Patents

Literature

130results about How to "Will not cause environmental pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for sustainably preparing nanometer cellulose

The invention discloses a method for sustainably preparing nanometer cellulose in an environment-friendly and economic mode. The preparing method includes the following steps that 1, cellulose raw materials and organic acid are hydrolyzed and esterified; 2, the treated cellulose is prewashed in a centrifugal sedimentation mode, the organic acid is separated to be continuously recycled, washed cellulose suspension liquid is dialyzed, and then reacted acid and accessory substances are removed; 3, the dialyzed suspension liquid is separated to obtain small-particle cellulose nanometer crystals; 4, cellulose solid precipitated on a lower layer of the suspension liquid is treated through a high-pressure homogenizer or an ultrasonication physical machine to obtain colloidal cellulose nanometer fibrils. According to the method, in the preparing process, the modified cellulose raw materials are synchronously hydrolyzed and esterified through relative-safety and environment-friendly food-grade organic acid; compared with inorganic strong acid, the used organic acid is low in corrosion performance, high in boiling point, small in reaction pressure and easy to control and operate, and the cellulose nanometer crystals with the stable quality and the cellulose nanometer fibril products with the stable quality can be obtained at the same time.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

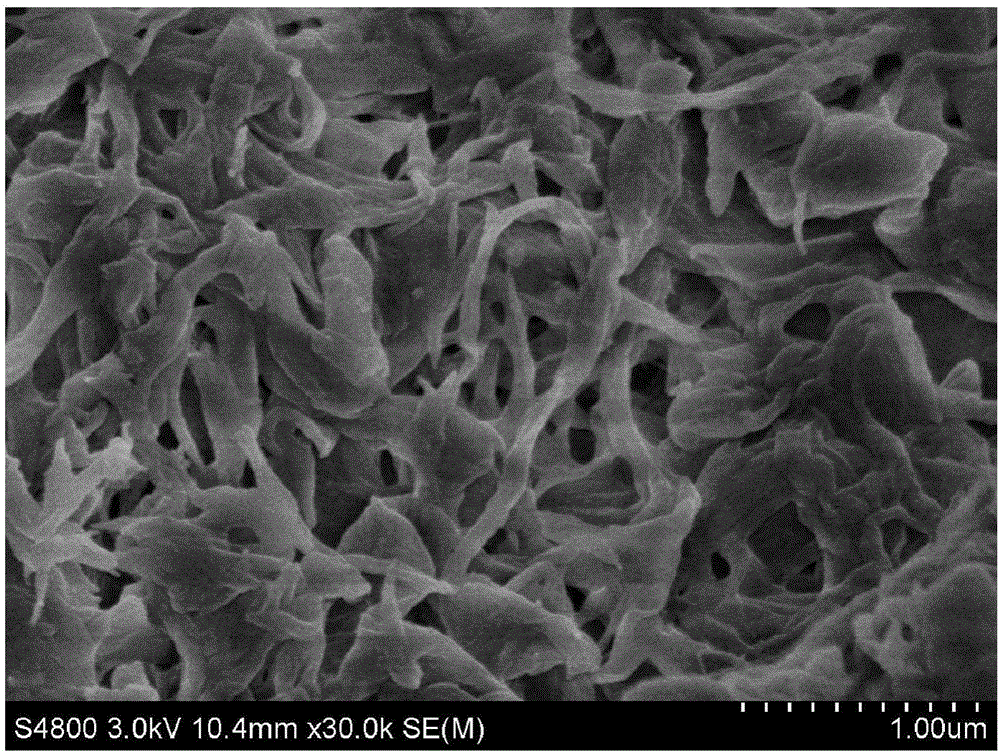

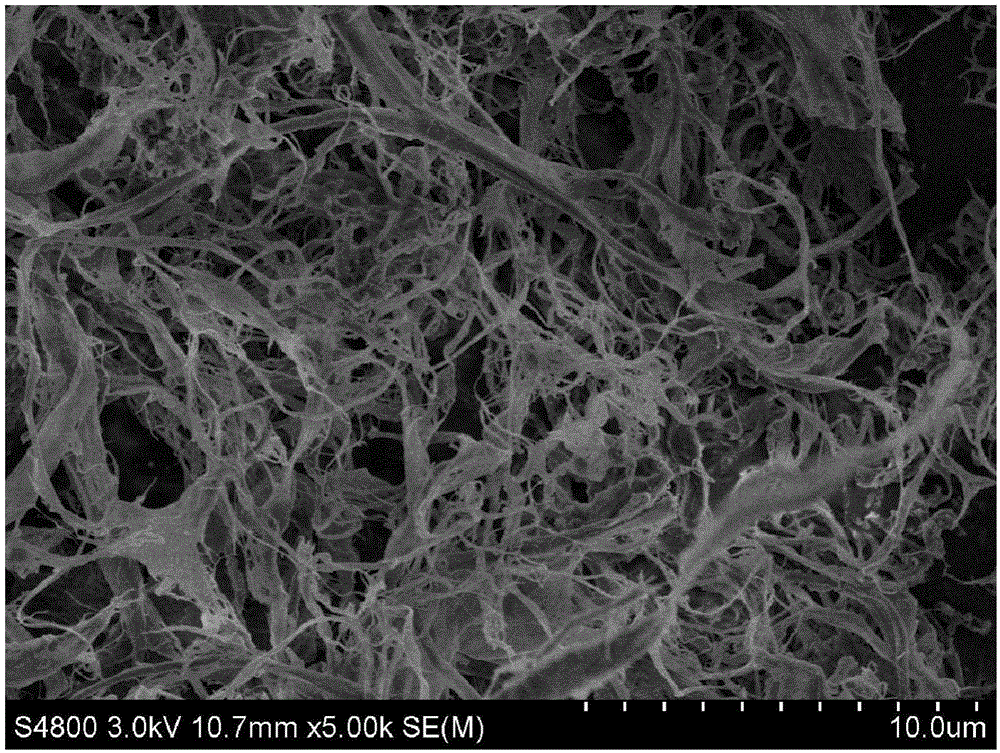

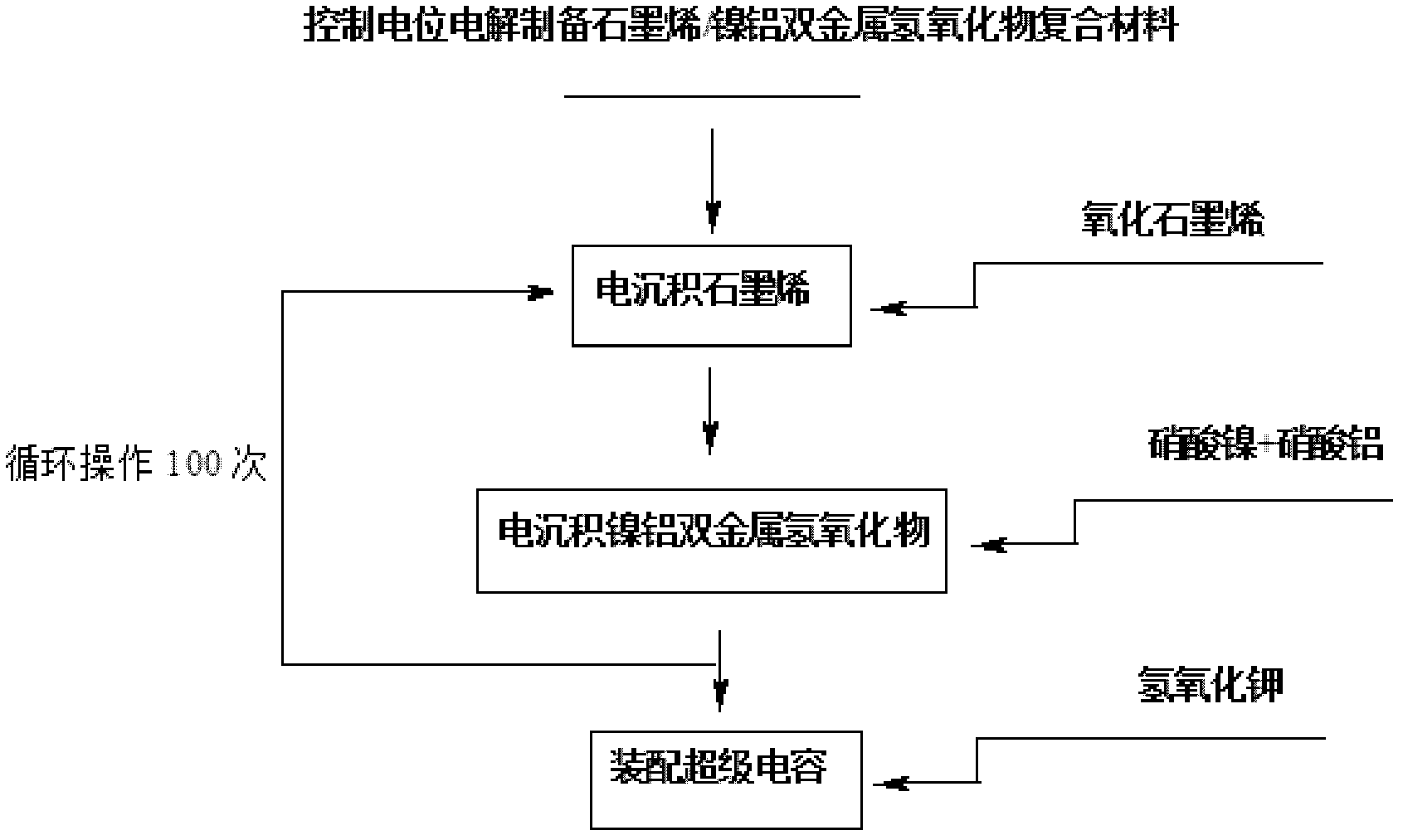

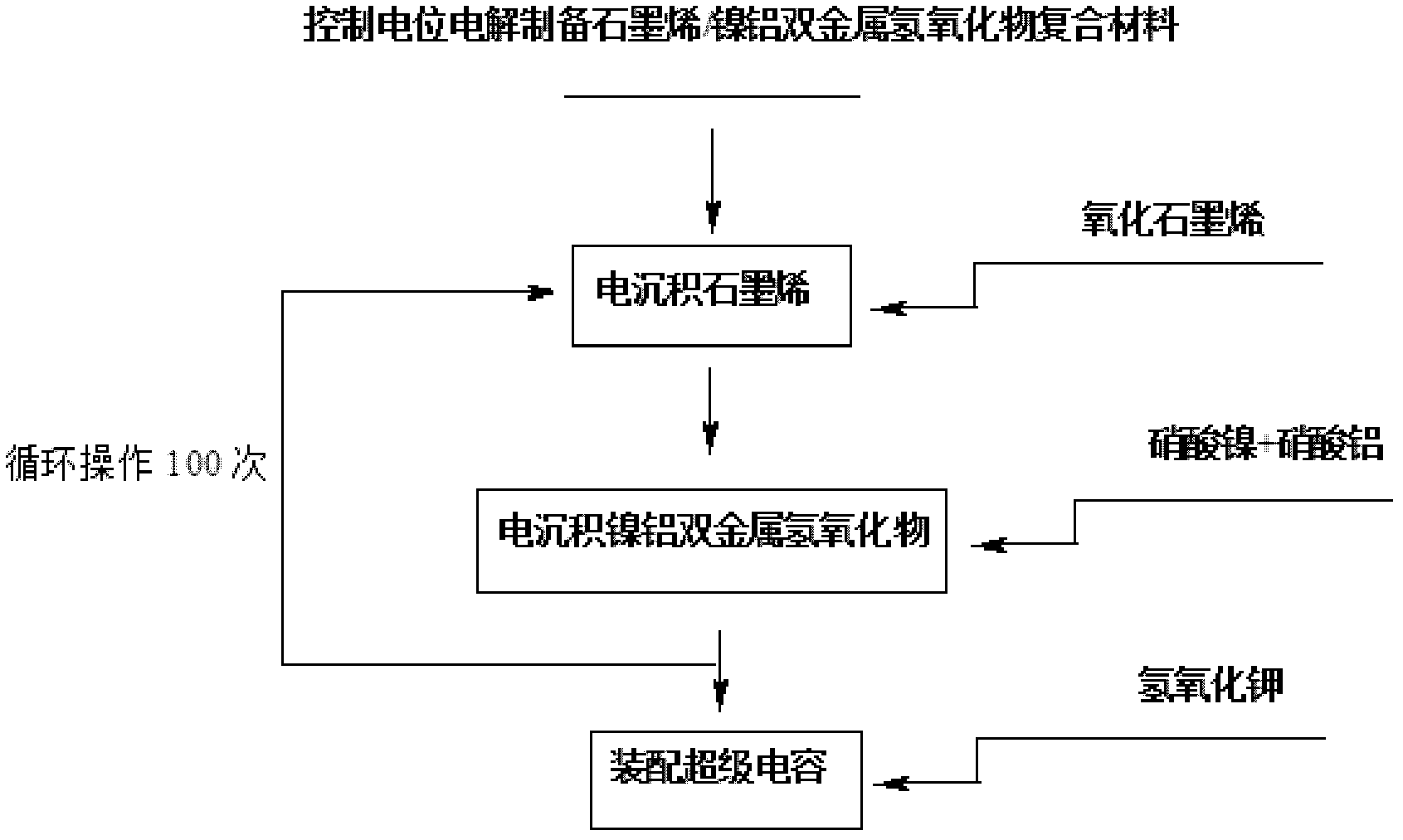

Electrochemical preparation method of graphene/nickel-aluminum bimetal hydroxide composite material for super capacitor

ActiveCN102509640ANo pollutionGood dispersionElectrolytic capacitorsCapacitanceSupporting electrolyte

The invention relates to an electrochemical preparation method of a graphene / nickel-aluminum bimetal hydroxide composite material for a super capacitor, belonging to the technical field of capacitor preparation. The method comprises the following steps of: putting graphite oxide in a beaker; adding deionized water and supporting electrolyte; performing ultrasonic oscillation and constant-potential electrolysis; taking out the electrode; washing the electrode with the deionized water and drying; putting the obtained graphene-modified electrode into a solution containing the precursor of nickel salt and aluminum salt; adding the supporting electrolyte; performing constant-potential electrolysis for 10 seconds; taking out the electrode; and washing the electrode with the deionized water and drying. In the invention, the electrolysis is performed under controlled potential to electrically and alternately deposit the graphene and bimetal hydroxide on the surface of the electrode, therefore, the reduction and deposition of the graphene oxide are finished at the same time, and more importantly, the accurate control on the layer thickness of graphene as well as the size and distribution density of bimetal hydroxide particles is realized; and moreover, the preparation of the material does not produce the 'three wastes' (waste gas, waste water and waste residues).

Owner:盐城市纺织染整产业园实业开发有限公司

Process for comprehensive utilization of plant discarded matter

InactiveCN100999673AQuality assuranceHigh recovery rateBiofuelsLiquid hydrocarbon mixture productionTarEngineering

The process of comprehensively utilizing plant fibrous waste includes the following steps: depurating plant fibrous waste as material, cutting, drying, burning in a charring furnace at 200-400 deg.c, recovering the plant vinegar liquid with one recovering device connected to the charring furnace, recovering tar, discharging charred plant waste, cooling and recovering and treating the plant char. The present invention has reduced air pollution, high plant vinegar liquid recovering rate, and high plant char yield. The plant char may be used as soil improving agent and fertilizer and pesticide applying assistant.

