Method for preparing novel polyethylene glycol-poly gamma butyrolactone di-block copolymer nano drug carrying microsphere

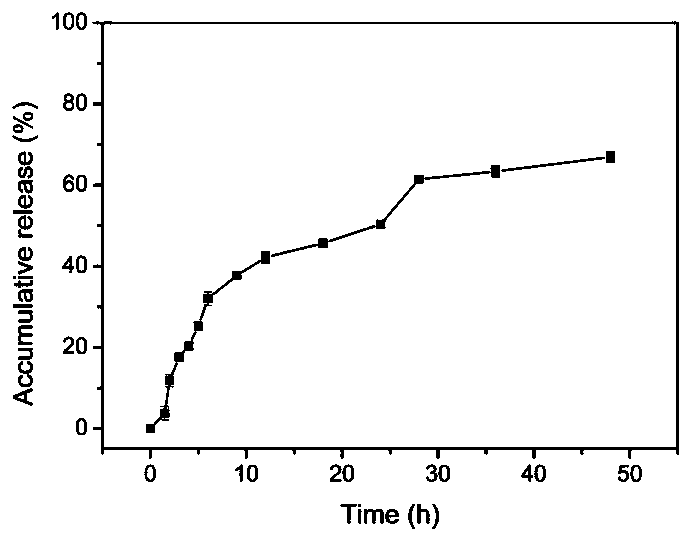

A technology of poly-gamma butyrolactone and block copolymer, which is used in pharmaceutical formulations, medical preparations without active ingredients, and medical preparations containing active ingredients, etc., to achieve adjustable sustained release performance and excellent biocompatibility , the effect of a good monodisperse state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

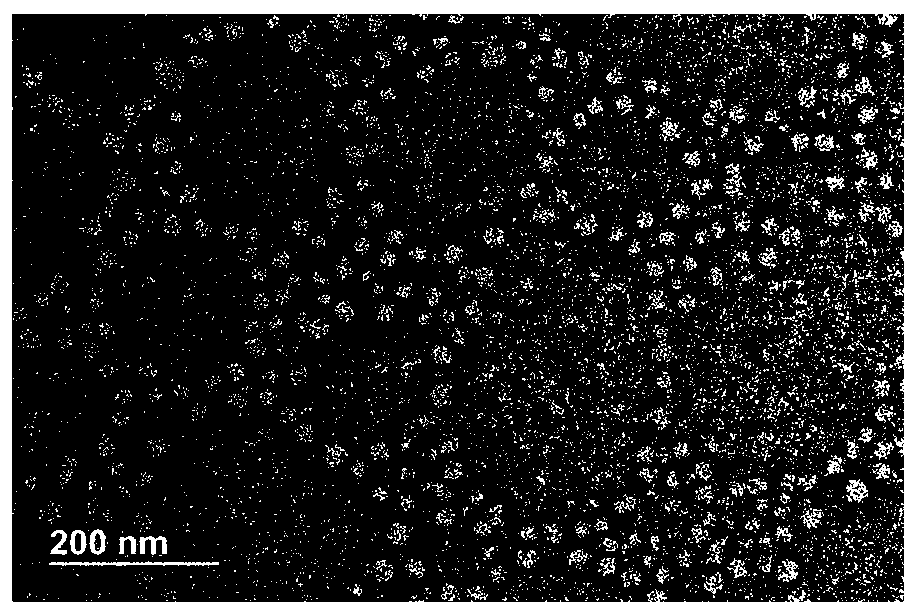

[0045] Embodiment 1, the preparation of loading doxorubicin PEG-PBL nano microsphere

[0046]Weigh 100mg PEG-PBL (weight average molecular weight 10000, copolymerization ratio 1:1), 20mg doxorubicin, add to 4mL dichloromethane, stir at 500rpm for 10min to dissolve PEG-PBL and drug, then add 30mL deionized Water, under the pressure of 100MPa, add the primary emulsion to the micro-fluidic homogenizer, select the 75μm and 400μm flow channels for processing, and repeat the homogenization 3 times. Stir at 100rpm for 12h to volatilize the solvent, and finally centrifuge the suspension of drug-loaded microspheres at 4°C and 20,000rpm for 10min to obtain a solid that is freeze-dried to remove water and stored at 4°C.

