Positive lithium supplement additive, positive pole piece, preparation method of positive pole piece and lithium ion battery

A positive electrode piece and additive technology, applied in the field of positive electrode lithium supplementary additive, positive electrode piece, and its preparation field, can solve the problems such as the lithium source cannot be completely consumed, the sintering temperature is low, and the processing of the electrode piece is affected, and the electrochemical performance is improved. , The slurry distribution is uniform, and the effect of improving the manufacturing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

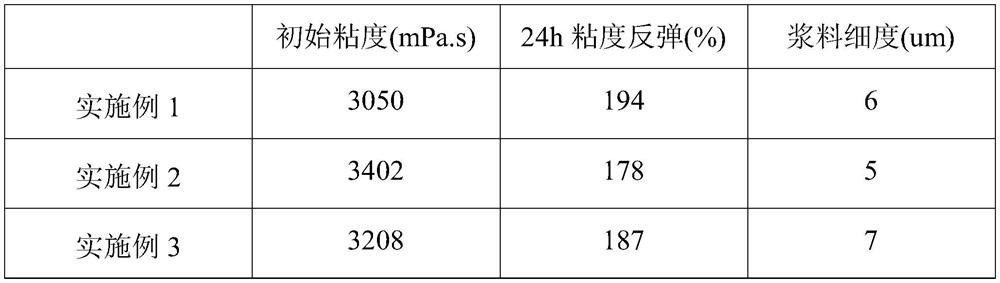

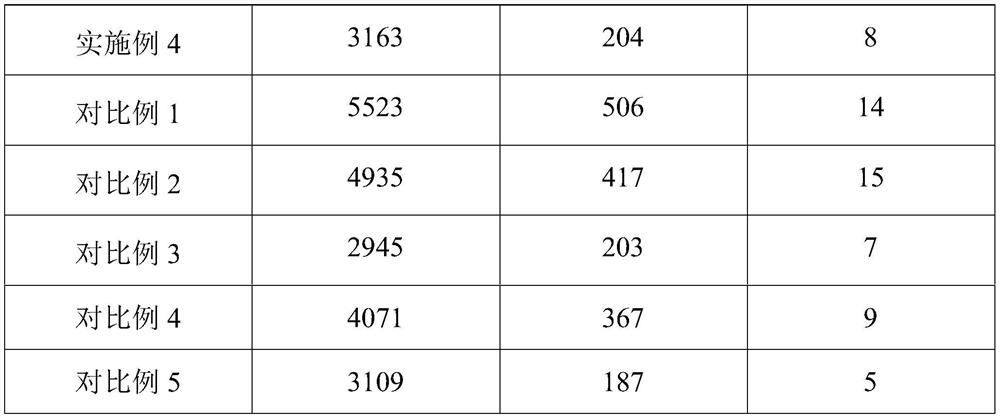

Examples

Embodiment 1

[0078] This embodiment provides a preparation method of a positive electrode lithium supplement additive, and the preparation method specifically includes the following steps:

[0079] (1) Lithium oxide and nickel oxide are mixed uniformly at a molar ratio of 1:1 to obtain a mixed material, and the grinding ball and the mixed material are ball milled at a speed of 500rpm / min for 13h at a mass ratio of 0.8:1, and then Gas atmosphere, calcination at 600°C for 18 hours, and after cooling, a lithium-rich lithium nickelate material was obtained;

[0080] (2) Mix the lithium-rich lithium nickelate material prepared in step (1) with the aluminum nitrate solution with a concentration of 3mol / L at a mass ratio of 1:1.6, and stir for 10min at a speed of 300rpm / min for wet coating , and then filter and separate the wet slurry, dry it in an argon atmosphere at a temperature of 100°C for 18 hours, then sinter it at a temperature of 600°C in an argon atmosphere for 18 hours, and obtain a po...

Embodiment 2

[0086] This embodiment provides a preparation method of a positive electrode lithium supplement additive, and the preparation method specifically includes the following steps:

[0087] (1) Lithium oxide and nickel oxide are mixed uniformly at a molar ratio of 0.9:1 to obtain a mixed material, and the grinding ball and the mixed material are ball milled at a speed of 400 rpm / min for 14 hours at a mass ratio of 0.5:1, and then Gas atmosphere, calcination at a temperature of 500 ° C for 24 hours, and obtained a lithium-rich lithium nickelate material after cooling;

[0088] (2) Mix the lithium-rich lithium nickelate material prepared in step (1) with the aluminum borate solution with a concentration of 1mol / L at a mass ratio of 1:2, and stir for 12min at a speed of 280rpm / min for wet coating , and then filter and separate the wet slurry, dry it in an argon atmosphere at a temperature of 60°C for 24 hours, then sinter it in an argon atmosphere at a temperature of 500°C for 24 hour...

Embodiment 3

[0094] This embodiment provides a preparation method of a positive electrode lithium supplement additive, and the preparation method specifically includes the following steps:

[0095] (1) Lithium oxide and nickel oxide are mixed uniformly at a molar ratio of 1.1:1 to obtain a mixed material, and the grinding ball and the mixed material are ball milled at a speed of 600rpm / min for 12h at a mass ratio of 1:1, and then Gas atmosphere, calcination at a temperature of 700°C for 12 hours, and after cooling, a lithium-rich lithium nickelate material was obtained;

[0096] (2) Mix the lithium-rich lithium nickelate material prepared in step (1) with the aluminum oxalate solution with a concentration of 5mol / L at a mass ratio of 1:1.2, and stir for 8min at a speed of 320rpm / min for wet coating , and then the wet slurry separated by filtration is dried in an argon atmosphere at a temperature of 150° C. for 12 hours, and then sintered in an argon atmosphere at a temperature of 700° C. f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com