High-performance environment-friendly aqueous film-forming foam extinguishing agent

An environment-friendly foam fire extinguishing agent technology, applied in fire prevention equipment, etc., can solve the problems of water film-forming foam fire extinguishing agent performance degradation, hazards, production and use restrictions, etc., to achieve excellent fire extinguishing performance, long storage period, fire extinguishing high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

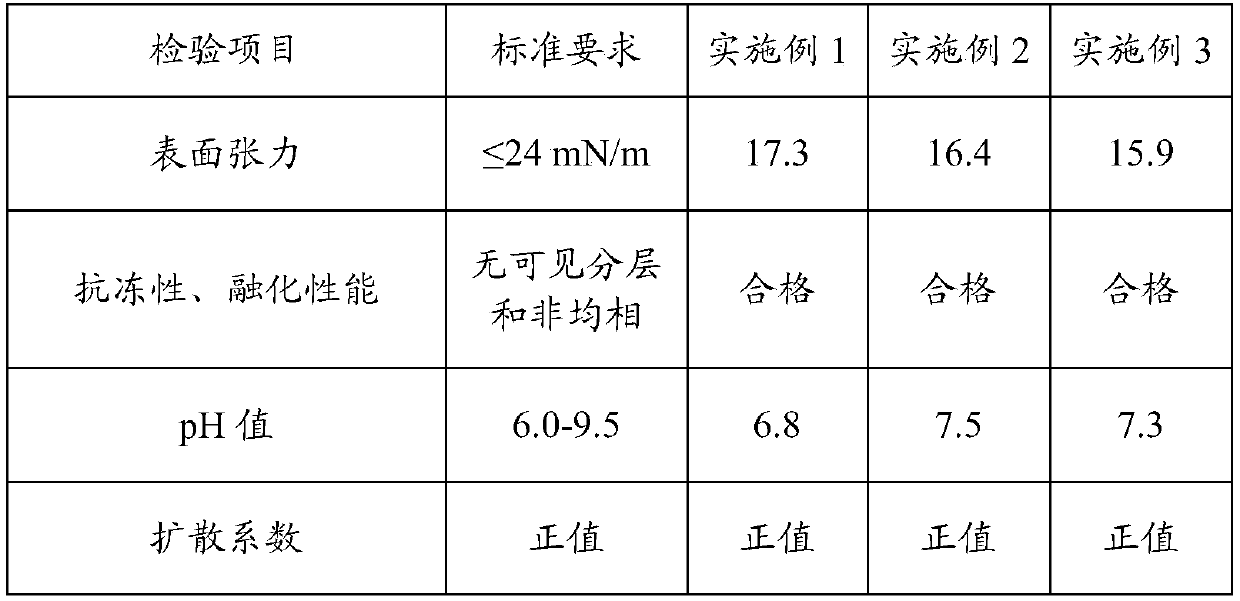

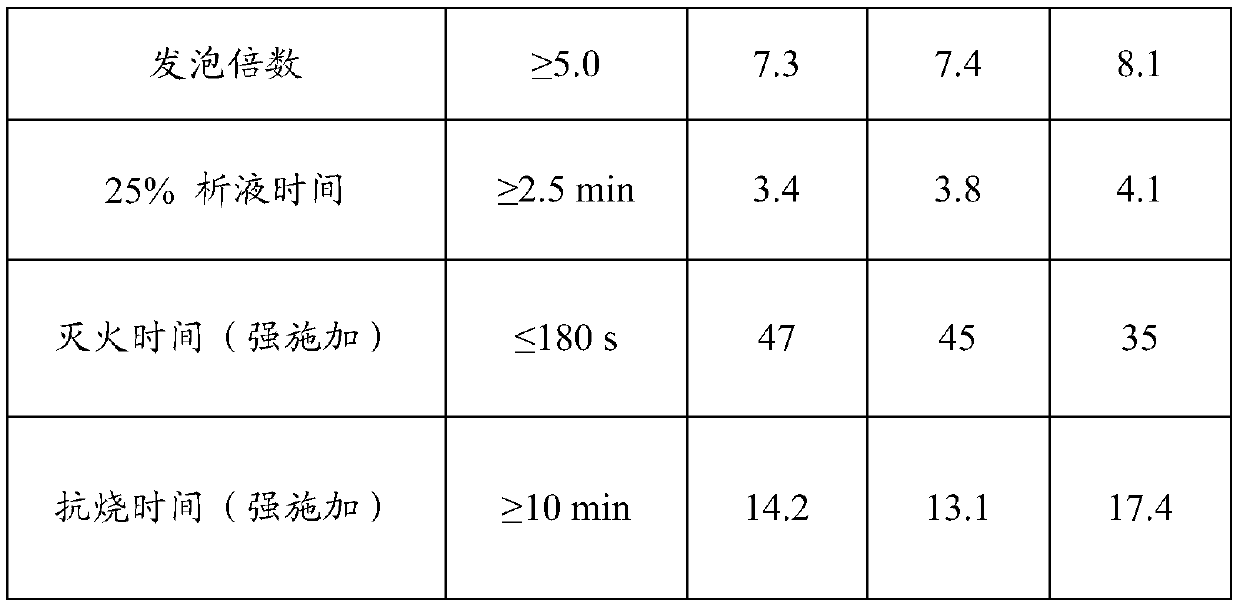

Examples

Embodiment 1

[0051] (1) Weigh FS-51 3kg, AS-40 3kg, oligomeric D-glucopyranose 5kg, Dow Corning 502W6kg, tetraglyme 10kg, sodium diamine tetramethylene phosphate 4kg, O-benzene Base phenol 0.2kg and water 70kg are slowly added in the reactor, start stirring, stirring speed 600 rpm.

[0052] (2) After the sample is dissolved, weigh 0.5 kg of locust bean gum again and add it to the reaction kettle, and continue to stir for 2 hours.

[0053] (3) Slowly add water to 100kg in the reaction kettle, and fully stir to obtain a high-performance environment-friendly aqueous film-forming foam fire extinguishing agent.

Embodiment 2

