Liposome Extrusion Filtration Device

A filter device and liposome technology, applied in the direction of filtration separation, fixed filter element filter, semi-permeable membrane separation, etc., can solve the problems of cross contamination, inconvenient maintenance, troublesome use and operation, etc., and achieve convenient use and maintenance, and realize Precise control to avoid cross-contamination effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

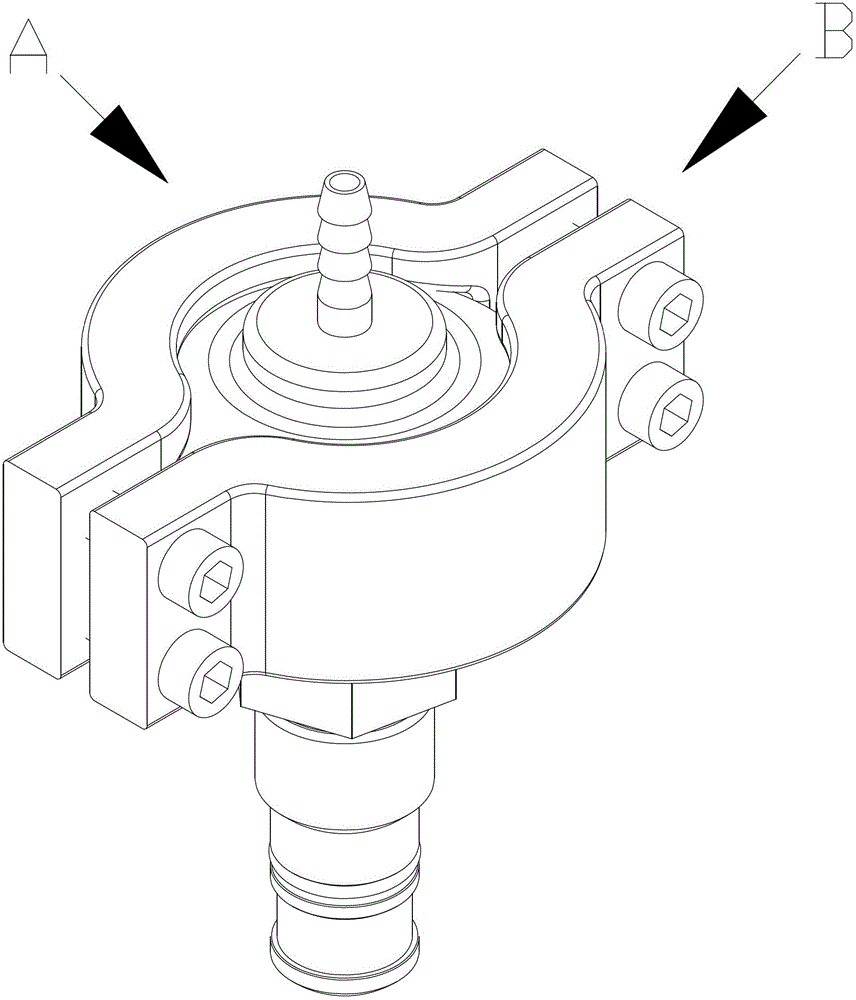

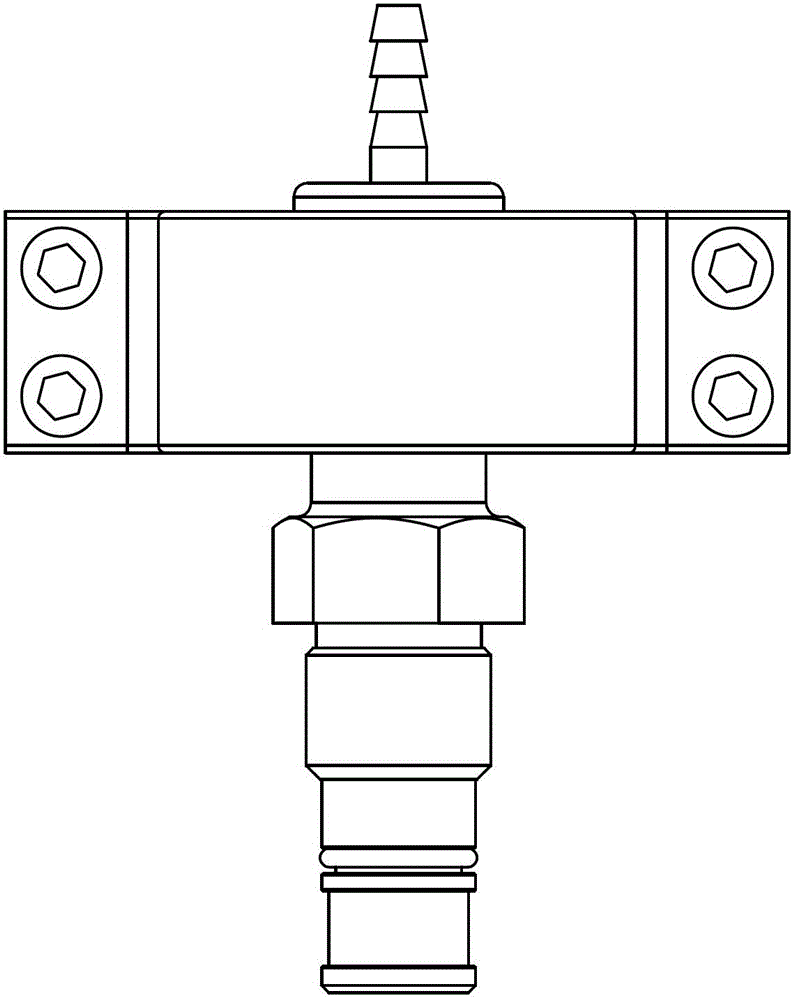

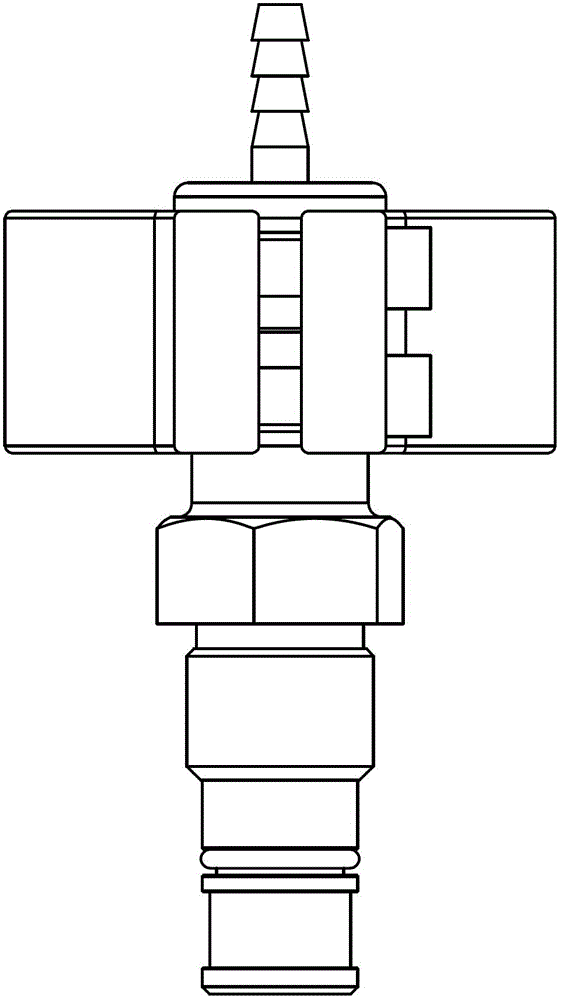

[0020] Example 1 , Liposome extrusion filter device

[0021] Such as Figure 1 to Figure 5 A kind of liposome extruding filtration device 13 shown, comprises: discharge pipe 1, loam cake 2, extrude outer gasket 3, support plate 4, filter plate 5, filter membrane 6, extrude inner gasket 7 , joint 8, valve body gasket 9, clamp 10, clamp locking bolt 11 and valve body seal groove 12, the valve body seal groove 12 is arranged on the outer edge of the lower end of the joint 8, and the valve body seal The gasket 9 is arranged inside the sealing groove 12 outside the valve body, and the center of the joint 8 is provided with a feed through hole; the center of the upper cover 2 is provided with a discharge through hole, and the center of the discharge through hole The upper opening is connected to the discharge pipe 1, and the bottom surface of the upper cover 2 is provided with an indented cylindrical groove and an annular sealing groove, and the annular sealing groove is located ...

Embodiment 2

[0022] Example 2 , Liposome extrusion filter device

[0023] Such as Figure 1 to Figure 5 A kind of liposome extruding filtering device 13 shown, comprises: discharge pipe 1, loam cake 2, extruding outer gasket 3, support plate 4, filter plate 5, polycarbonate filter membrane 6, extruding inner Sealing gasket 7, joint 8, sealing gasket 9 outside the valve body, clamp 10, clamp locking bolt 11 and sealing groove 12 outside the valve body, the sealing groove 12 outside the valve body is arranged on the outer edge of the lower end of the joint 8, the The sealing gasket 9 outside the valve body is arranged inside the sealing groove 12 outside the valve body, and the center of the joint 8 is provided with a feed through hole; the center of the upper cover 2 is provided with a discharge through hole, and the discharge The upper opening of the through hole is connected to the discharge pipe 1, and the bottom surface of the upper cover 2 is provided with an indented cylindrical gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com