Owner:孟知云 +1

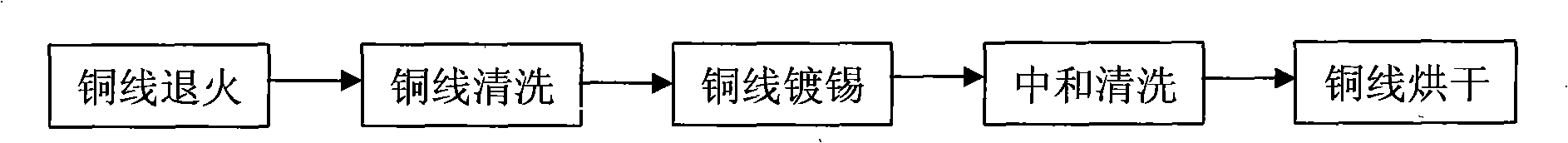

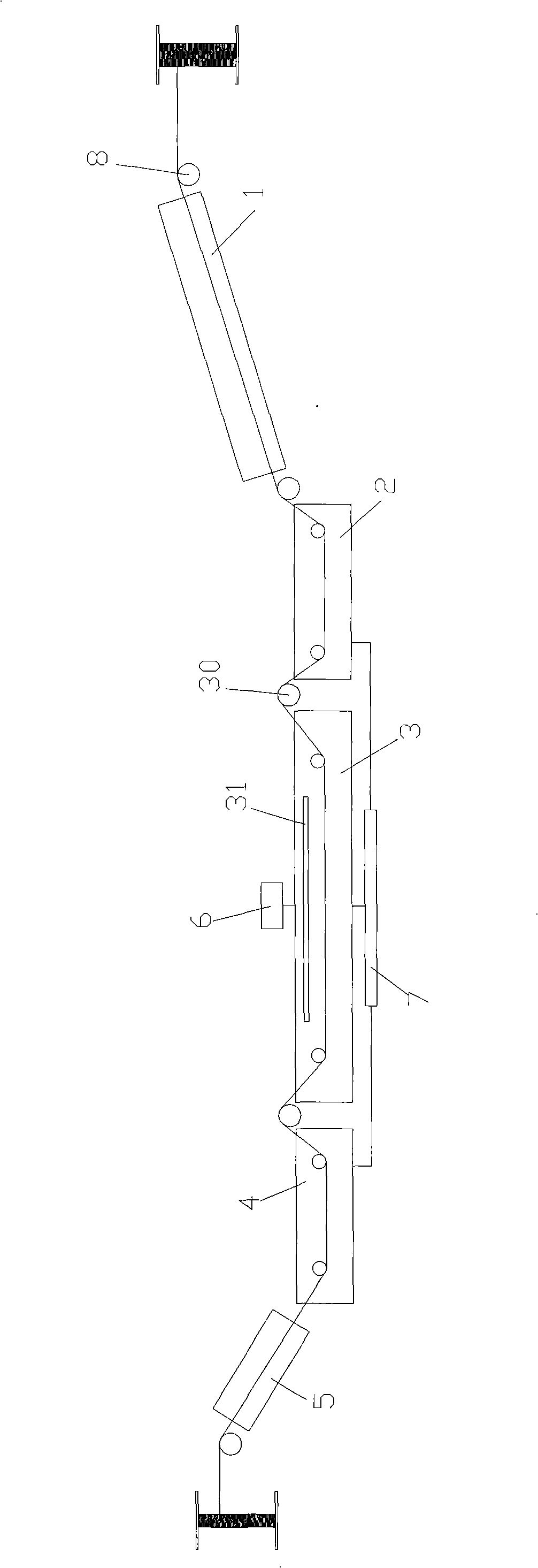

Plating solution formula of copper wire tin plating process and copper wire tin plating process

The invention relates to the electric plating technical field, in particular to a bath formula for a copper wire tin plating process and the copper wire tin plating process completely utilizing the bath formula. In order to be differentiated from the conventional hot tinning, the invention is called the copper wire cold tinning according to the industry habit. Due to the adoption of the technical proposal of the invention, the tinning can be continuously completed without breaking copper wires, and the operation is simple, labor resources are saved and the production efficiency is high; moreover, the production speed of tinning copper wires are in line with the running speed of copper wires, which means that copper wires pass through the production line and immediately become tinning copper wires; the tinning copper wires made by the invention also have the advantages of uniform coating and compact structure, perfect performance; tin materials also belong to environment friendly materials, thereby not causing the environmental pollution and the wasting of resources, saving tins by 70 percent and lowering costs.

Owner:彭旭林 +1

Environment protection type efficient aerating powder for shield construction

ActiveCN101462844AHigh foaming ratioEasy to operateTransportation and packagingMixingFoaming agentSlag

The invention discloses an environmental protection high efficiency foaming agent for shield construction. The foaming agent comprises the following components in percentage by weight: 5 to 20 percent of aliphatic alcohol polyethenoxy ether sulfate, 1 to 8 percent of alcohol amide, 0.5 to 8 percent of alcohol ether, and 64 to 93.5 percent of water. The foaming agent for shield construction has a high foaming ratio and produces abundant and fine foams with even diameter distribution. The produced bubbles have small pores, good lubricity and stability, simple production operation, and lower cost. The foaming agent can better meet the requirements of the slag soil improvement during the process of earth pressure balanced shield.

Owner:GUANGZHOU AORUN SYNTHETIC MATERIAL

Detergent for piggery of lactation sows

InactiveCN105255607AEasy to cleanPlay a role in killing insectsBiocideArthropodicidesPollutionEthanol

The invention discloses a detergent for a piggery of lactation sows, relating to the technical field of breeding industry. The detergent is prepared from the following raw materials in parts by weight: 50-60 parts of straw ash, 25-30 parts of tea seed s cakes, 15-20 parts of calamine powder, 12-15 parts of coffee grounds, 10-13 parts of a deodorant, 15-20 parts of folium artemisiae argyi, 15-20 parts of cortex meliae, 12-16 parts of sophora japonica, 10-14 parts of onions, 8-12 parts of mustard, 8-12 parts of radix puerariae powder, 6-10 parts of horseradish, 4-6 parts of realgar, 2-5 parts of sulfur, 8-12 parts of table vinegar and 200-300 parts of ethanol. The detergent disclosed by the invention not only has an excellent cleaning effect, but also can take insect killing, sterilizing and deodorizing effects and can be used for effectively improving the sanitation condition of the piggery, so that piglets are promoted to grow; the used raw materials are cheap and available; and environment pollution caused by wastewater obtained after the piggery is cleaned can be avoided.

Owner:王付献

Poly-pressed bait for trap fishing and preparation method thereof

ActiveCN101971926AOvercome the disadvantage of easy dispersionImprove solubilityAnimal feeding stuffOther angling devicesShrimpZoology

The invention relates to poly-pressed bait for trap fishing and a preparation method thereof. The bait comprises rice, corn, wheat bran, fermented wheat dry powder, shrimp meal, rice bran, alpha-starch, amino acid, phagostimulant, egg milk essence and the like. The preparation method of the bait comprises the following steps of: drying the rice, the corn and the wheat bran according to certain weight parts and grinding; adding the fermented wheat dry powder and the rice bran and mixing; adding the amino acid, the phagostimulant and the egg milk essence; mixing uniformly; adding the alpha-starch and stirring; spraying water to control water content to be 10 percent; poly-pressing the mixture to obtain flat square block bait; and molding and drying the bait. The physical structure of powder bait is changed and a fixed bait block is drawn to a certain fishing point under water by a rope and a fishing line, so that fixed-point trap fishing and fishing are realized.

Owner:湖北龙王恨渔具集团有限公司

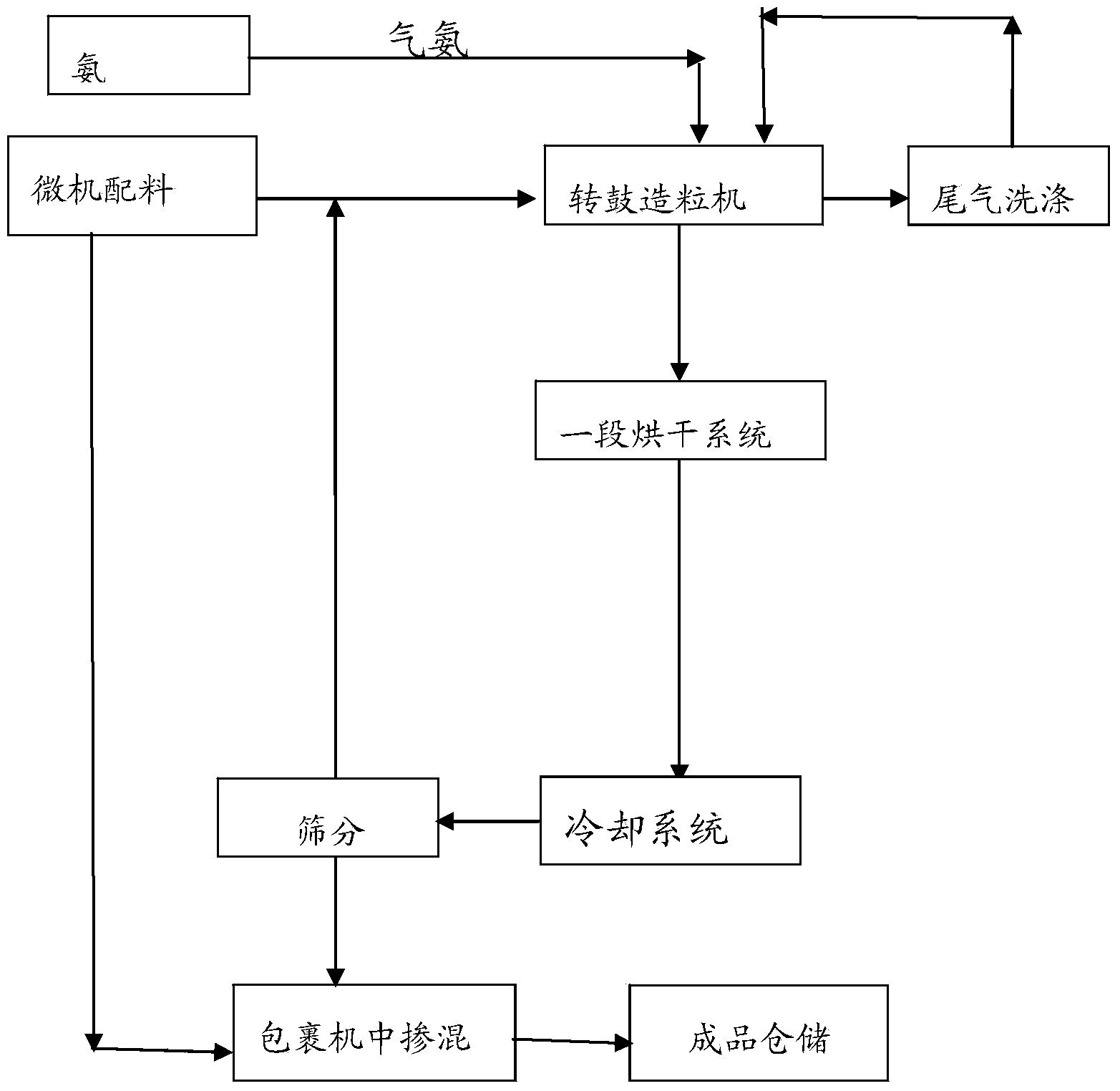

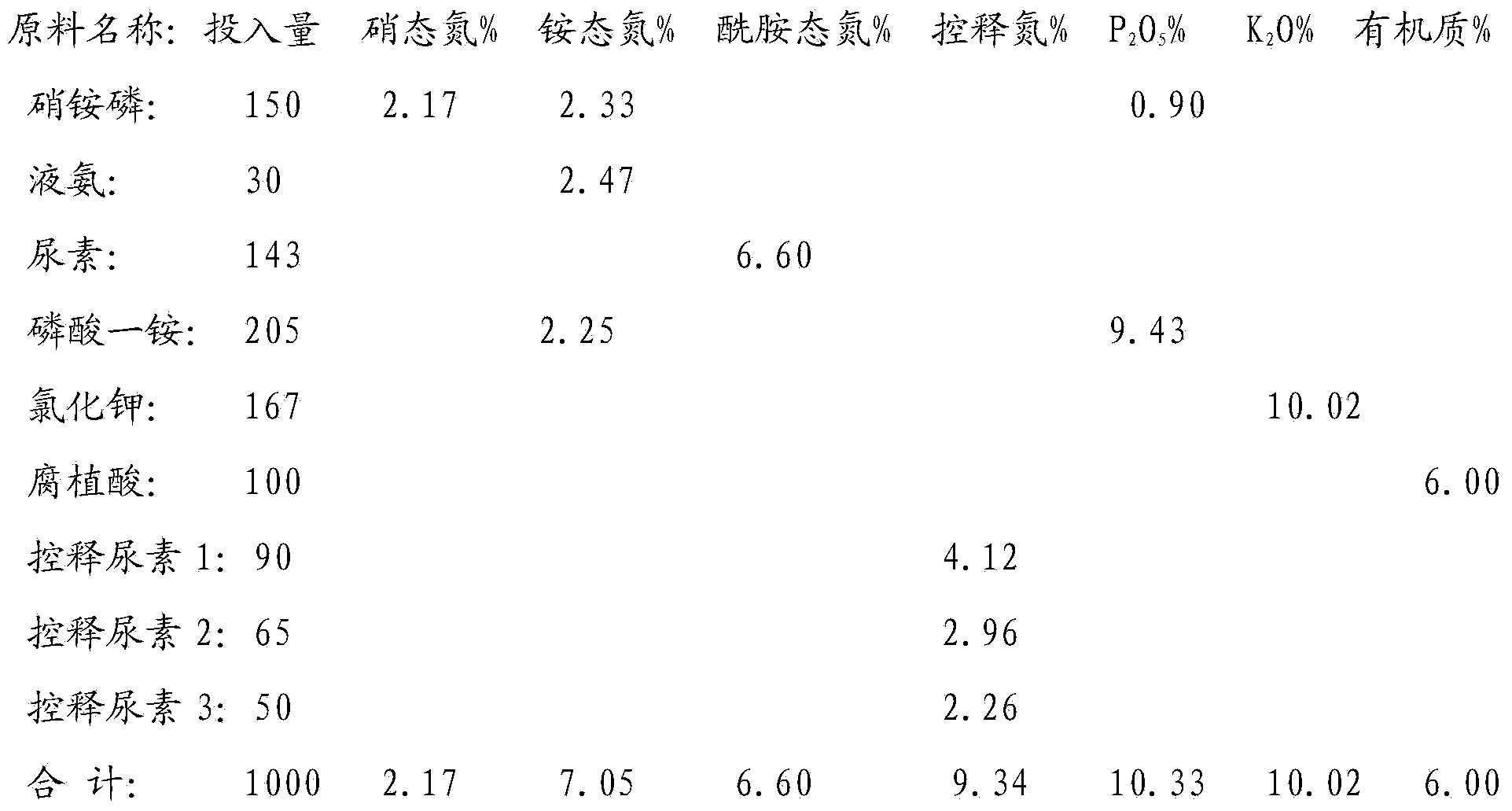

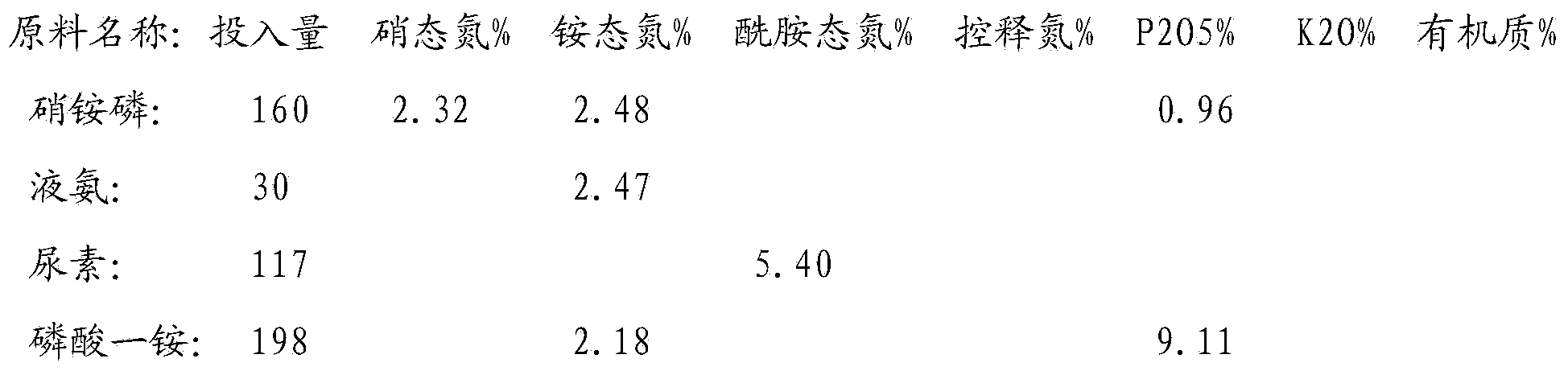

Whole-process nutrient supply type composite fertilizer and preparation method thereof

The invention discloses a whole-process nutrient supply type composite fertilizer and a preparation method thereof. A raw material containing nitrate nitrogen, ammonium nitrogen, amide nitrogen, controlled release nitrogen and organic matters is added in the material. The components of the whole-process nutrient feeding type composite fertilizer are effectively proportioned in percentage by mass on the basis of nitrogen content: 2-4% of nitrate nitrogen, 5-8% of ammonium nitrogen, 5-8% of amide nitrogen and 6-10% of controlled release nitrogen, the contents of phosphorus and potassium are determined according to different product proportions, and the content of the organic matters is not less than 6%. In the production process, the viscosity of urea nitrate generated in a reaction of ammonium nitrate phosphate and urea and granulation tail gas washing water are used as liquid phase amount necessary for granulation to finish the material granulation process, in order to prevent excessive urea nitrate from being generated in the granulation process, ammonia gas is directly introduced into the material layer of a rotor drum granulator to finish the ammoniation treatment of ammonium nitrate phosphate and control the quantity of the urea nitrate generated in the reaction. The fertilizer not only can improve the utilization rate of fertilizer nutrients and ensure the whole-process nutrient supply of crops so as to increase the yield of the crops and improve the quality, but also can avoid harm caused by escherichia coli and such toxic substances as heavy metal, improve the soil, reduce the soil salinity and fertilize the land.

