Nano-porous Al-Ni-M-RE-R amorphous alloy used as hydrogen evolution catalytic electrode, and preparation method thereof

An amorphous alloy, nanoporous technology, applied in electrodes, electrode shape/type, electrolysis process, etc., can solve problems such as difficulty in preparing nanoporous structures, achieve excellent hydrogen evolution catalytic performance, high specific strength and specific stiffness, and reduce hydrogen evolution. effect of overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

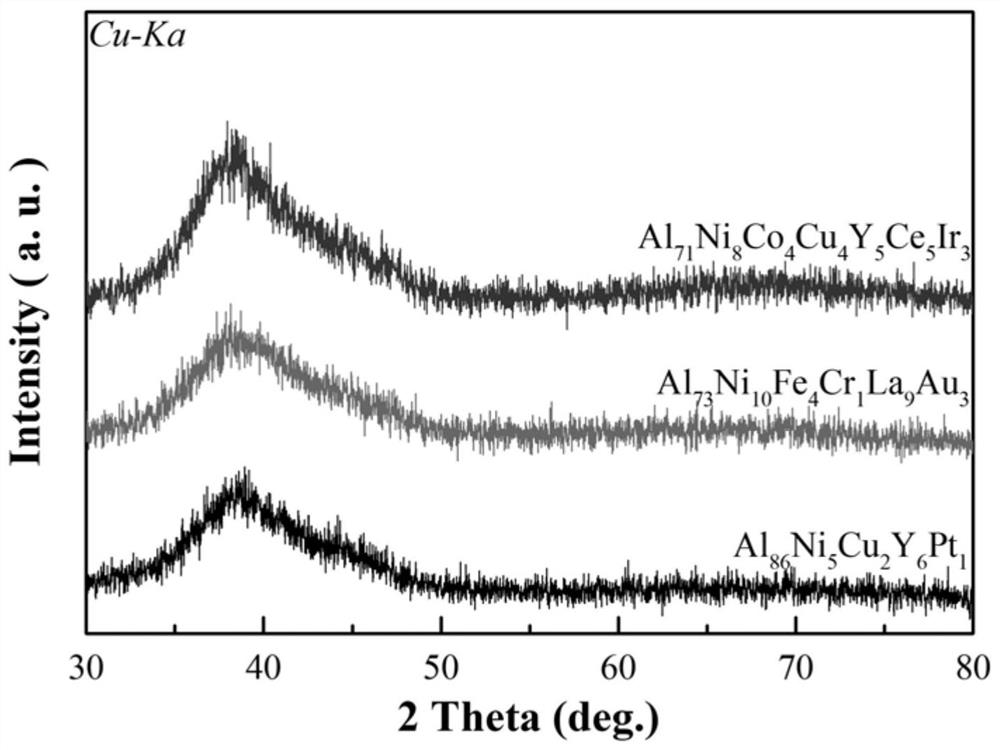

Embodiment 1

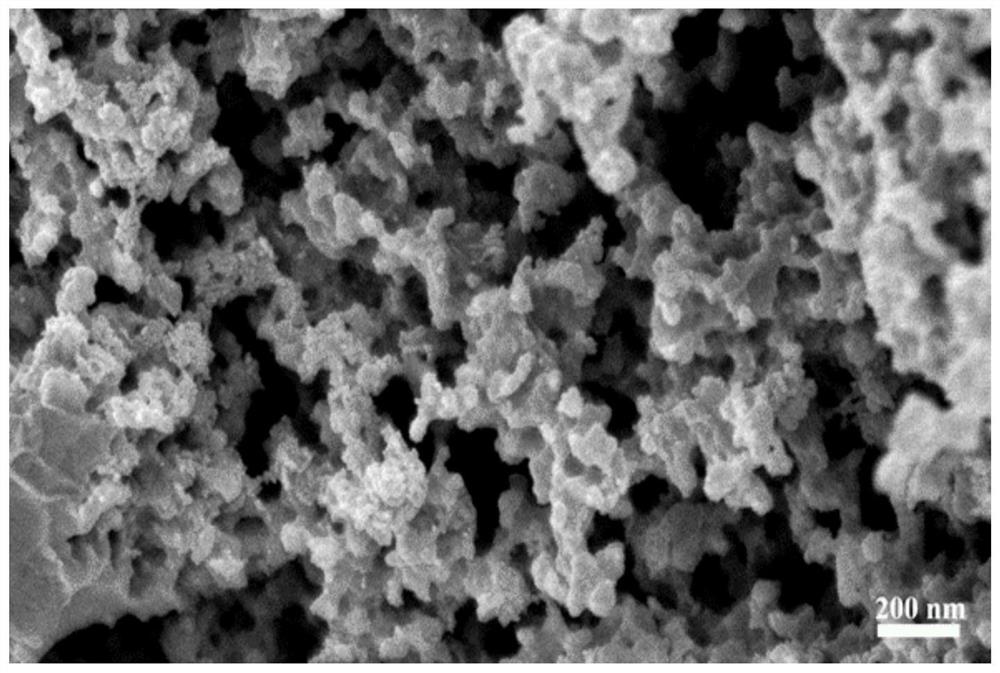

[0065] Preparation of nanoporous Al-5Ni-2Cu-6Y-1Pt (that is, Al 86 Ni 5 Cu 2 Y 6 Pt 1 ) Amorphous alloy hydrogen evolution catalytic electrode

[0066] Step 1: Dispensing ingredients according to the target ingredients;

[0067] According to the target composition Al-5Ni-2Cu-6Y-1Pt, Al, Ni, Cu, Y and Pt elemental raw materials with a mass percentage purity of not less than 99.9% are selected, and the smelting raw materials are obtained by batching;

[0068] In the present invention, the order of placing the smelting raw materials is set according to the melting point of the raw material components, the elements with low melting points in the raw material components are placed in the upper layer, and the elements with high melting point in the raw material components are placed in the lower layer.

[0069] Step 2: batch master alloy ingots produced by arc melting and high frequency induction melting;

[0070] In step 2A, vacuum arc melting is carried out on the elemental ...

Embodiment 2

[0080] Preparation of nanoporous Al-10Ni-4Fe-1Cr-9La-3Au (ie Al 73 Ni 10 Fe 4 Cr 1 La 9 Au 3 ) Amorphous alloy hydrogen evolution catalytic electrode

[0081] Step 1: Dispensing ingredients according to the target ingredients;

