A kind of preparation method of multi-element refractory alloy spherical powder

A technology of refractory alloy and spherical powder, which is applied in the field of preparation of multi-element refractory alloy spherical powder, can solve the problems of difficult and stable batch production, fast heat conduction, high impurity content, etc., and achieve suitable large-scale production and process Simple and controllable effect with uniform powder composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

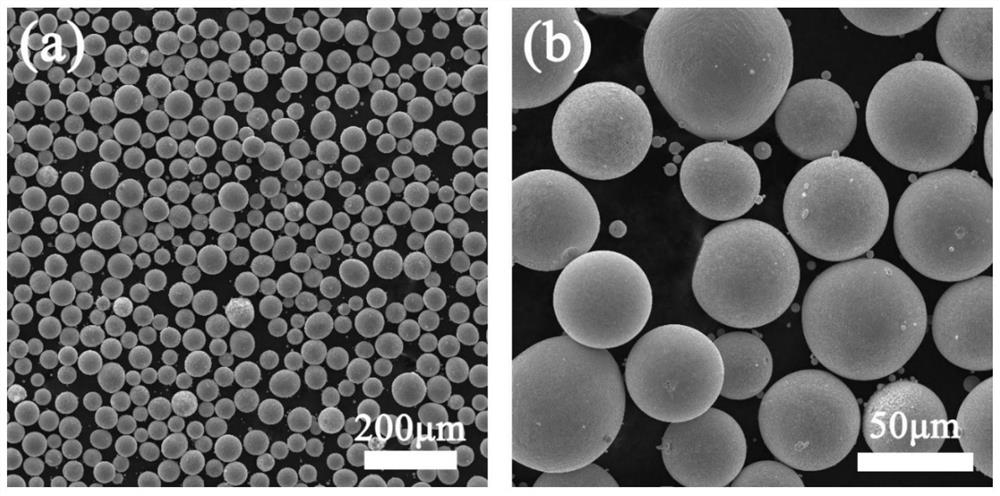

Embodiment 1

[0053] Preparation of WMoTaNbV refractory alloy spherical powder:

[0054] (1) Perform mechanical ball milling of niobium hydride powder, tantalum hydride powder, and vanadium hydride powder with a purity > 99.9% and a particle size > 75 microns (> 200 mesh). The ball milling time is 8 hours, the speed is 250r / min, and the ball-to-material ratio is 10 : 1, ball milling and sieving to obtain metal hydride powder with a particle size of 1-5 microns.

[0055] (2) Use 99.9% pure molybdenum powder with a particle size of 1 to 5 microns, tungsten powder with a particle size of 1 to 5 microns, and niobium hydride powder, tantalum hydride powder, and vanadium hydride powder after ball milling as refractory alloy raw material powders. Percentage 25% Weigh the raw materials of each component, the total mass is 25kg, and then add the refractory alloy powder raw material, 40% of the total mass of absolute ethanol and 6% of the total mass of vinyl acetate polymer to the ball mill for ball ...

Embodiment 2

[0063] Preparation of TaNbTiV refractory alloy spherical powder:

[0064] (1) The niobium hydride powder, tantalum hydride powder, and titanium hydride powder with a purity > 99.9% and a particle size > 75 microns (> 200 mesh) are mechanically ball milled, the ball milling time is 8 hours, the rotating speed is 250r / min, and the ball-to-material ratio is 10:1, ball milling and sieving to obtain metal hydride powder with a particle size of 1-5 microns.

[0065] (2) the niobium hydride powder, tantalum hydride powder, and titanium hydride powder after the ball milling of elemental vanadium powder with a particle size of 99.9% purity of 1 to 5 microns and a particle size of 1 to 5 microns are used as refractory alloy raw material powders, according to The atomic percentage is 25% and the raw material is weighed, the total mass is 5kg, and then the refractory alloy powder raw material, 25% of the total mass of absolute ethanol and 2% of the total mass of vinyl acetate polymer are ...

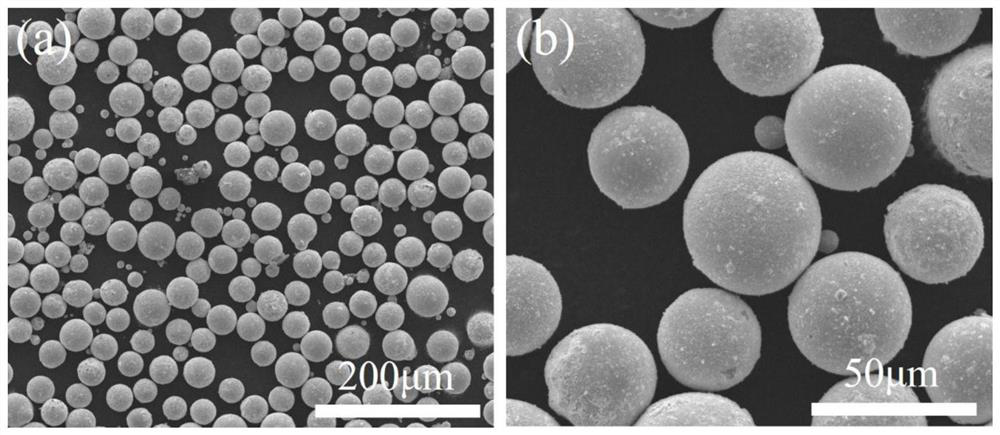

Embodiment 3

[0071] Preparation of WMoTaNb refractory alloy spherical powder:

[0072] (1) Perform mechanical ball milling of niobium hydride powder and tantalum hydride powder with a purity >99.9% and a particle size >75 microns (>200 mesh). Afterwards, sieve to obtain metal hydride powder with a particle size of 2-5 microns.

[0073] (2) Elemental molybdenum powder with a particle size of 99.9% of 1-5 microns, tungsten powder of 1-5 microns, niobium hydride powder and tantalum hydride powder after ball milling are used as refractory alloy raw material powder, according to the atomic percentage of 25% Weigh the raw materials of each component, the total mass is 5kg, and then add the refractory alloy powder raw material, 30% of the total mass of absolute ethanol and 4% of the total mass of vinyl acetate polymer to the stirring ball mill for ball milling to obtain the refractory alloy powder slurry Material, the control ball milling time is 4 hours, the rotating speed is 150r / min, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com