Owner:天津芦阳肥业股份有限公司

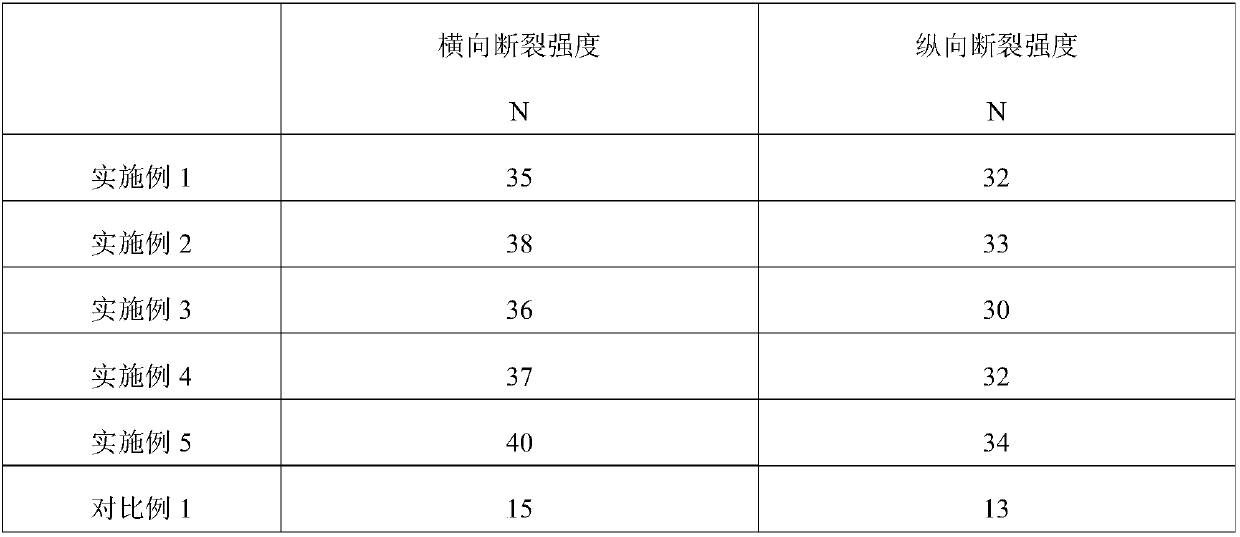

Mulching film prepared by utilizing rice straw and preparation method thereof

InactiveCN107915868AImprove mechanical propertiesIncreased Nitrogen and PotassiumCultivating equipmentsPaper material treatmentRice strawCorn starch

The invention provides a mulching film prepared by utilizing rice straw and a preparation method thereof and relates to the field of crop straw utilization. The mulching film comprises, by weight, 60-80% of rice straw fiber, 10-30% of waste silk fiber, 1-3% of biological organic fertilizer, 3-10% of polyvinyl alcohol, 1-5% of corn starch, 1-3% of glycerin, 1-3% of sorbitol fatty acid ester and 0.1-0.5% of mineral. The preparation method includes following steps: preparing the rice straw fiber; treating the waste silk fiber; performing nonwoven networking; bonding and curing. The mulching filmhas high strength and air permeability and is degradable, a lot of cellulose after degradation can play a role in improving soil, and utilization value is increased.

Owner:柳州市柳科科技有限公司

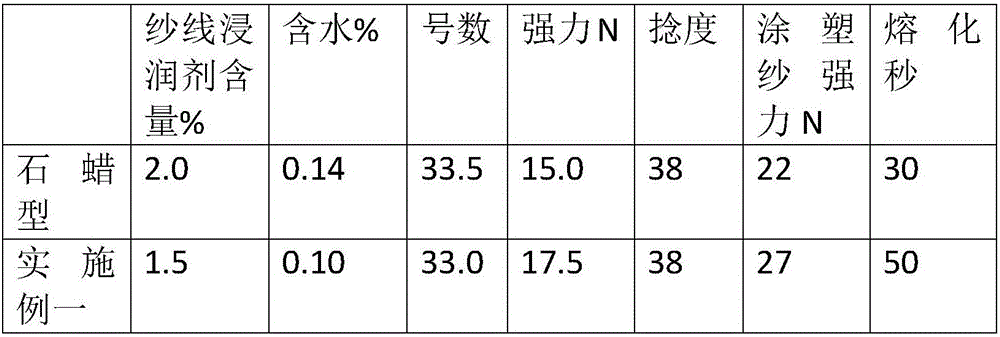

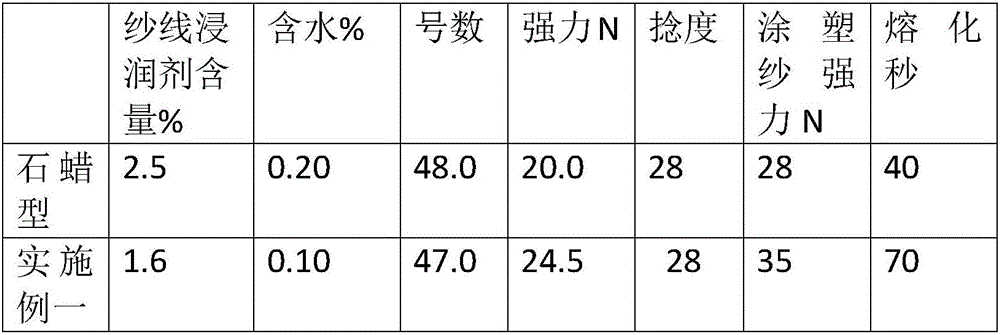

Microcrystalline-wax-containing enhanced textile-type wetting agent

The invention provides a microcrystalline-wax-containing enhanced textile-type wetting agent which comprises the following components in parts by weight: 0.5-2.5 parts of water-based epoxy resin, 2.0-5.0 parts of color fixative, 1.0-4.0 parts of water-based unsaturated polyester resin, 0.2-0.5 part of coupling agent, 1.0-3.0 parts of plasticizer, 0.2-0.6 part of microcrystalline wax, 0.2-0.6 part of lubricating oil, 0.1-0.3 part of cationic cartridge, 0.5-1.0 part of emulsifier, 0.5-1 part of coemulsifier, 0.02-0.06 part of pH regulator and 80-90 parts of deionized water. Compared with the traditional paraffin-type wetting agent and resin-type wetting agent, the wetting agent provided by the invention has the advantages of high wire drawing and film forming strength, high yarn flexibility and elasticity, favorable processability and no hair feather. The wetting agent provided by the invention has the characteristics of low viscosity, favorable flowability and high recoverability, and does not generate oil sludge; and the recovered wetting agent and wastewater are recyclable, thereby avoiding environmental pollution.

Owner:TIANJIN HENGTONG IND & TRADE DEV CO LTD

Feed special for high-yield and high-quality leeches

InactiveCN106260751APromote digestionPromote growthFood processingClimate change adaptationDiseaseBetaine

The invention discloses a feed special for high-yield and high-quality leeches. The feed is prepared from, by weight, 20-35 parts of fish meal, 5-15 parts of acetes chinensis, 20-40 parts of animal blood, 20-30 parts of earthworms, 5-15 parts of snails, 5-12 parts of freshwater mussels, 5-15 parts of puffed peanut meal, 5-15 parts of pregelatinized corn starch, 20-40 parts of millet, 2-8 parts of cottonseed cake, 2-10 parts of fermented biological protein, 1-10 parts of brewer's grain, 1-3 parts of kelp powder, 2-15 parts of modified gelatin, 1-6 parts of deep sea fish oil, 2-8 parts of corn oil, 1-5 parts of grape seed oil, 1-2 parts of soybean phospholipid, 1-2 parts of betaine, 0.01-0.06 part of composite trace elements, 0.2-0.8 part of vitamins, 0.2-1 part of mineral salt and 1-3 parts of EM bacterial solution. The feed can provide adequate balanced protein and energy for the leeches, effectively promote leech growth and improve the digestion and absorption rate and can improve the disease immunity of leeches.

Owner:安徽泰益生物科技有限公司

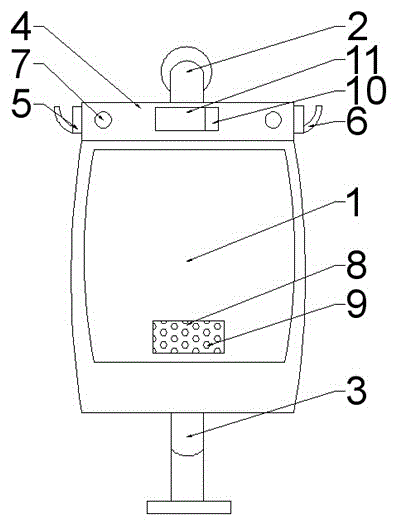

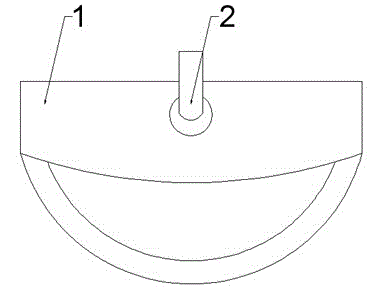

Multifunctional urinal

ActiveCN104060672AConvenient plug-inWill not cause environmental pollutionUrinalsLavatory sanitoryShortest distanceEngineering

The invention relates to a multifunctional urinal which comprises a pool body, a water inlet pipe and a sewer pipe. The upper end of the pool body is fixedly connected with a functional box; both the near left and right ends inside the functional box are fixedly connected with two electrical telescopic devices for extending and retracting left and right; the upper end of the functional box is fixedly connected with the lower end of the water inlet pipe; an electronic valve is fixedly connected inside the functional box; a water inlet of the electronic valve is communicated with a water outlet of the water inlet pipe; a water outlet of the electronic valve is communicated with the inside of the pool body; both left and right ends of the functional box are provided with through holes corresponding to the electrical telescopic device; and telescopic rods on the electrical telescopic device extend out of the functional box through the through holes to translate left and right. The multifunctional urinal disclosed by the invention adopts an electronic scoring manner to attract people to urinate into the urinal so as to enable people to be actively close to the urinal, and thus, the condition that urine is sprayed outside to pollute the environment cannot be generated; and moreover, by telescopic hanging rods, the multifunctional urinal is convenient for people to hang various articles outside and the articles cannot be dirtied due to the excessively short distance between hooks.

Owner:刘瑞

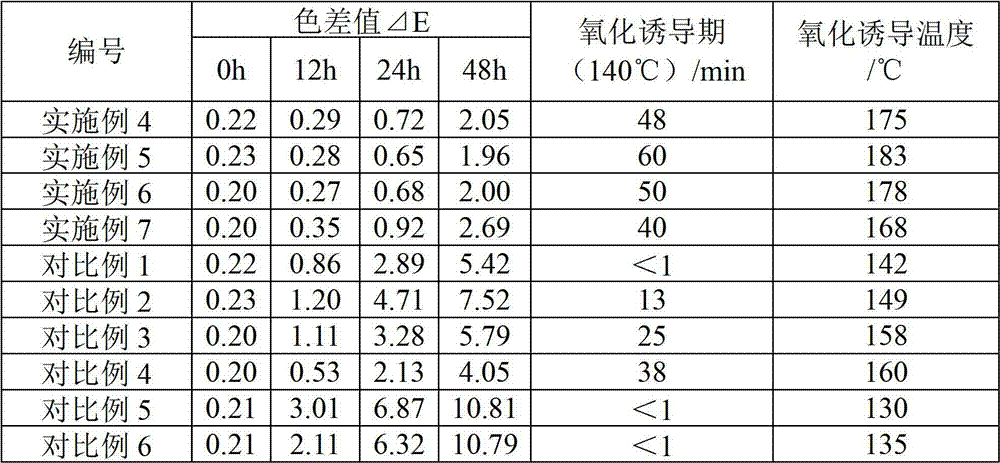

Antioxidant composition and its preparation method, styrene-based thermoplastic elastomer and its preparation method

The invention discloses an antioxidant composition, wherein, wherein the antioxidant composition comprises beta-(3,5-di-tert-butyl-4-hydroxy phenyl) n-octadecylpropionate, tris(2,4-di-tert-butylphenyl)phosphate and dilauryl dithiodipropionate, and the invention also provides a preparation method. The invention also provides a styrene-based thermoplastic elastomer, wherein the styrene-based thermoplastic elastomer contains a styrene-based segmented copolymer and the antioxidant composition, the antioxidant composition is the antioxidant composition provided by the invention, and the invention also provides a preparation method of the styrene-based thermoplastic elastomer. The antioxidant composition is used in the styrene-based thermoplastic elastomer, aging resistance and anti-yellowing performance of the styrene-based thermoplastic elastomer can be greatly increased; the ingredients of the antioxidant composition are harmfulless substances, so that environmental pollution can not be generated.

Owner:CHINA PETROLEUM & CHEM CORP +1

Mouse killing fumigation bomb and mouse killing method

InactiveCN1561719AGood rodent control effectEasy to implementBiocideAnimal repellantsDomestic animalSmoke

A fumigating bullet for killing mice in their cave is composed of cylindrical shell, clay block at one end of said shell, a nozzle at another end of said shell, fumigant in the shell, and fuse. Its fumigating method includes determining the primary entrance of the cave, blocking other entrances or exits, igniting the fuse, inserting it in the primary entrance, and spraying smoke in cave to kill the mice in wave.

