Patents

Literature

135results about How to "Ingredients adjustable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diagnosis and treatment of autism spectrum disorder

ActiveUS20140065132A1Improve behaviorImprove performanceBiocideNervous disorderClinical psychologyAutism spectrum disorder

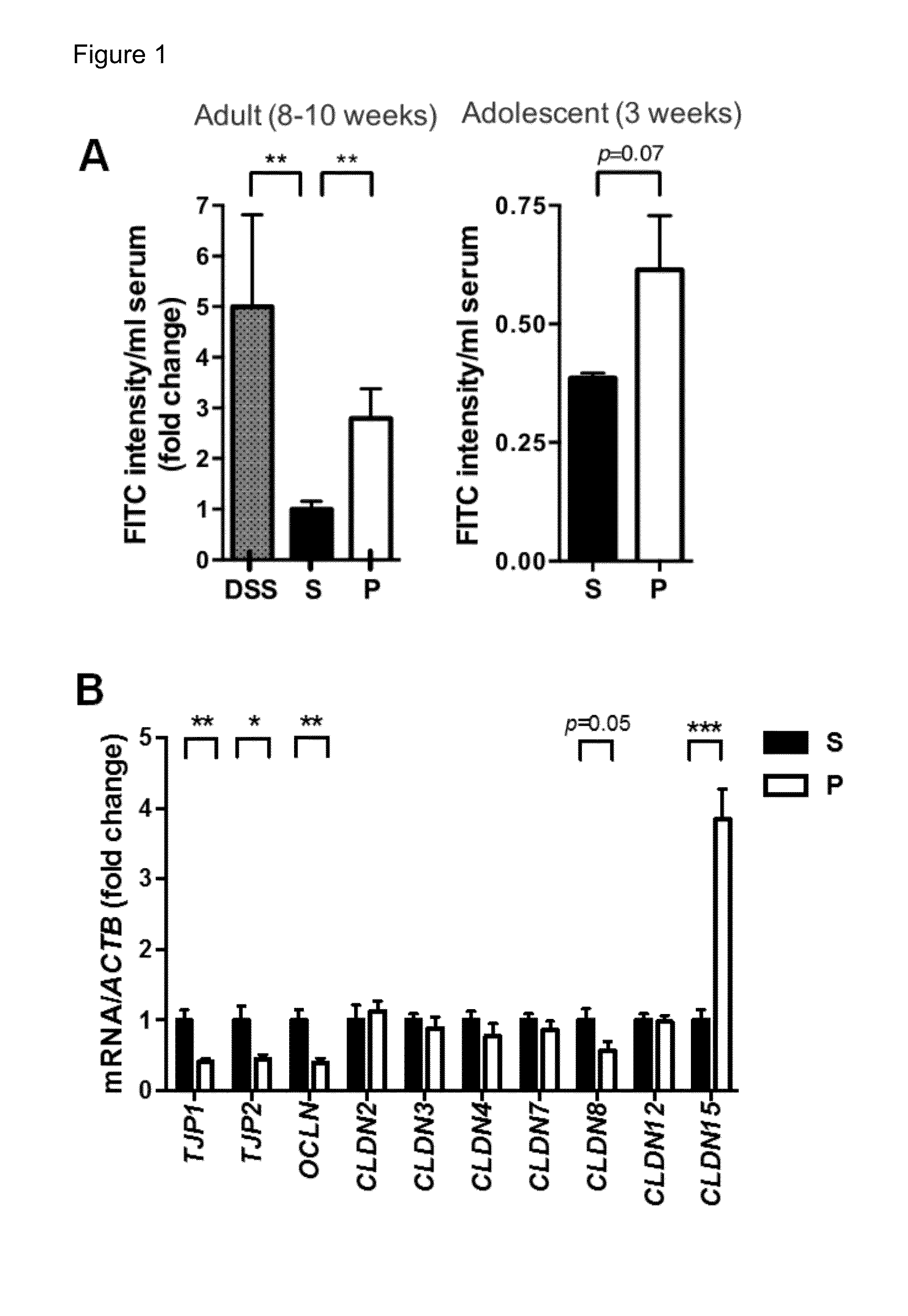

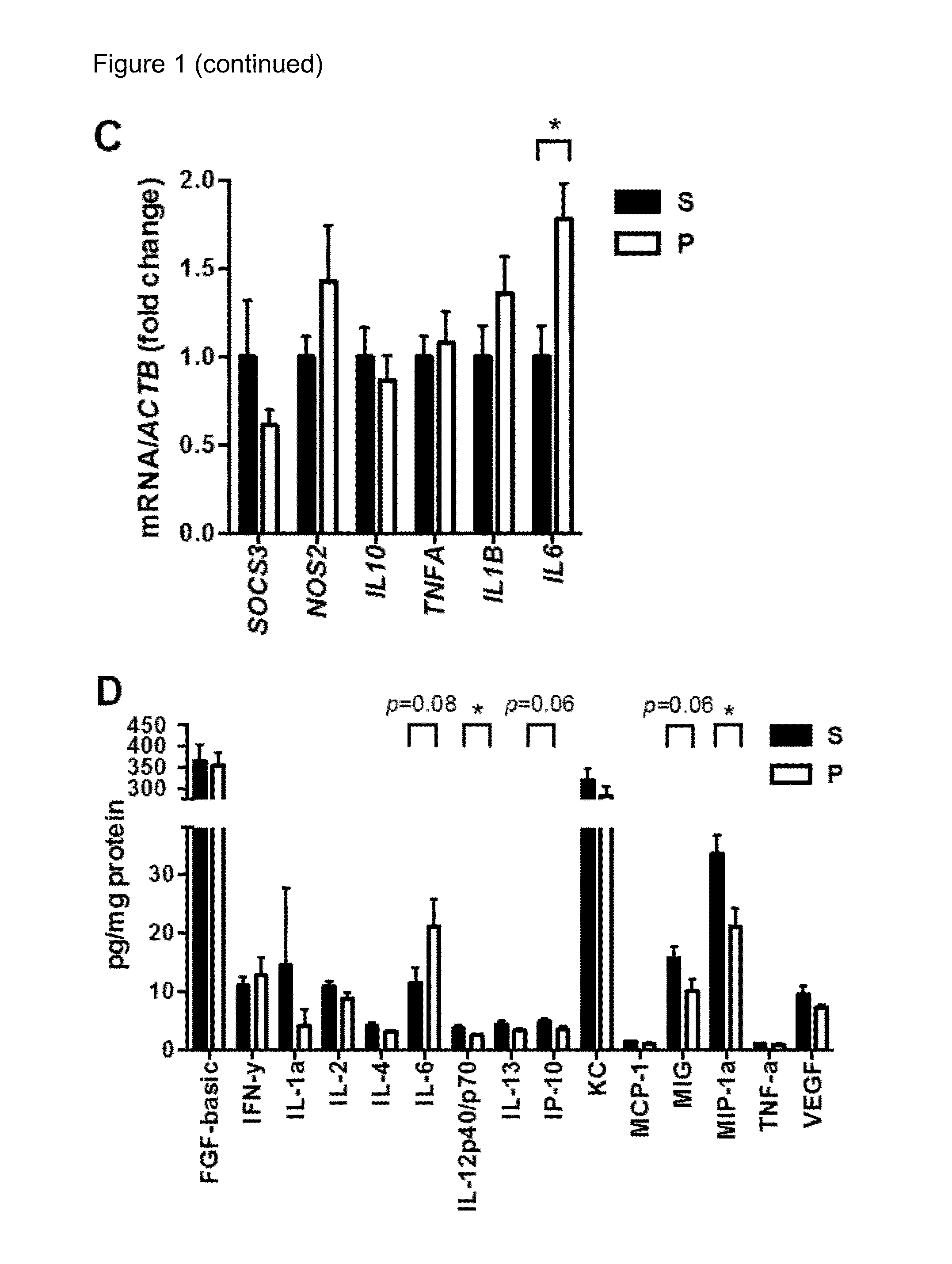

Disclosed herein are compositions, systems, and methods for diagnosing and treatment of subjects suffering from anxiety, autism spectrum disorder (ASD), or a pathological condition with one or more of the symptoms of ASD.

