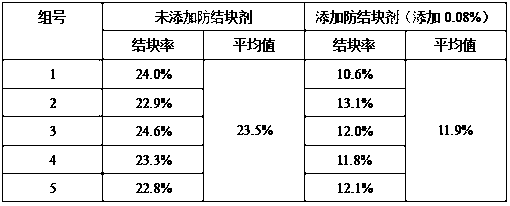

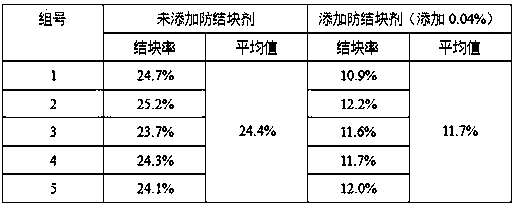

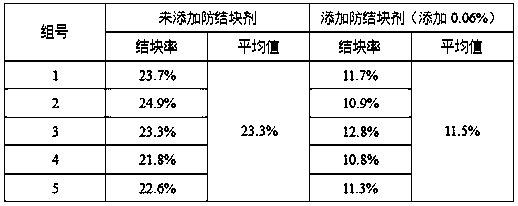

Special modified calcium carbonate for caking prevention of fertilizer and preparation method of modified calcium carbonate

InactiveCN108752088AHigh activityImprove adsorption capacityCalcareous fertilisersOrganic fertilisersParaffin waxDepolymerization

The invention discloses special modified calcium carbonate for caking prevention of fertilizer and a preparation method of modified calcium carbonate. For modified calcium carbonate, D99 is smaller than or equal to 13 mu m, D90 is smaller than or equal to 12 mu m, D75 is smaller than or equal to 10 mu m, and modified calcium carbonate is prepared from 55%-70% of calcium carbonate, 10%-15% of water-soluble natural polysaccharide, 20%-25% of liquid paraffin and 3-5% of a surfactant. The preparation method of modified calcium carbonate comprises the following steps: natural marble is crushed, ground and graded, and calcium carbonate is obtained; primary modified calcium carbonate is obtained by dry blending with liquid paraffin firstly; then primary modified calcium carbonate is subjected towet ball milling with water-soluble natural polysaccharide and the surfactant; finally, drying, depolymerization and packaging are performed, and special modified calcium carbonate for caking prevention of the fertilizer is obtained. Special modified calcium carbonate, prepared with the method, for caking prevention of the fertilizer has the characteristics of being low in cost, environmentally friendly and efficient, the lowest caking rate can reach 11.5% when adding amount is 0.06%, the caking prevention effect is remarkable, fertilizer quality is improved on the basis of the conventional fertilizer products, and modified calcium carbonate has broad market prospect.

Owner:贵州紫云月华新材料有限公司

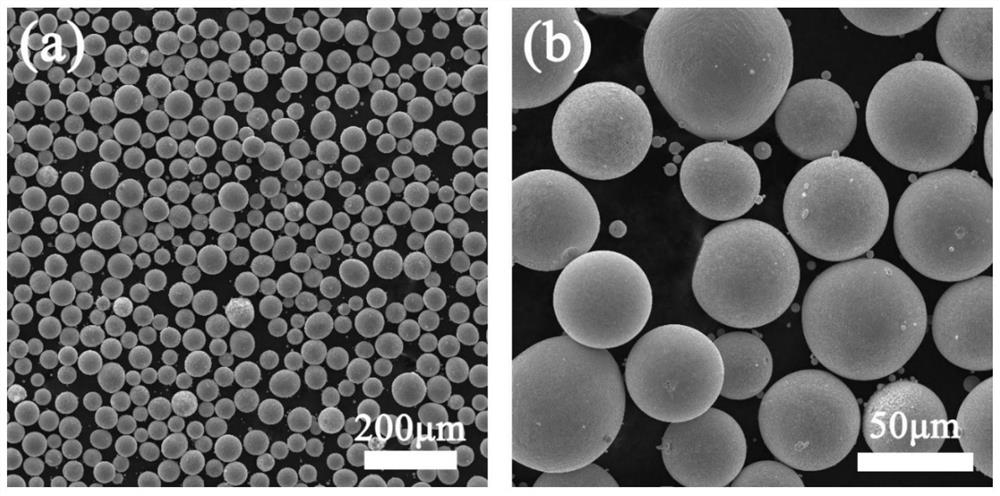

Preparation method of ceramic powder for plasma physical vapor deposition

The invention discloses a preparation method of ceramic powder for plasma physical vapor deposition, which comprises the following steps of in order to meet the porous requirement of a powder materialin a PS-PVD process, adding a pore-forming agent into ingredients, carrying out atomization granulation, and setting a burning step to remove the pore-forming agent in the powder material, and on thebasis of no influence on the strength of powder particles, realizing the requirement for the porosity of powder particles. Meanwhile, the mode that overflow classification and airflow classificationare combined is adopted, the granularity of the powder is accurately controlled, the technological requirement of PS-PVD is met, and finally the powder material which is small in particle size, porousin structure and good in fluidity is obtained. The preparation method has the advantages of being simple, easy to operate, suitable for application and popularization and the like.

