Standard Particle Generator

A technology for generating devices and particles, which is applied in measuring devices, particle suspension analysis, solid separation, etc., and can solve the problems of low production efficiency and poor quality of standard particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

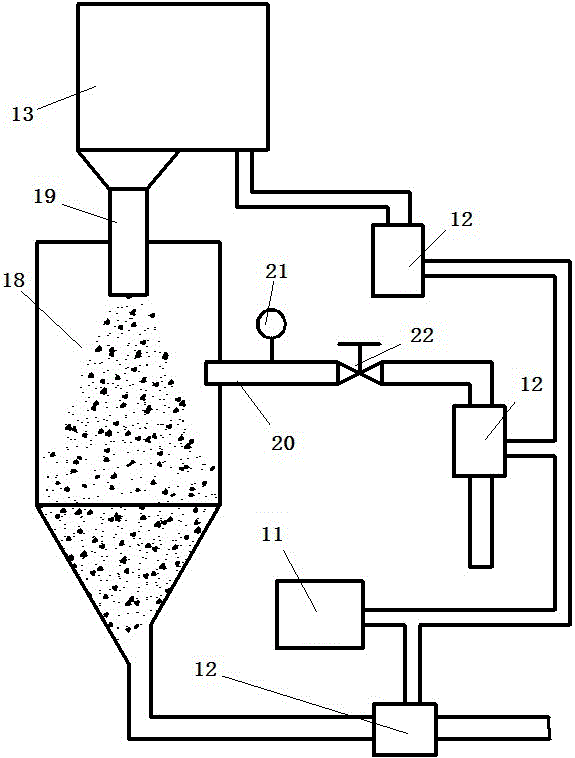

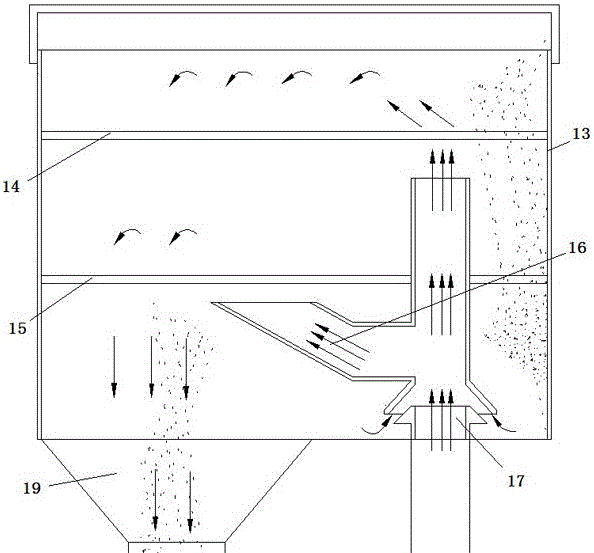

[0018] Examples of standard particle generating devices, such as Figure 1-3 As shown, the standard particle generating device includes a gas distribution mechanism, a boiling type particle screening device and a bucket type particle separation device, wherein the boiling type particle screening device and the bucket type particle separation device are arranged one above the other, and the two respectively constitute the standard Primary and secondary sorting device for particles.

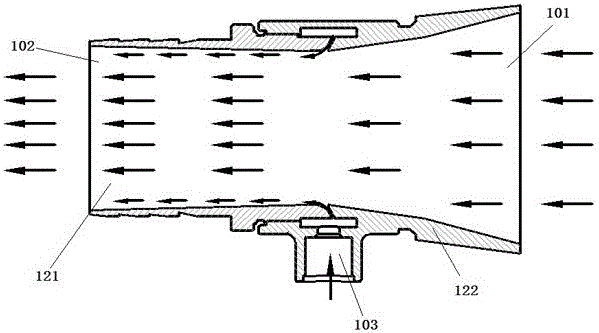

[0019] The air distribution mechanism includes an air pump 11 and a pipeline connected to the air pump 11. In this embodiment, the pipeline is specifically divided into three parallel paths, and the three paths are respectively provided with a pneumatic air extraction device 12. The pneumatic air extraction device 12 includes a gas pipe One end of the trachea is provided with an air suction port 101, and the other end is provided with an air exhaust port 102. In addition, an annular air chamber 103...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com