Owner:CALIFORNIA INST OF TECH

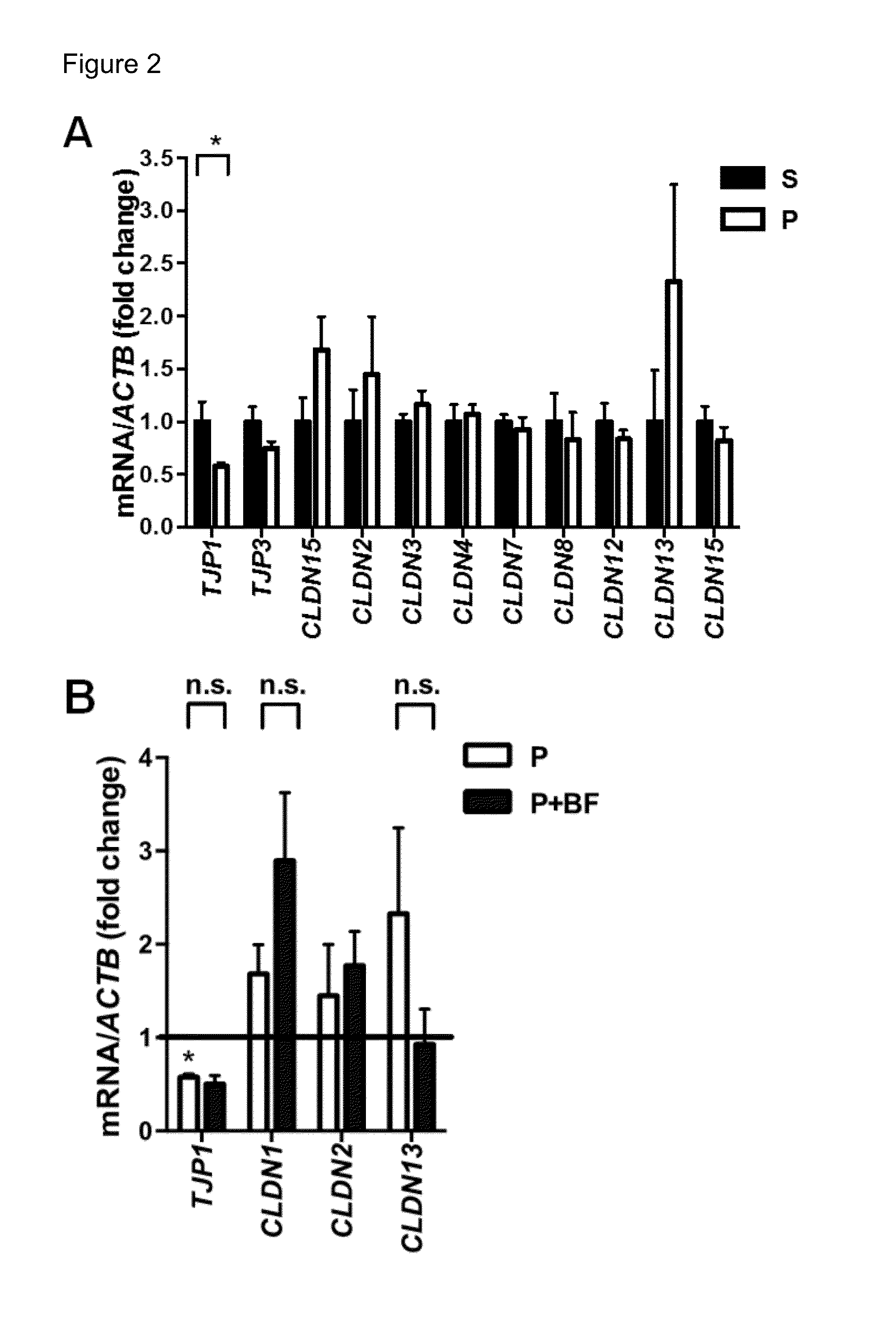

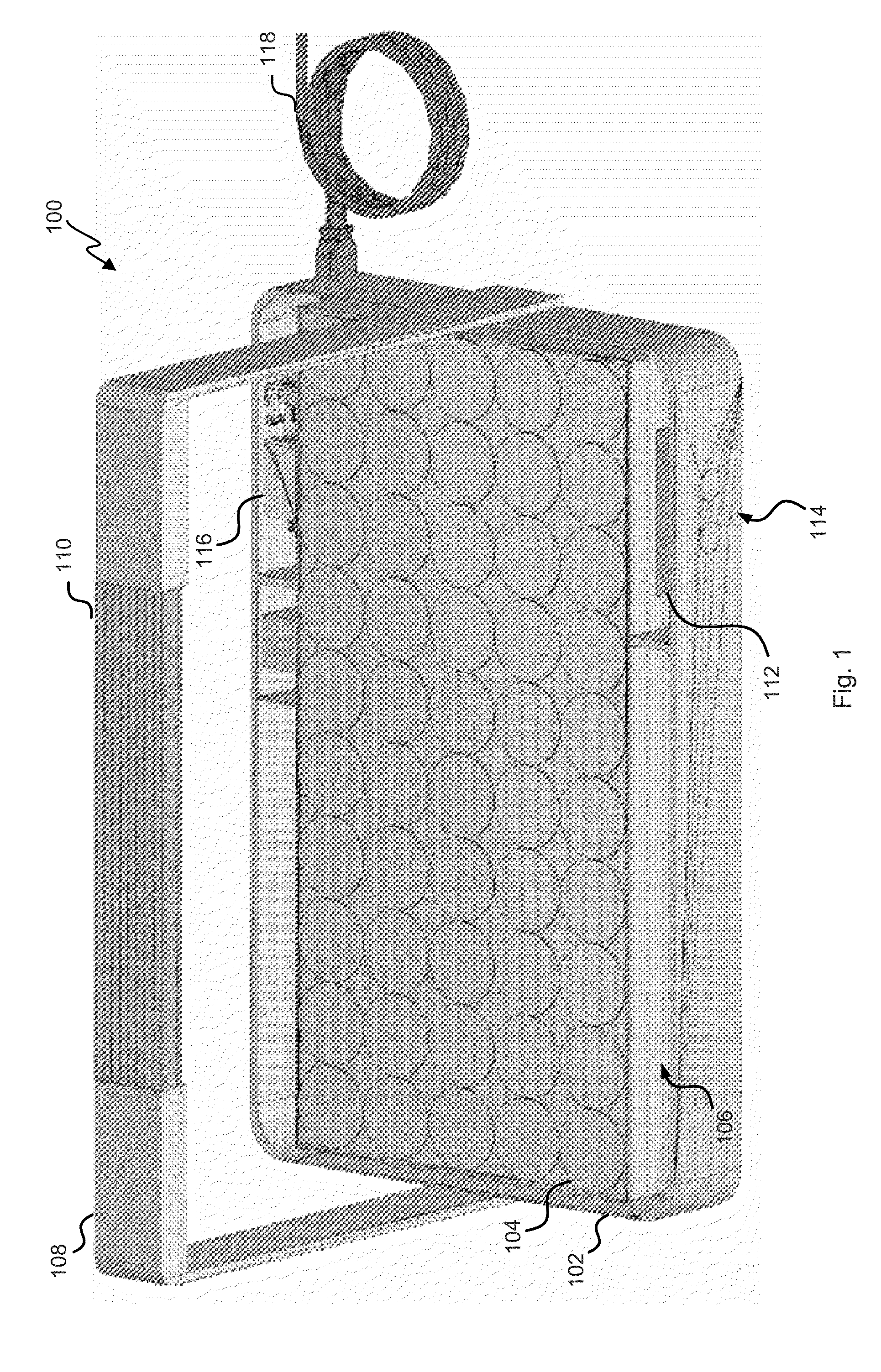

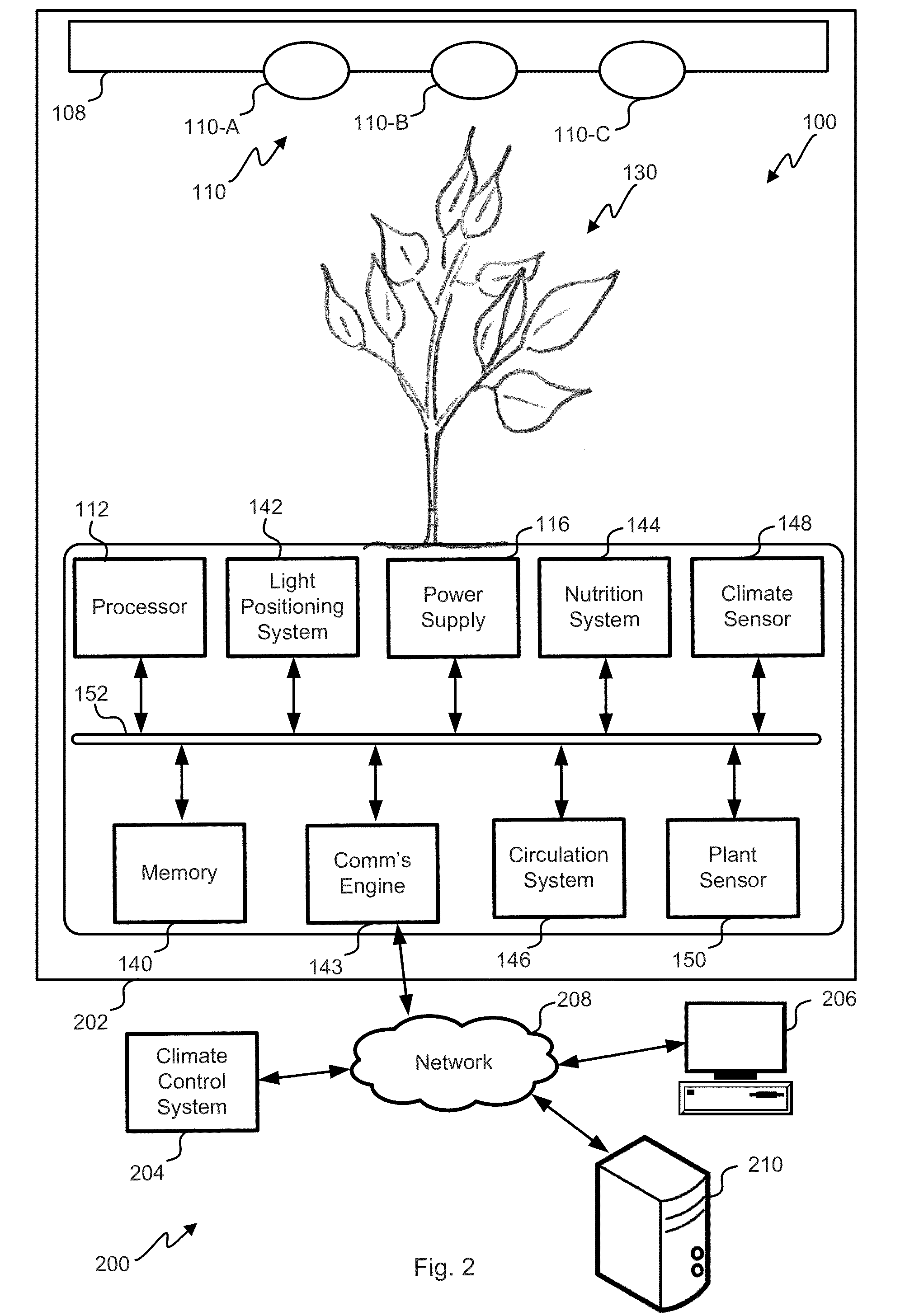

Intelligent light sources to enhance plant response

InactiveUS20150089866A1Without diminish power outputReduce outputMechanical apparatusRoot feedersLighting systemLight source

A grow system is disclosed herein. The grow system can include a grow device that can include a light system including a plurality of light sources, a light position controller, and a processor. The processor can receive information relating to a plant to be grown by the grow system and can, based on that information, identify an operation program that specifies lighting and positioning of the illumination system. Using the operation program, the processor can generate one or several control signals to control the operation of the light system and the light position system.