Owner:LIAONING SILICATE RES INST

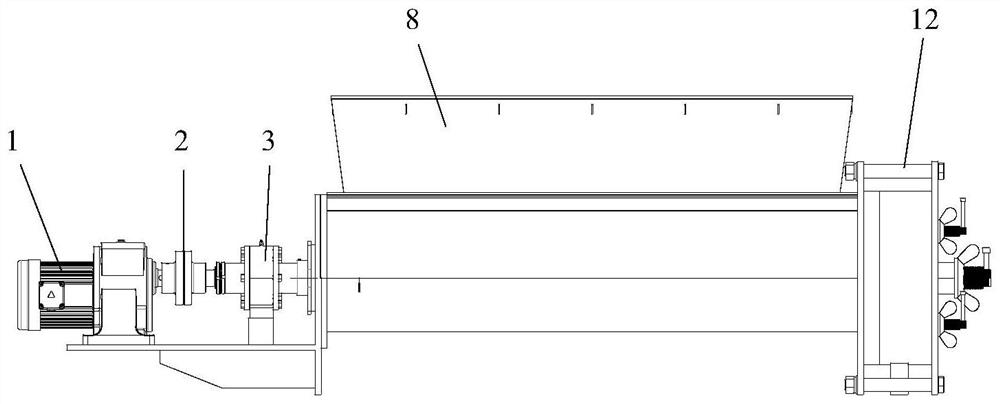

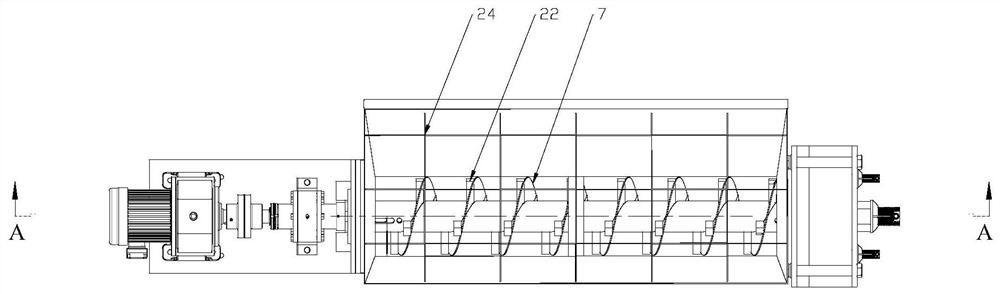

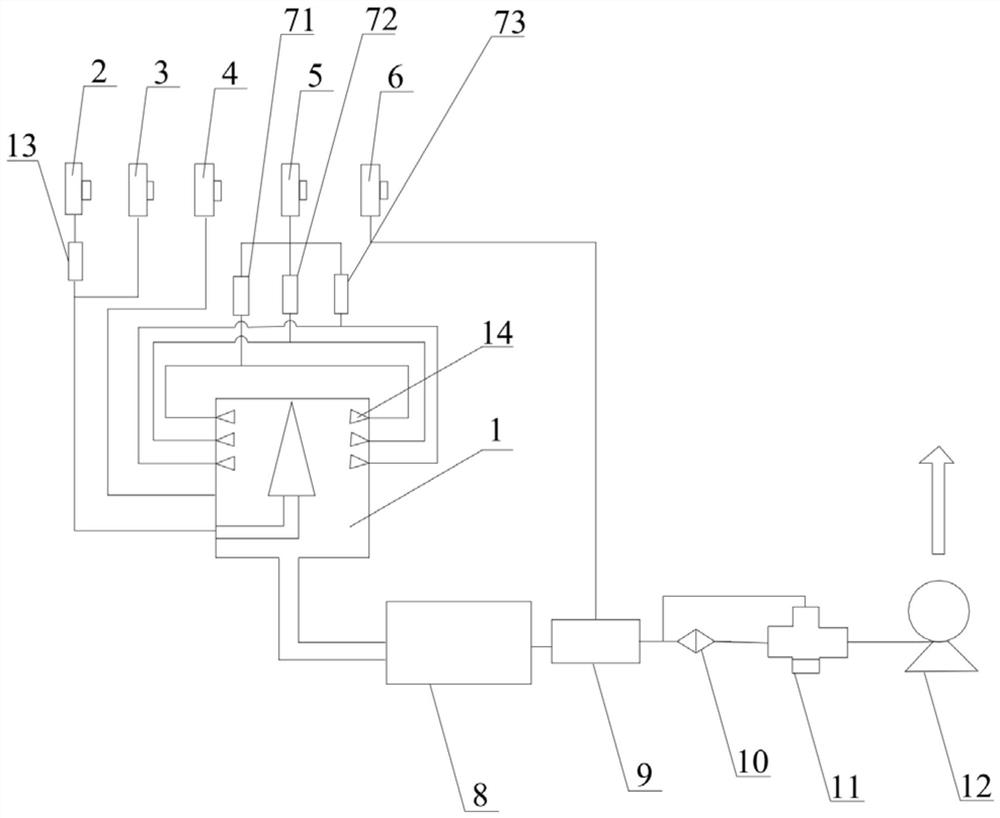

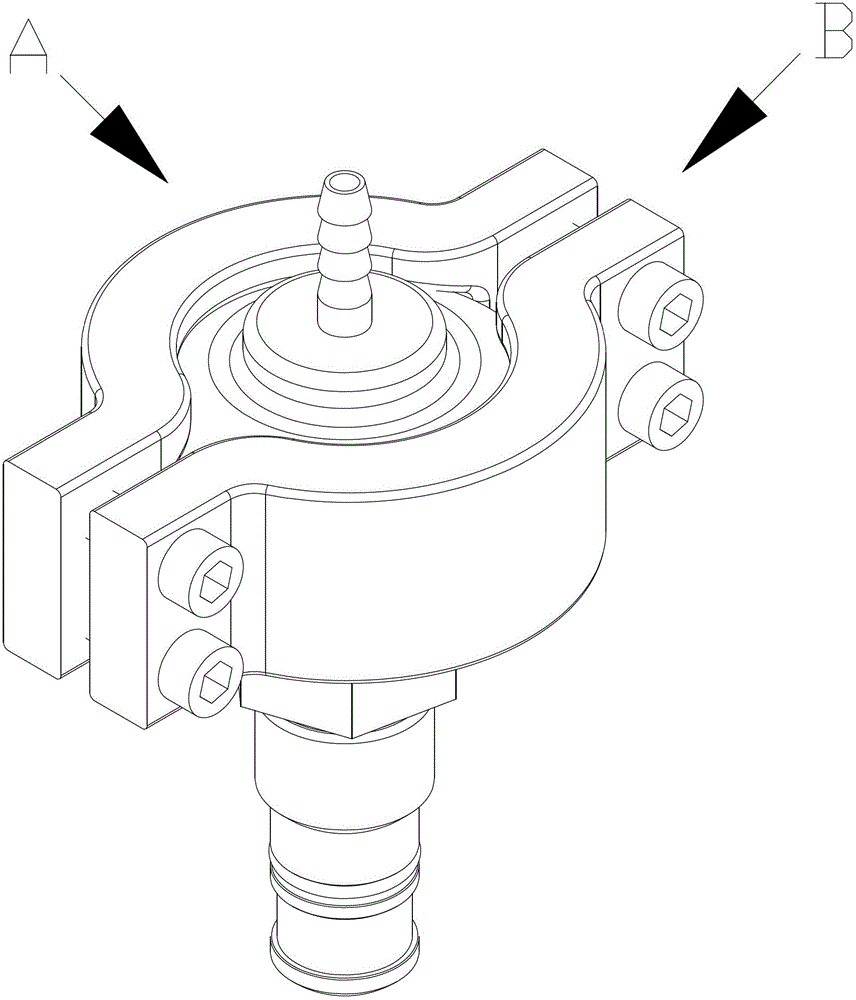

Adjustable solid material continuous feeding and discharging grinding method and device

InactiveCN112547206AImprove production efficiencyAvoid collisionCocoaGrain treatmentsMineral particlesCoal

The invention discloses an adjustable solid material continuous feeding and discharging grinding method and device. A feeding shaft is driven by a driving mechanism to rotate, a feeding strip on the feeding shaft coarsely crushes materials entering a shell, and then the coarsely crushed materials are fed into a grinding disc and an adjustable grinding disc through feeding holes; and the materialsare further crushed through relative rotation of the grinding disc and the adjustable grinding disc. The adjustable solid material continuous feeding and discharging grinding method and device provided by the invention are applied to the preparation process of coal or mineral particles and used for obtaining the coal or mineral particles with a certain particle size. Collision between metal objects is avoided in the preparation process of a coal sample, and the device is small in size, low in noise in the working period and high in sample preparation efficiency. By accurately adjusting the distance between grinding faces, collision between the grinding faces is avoided, and meanwhile the maximum particle size of ground material particles can be accurately controlled.