[0082] According to the target composition Al-10Ni-4Fe-1Cr-9La-3Au, select the elemental raw material with a mass percentage purity of not less than 99.9%, and mix the ingredients to obtain the smelting raw material;

[0083] In the present invention, the order of placing the smelting raw materials is set according to the melting point of the raw material components, the elements with low melting points in the raw material components are placed in the upper layer, and the elements with high melting point in the raw material components are placed in the lower layer.

[0084] Step 2: batch master alloy ingots produced by arc melting and high frequency induction melting;

[0085] In step 2A, vacuum arc melting is carried out on the elemental metal ...

Embodiment 3

[0095] Preparation of nanoporous Al-8Ni-4Co-4Cu-5Y-5Ce-3Ir (ie Al 71 Ni 8 co 4 Cu 4 Y 5 Ce 5 Ir 3 ) Amorphous alloy hydrogen evolution catalytic electrode

[0096] Step 1: Dispensing ingredients according to the target ingredients;

[0097] According to the target composition Al-8Ni-4Co-4Cu-5Y-5Ce-3Ir, select the elemental raw material with a mass percentage purity of not less than 99.9%, and mix the ingredients to obtain the smelting raw material;

[0098] In the present invention, the order of placing the smelting raw materials is set according to the melting point of the raw material components, the elements with low melting points in the raw material components are placed in the upper layer, and the elements with high melting point in the raw material components are placed in the lower layer.

[0099] Step 2: batch master alloy ingots produced by arc melting and high frequency induction melting;

[0100] In step 2A, vacuum arc melting is carried out on the elementa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com