Owner:李富绵

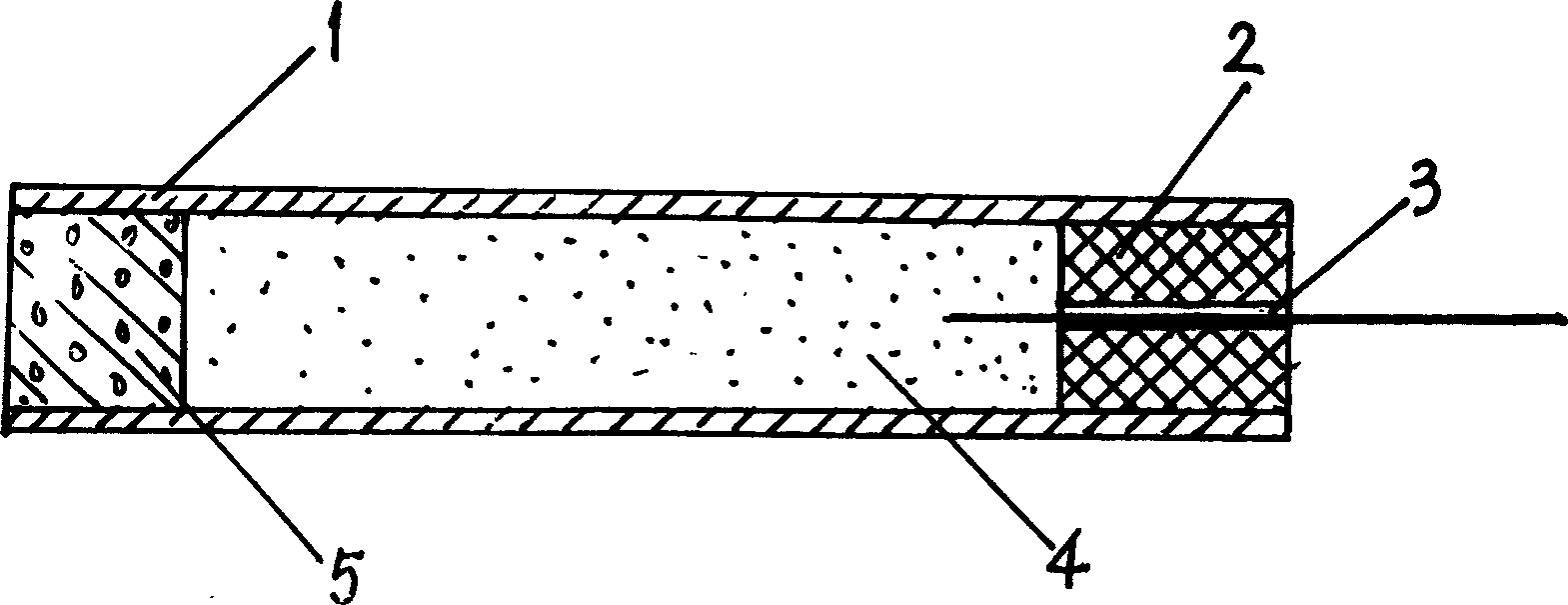

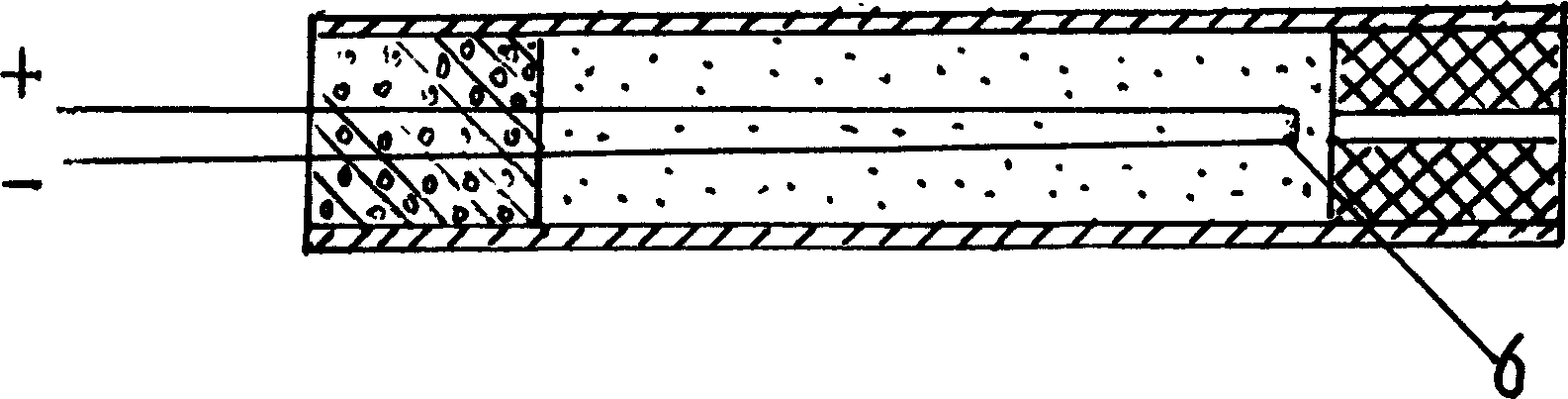

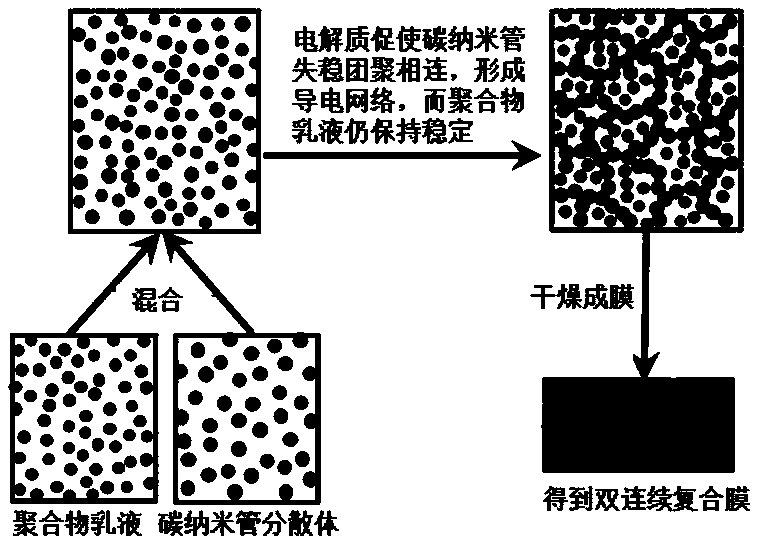

Carbon nanotube polymer composite conductive material and preparation method thereof

ActiveCN109754907AImproved random distributionAdd lessNon-conductive material with dispersed conductive materialCable/conductor manufactureOrganic solventCarbon nanotube

The invention relates to a carbon nanotube polymer composite conductive material. The carbon nanotube polymer composite conductive material is prepared from the following components in percentage by mass: 92-99.95% of polymer emulsion, and 0.05-8% of carbon nanotubes. A preparation method of the carbon nanotube polymer composite conductive material comprises the following steps that firstly, the carbon nanotube is dispersed in an aqueous solution through a dispersing agent and then evenly mixed with the polymer emulsion, an electrolyte solution is added to enable the carbon nanotubes to lose stability to form a mutually-connected gel network, thus agglomeration of the polymer emulsion is avoided, and drying is conducted. The carbon nanotube polymer composite conductive material and the preparation method have the beneficial effects that random distribution of the carbon nanotubes in polymer is effectively improved, the addition quantity of the carbon nanotubes is decreased, the contactresistance between the carbon nanotubes is lowered, and the conductivity of the composite material is improved; related equipment is simple, the operation process is simple and easy, and mass production is achieved advantageously; and water serves as the solvent, an organic solvent or toxic substances are avoided, and environmental pollution is avoided.

Owner:KUNMING UNIV OF SCI & TECH

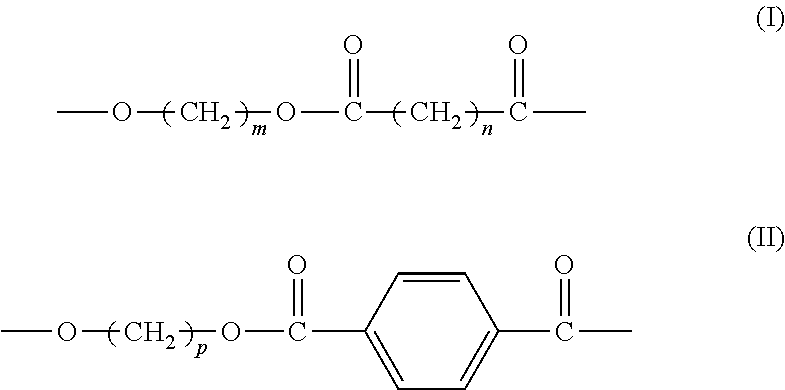

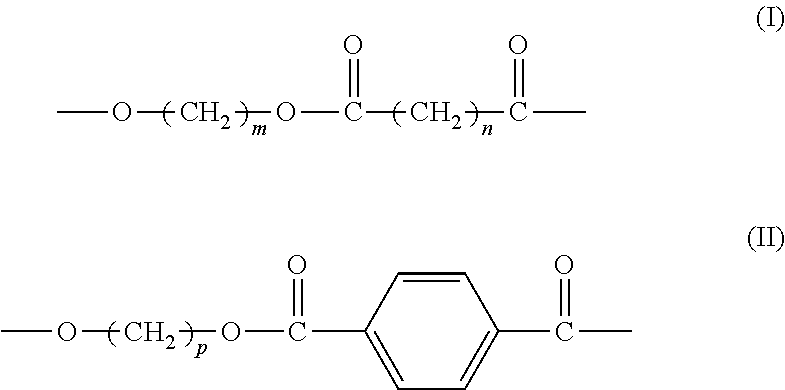

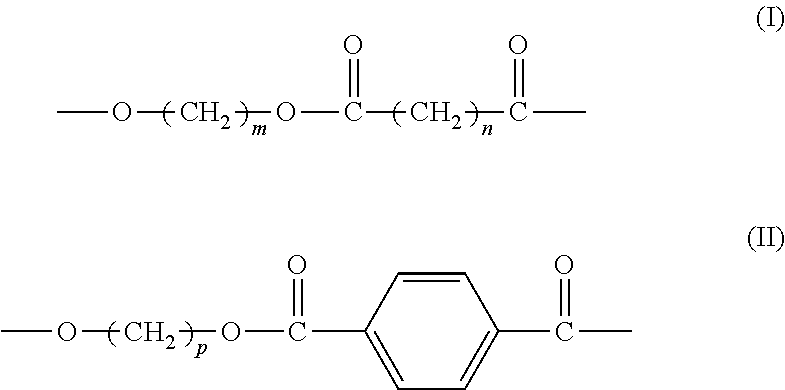

Biodegradable Composite, The Preparation Process Thereof, And A Disposable Article Made Therefrom

The present invention relates to a biodegradable composite and its preparation process, which composite is prepared by mixing feed stocks comprising a polylactic acid, an aliphatic-aromatic copolyester A, an aliphatic-aromatic copolyester B and an organic peroxide at a temperature between about 100 and about 200° C. The present invention also relates to a disposable article, which is prepared from said biodegradable composite.