Owner:英飞智信(北京)科技有限公司

Production process of foamed ceramic thermal insulation board by recycling ceramic fiber paper

InactiveCN111039693AHigh mechanical strengthImprove performanceCeramicwareClaywaresFiberThermal insulation

The invention relates to the field of materials, particularly to a production process of a foamed ceramic thermal insulation board by recycling ceramic fiber paper. The process comprises: mixing and grinding, drying, firing, and cooling, wherein in the firing step, the temperature of a firing furnace on the inner wall of the firing furnace is kept by using ceramic fiber paper to obtain waste ceramic fiber paper, and in the step of mixing and grinding, the waste ceramic fiber paper is added into raw materials. According to the invention, thermal insulation is performed by using ceramic fiber paper in a firing process so as to reduce energy consumption, and the fired waste ceramic fiber paper is added into raw materials, so that waste is utilized, and the mechanical strength of the foamed ceramic thermal insulation board can be improved.

Owner:ZHENGZHOU DENGDIAN KECHENG NEW MATERIAL CO LTD

Particle generating device

ActiveCN112782058AParticle size is easy to controlPrecise particle size controlIndividual particle analysisDiffusion flameCombustion chamber

The invention discloses a particle generating device, and relates to the technical field of detection of particle counters and smoke meters. The particle generating device comprises a combustion chamber, a plurality of nozzles and a pump body, fuel and a first diluent in a fixed proportion are introduced into the combustion chamber and then are ignited, and a combustion improver is used for supporting combustion so as to form diffusion flames with a fixed height. The plurality of nozzles are arranged on the side wall of the combustion chamber at intervals in the height direction of diffusion flames, the nozzles are all connected with an inert gas source, and switch valves are arranged between the nozzles located at different heights and the inert gas source; and particles generated in the combustion chamber are discharged through a pump body. The particle generating device provided by the invention can generate particles with higher efficiency, the particle size of the particles is convenient to control, the particle size of the particles is accurately controlled, the working efficiency is improved, and the fuel loss is reduced.

Owner:WEICHAI POWER CO LTD

Liposome Extrusion Filtration Device

ActiveCN103203127BEfficient exclusionRealize NanoizationSemi-permeable membranesStationary filtering element filtersEngineeringNanometre

The invention provides a lipidosome extruding and filtering device which comprises a material discharge pipe, an upper cover, an extruding outer seal gasket, a support plate, a filtering plate, a filtering membrane, an extruding inner seal gasket, a connector, a hoop and a hoop locking bolt; the center of the connector is provided with a material charge through hole; the center of the upper cover is provided a material discharge through hole of which the opening at the upper end is connected with the material discharge pipe; the bottom surface of the upper cover is provided with an annular seal groove and an internally sinking cylindrical groove; the support plate, the filtering plate, the filtering membrane and the extruding inner seal gasket are sequentially arranged in the cylindrical groove from inward to outward; the extruding outer seal gasket is arranged in the annular seal groove; the upper cover and the connector are fixed together through the hoop and the hoop locking bolt. According to the invention, nanocrystallized equipment and homogenized equipment are designed integrally; material particle size can be controlled accurately through replacing different filtering membranes; cross contamination is prevented; and the lipidosome extruding and filtering device is convenient to use, and can be widely applied to the nano medicament field.