Owner:INTELLIGENT LIGHT SOURCE

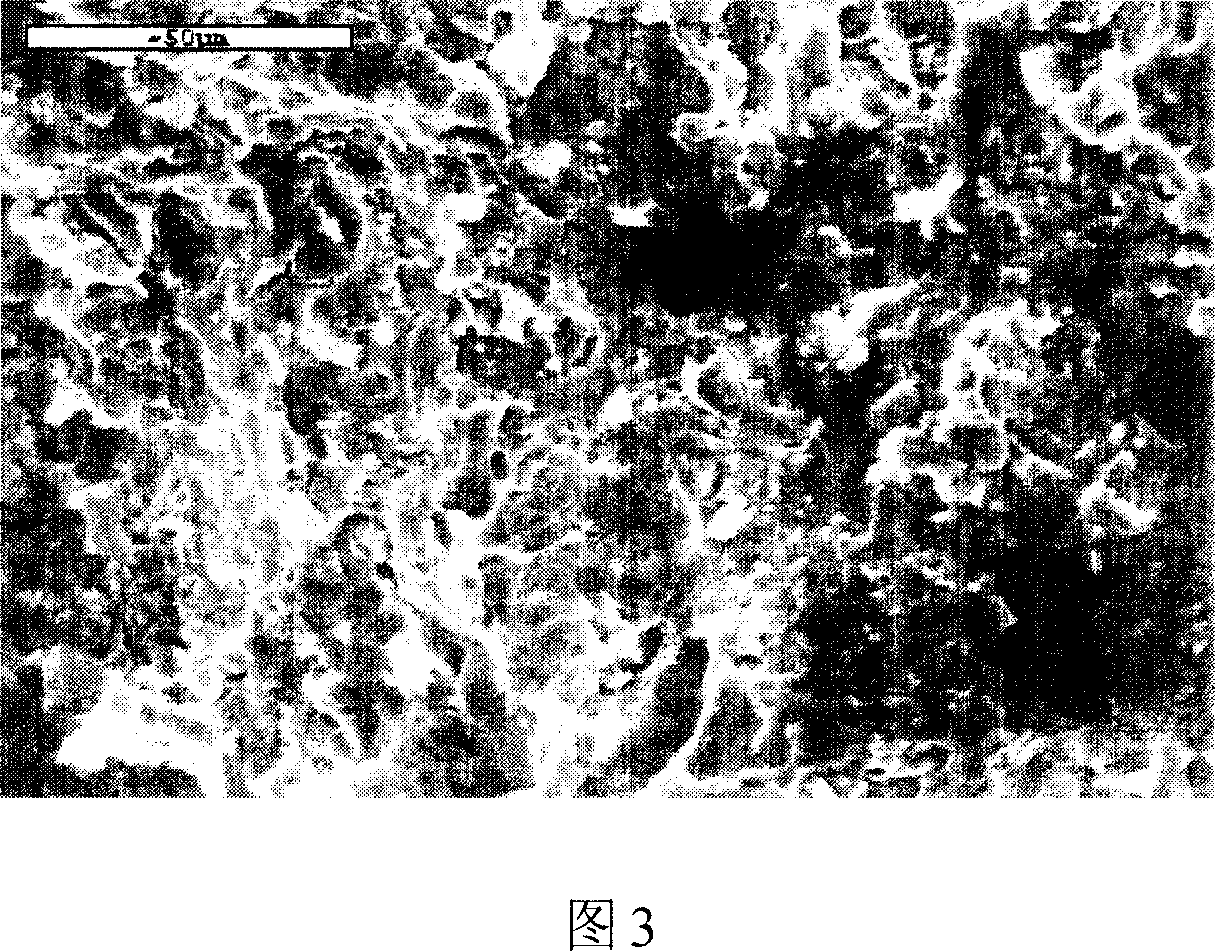

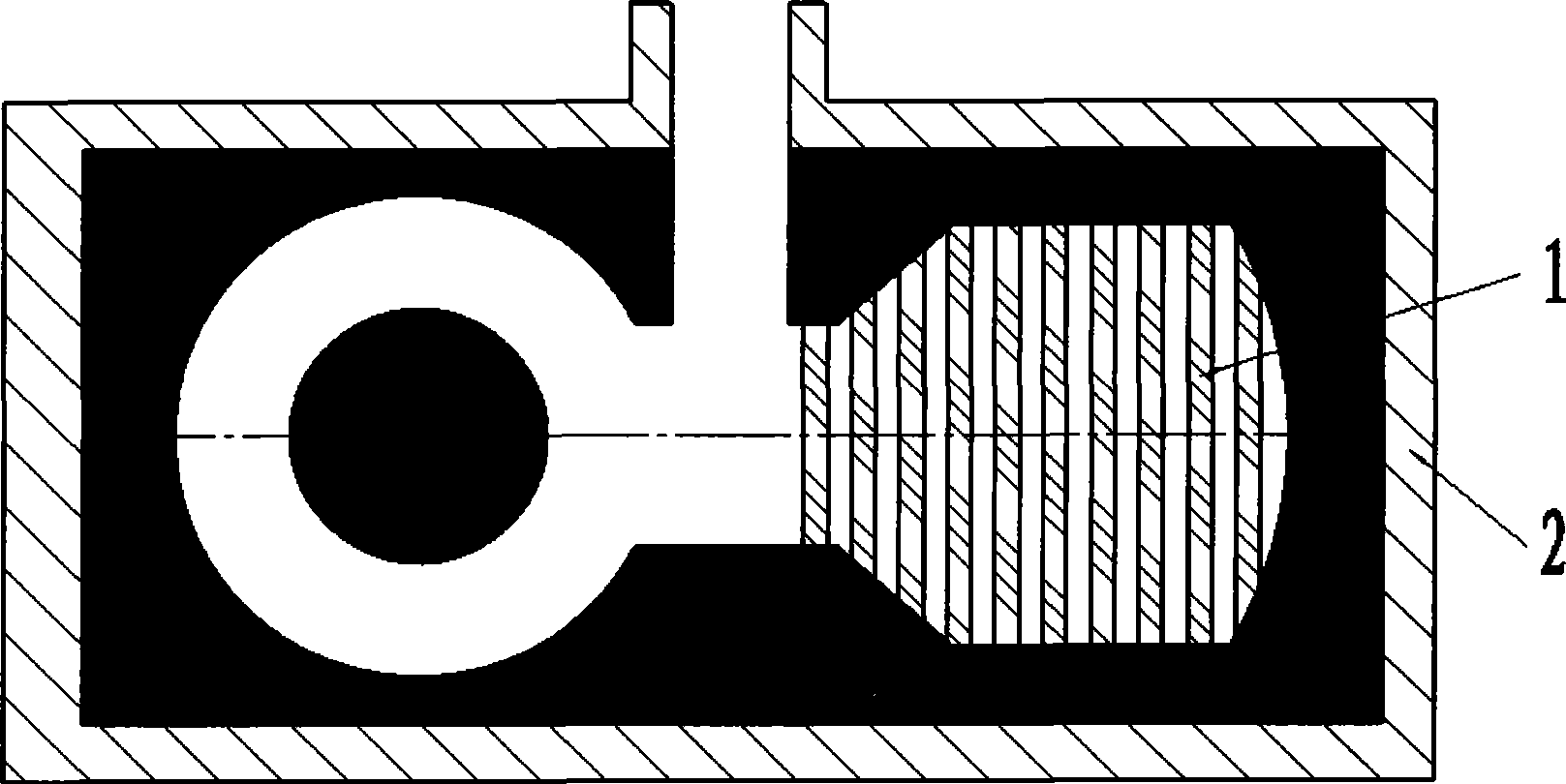

High strength and high toughness foamed SiC/Al material and its preparing method

The present invention relates to heterogeneous foamed ceramic / metal material, and is especially one kind of high strength and high toughness foamed SiC / Al material and its preparation process. The foamed SiC / Al material has basic units of closed polygonal ring to form connected 3D network structure, and each of the closed polygonal ring units is heterogeneous foamed ribs comprising SiC in 50-95 vol% and metal Al in 5-50 vol% and with the relative density not lower than 99 %. The foamed SiC / Al material is prepared through organic foam soaking, hot pressing to densify, pressure injection filling, thermal decomposition and reaction sintering. The preparation process is simple and low in cost.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

