Method for reducing residual alkali of high-nickel ternary material of lithium ion battery

A technology of high-nickel ternary materials and lithium-ion batteries, applied in electrical components, battery electrodes, secondary batteries, etc., can solve problems such as clogging pipes, reducing solid content, and attenuation of electrochemical performance of high-nickel ternary materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Configure mixed washing solution: add 5kg deionized water and 5kg ether (mass ratio 1:1) into a 25L reactor and stir evenly;

[0043] (2) 10 kg of high-nickel ternary material (Li 1.05 Ni 0.8 co 0.1 mn 0.1 o 2 ) was added into a reaction kettle equipped with a mixed washing solution for washing, filtered after washing for 30 minutes, and dried at 100° C. for 5 hours to obtain an intermediate product;

[0044] (3) the intermediate product that step (2) obtains is in O 2 The sintering treatment is carried out in the atmosphere, the calcination temperature is 700°C, and the calcination time is 3h. After the sintering is completed, the obtained sintered product is cooled with the furnace, crushed, and sieved to obtain the NCM811 material with low residual alkali. The content of LiOH, Li 2 CO 3 content and Li content are listed in Table 1.

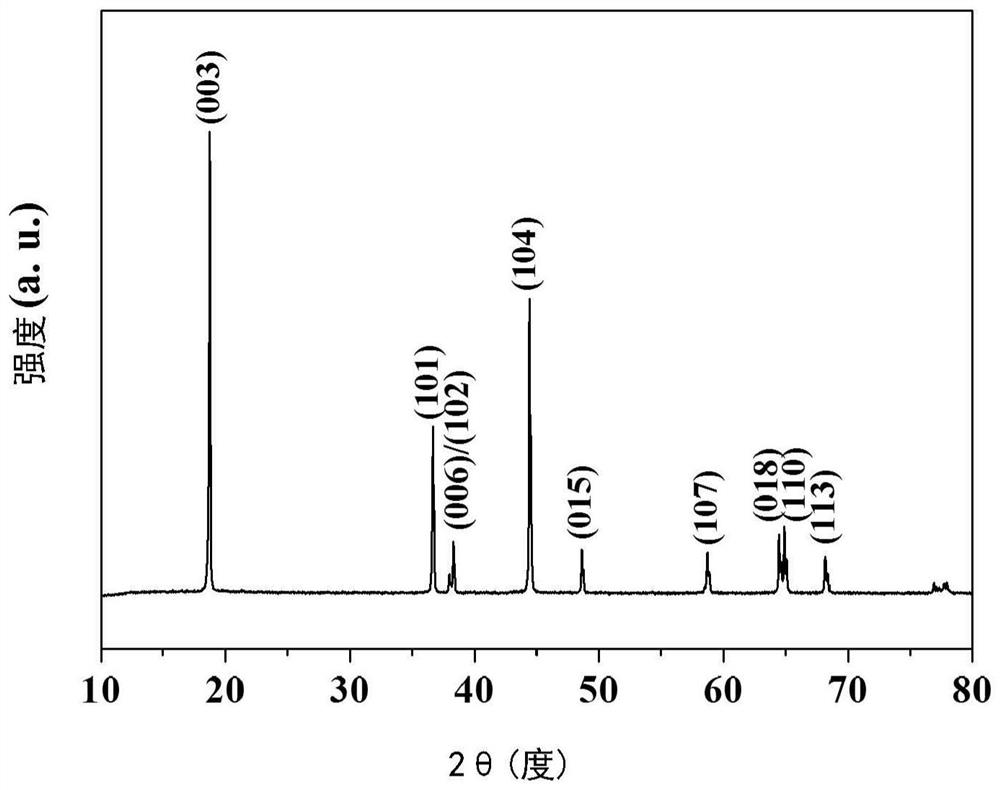

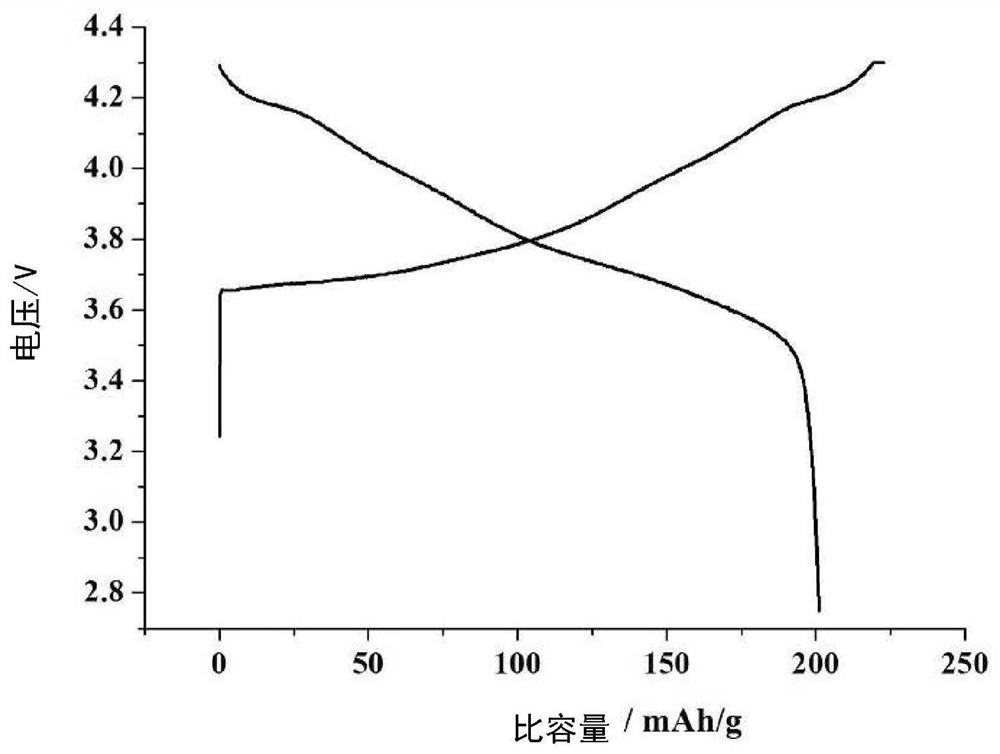

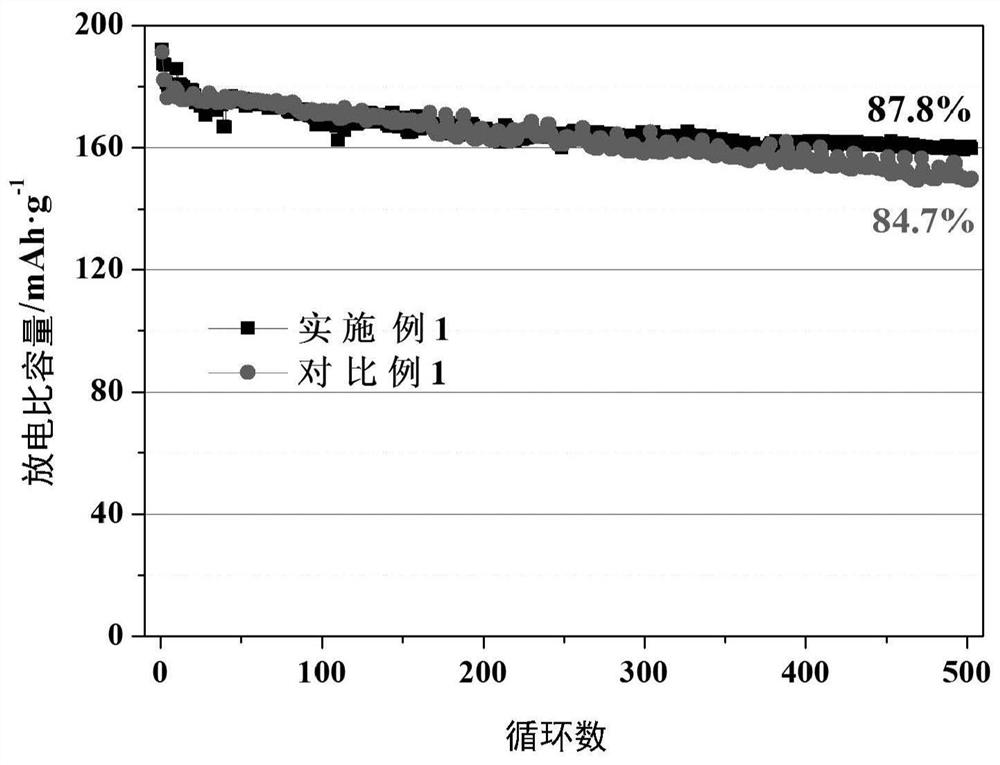

[0045] Measure its XRD spectrogram to the NCM811 material that the embodiment of the present invention 1 obtains, and measur...

Embodiment 2

[0048] (1) Configure mixed washing solution: add 5kg deionized water and 15kg cyclohexane (mass ratio 1:3) into a 25L reactor and stir evenly;