Owner:安拓思纳米技术(苏州)有限公司

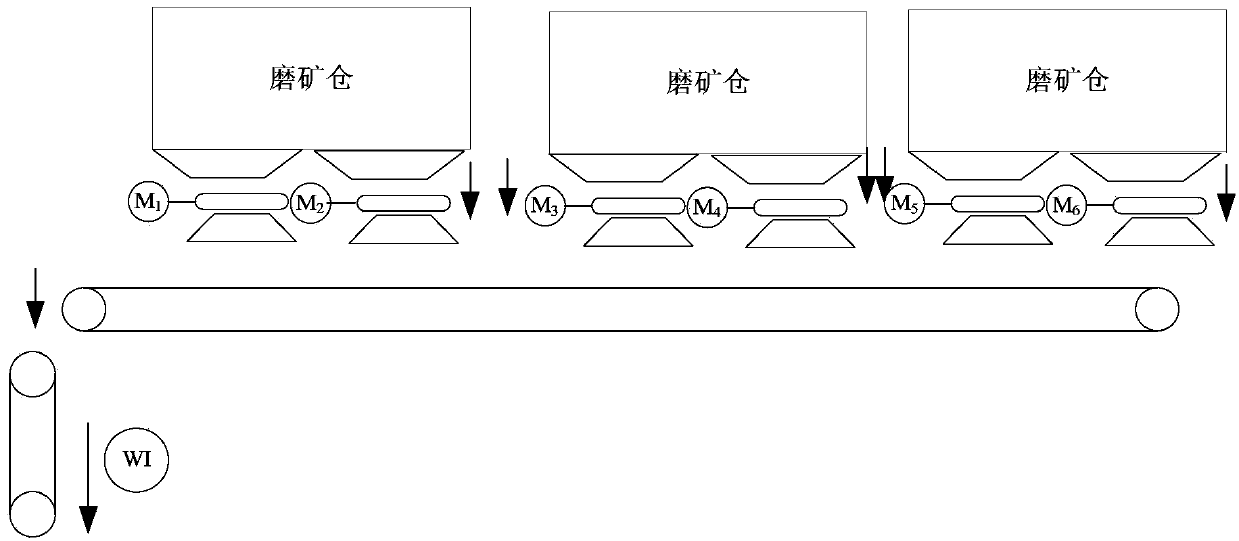

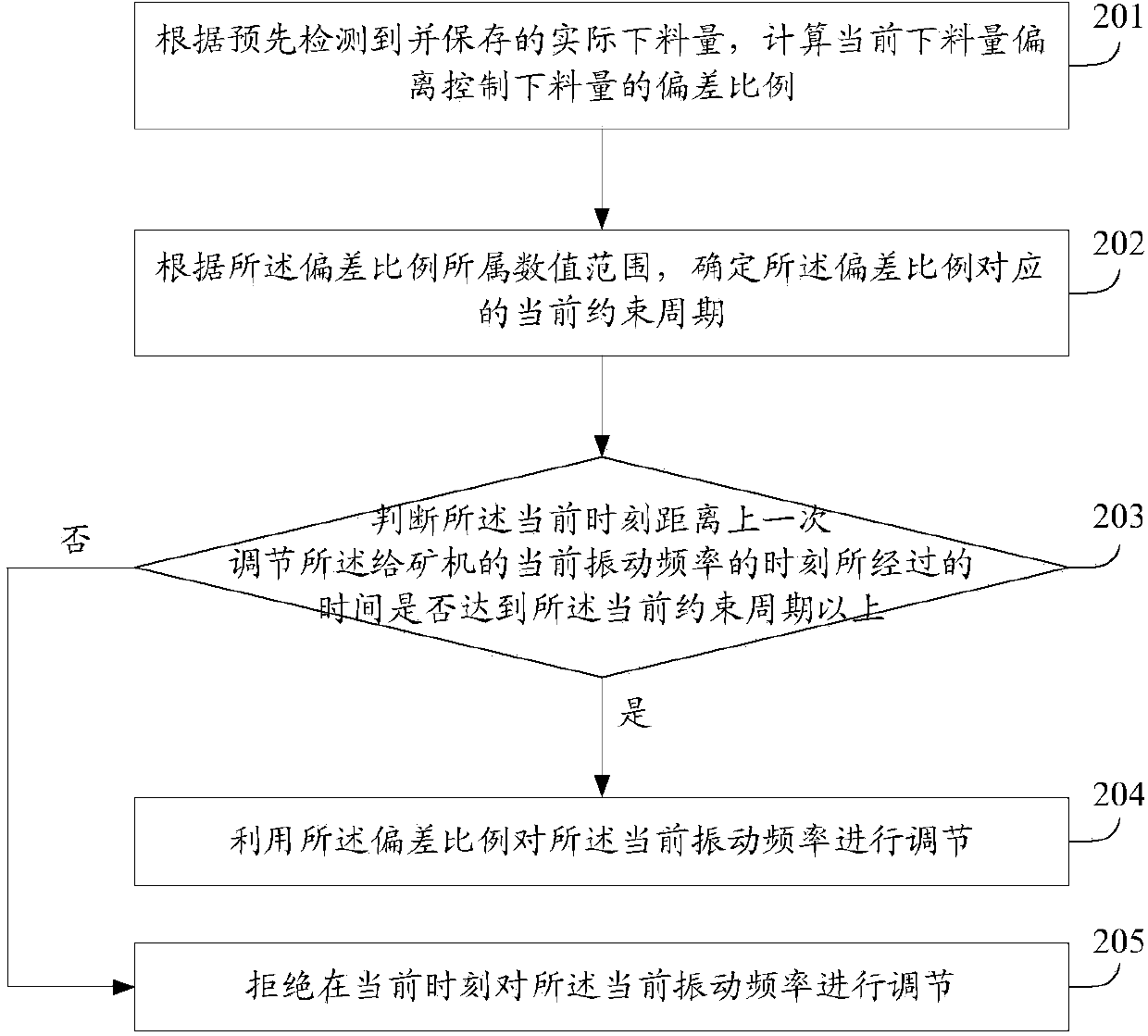

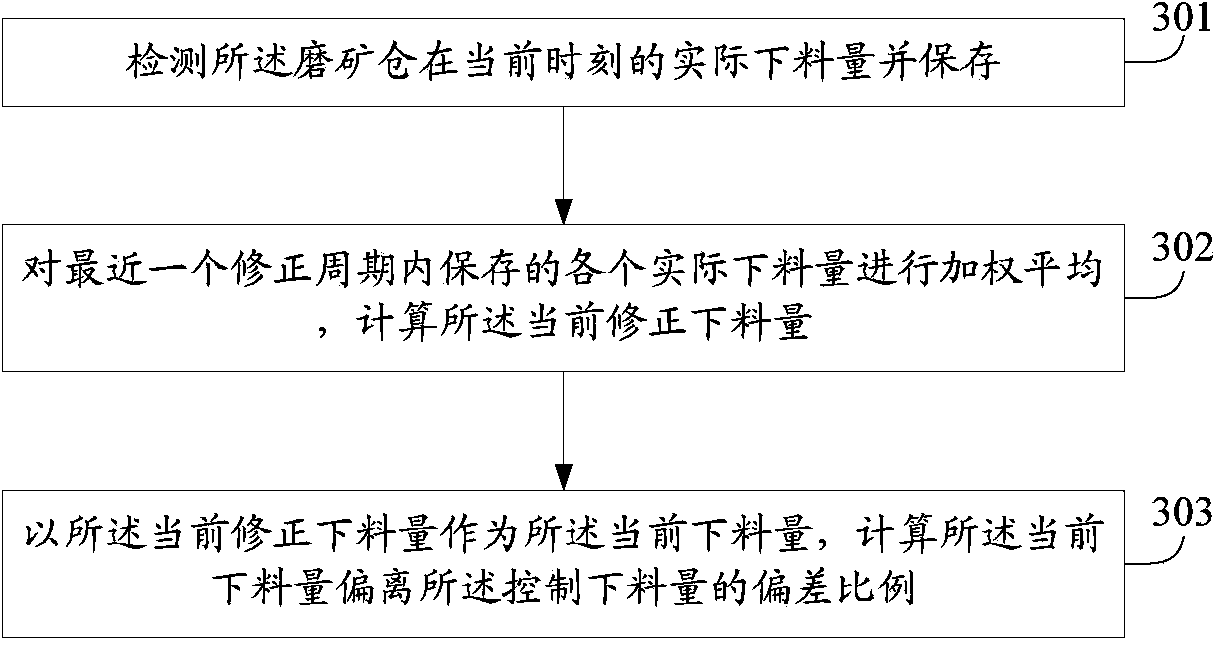

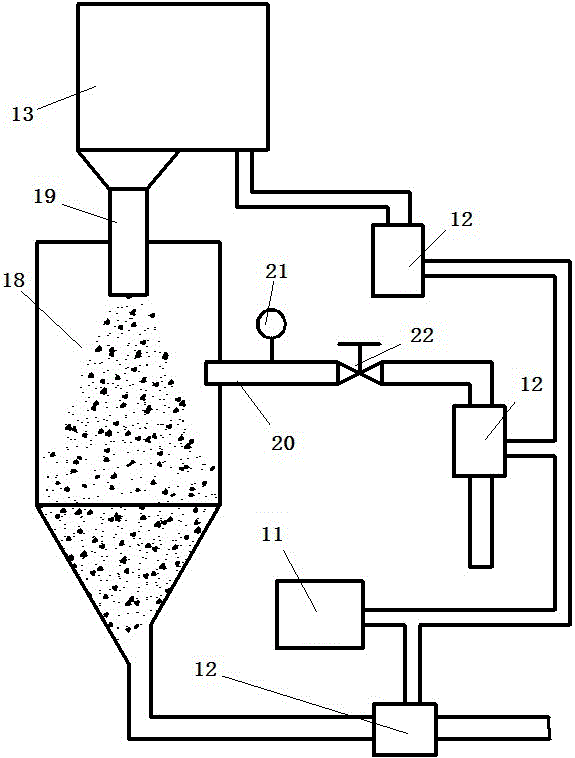

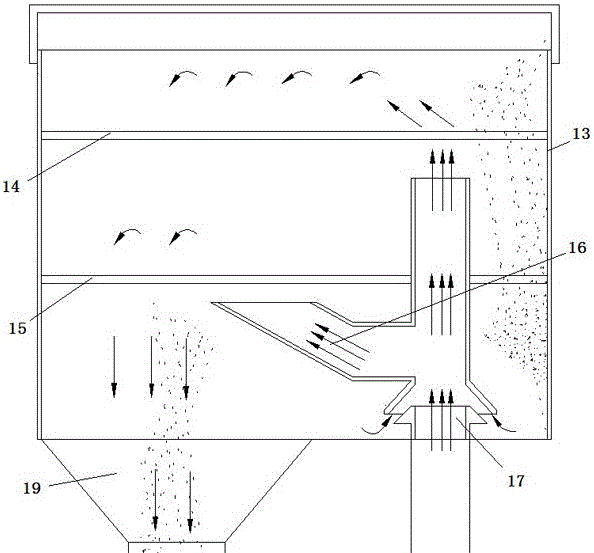

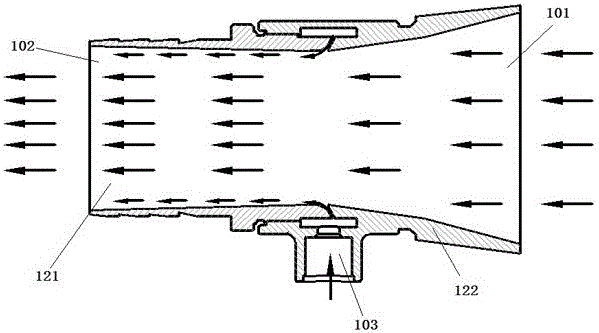

Method and device for adjusting vibration frequency of ore feeder in ore grinding process

ActiveCN103439991AAvoid over-regulationAccurate control of feeding volumeMechanical oscillations controlTotal factory controlGranularityNumerical range

The embodiment of the invention discloses a method and device for adjusting the vibration frequency of an ore feeder in the ore grinding process. The method comprises the steps that according to the actual feeding quantity which is detected and stored in advance, the deviation ratio that the current feeding quantity deviates from the control feeding quantity is calculated; according to the numerical range of the deviation ratio, a current constraint period corresponding to the deviation ratio is determined; whether time lasting from the moment when the current vibration frequency of the ore feeder is adjusted at the last time to the current moment is longer than the