Owner:CHINA PETROCHEMICAL CORP +1

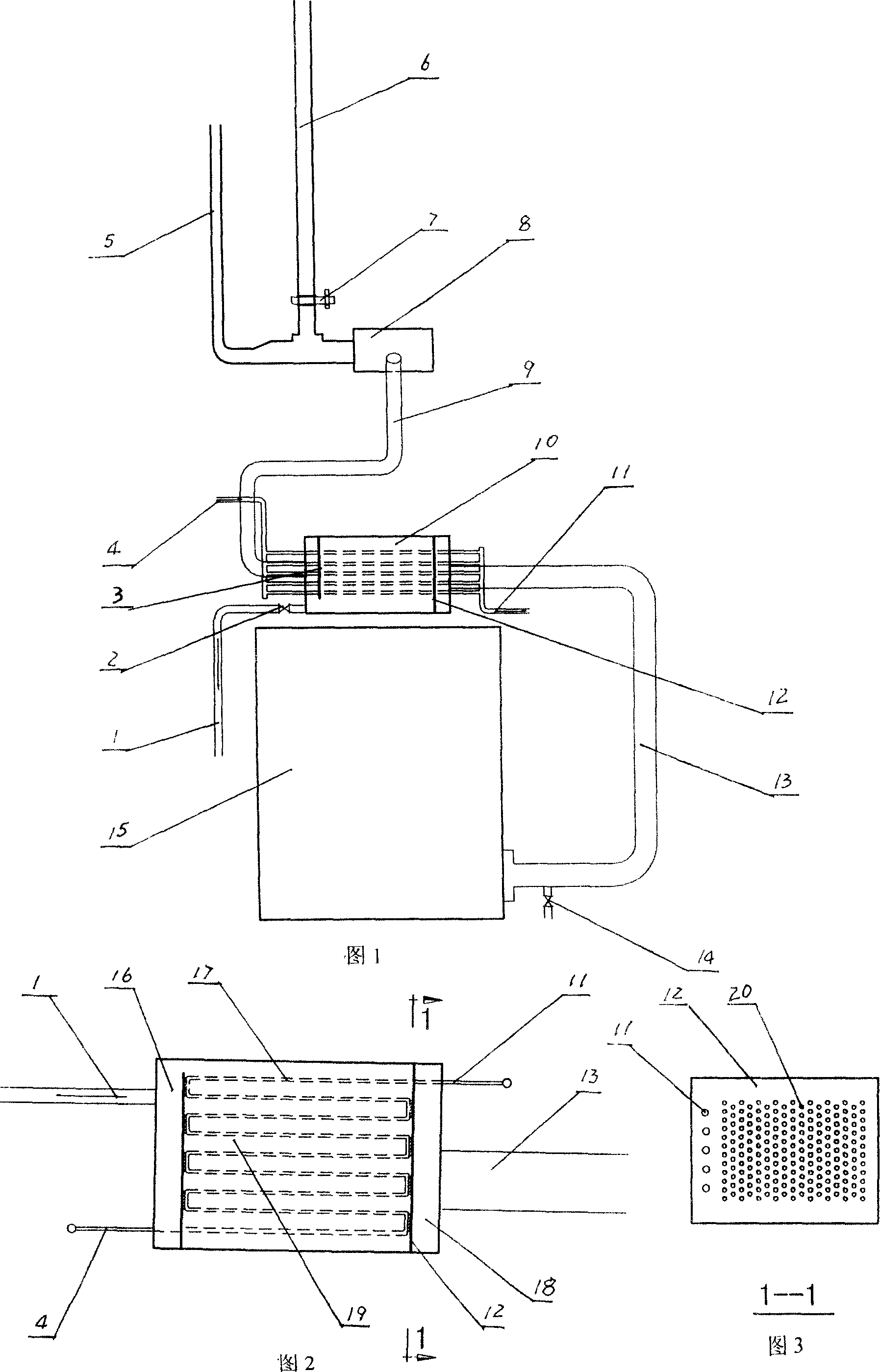

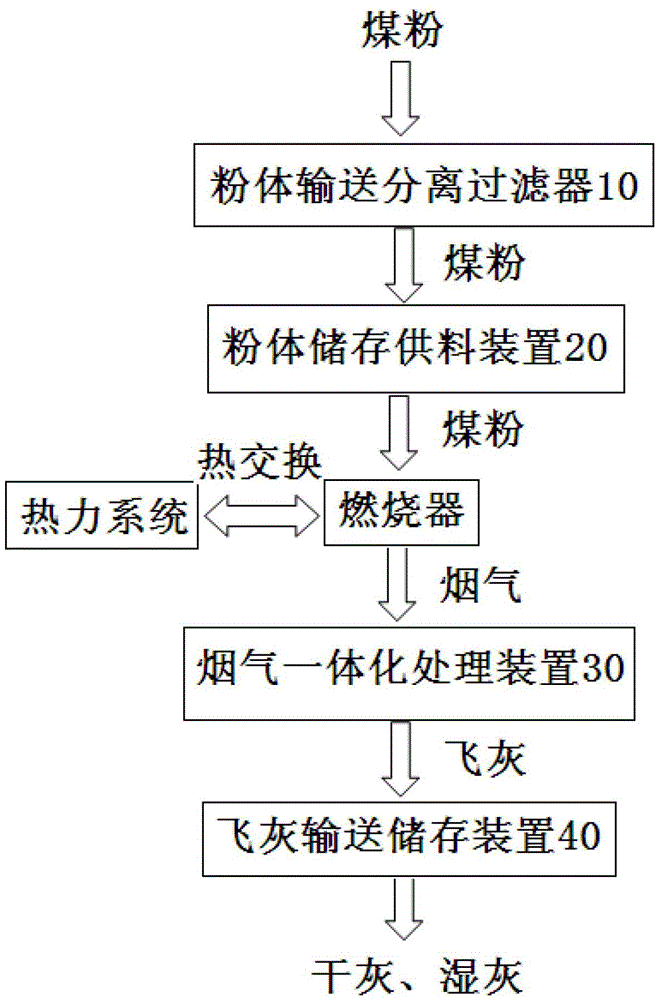

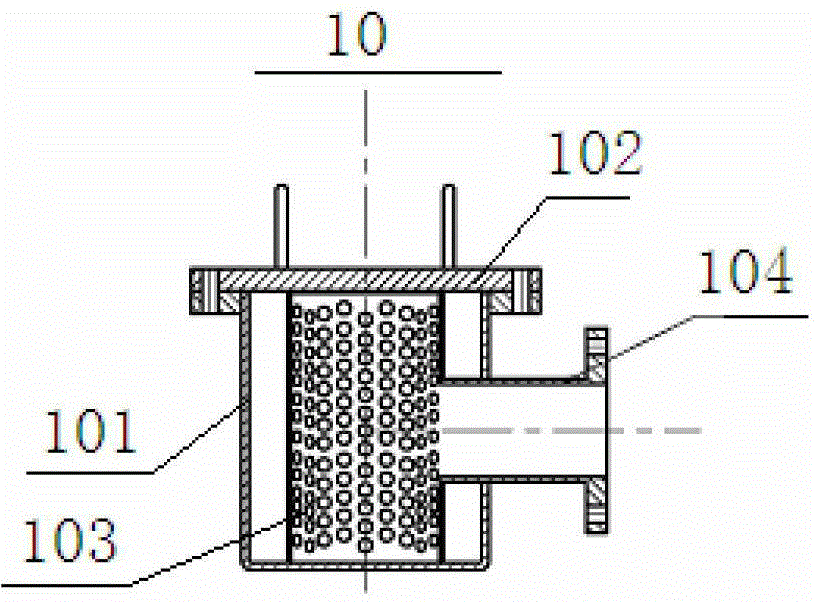

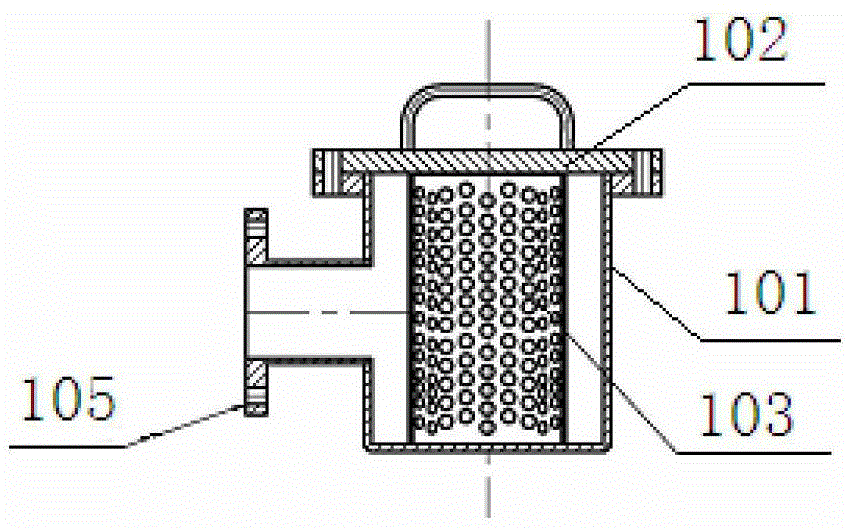

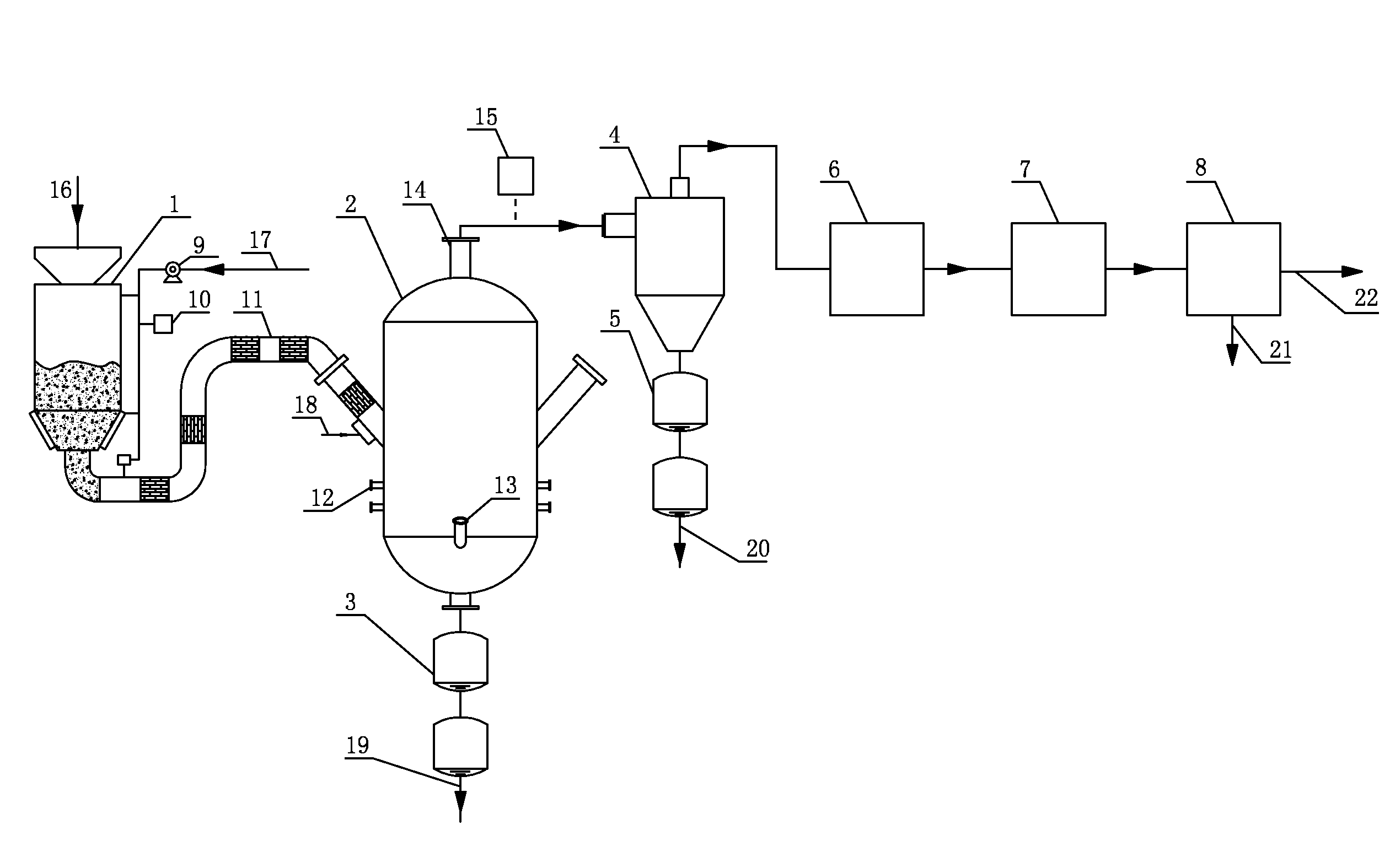

Pulverized coal industrial boiler system

ActiveCN102980200AStable deliveryDischarge cleaningSolid removalLump/pulverulent fuel feeder/distributionCombustorFlue gas

The invention relates to a pulverized coal industrial boiler system. The pulverized coal industrial boiler system is characterized by comprising a pulverized coal feeding and separating filter, a pulverized coal storing and feeding device, a boiler burner, a flue gas integrated treatment device, a fly ash delivering and storing device and an inert gas protecting device; the feeding and separating filter filters pulverized coal and then conveys the pulverized coal to the pulverized coal storing and feeding device, the pulverized coal storing and feeding device stores the pulverized coal and supplies the pulverized coal to the boiler burner, the boiler burner exchanges heat with a thermodynamic system during the burning process and supplies hot water or steam to users; and flue gas after the combustion of the boiler burner is treated through the flue gas integrated treatment device and is delivered to the fly ash delivering and storing device, wherein the pulverized coal in the pulverized coal storing and feeding device needs to be protected through inertia gases which are provided by the inert gas protecting device during the storing process. The system integrates pulverized coal delivering, storing, feeding, flue gas treating and recycling into a whole, has high function integration level, a small occupation area, low operation cost, high economy and no dust and flue gas leakage, cannot cause environmental pollution and can be widely used for a pulverized coal feeding process.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

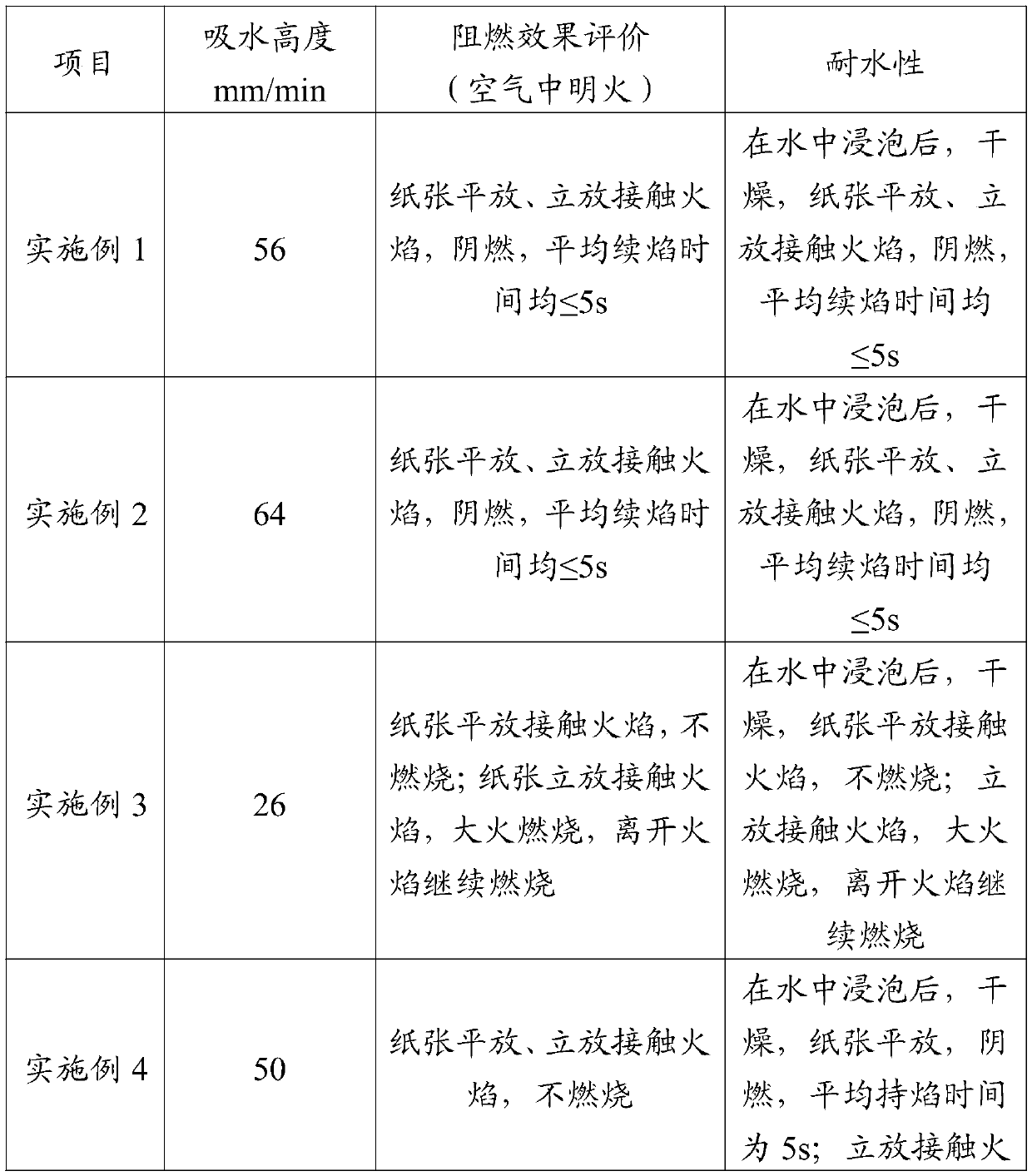

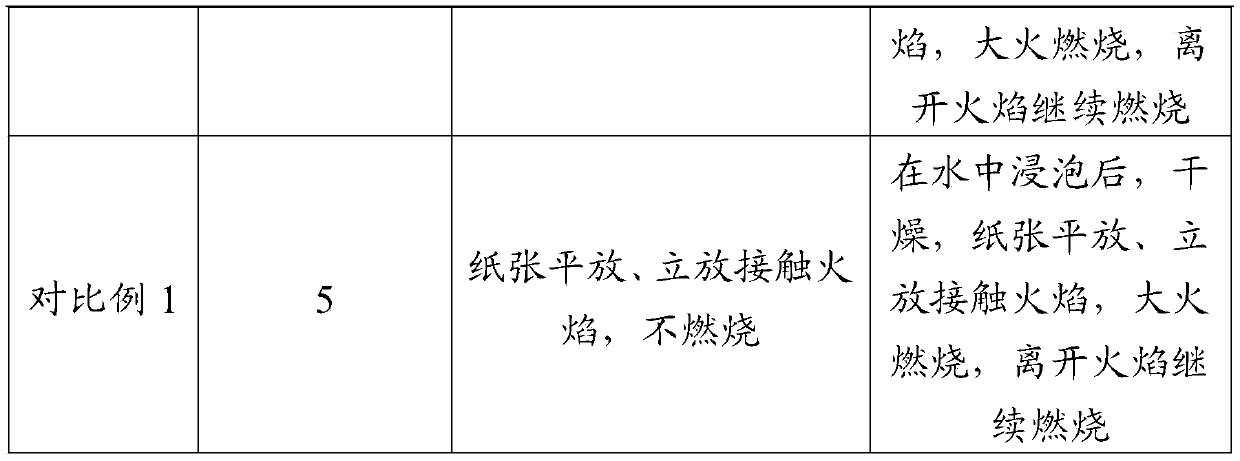

Waterproof and flame-retardant paper, and preparation method and application thereof

InactiveCN110644288AImprove water absorptionImprove water resistanceDefoamers additionSpecial paperPolymer sciencePlant fibre

The invention provides a waterproof and flame-retardant paper, and a preparation method and an application thereof, and belongs to the technical field of materials. The waterproof and flame-retardantpaper comprises fibers and assistants; the fibers comprise 70-90 wt% of flame-retardant fibers and 10-30 wt% of plant fibers; and the assistants comprise a wet strength agent and a defoaming agent, the using amount of the wet strength agent is 0.5-1.0% of the mass of the fibers, and the using amount of the defoaming agent is 0.01-0.1% of the mass of the fibers. The waterproof and flame-retardant paper has excellent water absorption, water resistance and flame retardancy, still has excellent flame retardancy after being soaked in water, has the advantage of low cost, and is suitable for being industrially applied.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

Graphene-based metal abrasion intelligent repair material and preparation method thereof

InactiveCN106635263AGood wear resistanceLow thermal shock resistanceLubricant compositionRevolutions per minuteWater content

The invention relates to a graphene-based metal abrasion intelligent repair material and a preparation method thereof. The repair material provided by the invention consists of the following components according to weight and volume: 5 to 10 g of graphene, 30 to 150 g of serpentine powder, 20 to 40 g of molybdenum powder, 15 to 55 g of rare earth powder, 90 to 210 g of copper powder, 35 to 95 g of nickel powder and 1000 to 2000 ml of 100N base oil. The preparation method comprises the steps of putting the serpentine powder into a plastic ware, rinsing with hot water at the temperature of 80 to 90 DEG C and enabling the water to naturally evaporate; putting the serpentine powder, the molybdenum powder, the rare earth powder, the copper powder and the nickel powder into drying equipment, and drying at the temperature of 110 to 130 DEG C for 100 to 130 minutes, wherein the water content of each of the serpentine powder, the molybdenum powder, the rare earth powder, the copper powder and the nickel powder is less than 2 percent after drying; putting the dried powder into a homogenizer, stirring at the stirring speed of 2000 to 3000 revolutions per minute, adding the base oil after stirring, and continuously stirring for 1 to 10 hours to obtain a colloidal mixture; and putting the colloidal mixture into an ultrasonic dispersing instrument to perform dispersion.

Owner:于贵

Buoy bait for trapping and angling, and its preparation method

Disclosed is a floatation type fishing lure for trapped fishing which integrates the conventional fishing lures, characterized in that the lure also comprises plant stem or leaf fiber whose percentage by weight is 15-50% of the conventional fishing lure in the form of granules with grain size of at least 30 meshes and maximum 100 meshes. The process for preparing the lure includes direct addition method and raw material blending method.

