Plating solution formula of copper wire tin plating process and copper wire tin plating process

A copper wire tinning and plating solution technology, applied in the field of electroplating, can solve problems such as difficult promotion, troublesome operation, and efficient production operations, and achieve the effects of saving human resources, high production efficiency, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Step 1: Plating solution tank opening agent preparation:

[0039] First, weigh 80kg of pure water, pure H 2 SO 4 20kg, pure SnSO 4 2kg, and respectively prepare 20ml of SS brightener, 3ml of SS additive, and 5ml of JH stabilizer provided by Dongguan Wanjiang Jinhui Hardware Products Factory;

[0040] Then, the pure H 2 SO 4 20kg was added to 80kg of pure water, and after natural cooling, 20ml of SS brightener, 3ml of SS additive, and 5ml of JH stabilizer were sequentially added to complete the preparation of the plating solution.

[0041] Step 2: Tin the Copper Wire

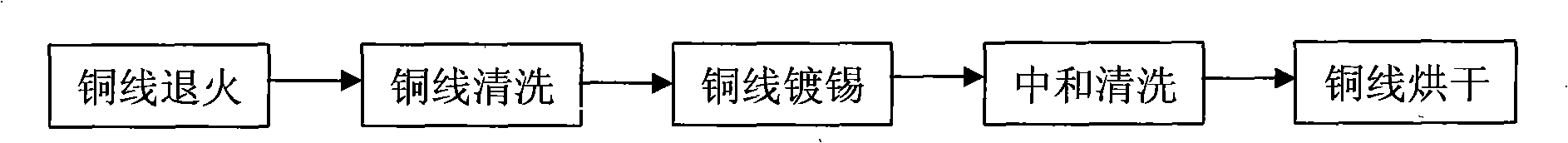

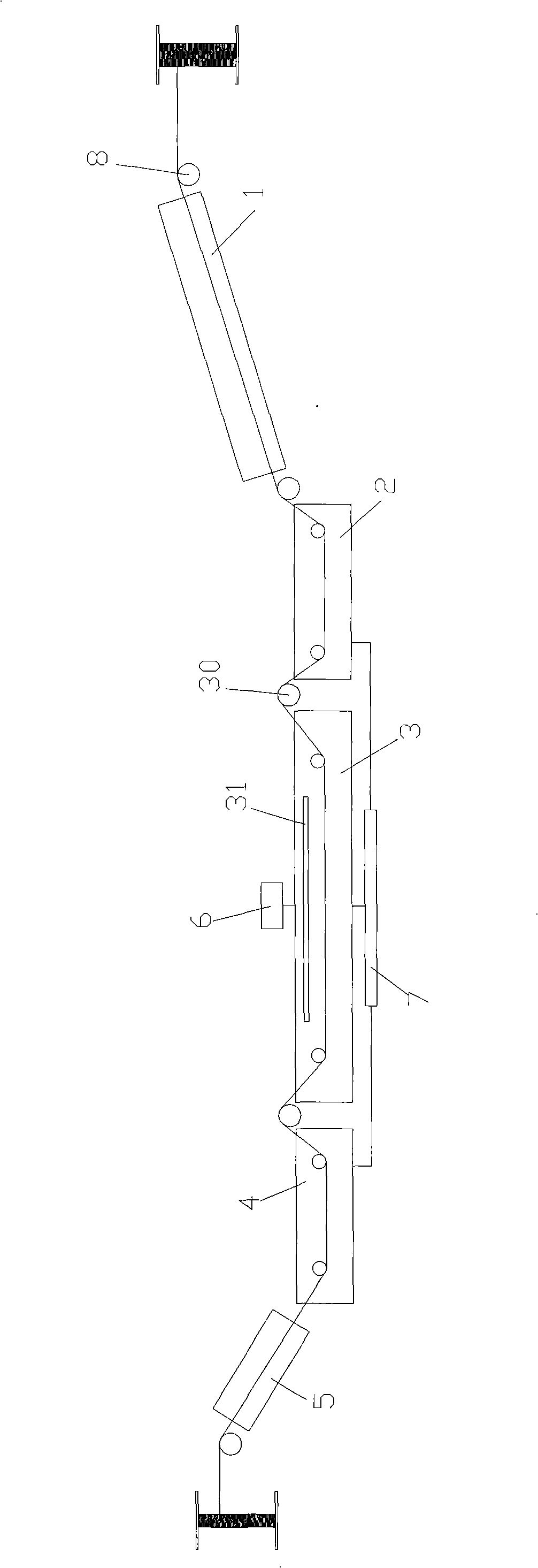

[0042] First add a certain amount (sufficient amount) of the above-mentioned plating solution into the tin plating tank as a potting agent, and then combine figure 1 , Figure 2, carry out the following steps continuously and uniformly on the copper wires:

[0043] A. copper wire annealing: copper wire is introduced into tubular annealing furnace 1;

[0044] B. Copper wire cleaning: introduce the an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com