Microcrystalline-wax-containing enhanced textile-type wetting agent

A technology of microcrystalline wax and sizing agent, applied in the field of textile auxiliaries, can solve the problems of poor fiber aggregation, serious loose filaments, and environmental impact, and achieve yarn softness, good elasticity, processing performance without hairiness, and high film-forming strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of reinforced textile sizing containing microcrystalline wax, comprising the following components in parts by weight, 4.0 parts of environmentally friendly color fixing agent; 1.5 parts of water-based epoxy resin; 2.0 parts of water-based unsaturated polyester resin; 0.6 parts of microcrystalline paraffin ; 1.0 parts of dibutyl ester; 0.5 parts of Pingpingjia; 0.5 parts of stearic acid; 0.5 parts of No. 7 motor oil; 0.25 parts of fatty amide cationic film; The wetting agent has a pH value of 6.5.

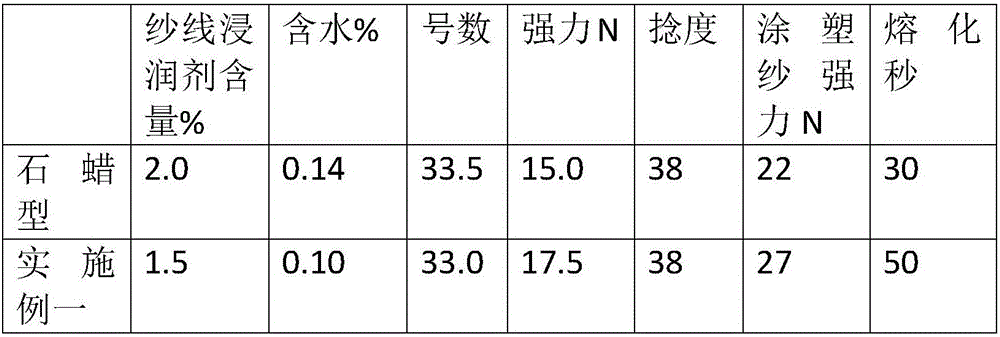

[0020] Compared with the traditional paraffin-type sizing after drawing and spinning with the sizing of Example 1 of the present invention, the performance of the yarn is as follows:

[0021] Production variety CC9033*1

[0022]

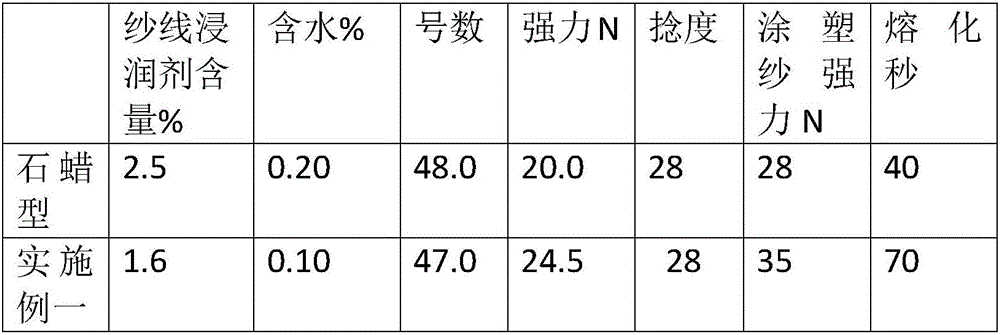

[0023] Production variety CC1148*1

[0024]

[0025] Note: Melting refers to the use of a specific solvent to dissolve the coating on the surface of the fiber, and the time from entering the solvent to the time when the coating falls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com