Battery positive electrode lithium supplement additive and preparation method thereof, positive electrode sheet and preparation method thereof, and lithium ion battery

A battery positive electrode and additive technology, applied to battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of increasing battery gas production or impedance, affecting the quality of positive electrodes, and prone to chemical gelation, etc., to reduce residual alkali value, improve manufacturing quality, and improve fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

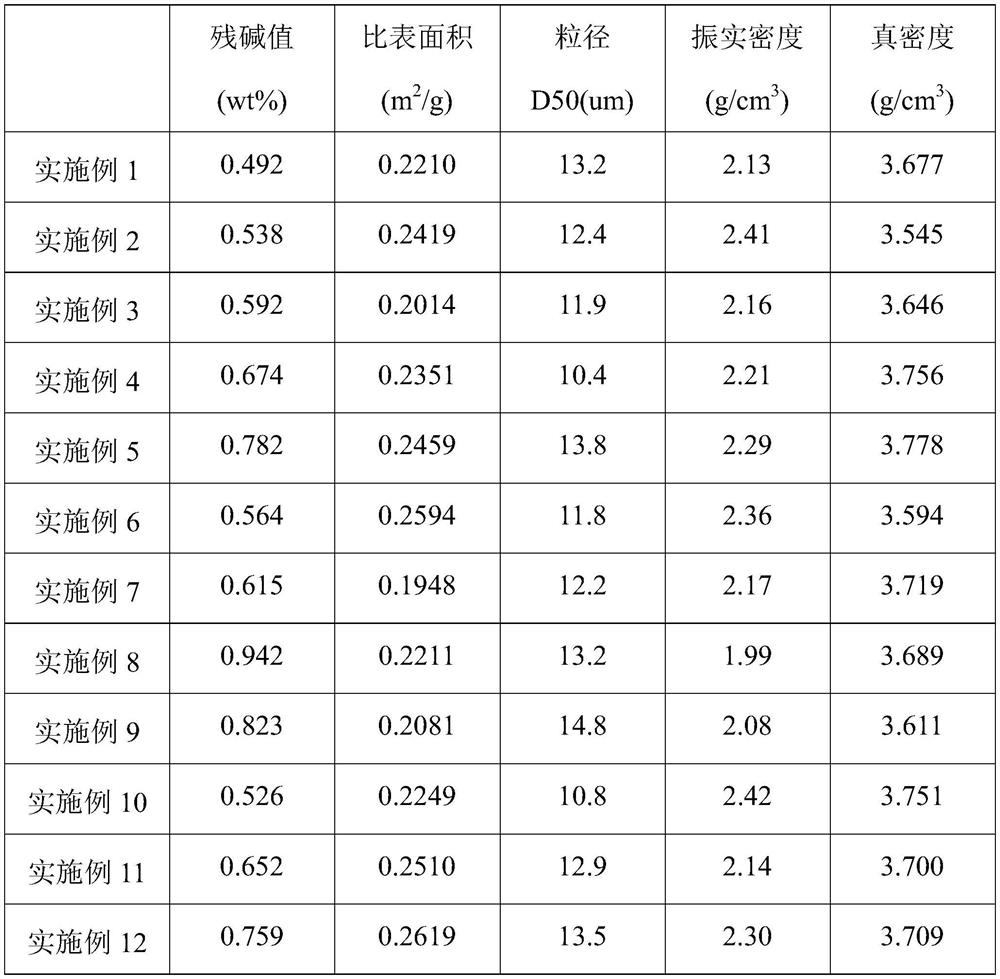

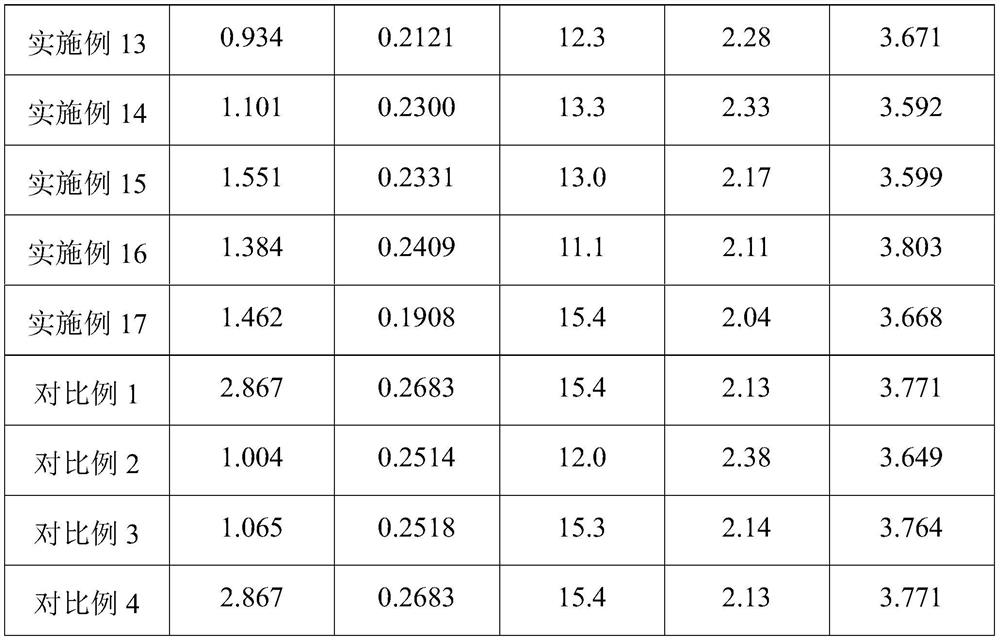

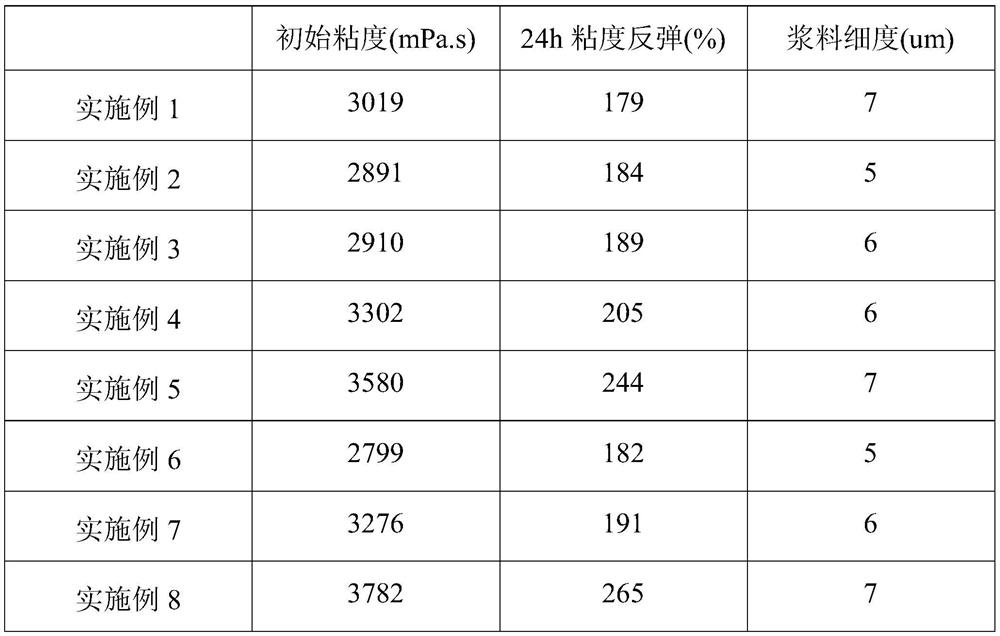

Examples

Embodiment 1

[0073]This embodiment provides a method for preparing a battery positive electrode lithium additive, the preparation method specifically comprising the steps of:

[0074] (1) After mixing the lithium oxide and nickel, the molar ratio of 1: 1 is mixed, and the grinding ball and mixed material are 0.8: 1 mass than the ball milling for 13 h at a rotational speed of 500 rpm / min, and then in argon The gas atmosphere, calcined at a temperature of 600 ° C for 18 h, and the lithium nickel sink material is obtained after cooling;

[0075] (2) The lithium-rich nickel-free lithium-rich material obtained by step (1) is mixed with water, and the mass of 25 ° C is carried out at a temperature of 25 ° C, and the water was washed at 300 rpm / min, followed by filtration. The moisture slurry is carried out at a temperature of 100 ° C for drying treatment at a temperature of 100 ° C to obtain the cell positive electrode lithium additive.

[0076] This embodiment also provides a method of preparin...

Embodiment 2

[0081] This embodiment provides a method for preparing a battery positive electrode lithium additive, the preparation method specifically comprising the steps of:

[0082] (1) After mixing the lithium oxide and nickel, the molar ratio of 1: 1 is mixed, and the grinding ball and mixed material are 0.8: 1 mass than the ball milling for 13 h at a rotational speed of 500 rpm / min, and then in argon The gas atmosphere, calcined at a temperature of 600 ° C for 18 h, and the lithium nickel sink material is obtained after cooling;

[0083] (2) The lithium nickellate material obtained by step (1) is mixed with water at a mass ratio of 1: 3, at a temperature of 25 ° C, washed at 300 rpm / min, and then the filtration is separated. The moisture slurry is carried out at a temperature of 100 ° C for drying treatment at a temperature of 100 ° C to obtain the cell positive electrode lithium additive.

[0084] This embodiment also provides a method of preparing a battery positive electrode sheet...

Embodiment 3

[0089] This embodiment provides a method for preparing a battery positive electrode lithium additive, the preparation method specifically comprising the steps of:

[0090] (1) After mixing the lithium oxide and nickel, the molar ratio of 1: 1 is mixed, and the grinding ball and mixed material are 0.8: 1 mass than the ball milling for 13 h at a rotational speed of 500 rpm / min, and then in argon The gas atmosphere, calcined at a temperature of 600 ° C for 18 h, and the lithium nickel sink material is obtained after cooling;

[0091] (2) The lithium nickellate material obtained by step (1) is mixed with water at a mass ratio of 1: 5, at a temperature of 25 ° C, washed at 300 rpm / min, and then the filtration is separated. The moisture slurry is carried out at a temperature of 100 ° C for drying treatment at a temperature of 100 ° C to obtain the cell positive electrode lithium additive.

[0092] This embodiment also provides a method of preparing a battery positive electrode sheet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com