Whole-process nutrient supply type composite fertilizer and preparation method thereof

A compound fertilizer, the whole process technology, applied in the direction of fertilizer mixture, fertilization device, application, etc., can solve the problem of difficult humic acid granulation, etc., to achieve the effect of improving nutrient utilization rate, prolonging fertilizer efficiency, and enhancing disease resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

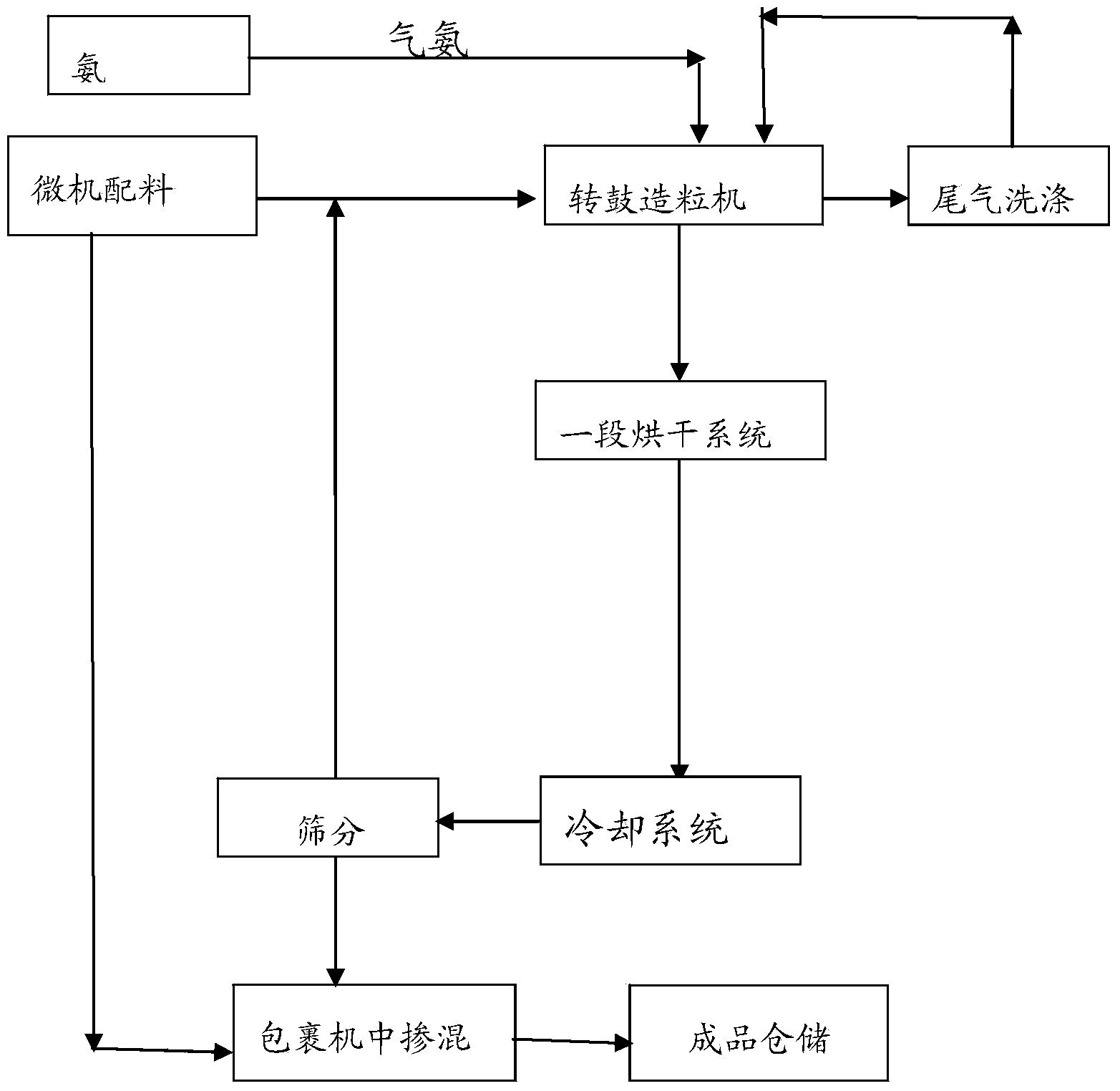

[0029]In the preparation method of the whole-process nutrient-supplying compound fertilizer, in the production of compound fertilizer by granulation method, raw materials containing nitrate nitrogen, ammonium nitrogen, and amide nitrogen are added to the material, in order to prevent excessive Urea nitrate, the gaseous ammonia is directly passed to the material layer of the drum granulator to complete the ammoniation treatment of ammonium nitrate, and granulate with urea and other powdery basic fertilizers containing nitrogen, phosphorus, potassium and organic matter. After drying, cooling, sieving, adding controlled-release urea, and anti-caking treatment, the whole process of nutrient-supplying compound fertilizer is obtained.

