Generating method and device capable of adjusting particle size of atomized single liquid drops

A generation device and adjustable technology, applied in the direction of spray device, electrostatic spray device, etc., can solve the problems of difficult maintenance, narrow flow channel of droplet generator, blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

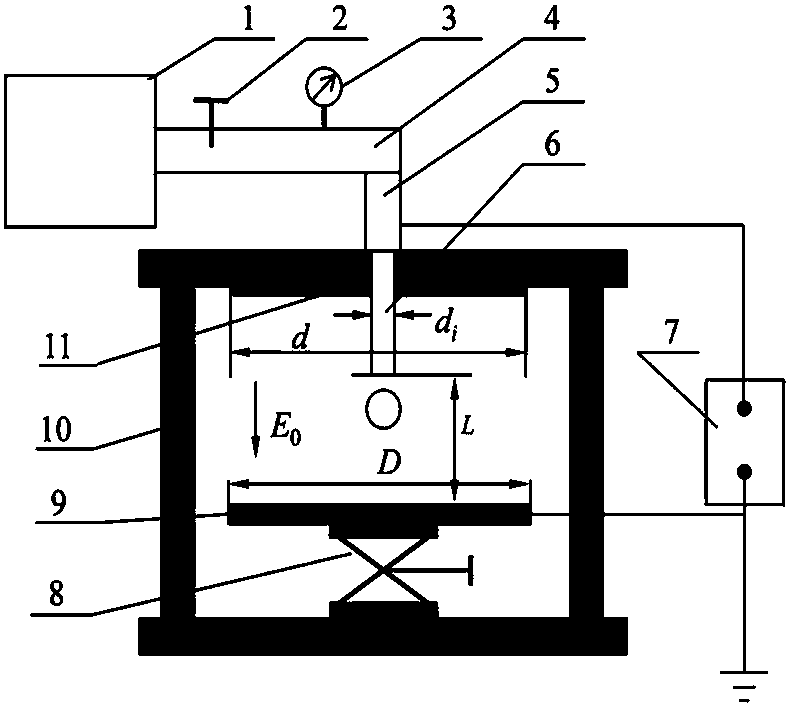

[0024] see figure 1 According to the present invention, a generating device capable of adjusting the diameter of atomized single droplet has a liquid storage tank 1, which is filled with atomized liquid. The liquid storage tank 1 is connected with a metal capillary 6 through a conduit 4 , and a flow control valve 2 and a flow meter 3 are installed on the conduit 4 . A capillary support 5 is tightly and fixedly sheathed outside the upper section of the metal capillary 6, and the capillary support 5 is fixed on the device support 10 by strong glue, so that the metal capillary 6 is fixed. The capillary support 5 is connected with a high-voltage electrostatic generator 7 through wires. The device support 10 is composed of two parallel square plates up and down and four vertical solid cylinders connected between the two square plates, and the four corners of the two square plates are connected by vertical solid cylinders. There is enough up and down distance between the two squar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com