Absorption-reactivator for continuously trapping carbon dioxide in flue gas

A carbon dioxide and regenerator technology, applied in the direction of direct carbon dioxide emission reduction, filter regeneration, combustible gas purification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

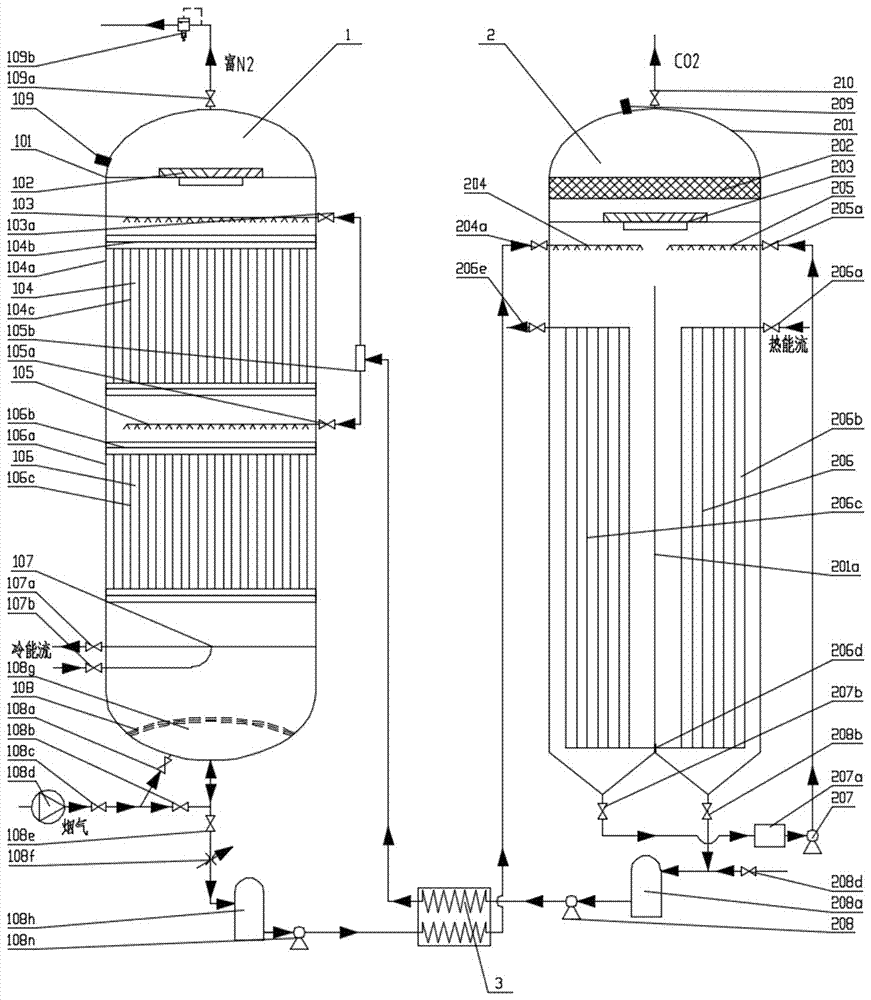

[0067] refer to figure 1 , figure 2 and image 3 , an absorber-regenerator adapted to continuously capture CO2 in flue gas, including flue gas CO 2 Continuous absorption regeneration unit, flue gas CO 2 The continuous absorption regeneration unit consists of continuous CO 2 Absorption tower 1, continuous CO 2 The regeneration tower 2 and the cold / heat exchange device 3 are connected in series, and the continuous CO 2 Absorber and Continuous CO 2 The regeneration towers are connected through the cold / heat exchange device 3 .

[0068] The continuous CO 2 The absorption tower 1 includes a shell 101, and the shell 101 is provided with a gas-liquid separation device 102, at least one atomizing liquid spraying device, at least one wire mesh capture bed device, a cooling device 107, and a gas inlet and distribution device in order from top to bottom. CO with drain 108 2 Hydrate storage chamber 108g.

[0069] In this embodiment, the number of stages of the atomizing liquid ...

Embodiment 2

[0083] The difference between this embodiment and embodiment 1 is:

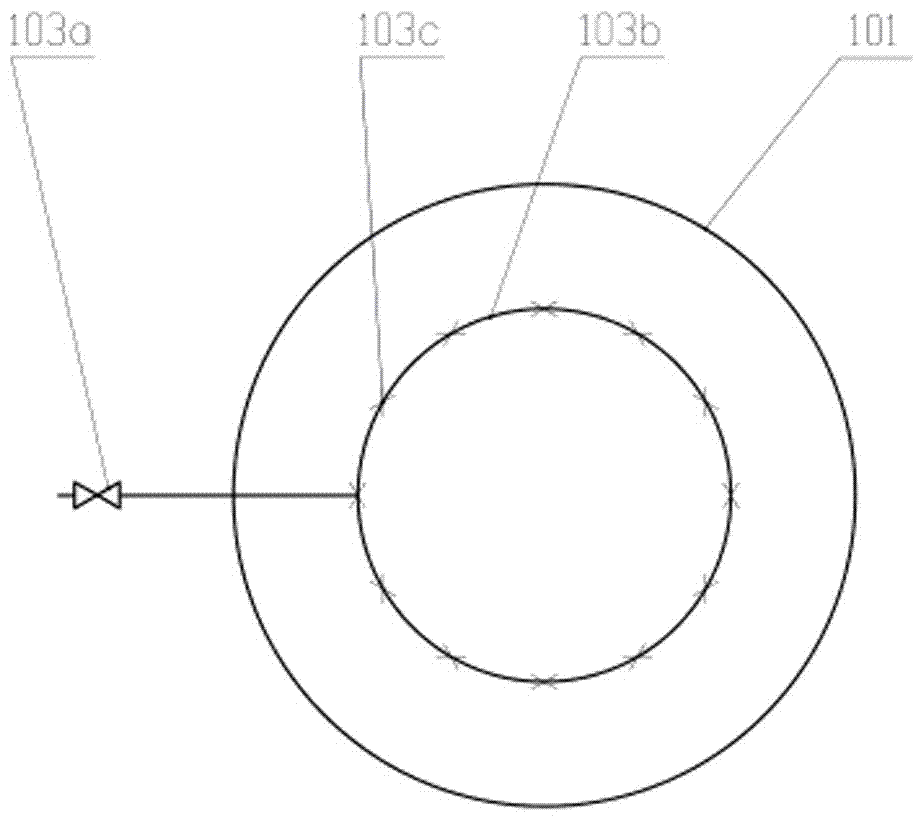

[0084] refer to Figure 4 , the number of stages of the atomizing liquid spraying device and the number of stages of the wire mesh trapping bed device are one level, that is, the first stage atomizing liquid spraying device 103, the first stage wire mesh trapping bed device 104, the first stage atomizing spraying device The liquid device 103 is arranged above the first-stage wire mesh capture bed device 104 .

[0085] The casing 101 is provided with a trapping agent inlet pipe, the inlet end of the trapping agent liquid inlet pipe is connected to the cold / heat exchange device 3, and the outlet end of the collector agent liquid inlet pipe is provided with a seventh pipe valve 103a. The inlet end of the stage atomizing liquid spraying device is connected with the outlet end of the collecting agent inlet pipe.

[0086] All the other are with embodiment 1.

Embodiment 3

[0088] The difference between this embodiment and embodiment 1 is:

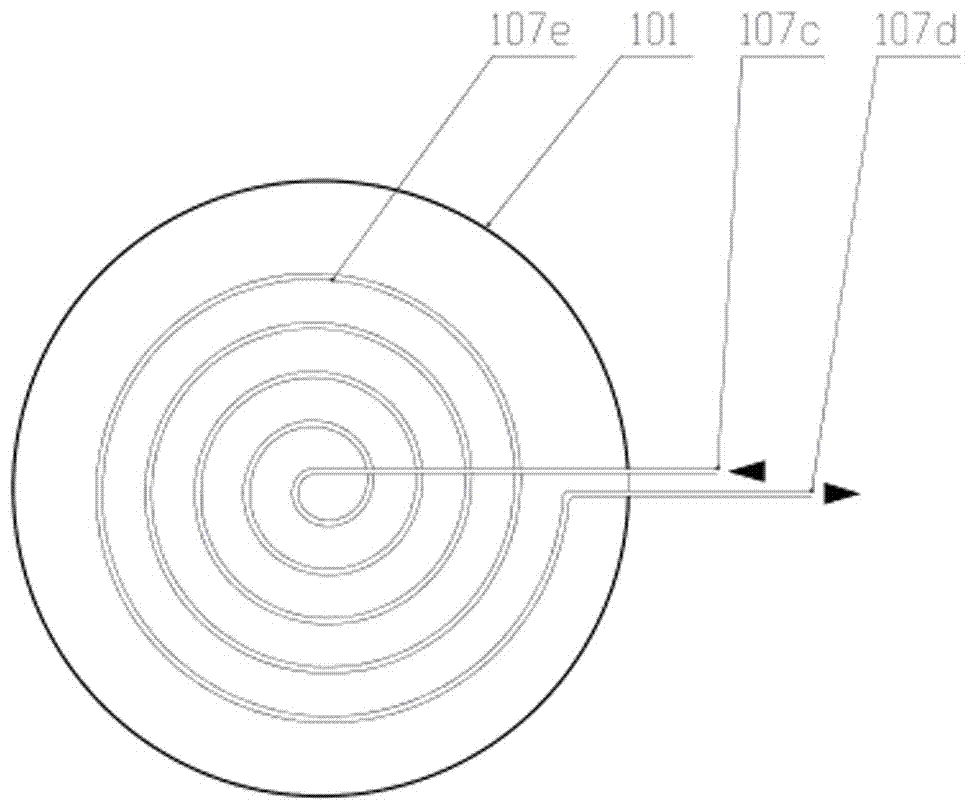

[0089] refer to Figure 5 , the number of stages of the atomizing liquid spraying device and the number of stages of the wire mesh trapping bed device are one level, that is, the first stage atomizing liquid spraying device 103, the first stage wire mesh trapping bed device 104, the first stage atomizing spraying device The liquid device 103 is arranged above the first-stage wire mesh capture bed device 104 .

[0090] The casing 101 is provided with a trapping agent inlet pipe, the inlet end of the trapping agent liquid inlet pipe is connected to the cold / heat exchange device 3, and the outlet end of the collector agent liquid inlet pipe is provided with a seventh pipe valve 103a. The inlet end of the stage atomizing liquid spraying device is connected with the outlet end of the collecting agent inlet pipe.

[0091] The heating device 206 only includes a first-stage decarburization device, that is, a first-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com