Owner:何蔚蓝

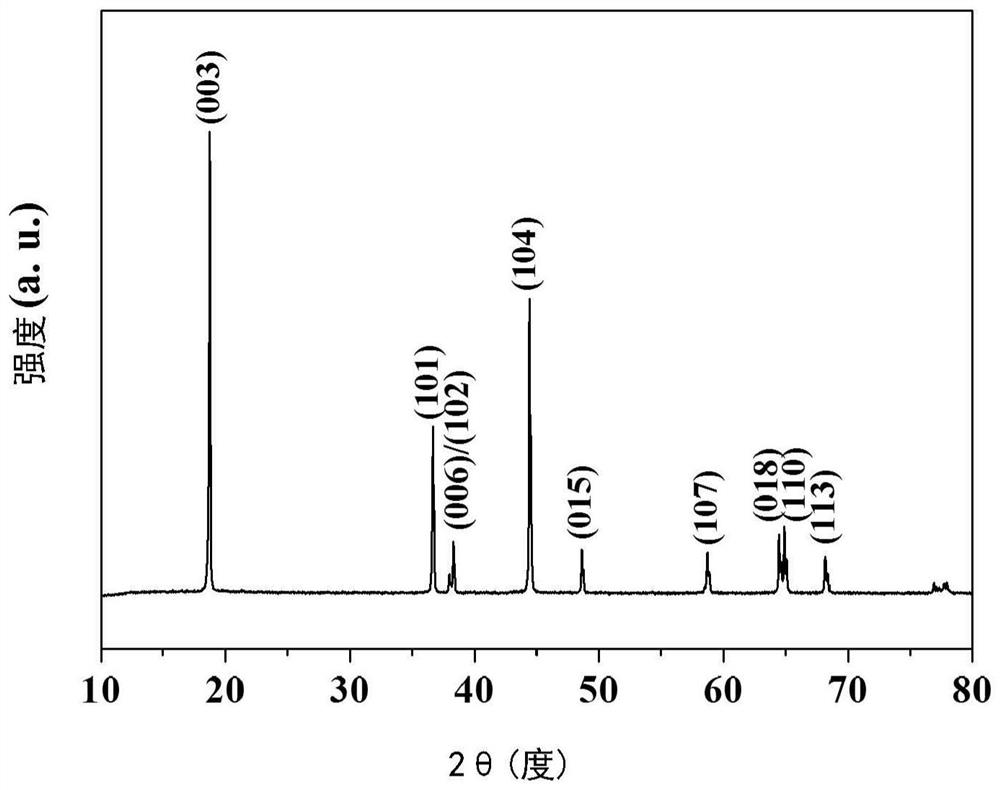

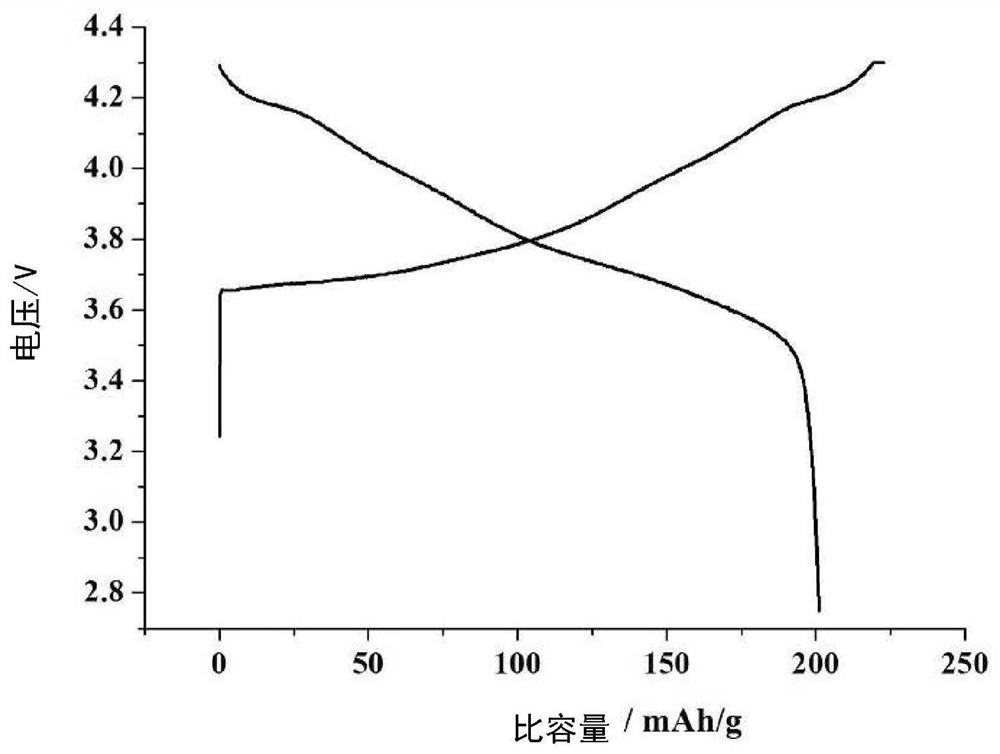

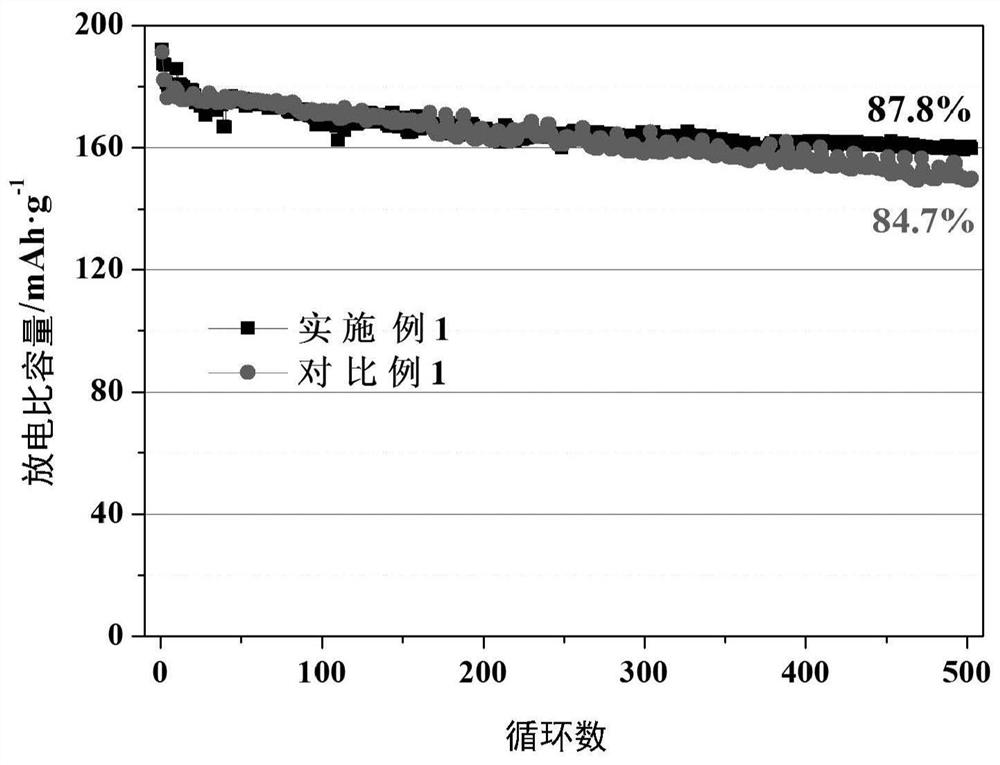

Method for reducing residual alkali of high-nickel ternary material of lithium ion battery

PendingCN113394390AReduce the residual alkali valueDoes not degrade electrochemical performanceCell electrodesSecondary cellsOrganic solventElectrical battery

The invention relates to a method for reducing residual alkali of a high-nickel ternary material of a lithium ion battery. The method comprises the following steps: (1) providing a washing solution, wherein the washing solution comprises water and an organic solvent which is immiscible with the water; (2) washing the high-nickel ternary material of the lithium ion battery by using the washing solution, filtering and drying to obtain an intermediate; and (3) roasting the intermediate in O2 atmosphere to obtain the positive electrode material with low residual alkali value. The method not only reduces the residual alkali value of the high-nickel ternary material, but also improves the electrochemical cycle performance of the material.

Owner:CHINA PETROLEUM & CHEM CORP +1

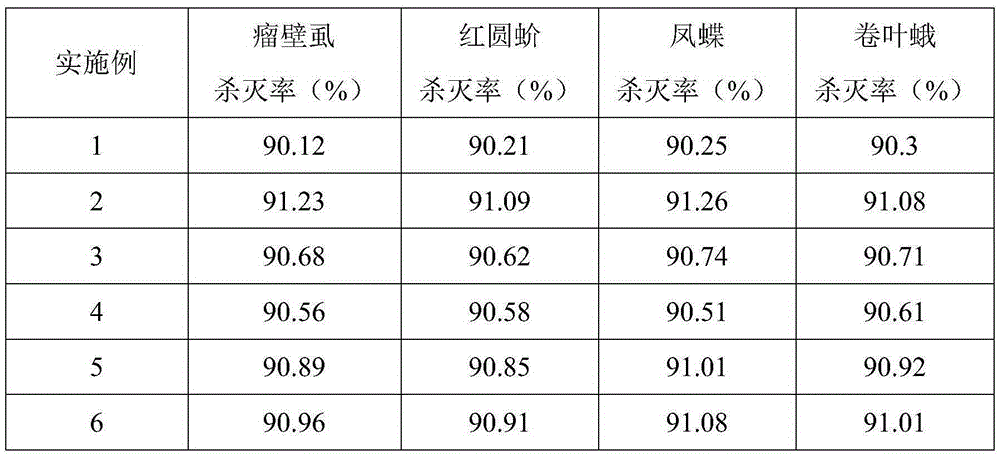

Pesticide, as well as preparation method and application thereof

InactiveCN105379780ANo pollutionWill not cause environmental pollutionBiocideDead animal preservationPaulowniaAdditive ingredient

The invention discloses a pesticide, as well as a preparation method and application thereof, and belongs to the technical field of preparation of pesticides. The pesticide comprises the following raw materials in parts by weight: 30-60 parts of Chinese arborvitae twigs and leaves, 30-60 parts of mint, 30-60 parts of lettuces, 30-40 parts of anabasis aphylla, 30-40 parts of paulownia leaves, 30-40 parts of sophora alopecuroides, 20-30 parts of absinthium, 20-30 parts of yellow ginger, 20-30 parts of aloe and 1000-4000 parts of water. The pesticide is prepared through the steps of extraction of liquid medicines, concentration, drying, crushing, screening, sterilization and the like. The pesticide disclosed by the invention is non-toxic in ingredients, free from residues, pollution-free and environment-friendly; the pesticide disclosed by the invention is simple in production method, low in cost, and good in application effect; the pesticide disclosed by the invention can effectively prevent and treat plant pests including citrus bud mites, aonidiella aurantii, papilionidae, leaf rollers and the like, the one-time kill ratio reaches 90.12% or above, and drug tolerance is not caused.