[0047] The obtained nano drug-loaded microspheres of PEG-PBL and doxorubicin have an average particle diameter of 100 nm and a drug encapsulation rate of 85%.

Embodiment 2

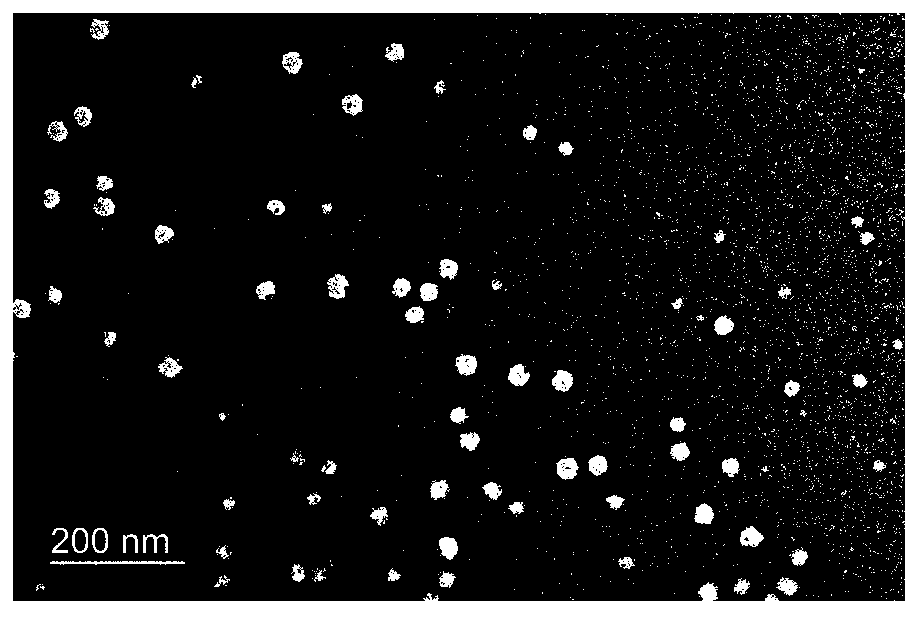

[0048] Embodiment 2, preparation of paclitaxel-loaded PEG-PBL nano-microspheres

[0049] Weigh 150mg PEG-PBL (weight average molecular weight 10000, copolymerization ratio 1:1), 20mg paclitaxel, add into 4mL dichloromethane, stir at 800rpm for 10min to dissolve PEG-PBL and drug, then add 30mL deionized water to it, Under the pressure of 100MPa, the primary emulsion was added to the micro-fluidic homogenizer, and the 75 μm and 400 μm flow channels were selected for processing, and the homogenization was repeated 3 times. Stir at 100rpm for 12h to volatilize the solvent, and finally centrifuge the suspension of drug-loaded microspheres at 4°C and 20,000rpm for 10min to obtain a solid that is freeze-dried to remove water and stored at 4°C. The obtained nano drug-loaded microspheres of PEG-PBL and paclitaxel have an average particle diameter of 100 nm and a drug encapsulation rate of 90%.

Embodiment 3

[0050] Embodiment 3, preparation of paclitaxel-loaded PEG-PBL nano-microspheres

[0051] Weigh 200mg PEG-PBL (weight average molecular weight 15000, copolymerization ratio 1:2), 20mg paclitaxel, add into 4mL dichloromethane, stir at 1000rpm for 10min to dissolve PEG-PBL and drug, then add 30mL deionized water to it, Under the pressure of 40MPa, the primary emulsion was added to the micro-fluidic homogenizer, and the 75 μm and 400 μm flow channels were selected for processing, and the homogenization was repeated 3 times. Stir at 100rpm for 24h to volatilize the solvent, and finally centrifuge the suspension of drug-loaded microspheres at 4°C and 20,000rpm for 15min to obtain a solid that is freeze-dried to remove water and stored at 4°C.

[0052] The obtained nano drug-loaded microspheres of PEG-PBL and paclitaxel have an average particle diameter of 150 nm and a drug encapsulation efficiency of 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com