High-pressure extruding and filtering system for preparing liposome

A filtration system and high-pressure technology, which is applied in the direction of making medicines into special physical or taking forms of devices, etc., can solve the problem of liposome-susceptible bacteria, inability to meet the requirements of liposome pharmaceutical production, and troublesome use, operation and maintenance. and other problems, to achieve precise control of particle size, improve efficiency, and avoid the effects of contamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

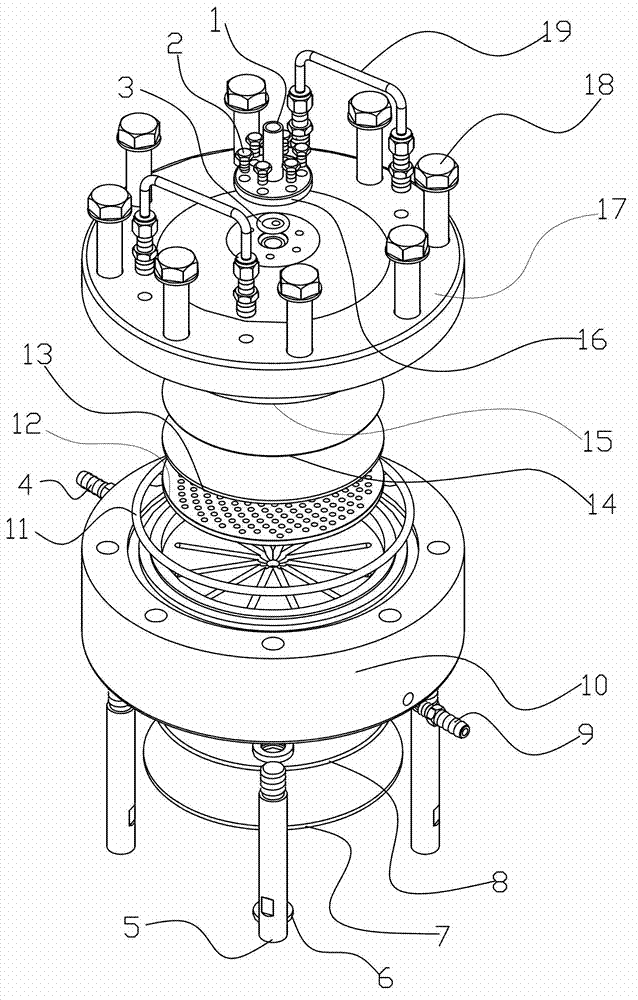

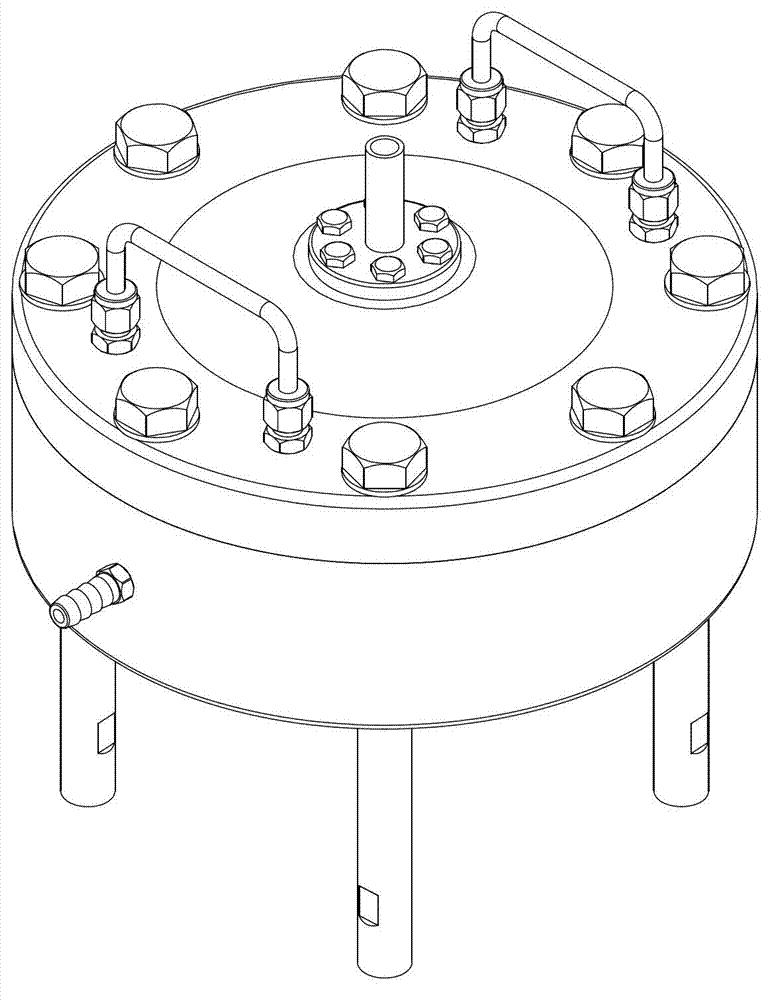

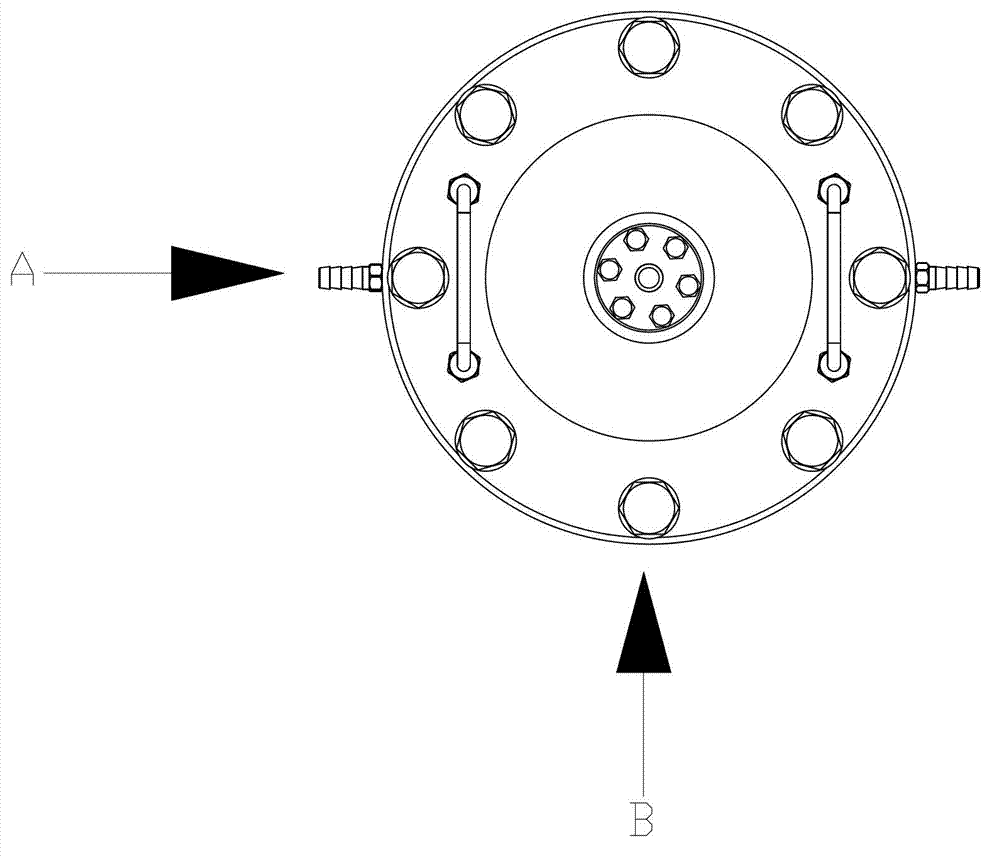

[0023] Example 1 , Liposome preparation high pressure extrusion filtration system

[0024] Such as Figure 1 to Figure 6 A kind of liposome shown prepares high-pressure extrusion filtration system, comprises high-pressure homogenizer 21 and four high-pressure extruders 20 that are placed side by side, and described high-pressure extruder 20 comprises feed pipe 1, flange fixing bolt 2. The inner gasket of the feeding flange 3, the constant temperature water outlet 4, the support foot 5, the discharge pipe 6, the bottom plate of the constant temperature tank 7, the outer gasket 8 of the bottom plate, the constant temperature water inlet 9, and the base 10, Extrusion outer gasket 11, support plate 12, filter plate 13, filter membrane 14, extrusion inner gasket 15, feed flange 16, upper cover 17, locking bolt 18 and handle 19, the support foot 5 Connected with the base 10 through threads; the bottom plate 7 of the constant temperature bath is connected with the base 10 through ...

Embodiment 2

[0025] Example 2 , Liposome preparation high pressure extrusion filtration system