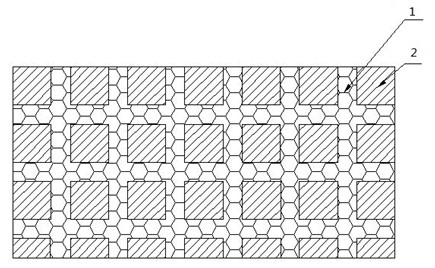

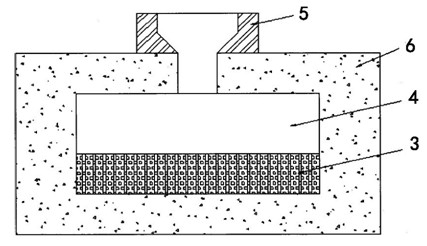

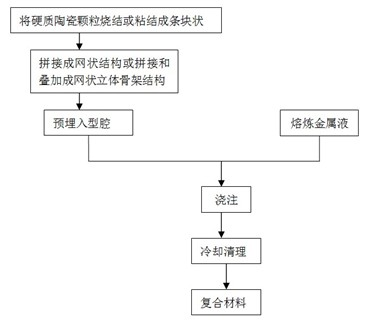

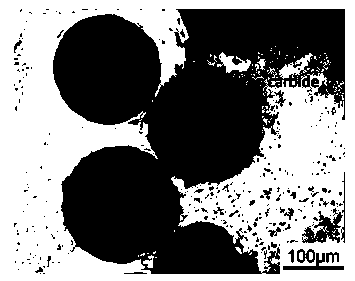

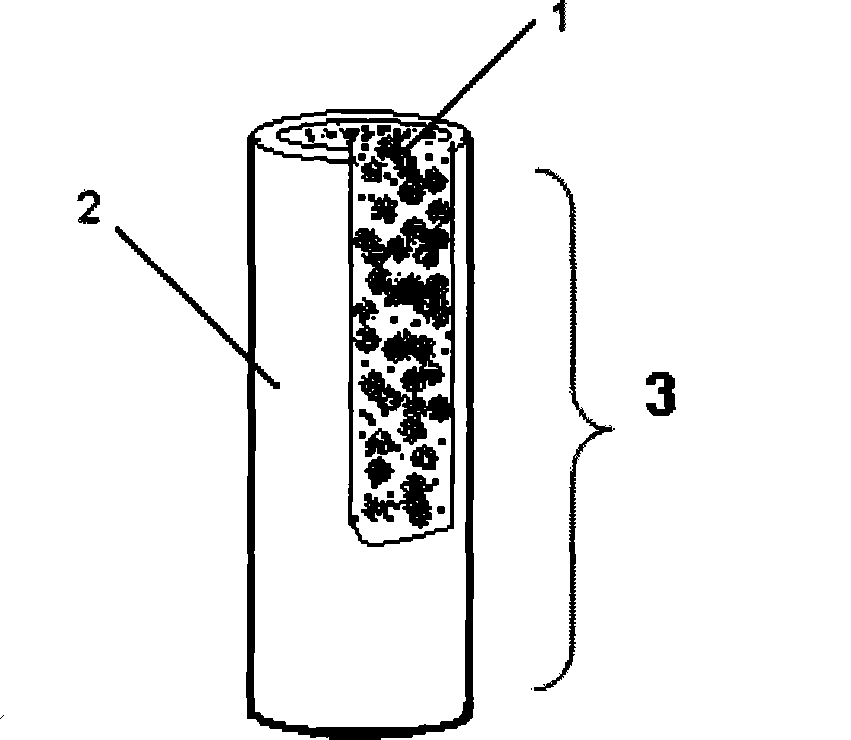

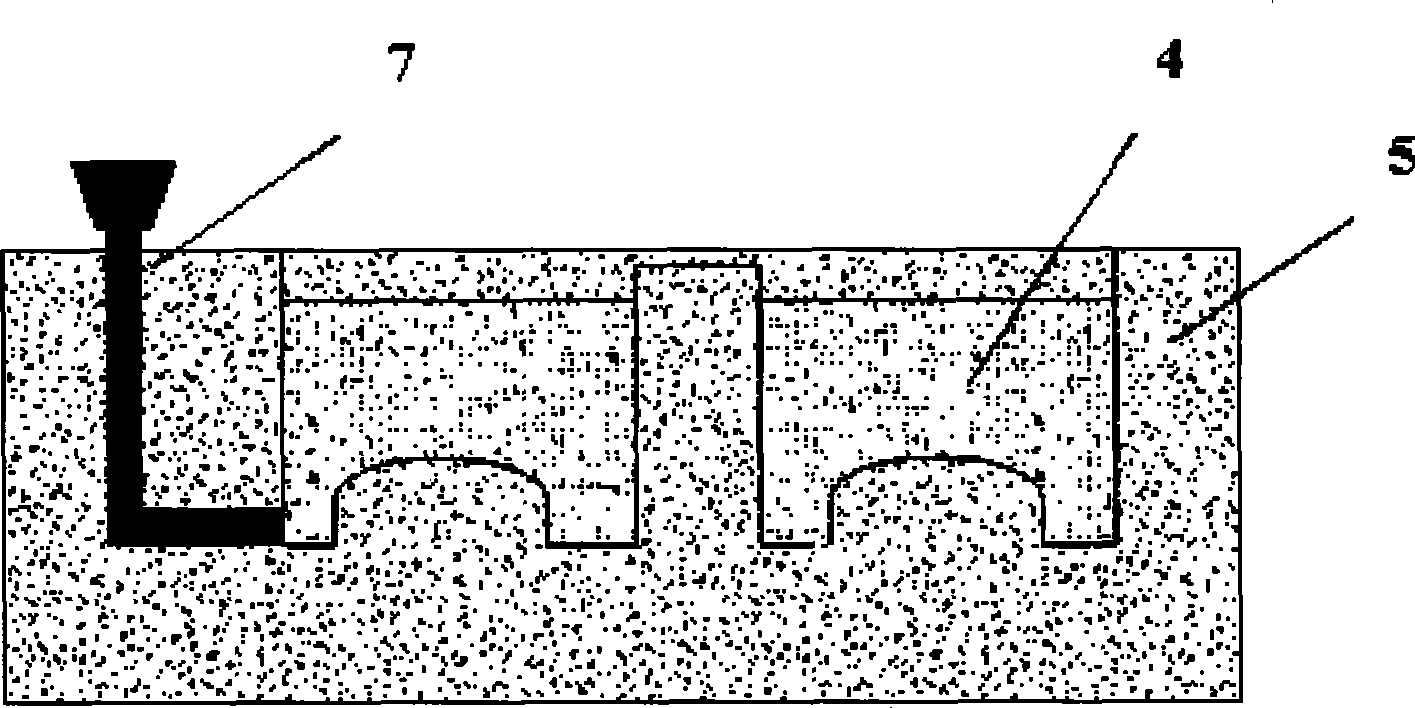

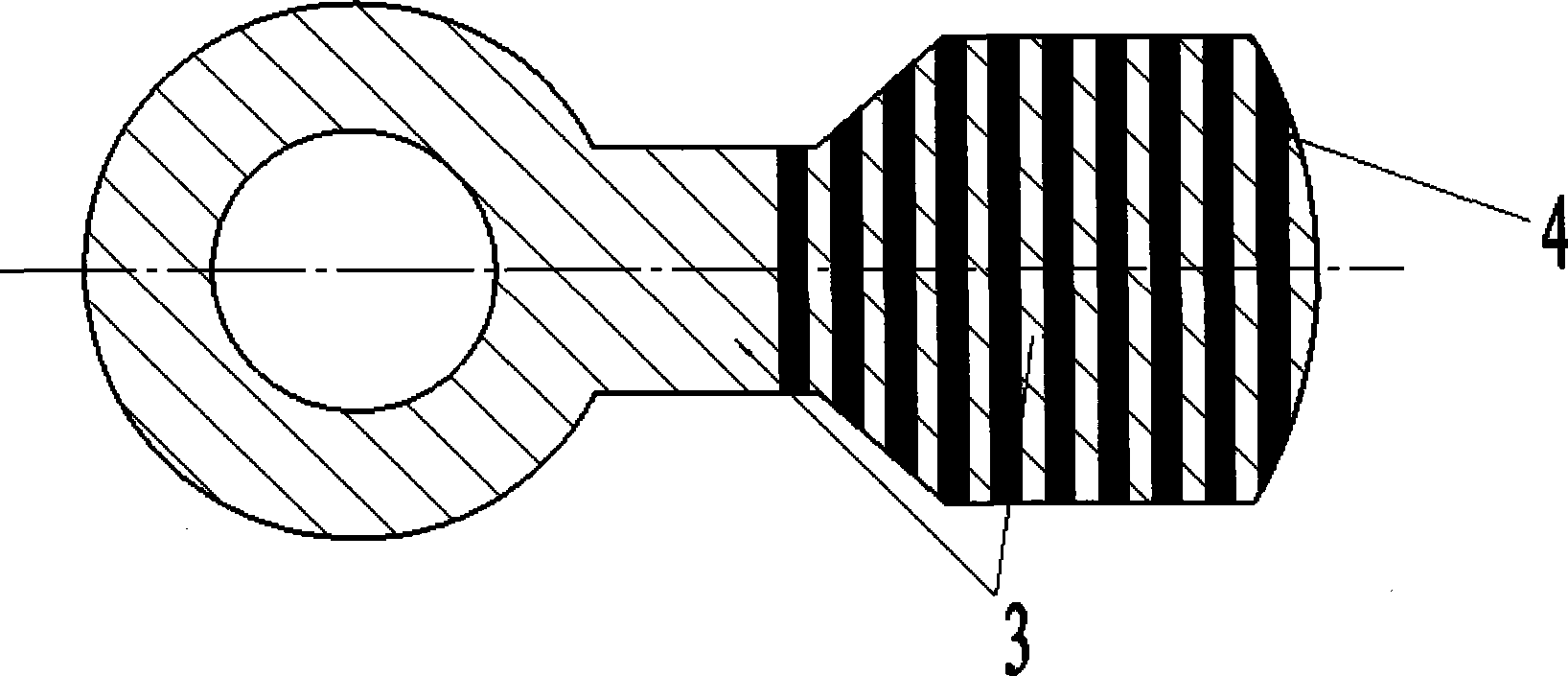

Method for preparing ceramic particle reinforced steel-based mesh material

The invention provides a method for preparing a ceramic particle reinforced steel-based mesh material, which comprises: forming a mixture of hard ceramic particles and alloy powder into strip blocks by powder sintering or by using and adhesive; joining the strip blocks into a corresponding mesh structure or joining and overlapping the strip blocks into mesh three-dimensional framework structure; and performing normal sand casting or lost foam casting, namely melting a substrate metal material, pouring the molten substrate metal material in a molding cavity, allowing the molten substrate metal material to cool and condense at room temperature, removing sand and obtaining the ceramic particle reinforced steel-based mesh material. The obtained ceramic particle reinforced steel-based mesh material gives full play to the high wear resistance of the ceramic particle hard phase and the toughness of the steel base; and the method with convenience for regulation and reliable process solves the problem of incomplete reaction of the composite material, nonuniform reinforcing phase particle distribution, pollution weakening on a reinforcing phase interface and the like and is used in wear resistance fields of mines, power, metallurgy, coal, building materials and the like.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of particle-reinforced metal matrix composite material

The invention discloses a preparation method of a particle-reinforced metal matrix composite material, and belongs to the technical field of a novel material. The method comprises the following steps: firstly, putting reinforced particles and matrix powder into a ball grinder, so as to evenly mix; then putting the mixed powder into a graphite jig, putting into spark plasma sintering (SPS) equipment; setting a proper sintering parameter, and putting the sintered sample into a vacuum tube furnace to set heating temperature, so as to change a bonding interface between the reinforced particles and the matrix in the composite material, or prompt interface reaction. The reinforced particles in the composite material prepared by the method can be well evenly distributed inside a composite layer, so that the comprehensive properties of the materials are greatly improved, the composite material is even and single in texture, the mechanical property can be changed to a certain extent, and reference is provided for high-temperature wear-resisting fields, such as steel, metallurgy, coal and the like, parts under chilled and heated conditions or other researchers for researching the composite material performances.