[0055] (1) Weigh FS-51 2kg, FS-60 3kg, polyethylene glycol p-isooctyl phenyl ether 5kg, Dow Corning502W 4kg, butyl carbitol 10kg, tetrasodium iminodisuccinate 4kg, bis 0.2kg of sodium biacetate and 70kg of water are slowly added to the reaction kettle, and the stirring is started at a stirring speed of 600 rpm.

[0056] (2) After the sample is dissolved, weigh again 0.2 kg of locust bean gum and 0.2 kg of linseed gum and add them into the reaction kettle, and continue to stir for 2 hours.

[0057] (3) Slowly add water to 100kg in the reaction kettle, and fully stir to obtain a high-performance environment-friendly aqueous film-forming foam fire extinguishing agent.

Embodiment 3

[0059] (1) Weigh 2kg of S-111, 3kg of FS-51, 2kg of polyethylene glycol p-isooctylphenyl ether, 4kg of oligomeric D-glucopyranose, 3kg of Dow Corning 502W, and 5kg of butyl carbitol , 5 kg of tetraglyme, 4 kg of tetrasodium iminodisuccinate, 0.2 kg of sodium biacetate and 70 kg of water were slowly added to the reaction kettle, and the stirring was started at a stirring speed of 600 rpm.

[0060] (2) After the sample is dissolved, weigh again 0.1 kg of locust bean gum and 0.3 kg of 6-deoxy-L-galactose into the reaction kettle, and continue to stir for 2 hours.

[0061] (3) Slowly add water to 100kg in the reaction kettle, and fully stir to obtain a high-performance environment-friendly aqueous film-forming foam fire extinguishing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com