[0026] Such as Figure 1 to Figure 6Shown a kind of liposome prepares high-pressure extrusion filtration system, comprises high-pressure homogenizer 21 and two high-pressure extruders 20 that are placed side by side, and described high-pressure extruder 20 comprises feed pipe 1, flange fixing bolt 2. The inner gasket of the feeding flange 3, the constant temperature water outlet 4, the support foot 5, the discharge pipe 6, the bottom plate of the constant temperature tank 7, the outer gasket 8 of the bottom plate, the constant temperature water inlet 9, and the base 10, Extrusion outer gasket 11, support plate 12, filter plate 13, filter membrane 14, extrusion inner gasket 15, feed flange 16, upper cover 17, locking bolt 18 and handle 19, the support foot 5 Connected with the base 10 through threads; the bottom plate 7 of the constant temperature bath is connected with the base 10 through th...

Embodiment 3

[0027] Example 3 , Liposome preparation high pressure extrusion filtration system

[0028] Such as Figure 1 to Figure 6 A kind of liposome shown prepares high-pressure extrusion filtration system, comprises high-pressure homogenizer 21 and four high-pressure extruders 20 that are placed side by side, and described high-pressure extruder 20 comprises feed pipe 1, flange fixing bolt 2. The inner gasket of the feeding flange 3, the constant temperature water outlet 4, the support foot 5, the discharge pipe 6, the bottom plate of the constant temperature tank 7, the outer gasket 8 of the bottom plate, the constant temperature water inlet 9, and the base 10, Extrusion outer gasket 11, support plate 12, filter plate 13, filter membrane 14, extrusion inner gasket 15, feed flange 16, upper cover 17, locking bolt 18 and handle 19, the support foot 5 Connected with the base 10 through threads; the bottom plate 7 of the constant temperature bath is connected with the base 10 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com