Owner:KUNMING UNIV OF SCI & TECH

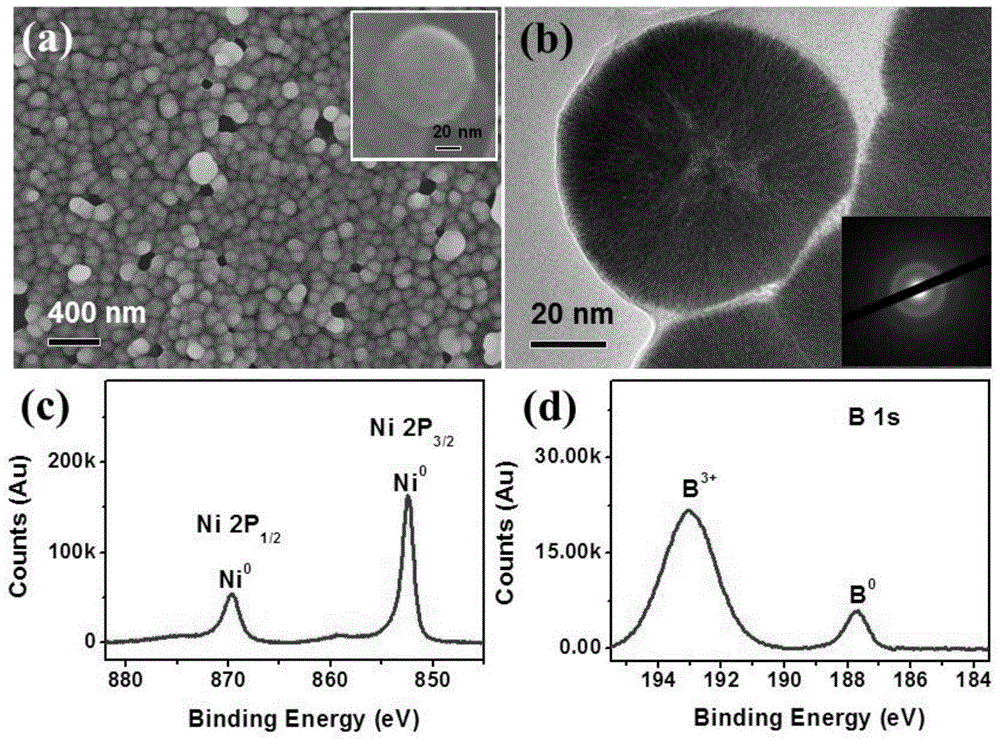

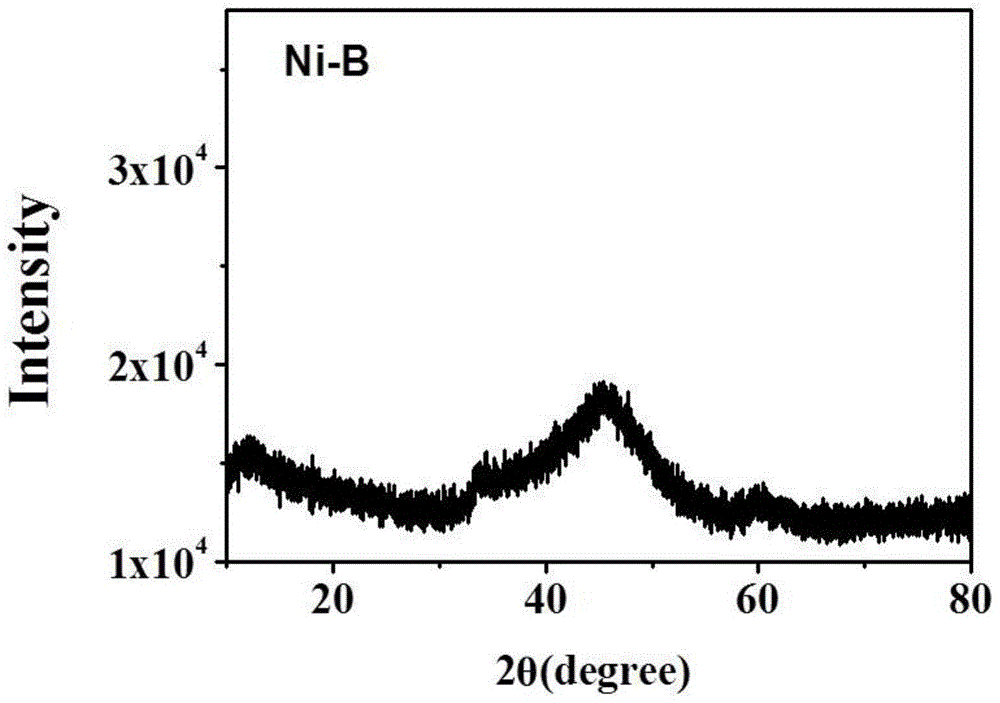

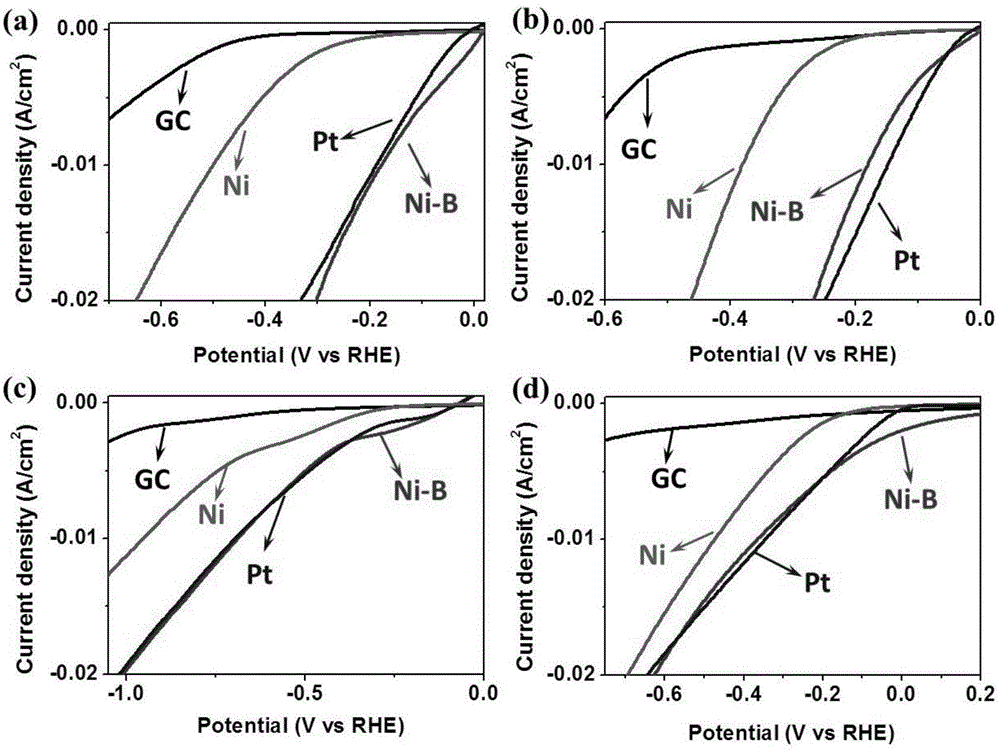

Catalyst used for preparation of hydrogen through water electrolysis, and preparation method thereof

ActiveCN103952719AReduce hydrogen evolution overpotentialHigh activityLiquid/solution decomposition chemical coatingMetal/metal-oxides/metal-hydroxide catalystsPlatinumElectrolysis

The invention provides a catalyst used for the preparation of hydrogen through water electrolysis. The catalyst is amorphous Ni-B, and an atom ratio of Ni to B is 1.0-5.0. The invention also provides a preparation method for the catalyst. The method is characterized in that Ni-B is loaded on the surface of a carrier through a chemical plating method, and the feeding atom ratio of B to Ni in a chemical plating liquid is 3.0-10.0. The amorphous Ni-B is successfully applied in the catalysis of a hydrogen evolution reaction through water decomposition, and the reaction activity of the amorphous Ni-B can be comparable with that of platinum. The amorphous Ni-B has the advantages of low hydrogen evolution over-potential, high catalytic efficiency, stable performances, low price and simple preparation, and becomes one of the most ideal catalysts for substituting the present noble metal Pt catalyst.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