time of the current constraint period or not is judged, if the answer is positive, the current vibration frequency is adjusted according to the deviation ratio, and if the answer is negative, the current vibration frequency is not adjusted at the current moment. According to the technical scheme, excessive adjustment to the current vibration frequency can be avoided and the actual feeding quantity of an ore grinding chamber is prevented from being over adjusted and deviating from the control feeding quantity, so that accurate control over the feeding quantity of the ore grinding chamber is achieved and accurate control over granularity of ground ore is indirectly achieved.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Standard Particle Generator

ActiveCN104801491BImprove production efficiencyPrecise particle size controlGas current separationParticle suspension analysisPoor qualityMechanics

The invention relates to the field of calibrating dust concentration and powder particle size, in particular to a standard particle generating device. The standard particle generating device comprises a gas distribution mechanism, a boiling-type particle screening device and a bucket-type particle separating device, wherein the boiling-type particle screening device and the bucket-type particle separating device are sequentially and vertically arranged; the boiling-type particle screening device comprises a shell, at least one layer of screen mesh, and an air blowing mechanism; the screen mesh is arranged in the shell; the air blowing mechanism is connected with the shell, and is used for enabling particles on the screen mesh to be in a fluidized boiling state; the bucket-type particle separating device comprises a separating tank; a negative pressure suction-separation mechanism is connected between the upper end of the separating tank and the lower end of the separating tank; the air blowing mechanism and the negative pressure suction-separation mechanism are both connected with the gas distribution mechanism; the shell of the boiling-type particle screening device is connected with the separating tank through an outlet which is formed in the lower part of the boiling-type particle screening device. According to the standard particle generating device, the problems of low efficiency and poor quality of existing standard particle fabrication are solved.

