A method for preparing concave cubic platinum-rare earth alloy nanocrystals based on a eutectic solvent

A technology of deep eutectic solvent and rare earth alloy, which is applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science. layer and other problems, to achieve excellent electrocatalytic performance and enhance the effect of poisoning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

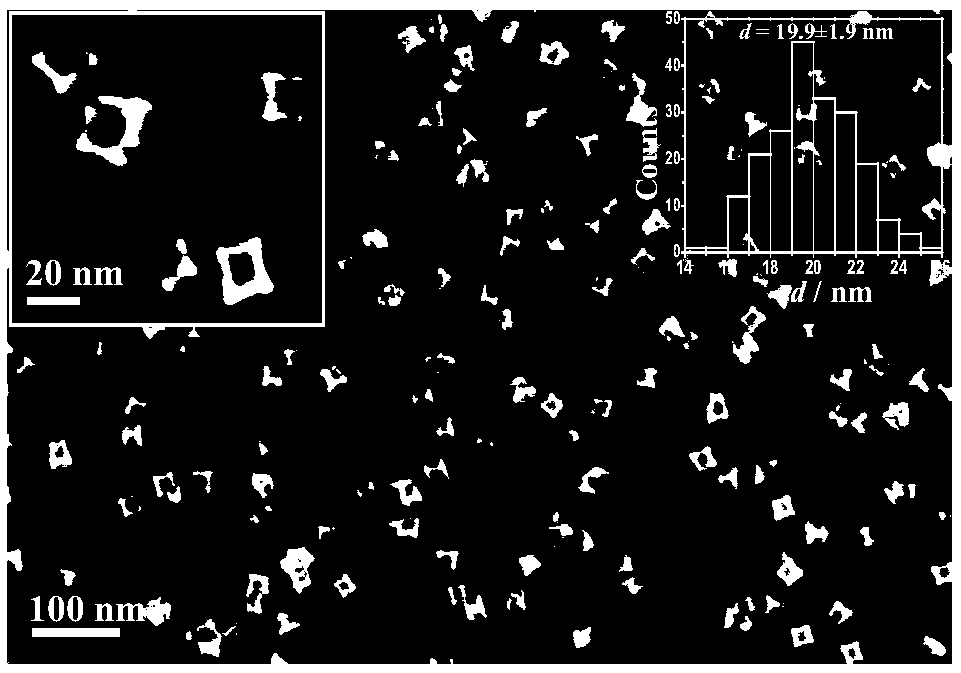

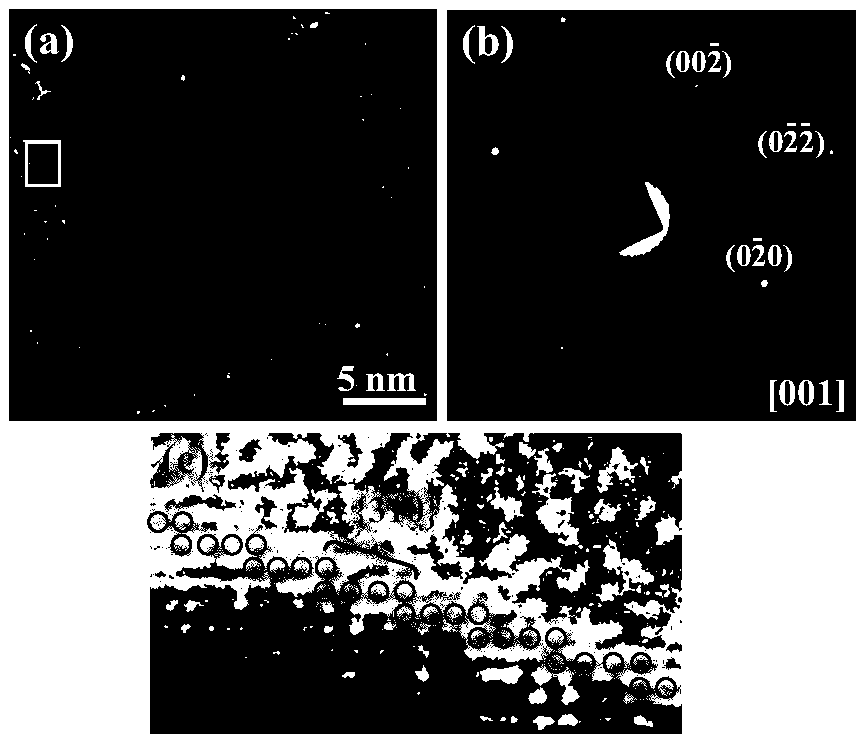

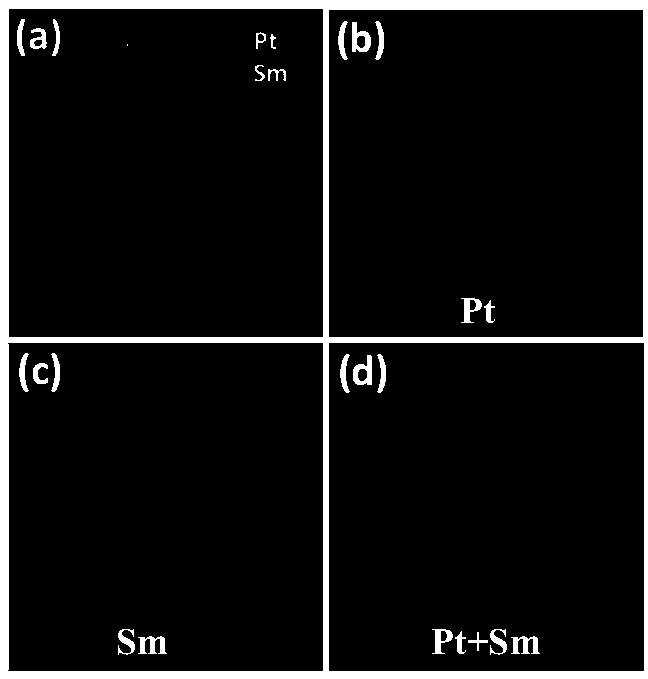

[0026] In this embodiment, the preparation method of platinum-rare earth alloy nanocrystals based on deep eutectic solvent concave cubes is realized in the following steps:

[0027] (1) Preparation of urea-choline chloride-based deep eutectic solvent: Add urea and choline chloride into a round-bottomed flask with a molar ratio of 1:2, seal it, place it in a glycerin bath at 80°C, and wait to form a molten state Afterwards, it was stirred by magnetic force until it became a colorless liquid, and the choline chloride-urea group deep eutectic solvent was obtained, which was set aside.

[0028] (2) Preparation of alloy plating solution: weigh 485.99mg potassium hexachloroplatinate and 44.47mg samarium nitrate, and dissolve them in the deep eutectic solvent prepared by the step (1) of 100ml, be mixed with 10mM hexachloroplatinum Potassium chloride and 1 mM samarium nitrate in a choline chloride-ureido deep eutectic solvent solution.

[0029] (3) Preparation of glassy carbon electr...

Embodiment 2

[0034] In this embodiment, the preparation method of platinum-rare earth alloy nanocrystals based on deep eutectic solvent concave cubes is realized in the following steps:

[0035] "44.47mg samarium nitrate" used in step (2) in Example 1 was changed to "45.14mg gadolinium nitrate". The remaining steps in this embodiment are the same as those in Example 1, and concave cubic Pt-Gd alloy nanocrystals can be prepared.

Embodiment 3

[0037] In this embodiment, the preparation method of platinum-rare earth alloy nanocrystals based on deep eutectic solvent concave cubes is realized in the following steps:

[0038] "44.47mg samarium nitrate" used in step (2) in Example 1 was changed to "32.49mg lanthanum nitrate". The remaining steps in this embodiment are the same as those in Example 1, and concave cubic Pt—La alloy nanocrystals can be prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com