Method for preparing granularity controllable narrow range polymer micro-nano spheres

A polymer and micro-nanosphere technology, applied in the field of polymer micro-nanosphere preparation, can solve the problem of difficulty in preparing microspheres with a particle size of less than 100 μm, and can only prepare microspheres with a particle size of less than 0.5 μm, which cannot meet the requirements of fast and efficient Production and other issues, to achieve the effect of low cost, low production cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

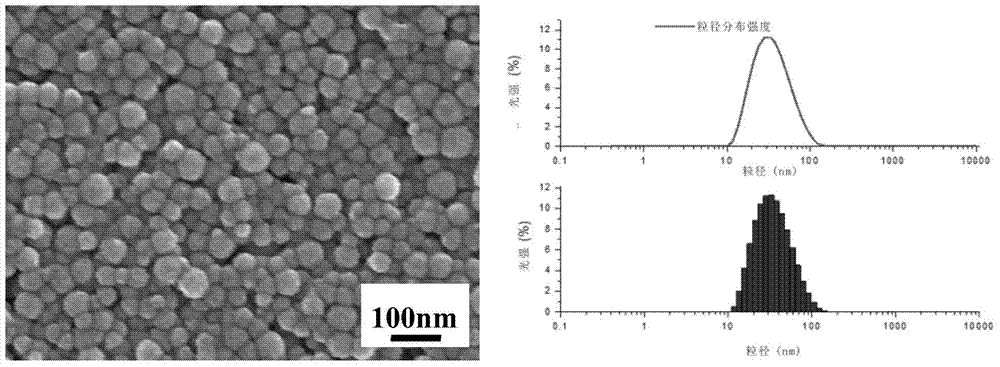

[0058] Example 1: Preparation of Narrowly Distributed Polystyrene Nanospheres

[0059] (1) Add 2g of industrial-grade polystyrene (molecular weight: 100,000, molecular weight distribution: 1.8) into 100ml of dichloromethane, stir to dissolve it completely to form an organic phase, and then add it to 1L of sodium lauryl sulfate dissolved in it. In ionized water, stir at high speed to obtain colostrum;

[0060] (2) Under the pressure of 206MPa, pour the colostrum into the feeding chamber of the micro-fluidic equipment (M-110P) for homogeneous emulsification. The product is poured back into the feeding chamber and homogenized repeatedly 8 times;

[0061] (3) Put the emulsion after homogenizing 8 times into a beaker, stir and evaporate the organic solvent for 8 hours at a low speed, make the dichloromethane volatilize completely, collect the solid product by centrifugation, wash it three times with deionized water, and wash away its surfactant ten Sodium dialkylsulfate and dried...

Embodiment 2

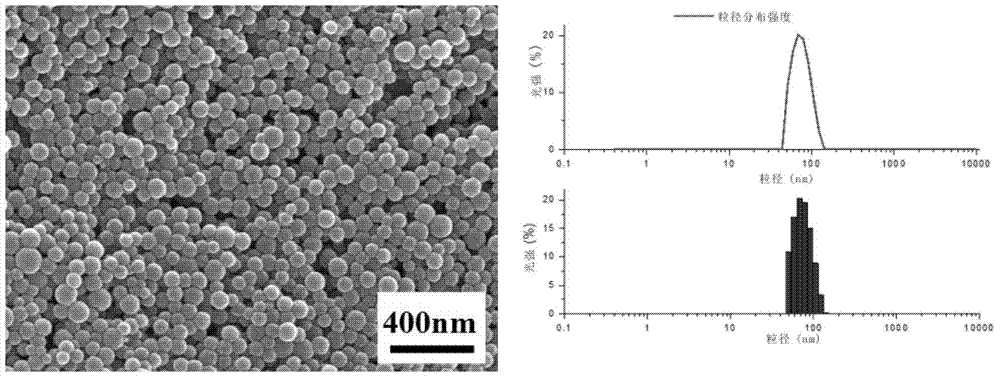

[0062] Embodiment 2: Preparation of narrow distribution polystyrene nanospheres

[0063] (1) Add 2g of industrial-grade polystyrene (molecular weight: 100,000, molecular weight distribution: 1.8) into 100ml of dichloromethane, stir to dissolve it completely to form an organic phase, and then add it to 1L of 3g of sodium lauryl sulfate. In ionized water, stir at high speed to obtain colostrum;

[0064] (2) Under the pressure of 136MPa, pour the colostrum into the feeding chamber of the micro-fluidic equipment (M-110P) for homogeneous emulsification. The product is poured back into the feeding chamber and homogenized repeatedly 8 times;

[0065] (3) Put the emulsion after homogenizing 8 times into a beaker, stir and evaporate the organic solvent for 8 hours at a low speed, make the dichloromethane volatilize completely, collect the solid product by centrifugation, wash it three times with deionized water, and wash away its surfactant ten Sodium dialkylsulfate and dried to obta...

Embodiment 3

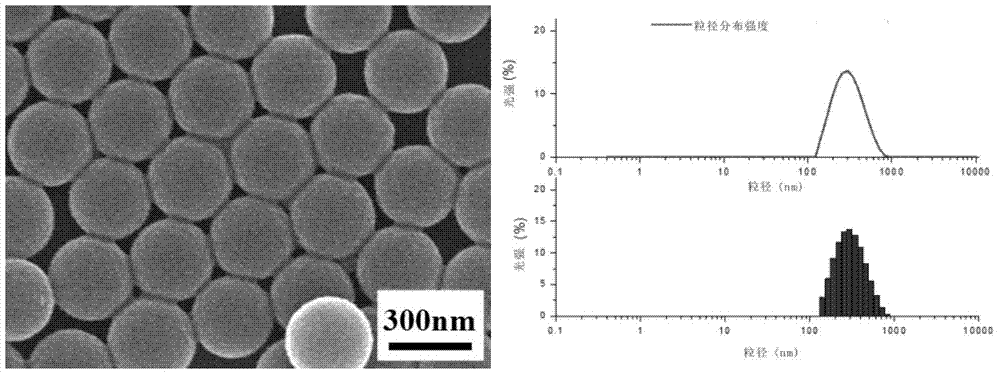

[0066] Embodiment 3: Preparation of narrow distribution polystyrene nanospheres

[0067] (1) Add 2g of industrial grade polystyrene (molecular weight 100,000, molecular weight distribution 1.8) into 100ml of dichloromethane, stir to make it completely dissolve to form an organic phase, and then add it to 1L of deionized water dissolved in 250mg of polyvinyl alcohol 1788 , stirring at high speed to obtain colostrum;

[0068] (2) Under the pressure of 103MPa, pour the colostrum into the feeding chamber of the micro-fluidic equipment (M-110P) for homogeneous emulsification. The product is poured back into the feeding chamber and homogenized repeatedly 8 times;

[0069] (3) Put the emulsion after homogenizing 8 times into a beaker, stir and evaporate the organic solvent for 8 hours at a low speed, make dichloromethane volatilize completely, collect the solid product by centrifugation, wash three times with deionized water, and wash away its surfactant polymerization Vinyl alcoho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com