[0049] (2) 10kg of high-nickel ternary material (Li 1.02 Ni 0.6 co 0.2 mn 0.2 o 2 ) was added into a reaction kettle equipped with a mixed washing solution for washing, filtered after washing for 60 minutes, and dried at 120° C. for 5 hours to obtain an intermediate product;

[0050] (3) the intermediate product that step (2) obtains is in O 2 The sintering treatment is carried out in the atmosphere, the calcination temperature is 800°C, and the calcination time is 10h. After the sintering is completed, the obtained sintered product is cooled with the furnace, crushed, and sieved to obtain the NCM622 material with low residual alkali. The content of LiOH, Li 2 CO 3 content and Li content are listed in Table 1.

Embodiment 3

[0052] (1) Configure mixed washing liquid: add 10kg deionized water and 10kg benzene (mass ratio 1:2) into a reaction kettle with a volume of 25L and stir evenly;

[0053] (2) 10 kg of high-nickel ternary material (Li 1.1 Ni 0.9 co 0.05 mn 0.05 o 2 ) was added into a reaction kettle equipped with a mixed washing solution for washing, filtered after washing for 5 minutes, and dried at 100° C. for 5 hours to obtain an intermediate product;

[0054] (3) the intermediate product that step (2) obtains is in O 2 The sintering treatment is carried out in the atmosphere, the sintering temperature is 500°C, and the sintering time is 5h. After the sintering is completed, the obtained sintered product is cooled with the furnace, crushed, and sieved to obtain the NCM955 material with low residual alkali. The content of LiOH, Li 2 CO 3 content and Li content are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com