Owner:广西农垦立新农场有限公司

Leadless silicate glass composition and pipe cone glass for cathode ray tube

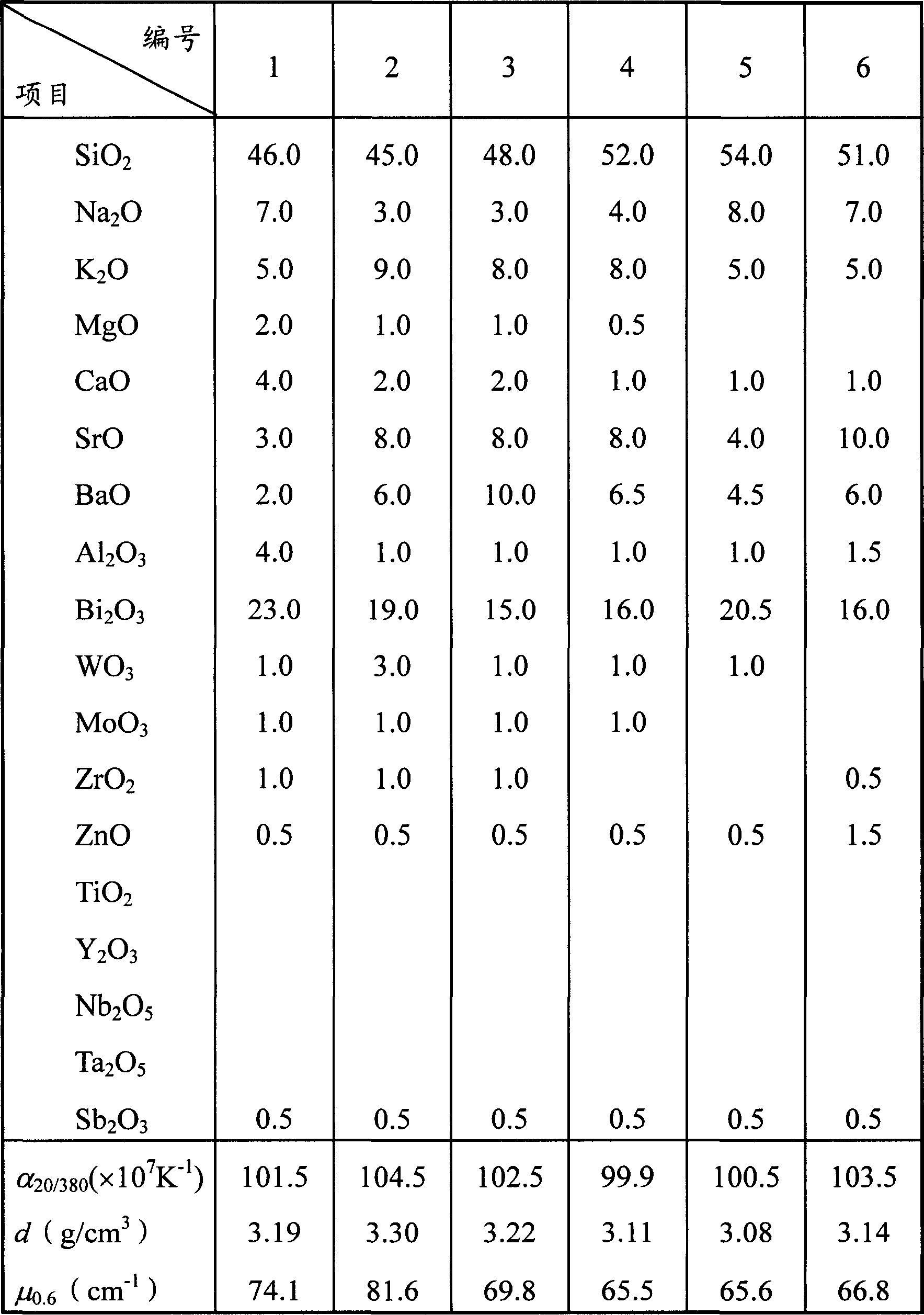

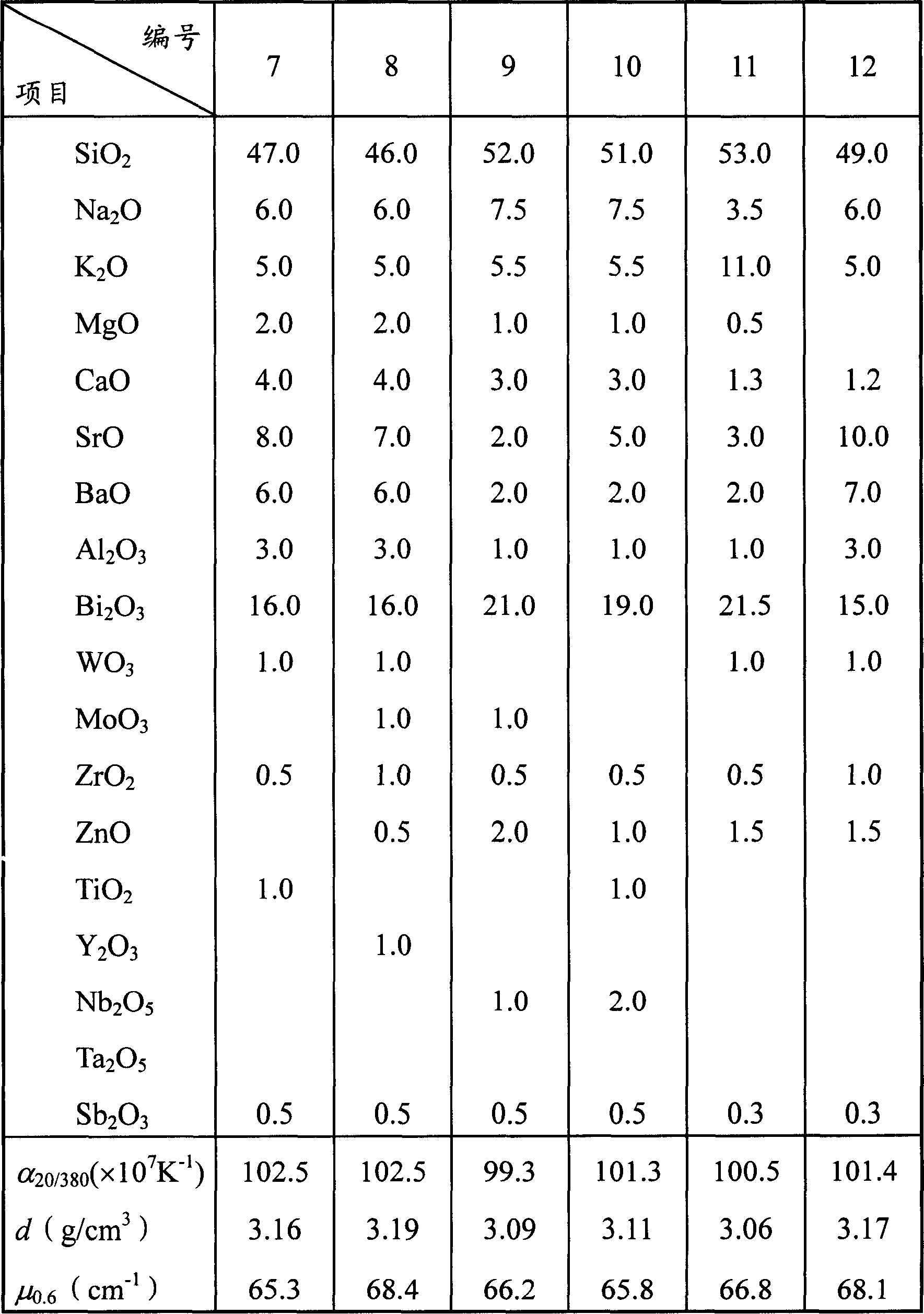

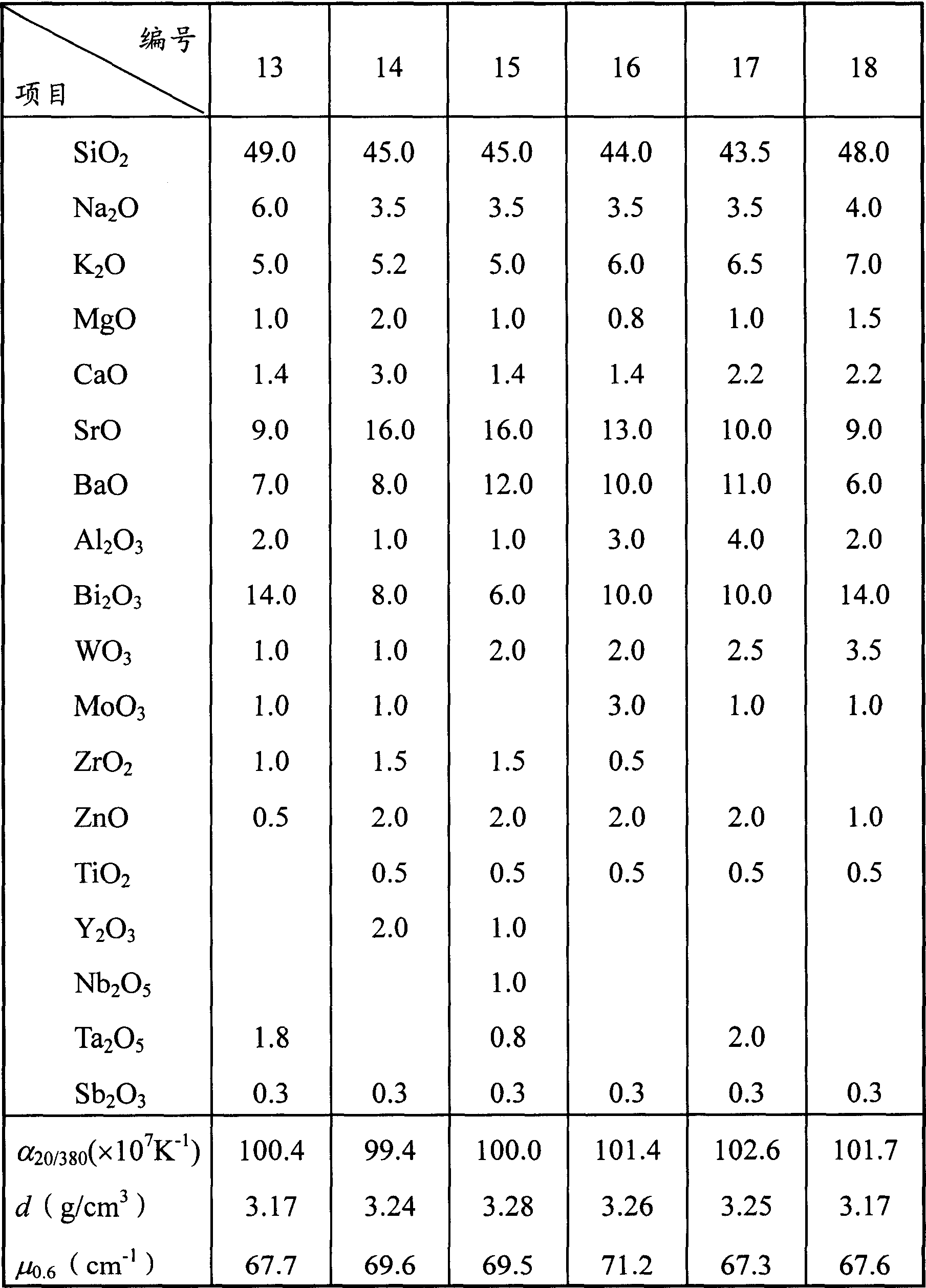

The present invention provides a leadless silicate glass composition and leadless funnel neck glass for cathode ray tube. Its composition contains (by mass percentage): 40-57% of SiO2, 2-8.5% of Na2O, 3.5-12% of K2O, 6-18% of sigma Na2O+K2O, 0-3.5% of MgO, 0.8-4.5% of CaO, 1-18% of SrO, 1-14% of Ba2O, 3-30% of sigma SrO+BaO, 0.5-4.5% of Al2O3, 0-2.5% of ZrO2, 0.5-6% of sigma Al2O3+ZrO2, 0-3% of ZnO, 0-2% of TiO2, 0-4% of sigma ZnO+TiO2, 5-25% of Bi2O3, 0-4.5% of WO3, 0-4% of MoO3 0-3% of Y2O3, 0-3% of Nb2O5, 0-3% of Ta2O5, 0.5-7% of sigma WO3+M0O3+Y2O3+Nb2O5+Ta2O5 and 0-0.8% of Sb2O3. said composition contains no PbO, the X-ray absorption coefficient at 0.6 angstrom wavelength is 65 cm(-1) or more than that, the average linear expansion coefficient at 20-380deg.C is 98-105X10 to the power-7k(-1).

Owner:HENAN ANCAI HI-TECH

Mulching film prepared from corn straws and preparation method thereof

InactiveCN107936304AImprove mechanical propertiesSimple structurePaper material treatmentPlant protective coveringsFiberCellulose

The invention provides a mulching film prepared from corn straws and a preparation method thereof and relates to the field of utilization of crop straws. The mulching film provided by the invention isprepared from the following components in percentage by weight: 60 to 80 percent of corn straw fibers, 10 to 30 percent of waste cotton fibers, 1 to 3 percent of biological organic fertilizer, 3 to 10 percent of polyvinyl alcohol, 1 to 5 percent of corn starch, 1 to 3 percent of glycerol, 1 to 3 percent of sorbitol fatty acid ester and 0.05 to 0.5 percent of a crosslinking agent. The preparationmethod comprises the following steps: preparing the corn straw fibers, treating the waste cotton fibers, carrying out non-woven net formation, and bonding and curing. The mulching film provided by theinvention has relatively good strength and air permeability and can be degraded; after the mulching film is degraded, a lot of cellulose can have the effect of improving soil and the utilization value is improved.

Owner:柳州市柳科科技有限公司

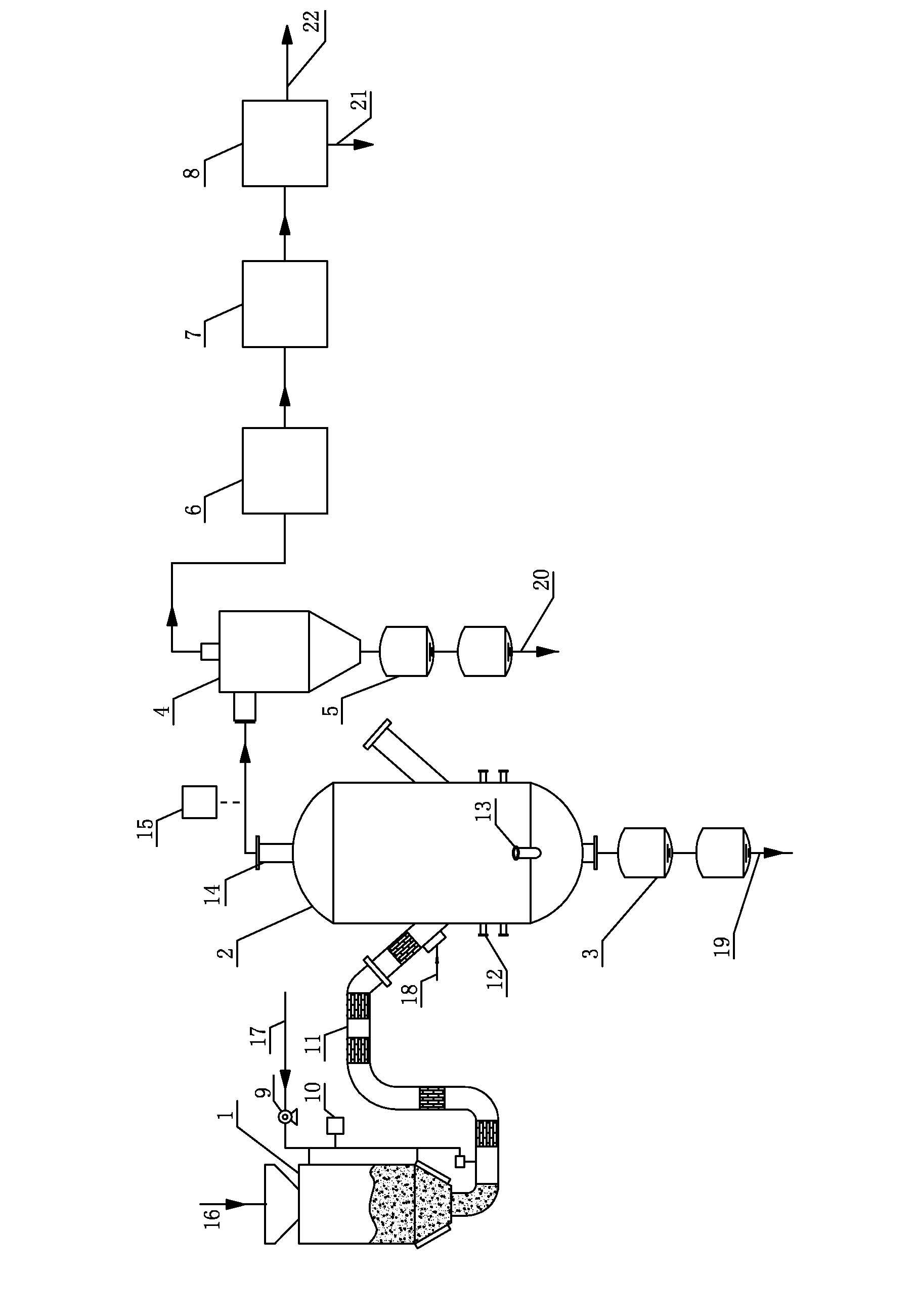

Method and device for pyrolysis of biomass to produce syngas

InactiveUS20160272902A1Improve carbon conversion efficiencyQuality improvementElectrical coke oven heatingProductsPlasma jetSyngas

A method for pressurized pyrolysis of biomass in a pressurized pyrolysis furnace, including: 1) crushing and screening biomass; collecting biomass having desired particle sizes; and delivering the biomass having desired particle sizes to a pulse-type feeding system; 2) transporting the biomass to a pyrolysis furnace via the pulse-type feeding system; synchronously initiating microwave and a plasma torch, the microwave producing a microwave field in the pyrolysis furnace, working gas of the plasma torch being ionized for the first time to produce plasma jet entering the pyrolysis furnace; and 3) allowing the syngas generated in 2) to continue moving upwards and introducing the syngas out from the top of the pyrolysis furnace; chilling the syngas; introducing the syngas to a cyclone separator to separate residues; and then cooling and purifying the syngas using a cooling device and a purifying device, respectively, to produce clean syngas.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

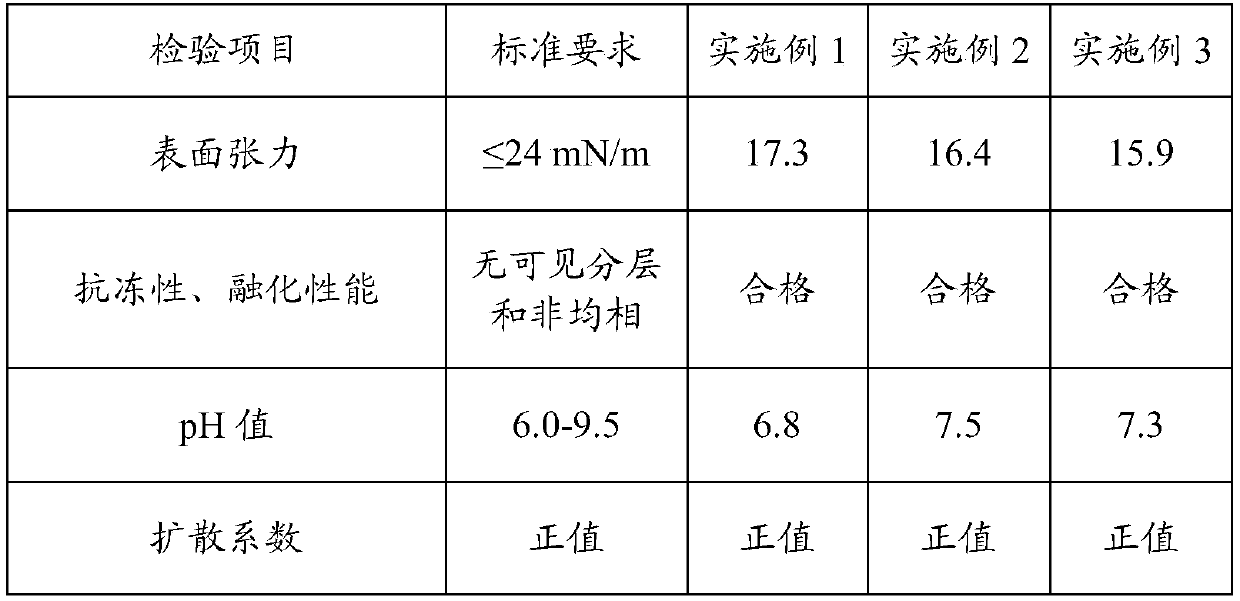

High-performance environment-friendly aqueous film-forming foam extinguishing agent

ActiveCN110523044AImprove fire extinguishing efficiencyImprove performanceFire extinguisherPollutionExpansion rate

The invention provides a high-performance environment-friendly aqueous film-forming foam extinguishing agent which comprises the following components in percentage by weight: 3-6% of a fluorine-containing surfactant, 3-20% of a carbon hydrogen surfactant, 3-6% of an organosilicon surfactant, 0.1-4% of plant polysaccharides, 8-20% of a solubilizer, 0.1-4% of an ion complexing agent, 0.1-2% of an antibacterial agent and the balance of water. Under interactions of the components of the contents, the extinguishing agent has an excellent fire extinguishing function and is good in foam performance,high in fire extinguishing efficiency, rapid in fire extinguishing speed, good in after-combustion prevention and sealing performance, long in preservation life, easy in raw material obtaining, environment-friendly and easy in biodegradation, free of PFOS (perfluorooctane sulfonates) or salts thereof, and free of environment pollution; and under a condition that the foam expansion rate is 7.3-8.1,the 25% drainage time of the extinguishing agent is 3.4-4.1 minutes, the fire extinguishing time (compulsive application) is 35-47 seconds, and the burning resistance time (compulsive application) is13.1-17.4 minutes.