[0030] The controlled-release urea is added before wrapping, and a wrapping machine is used to complete the blending process.

[0031] Use granulation tail steam washing water as the liquid phase amount required for granulation.

[0032] The princip...

Embodiment 1

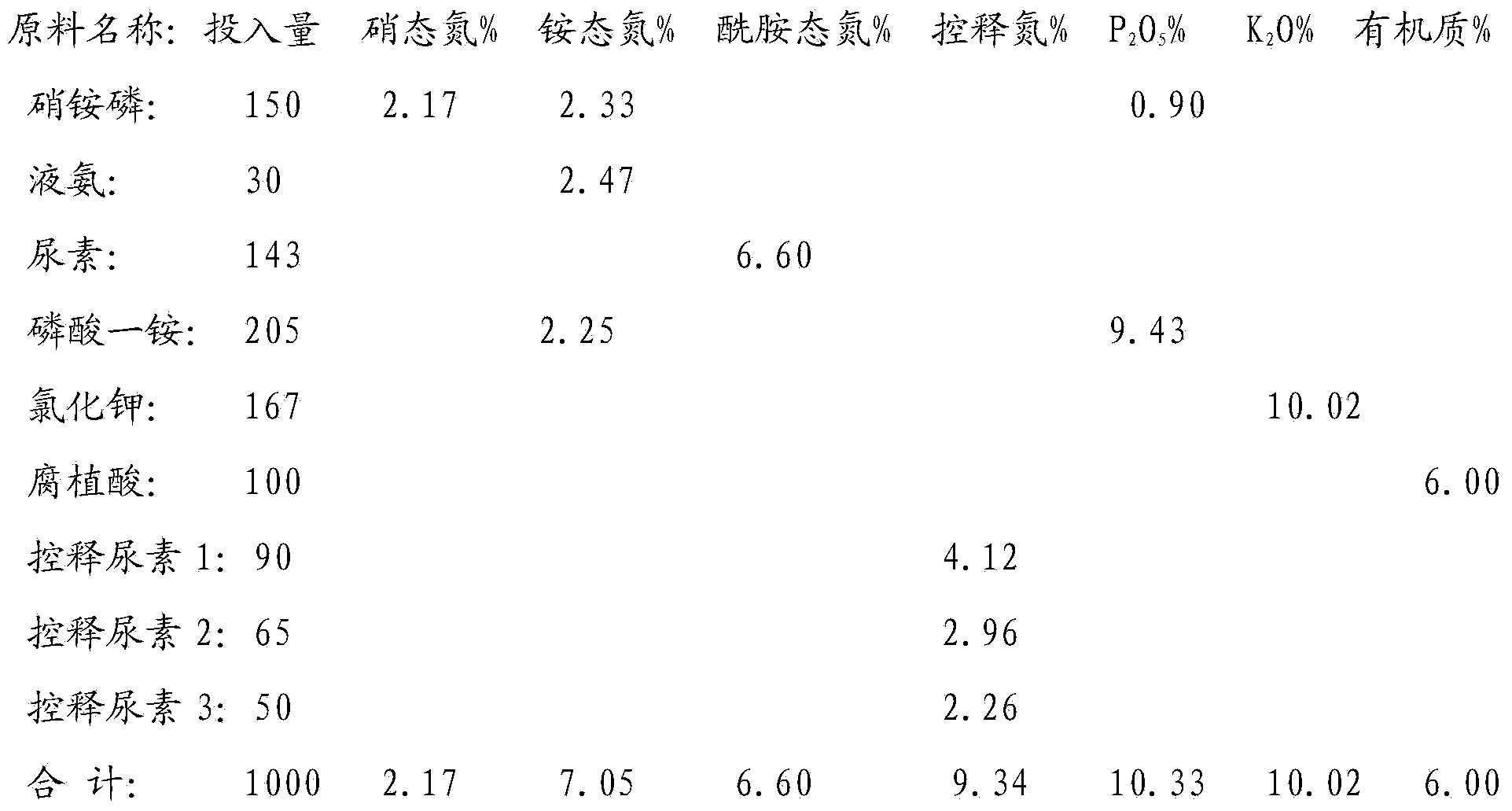

[0037] To prepare high-nitrogen products with nitrogen, phosphorus and potassium content of 25-10-10, take the raw material consumption quota of 1 ton product as an example:

[0038]

[0039] Note: Controlled release urea 1 refers to the controlled release of urea by one layer of membrane, controlled release urea 2 refers to the controlled release of urea by two layers of membrane, and controlled release urea 3 refers to the controlled release of urea by three layers of membrane.

[0040] The specific preparation method: add urea into the mixing tank by metering, the addition amount is 1 ton, add 6 kg of polymer resin, stir for 6 minutes, and pack it to form a layer of film body to control the release of urea. A layer of controlled-release urea that has been stored for more than 24 hours is added to the stirring tank by metering. The amount of addition is 1 ton, and 5 kg of polymer resin is added. After stirring for 7 minutes, it is packaged to make a two-layer controlled-re...

Embodiment 2

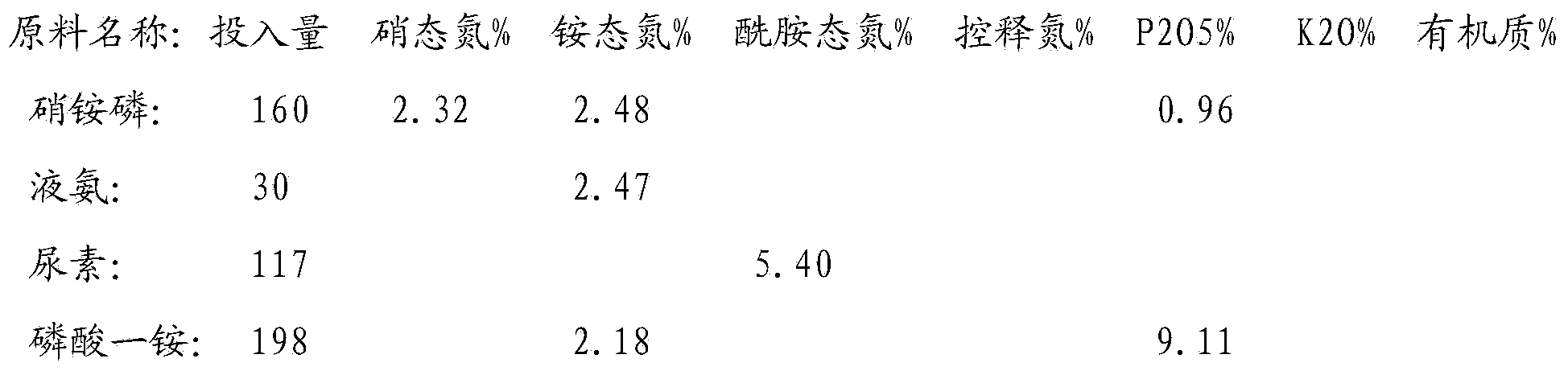

[0043] Embodiment 2: prepare nitrogen, phosphorus, potassium content 21-10-15 high-potassium product, take 1 ton of product raw material consumption quota as example:

[0044]

[0045]

[0046] Note: Controlled release urea 1 refers to the controlled release of urea by one layer of membrane, controlled release urea 2 refers to the controlled release of urea by two layers of membrane, and controlled release urea 3 refers to the controlled release of urea by three layers of membrane.

[0047] Specific production process: Add 30 kg of gaseous ammonia (containing N82.3%, mass percentage, the same below) to the material layer of the drum granulator after metering, and add ammonium nitrate phosphorus (containing N30%, Which contains 14.5% nitrate nitrogen, 15.5% ammonium nitrogen, P 2 o 5 6%) 160 kg, urea (containing N46.2%) 117 kg, powdered monoammonium phosphate (containing N11%, P 2 o 5 46%) 198 kg, potassium chloride (contains K 2 O60%) 250 kg, humic acid (containing 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com