Carbon nanotube polymer composite conductive material and preparation method thereof

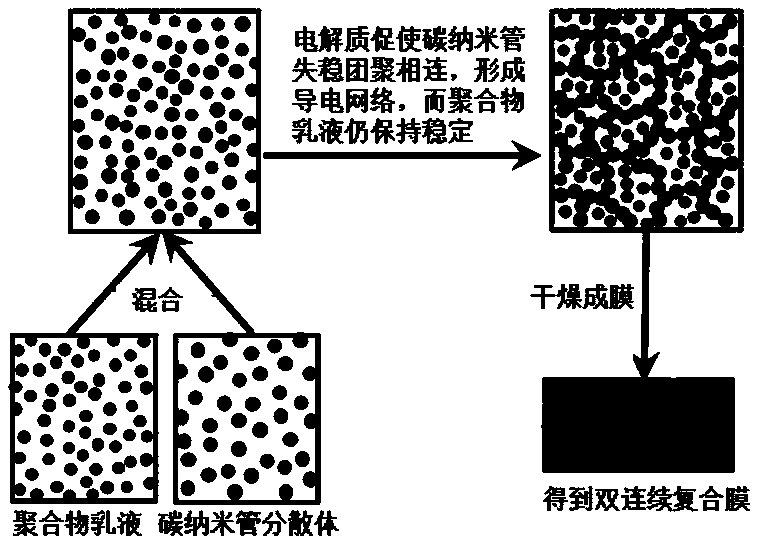

A technology of carbon nanotubes and composite conduction, which is applied in the field of nanomaterials, can solve the problems of complex operation, large amount of carbon nanotubes, and unsatisfactory conductivity, etc., and achieve simple equipment, large-scale production, and improved random distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of preparation method of carbon nanotube polymer composite conductive material, prepares (electrolyte solution is sodium chloride solution) with colloid agglomeration method, and the steps that it comprises are as follows:

[0031] (1) Preparation of carbon nanotube dispersion: 1.0g carbon nanotubes are mixed with 0.03g sodium dodecylbenzene sulfonate and added to 40ml deionized water, and the ultrasonic treatment with a power of 1100W and a frequency of 19.5 for 35min or Or homogenize 6 times at 1200bar, centrifuge at 900rpm for 25min to remove undispersed carbon nanotube aggregates, and take the supernatant for later use;

[0032] (2) Uniform mixing of carbon nanotubes and water-based polyurethane emulsion: take 0.06g of the carbon nanotube dispersion prepared in (1) and 15g of water-based polyurethane emulsion, and use a power of 200W and a frequency of 40KHz for ultrasonic treatment for 30min to achieve nanoscale uniformity. mix;

[0033] (3) Add electrolyte...

Embodiment 2

[0037] A kind of preparation method of carbon nanotube polymer composite conductive material, prepares (electrolyte solution is potassium chloride solution) with colloid agglomeration method, and the steps that it comprises are as follows:

[0038] (1) Preparation of carbon nanotube dispersion: 2.0g of carbon nanotubes and 0.03g of sodium dodecylbenzenesulfonate were mixed and added to 80ml of deionized water, and subjected to ultrasonic treatment with a power of 1500W and a frequency of 20.5KHz for 50min Or homogenize at 1200bar for 8 times, centrifuge at 1400rpm for 35min to remove undispersed carbon nanotube aggregates, and take the supernatant for later use.

[0039](2) Uniform mixing of carbon nanotubes and water-based polyurethane emulsion: take 0.08g (1) of the prepared carbon nanotube dispersion and 16g of water-based polyurethane emulsion through a power of 250W, a frequency of 40KHz ultrasonic treatment for 40min, to reach the nano-scale Mix well.

[0040] (3) Add e...

Embodiment 3

[0044] A preparation method of carbon nanotube polymer composite conductive material, prepared by colloidal agglomeration (electrolyte solution is calcium chloride solution), the steps it includes are as follows:

[0045] (1) Preparation of carbon nanotube dispersion: After mixing 1.5g carbon nanotubes with 0.04g sodium octadecyl sulfate, add them to 60ml deionized water, and after the power is 1500W, the frequency is 20KHz ultrasonic treatment for 40min or 1300bar. 8 times, centrifuged at 1000 rpm for 30 min to remove undispersed carbon nanotube aggregates, and the supernatant was taken for later use.

[0046] (2) Uniform mixing of carbon nanotubes and water-based polyurethane emulsion: get 0.06g (1) prepared carbon nanotube dispersion and 15g water-based polyurethane emulsion polyacrylic acid emulsion at a power of 200W and a frequency of 40KHz for 30min of sonication, reaching Homogeneous mixing at the nanometer level.

[0047] (3) Add electrolyte: add 0.03mol / L calcium ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com