Owner:UNIV OF SCI & TECH OF CHINA

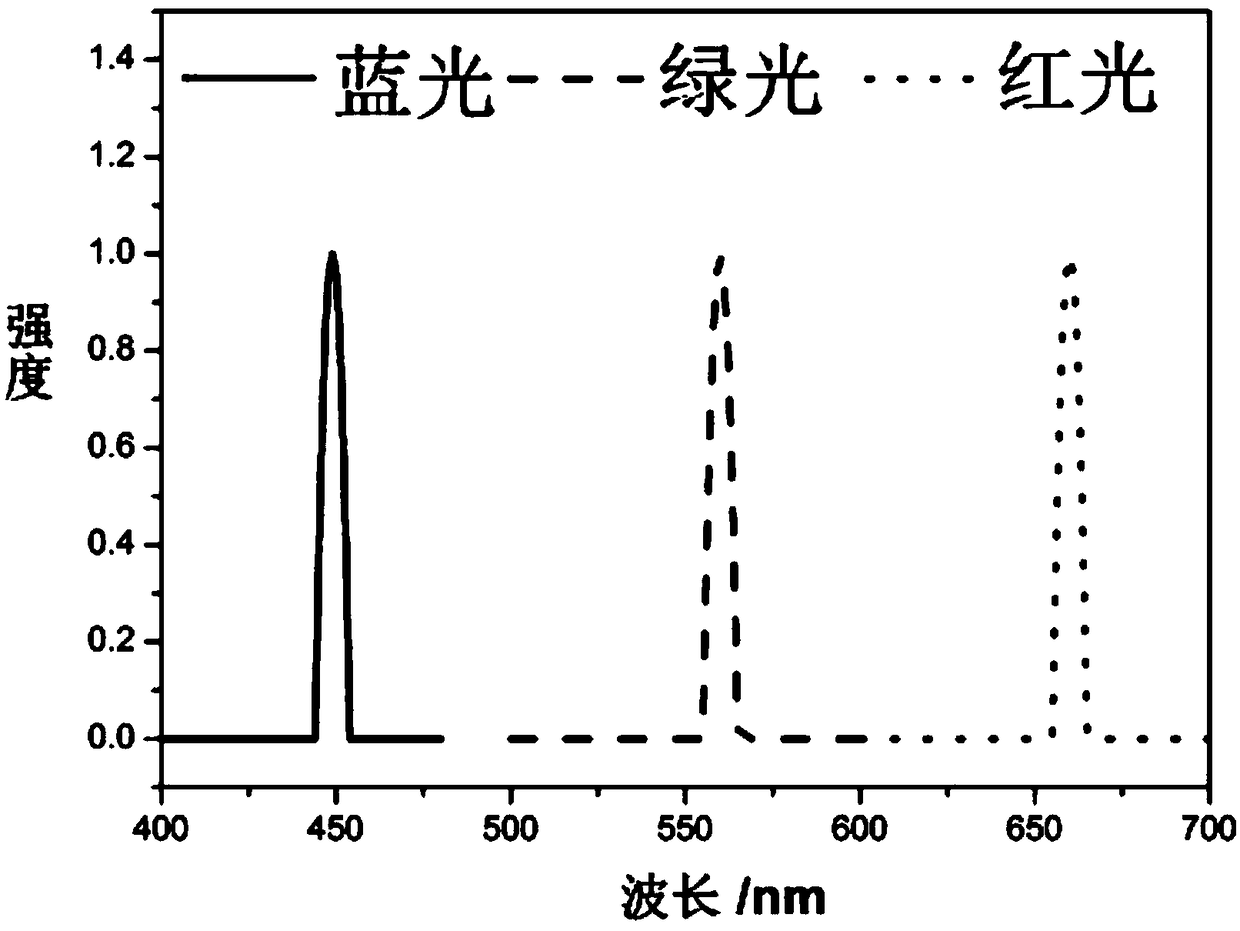

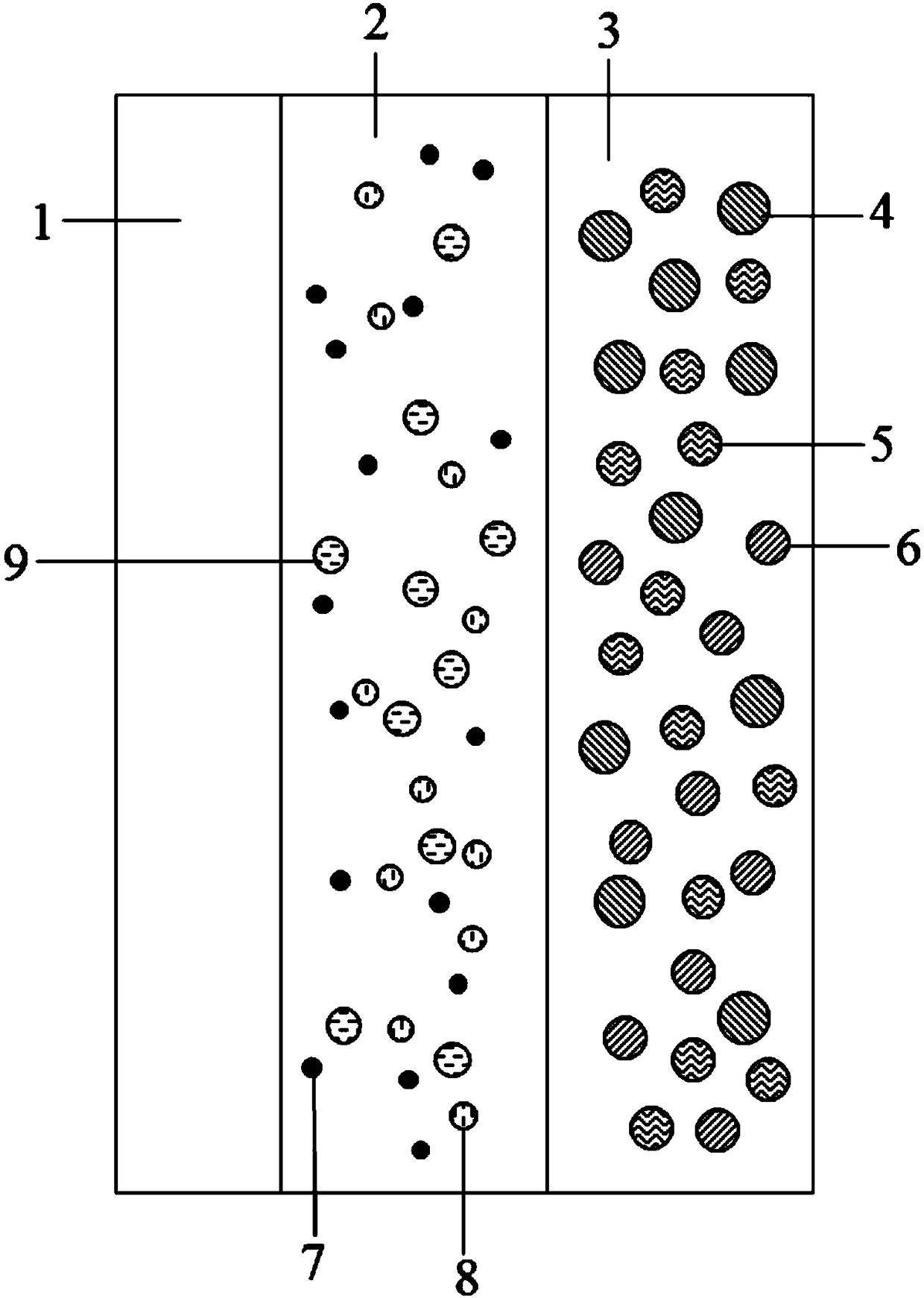

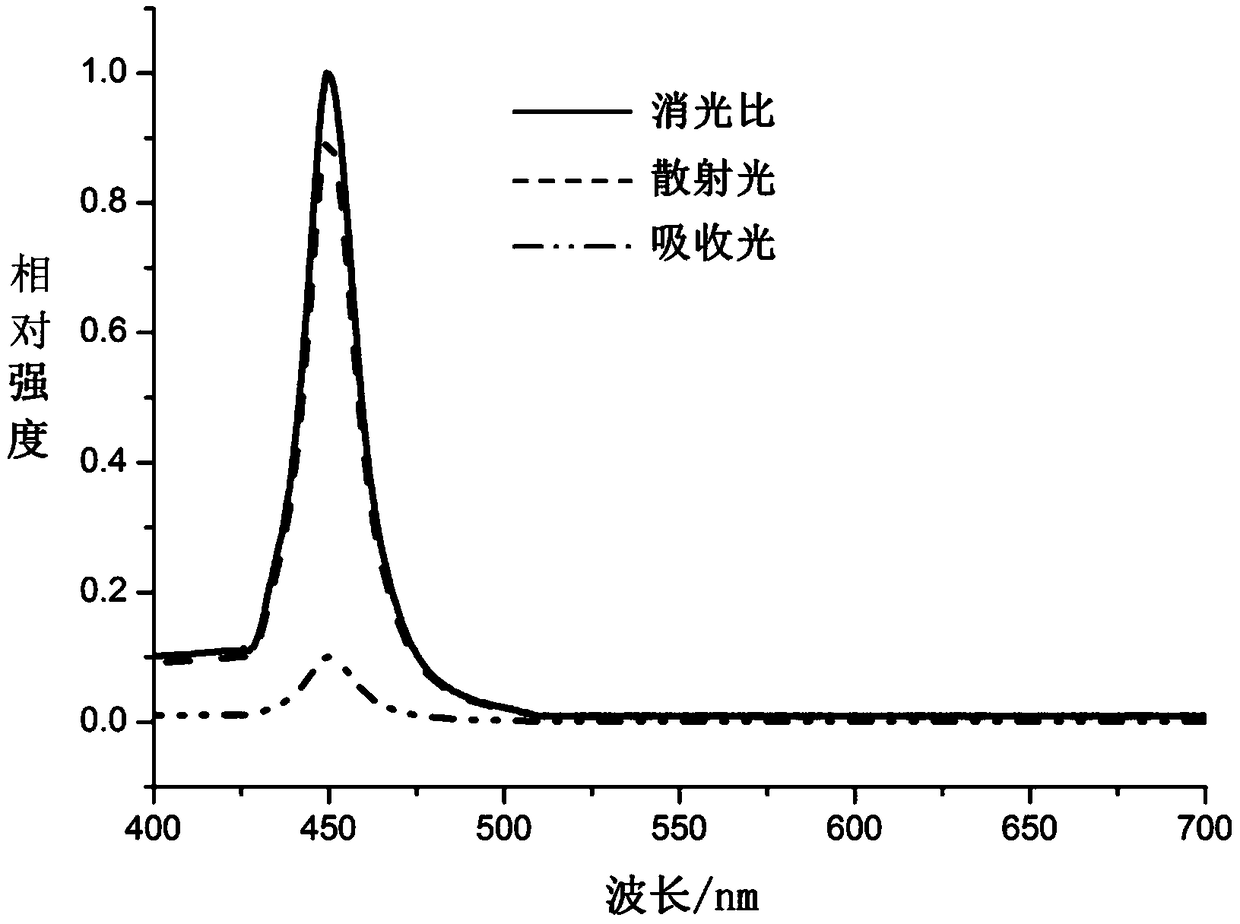

High-contrast transparent projection display screen and manufacturing method thereof

PendingCN108693693AIncrease contrastReduce brightnessLayered productsProjectorsBack projectionReflective layer

The invention provides a high-contrast transparent projection display screen and a manufacturing method thereof. The projection display screen comprises an imaging layer, a light absorbing layer and an anti-reflection layer, wherein the light absorbing layer is located between the imaging layer and the anti-reflection layer. The projection display screen has high contrast, is flexible and foldable, and can be restored completely after bending and folding, and the display effects are not influenced. The projection display screen provided in the invention can be used for both front projection and back projection, and the obtained projection display screens can be seamlessly joined to form a display screen with an extra large size.

Owner:江苏坦能纳米材料科技有限公司

Method for producing bacillus amyloliquefaciens bacterial agent through solid-state fermentation

InactiveCN105886430AReduce consumptionReduce manufacturing costBacteriaMicroorganism based processesChlorine Dioxide SterilizationCulture mediums

The invention relates to a method for producing a bacillus amyloliquefaciens bacterial agent through solid-state fermentation. Wheat bran, soybean meal and corn flour are used as main raw materials to make a solid-state fermentation culture medium. The made culture medium is wetted with water, standing culture is performed at the temperature of 28-30 DEG C for 7-8 hours, and then the culture medium is mixed with a chlorine dioxide disinfectant for sterilization at room temperature; the culture medium subjected to sterilization is inoculated with a bacillus amyloliquefaciens seed solution by using the chlorine dioxide disinfectant for solid-state fermentation; after the fermentation is completed, and a solid-state fermented mash is subjected to hot-air drying and smashing to obtain the bacillus amyloliquefaciens bacterial agent, wherein the spore number of the fungicide is up to 200-22 billion / g, and the spore rate is up to 97%-99%. The method adopts chlorine dioxide sterilization to replace traditional high-temperature steam sterilization and is short in time and high in efficiency, the production costs of the bacillus amyloliquefaciens bacterial agent are greatly reduced, and environmental pollution is reduced.

Owner:SHIJIAZHUANG DAZHONG FERTILIZER CO LTD

Method of producing pure cotton voile fabric

InactiveCN105113163ATwist stabilityAchieving Surface Tension DifferentiationSucessive textile treatmentsVegetal fibresCelluloseSpinning

The invention discloses a method of producing pure cotton voile fabric. The method comprises the steps of spinning, spooling, wet steaming and twist setting, beam warping, slashing, weaving, finishing and drying; the method is characterized in that a finishing process comprises the step of carrying out sand washing on textile fabric; during the sand washing process, a hydroxide agent is adopted as an alkaline agent, the dosage of the hydroxide agent is 7 to 10 g / L, and meanwhile, 10 g / L of urea is added. According to the method of producing the pure cotton voile fabric, disclosed by the invention, the hydroxide agent is adopted as the alkaline agent in the sand washing process, a certain dosage of the urea is simultaneously added, hydrogen bonds between polysaccharide molecules are effectively destroyed, cellulose dissolving is accelerated, a gel solution can be prevented from being formed, the finishing effect is increased through the synergistic effect of the hydroxide agent and the urea, and finishing residual liquid can be used for fertilizer production, and environmental pollution cannot be caused.

Owner:张家港市金陵纺织有限公司

Method for cultivating salt willow

The invention relates to a method for cultivating a salt willow. The method comprises the following steps of: selecting seedlings of a salix willow, a rose willow and a bamboo willow in spring; planting the salix willow, the rose willow and the bamboo willow in a mixed mode; selecting the salix willow and the rose willow of which braches are turned from light green into dark green or light red in the second year of the spring; cutting the branches which turn light green into dark green or light red into branch sections and cutting the branch sections; shifting the seedlings which are cut at an interval, cutting the branches of the remained seedlings and leaving the strongest branches in the third year of spring; and enabling the remained seedlings to grow to the salt willow in the third year of the autumn. The salt willow obtained by the method is high in survival ratio of planting, straight in trunks, dense in leaves, strong in roots, high in salt and alkali resistant ability, and good in greening effect; the crown is umbrella-shaped; and the generation of willow catkins and the damage to the environment are avoided.

Owner:WEIFANG HUANHAI AGRI & FORESTRY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com