Owner:GL TECH CO LTD

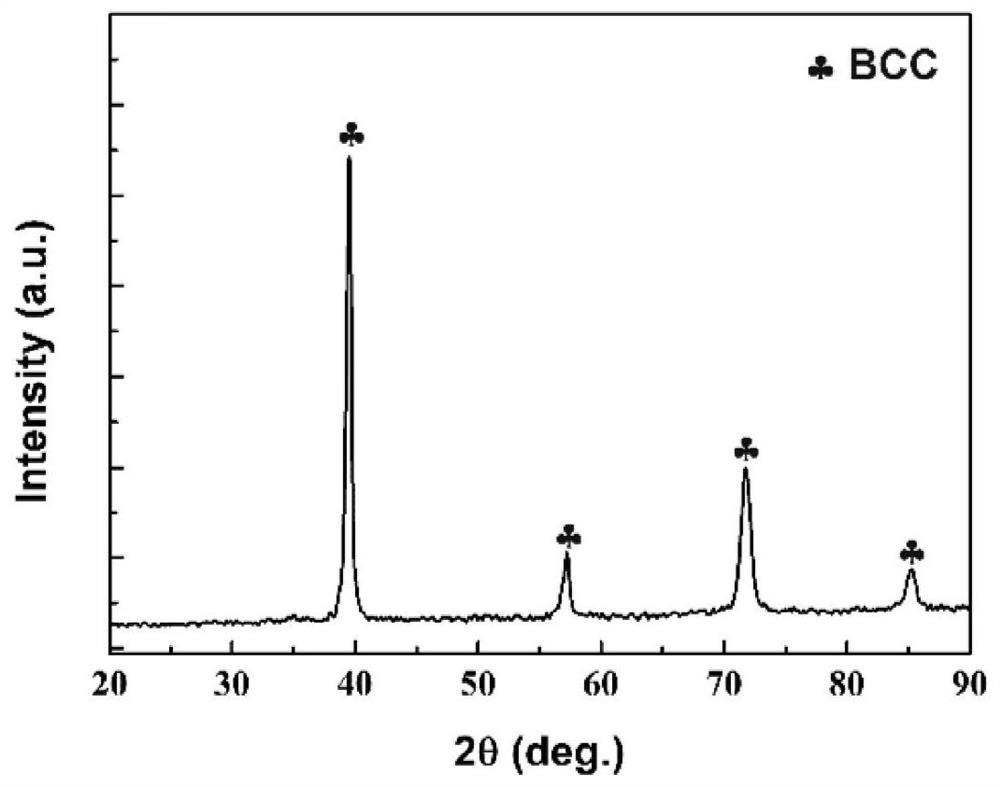

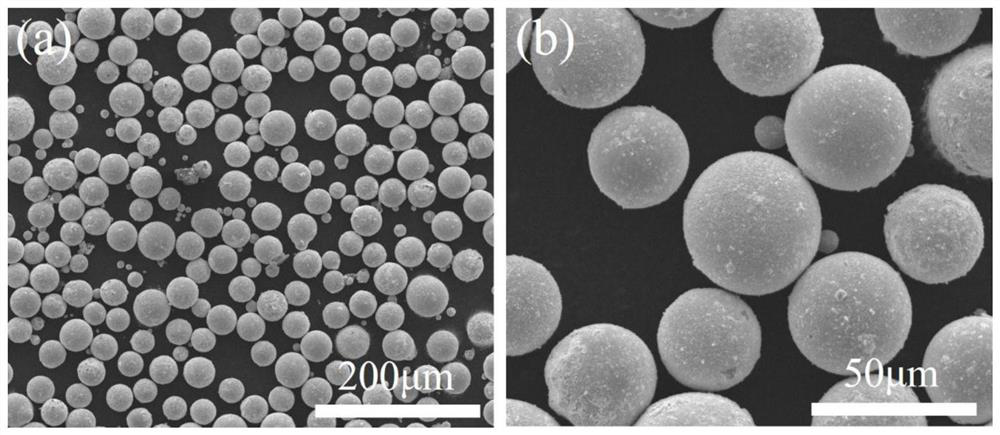

A kind of preparation method of multi-element refractory alloy spherical powder

ActiveCN111097919BWide range of ingredientsUniform powder compositionTransportation and packagingMetal-working apparatusNiobiumHafnium

The invention discloses a method for preparing a refractory alloy spherical powder with multi-component complex components, which comprises the following steps: mechanically ball milling refractory metal hydride powder to a particle size of 1-5 μm; The refractory metal simple substance powder is used as the refractory alloy raw material powder, and the solvent and the binder are added to mix to obtain a slurry, which is granulated to obtain a spherical powder with a particle size of 15-70 μm, and the spherical powder is placed in the plasma spheroidization system In the powder device, the spheroidization is carried out under the mixed atmosphere of argon and hydrogen, that is, the refractory alloy spherical powder with multiple components and complex components; the refractory alloy raw material is selected from chromium source, tungsten source, molybdenum source, tantalum source, niobium source source, hafnium source, vanadium source, titanium source, zirconium source at least three. The process of the invention is simple and controllable, and the refractory alloy spherical powder with multi-component complex components has uniform composition, compact structure, smooth surface, high sphericity, low impurity content and controllable particle size distribution.

Owner:CENT SOUTH UNIV

Precise Control Method of Particle Size of Primary Titanium Dioxide

ActiveCN106946287BPrecise particle size controlLarge scattering powerTitanium dioxideOptical propertyTitanium

The invention relates to the technical field of preparation of titanium dioxide and in particular relates to a precise control method for grain size of a coarse titanium dioxide product, aiming at solving the problem that in the prior art, the grain size cannot be precisely controlled to a required range. The method comprises the following three steps: titanium liquid hydrolysis, metatitanate treatment and calcining. During titanium liquid hydrolysis, parameters such as the initial concentration of a titanium liquid, the stirring speed and the heating temperature and time of the titanium liquid are adjusted; types and contents of salts are adjusted during metatitanate treatment; the calcining treatment is divided into three sections, and the calcining temperature and time of each section are precisely controlled, so that the grain size of the coarse titanium dioxide product is precisely controlled. The method provided by the invention is simple to operate, and the average grain size of the coarse titanium dioxide product can be effectively controlled in a range of 250-270nm, so that the coarse titanium dioxide product is great in scattering force and good in optical property, and the coarse titanium dioxide product is universal titanium dioxide suitable for the field of coatings and the like.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com