Method for preparing large-particle high-purity vanadium pentoxide

A technology of vanadium pentoxide and large particles, which is applied in the field of vanadium chemical industry, can solve the problems of high production cost, long process flow, and insufficient purity of vanadium pentoxide products, and achieve easy realization, simple process operation and good application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

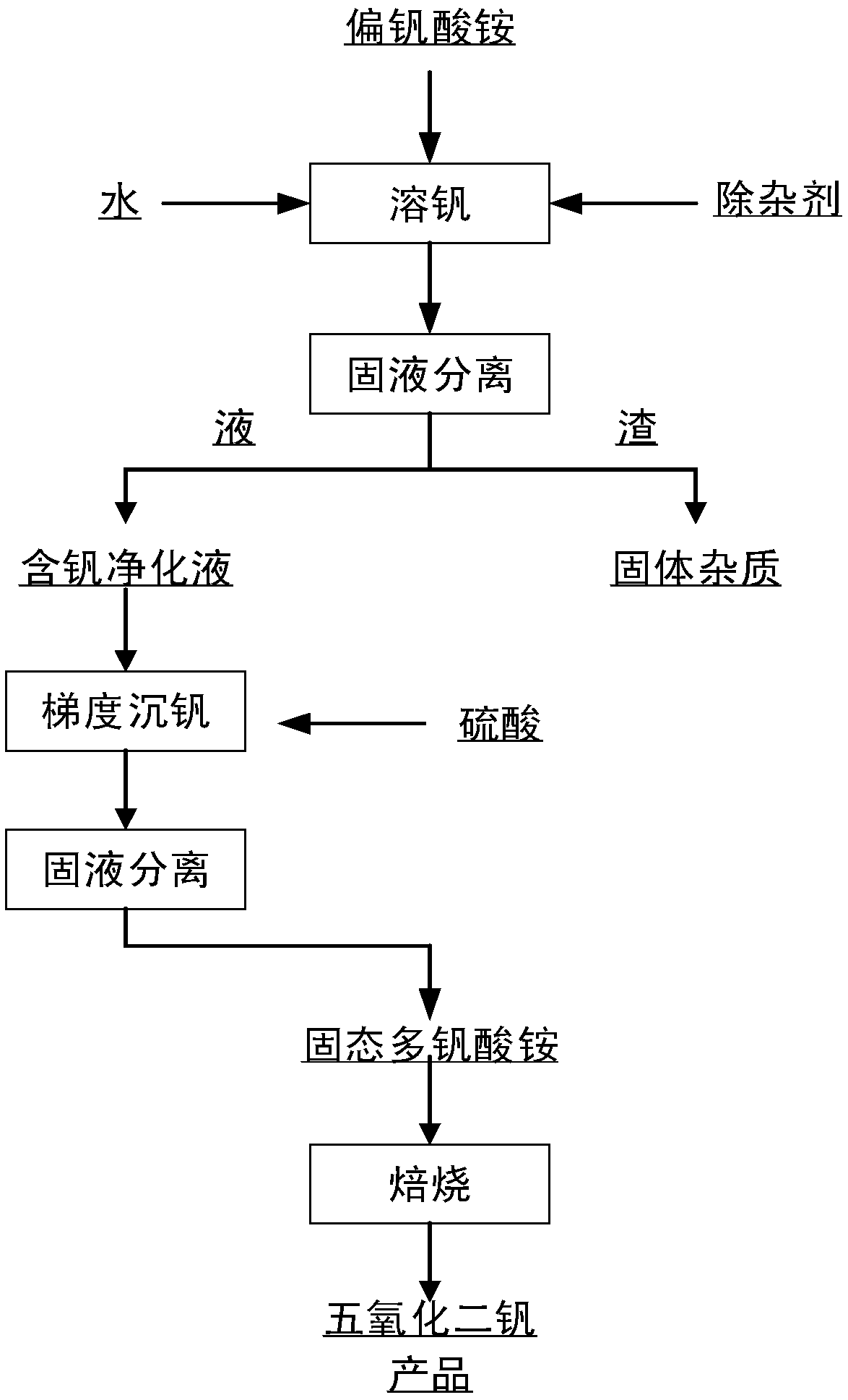

[0041] Such as figure 1 Shown, the present invention prepares large particle high-purity vanadium pentoxide according to the following steps.

[0042] (1) Weigh 300g of ammonium metavanadate with a water content of about 10%, put it into 5L of water, heat to 98°C to dissolve, add ammonia water until the pH value is 7.0, and after 10min, filter to obtain a vanadium-containing vanadium with a vanadium concentration of 23g / L purification fluid;

[0043] (2) Heat the vanadium-dissolved purification solution obtained in step (1) to boiling, gradient acid precipitation, add sulfuric acid dropwise to the vanadium-containing purification solution to adjust the pH, and stop at the pH values of 5.8, 5.6, and 4.4 for 10 minutes to precipitate vanadium , continue to drop sulfuric acid to adjust the pH to 2.1, and precipitate vanadium for 60 minutes. During the entire process of vanadium precipitation, the temperature is controlled at 95-100°C. After the reaction is completed, filter to...

Embodiment 2

[0047] (1) Weigh 150g of ammonium metavanadate with a water content of about 10%, put it into 5L of water, heat to 95°C to dissolve, add ammonia water until the pH value is 7.5, and after 20min, filter to obtain a vanadium concentration of 11.5g / L. Vanadium purification solution;

[0048] (2) Heat the vanadium-dissolved purification solution obtained in step (1) to boiling, gradient acid precipitation, add sulfuric acid dropwise to the vanadium-containing purification solution to adjust the pH, and stop at the pH values of 5.9, 5.5, and 4.7 for 15 minutes to deposit vanadium , continue to drop sulfuric acid to adjust the pH to 2.0, react for 50 minutes, and control the temperature at 90-100°C during the whole process of vanadium precipitation, filter after the reaction, and obtain the mother liquor of vanadium precipitation and high-purity large-particle solid-phase ammonium polyvanadate;

[0049] (3) Washing the high-purity large-particle solid-phase ammonium polyvanadate o...

Embodiment 3

[0052] (1) Weigh 300g of ammonium metavanadate with a water content of about 10%, put it into 5L of water, heat to 98°C to dissolve, add ammonia water until the pH value is 6.5, and after 30min, filter to obtain vanadium with a vanadium concentration of 23g / L purification fluid;

[0053] (2) Heat the vanadium-dissolved purification solution obtained in step (1) to boiling, gradient acid precipitation, add sulfuric acid to the vanadium-containing purification solution to adjust the pH, and stop at the pH values of 6, 5.7, and 4.8 for 20 minutes to precipitate vanadium , continue to add sulfuric acid dropwise to adjust the pH to 2.4, react for 80 minutes, and control the temperature at 90-100°C during the whole process of vanadium precipitation, filter after the reaction, and obtain the mother liquor of vanadium precipitation and high-purity large-particle solid-phase ammonium polyvanadate;

[0054] (3) Washing the high-purity large-particle solid-phase ammonium polyvanadate o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com