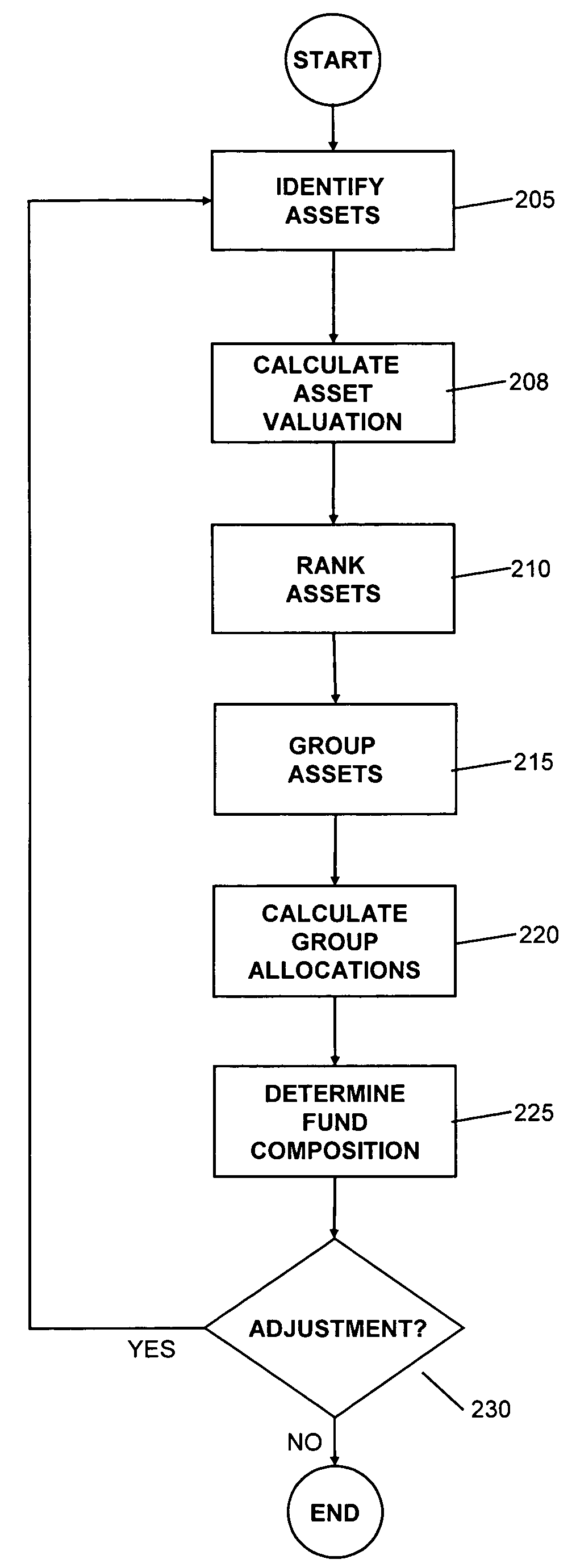

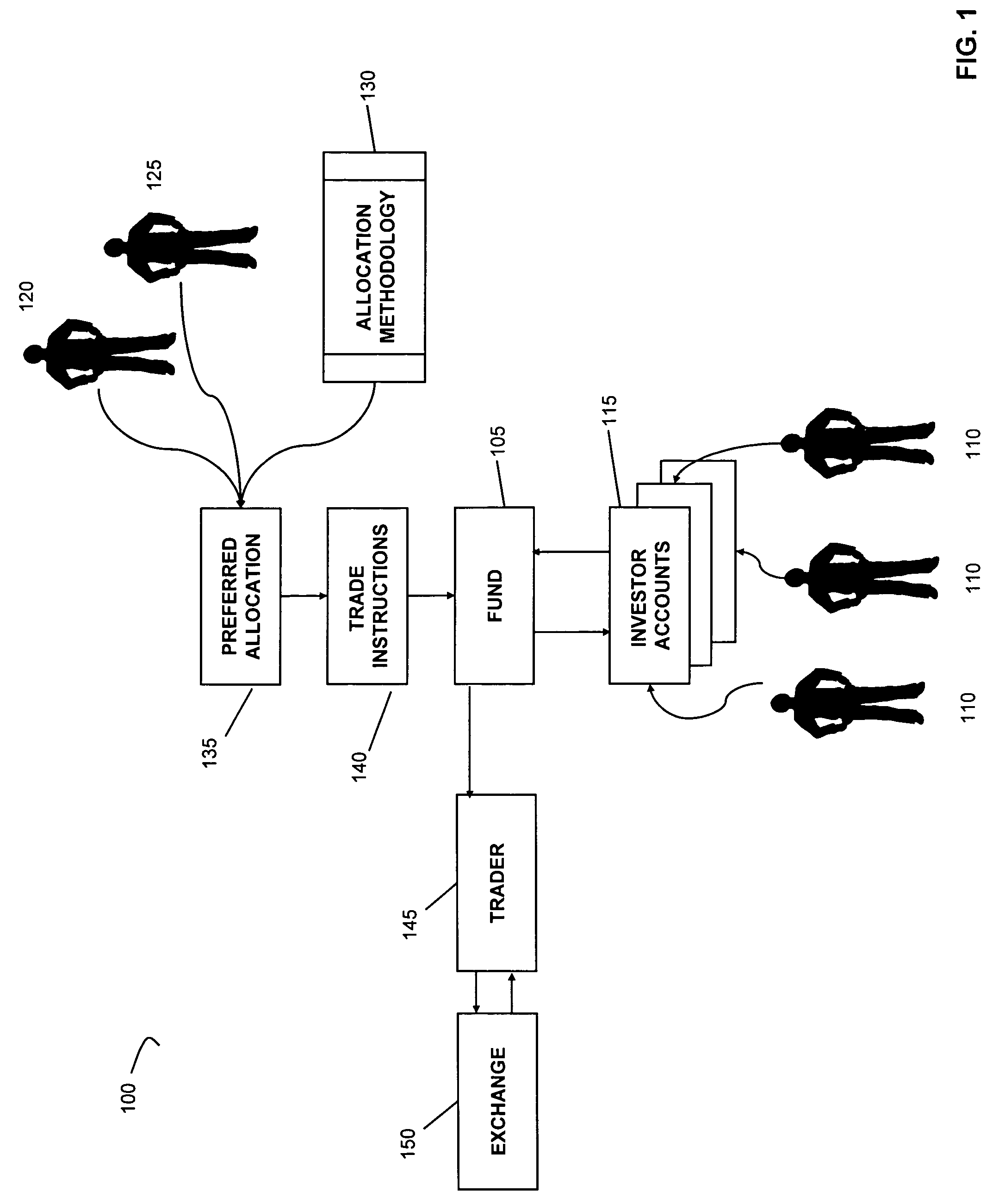

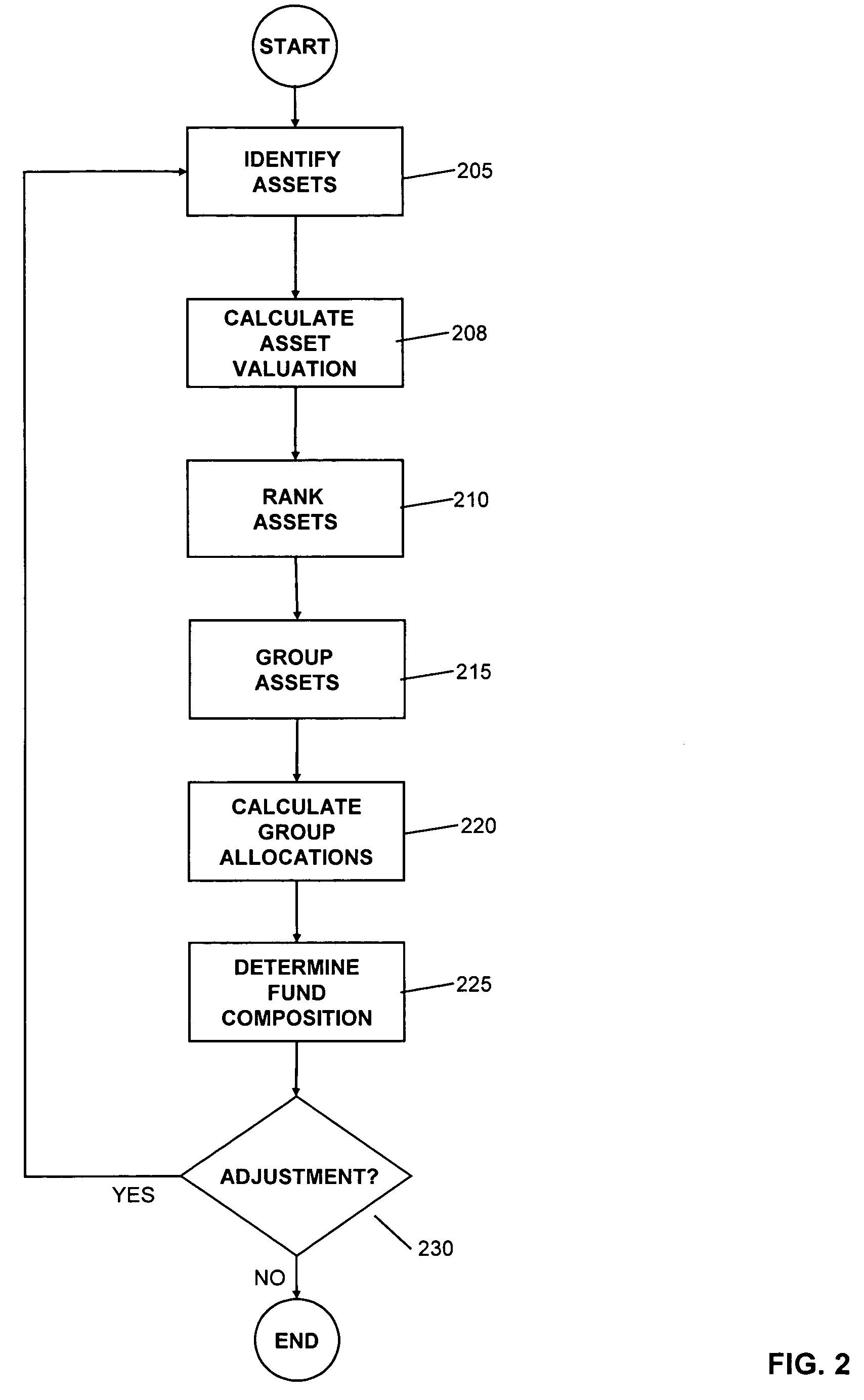

Valuation-tilted capitalization weighted investment methods and products

Investment vehicles and methods for determining the composition of such investment vehicles based on a valuation-tilted, capitalization-weighted technique includes identifying assets to be included in an investment vehicle, calculating a asset valuation for each of the assets, ranking the assets based on their respective asset valuations, based on the ranking, identifying groupings of the assets, determining a group weighting factor for each of the groupings, and determining the composition of the investment vehicle based on the group weighting factors attributed to each of the groupings.

Owner:STATE STREET GLOBAL ADVISORS

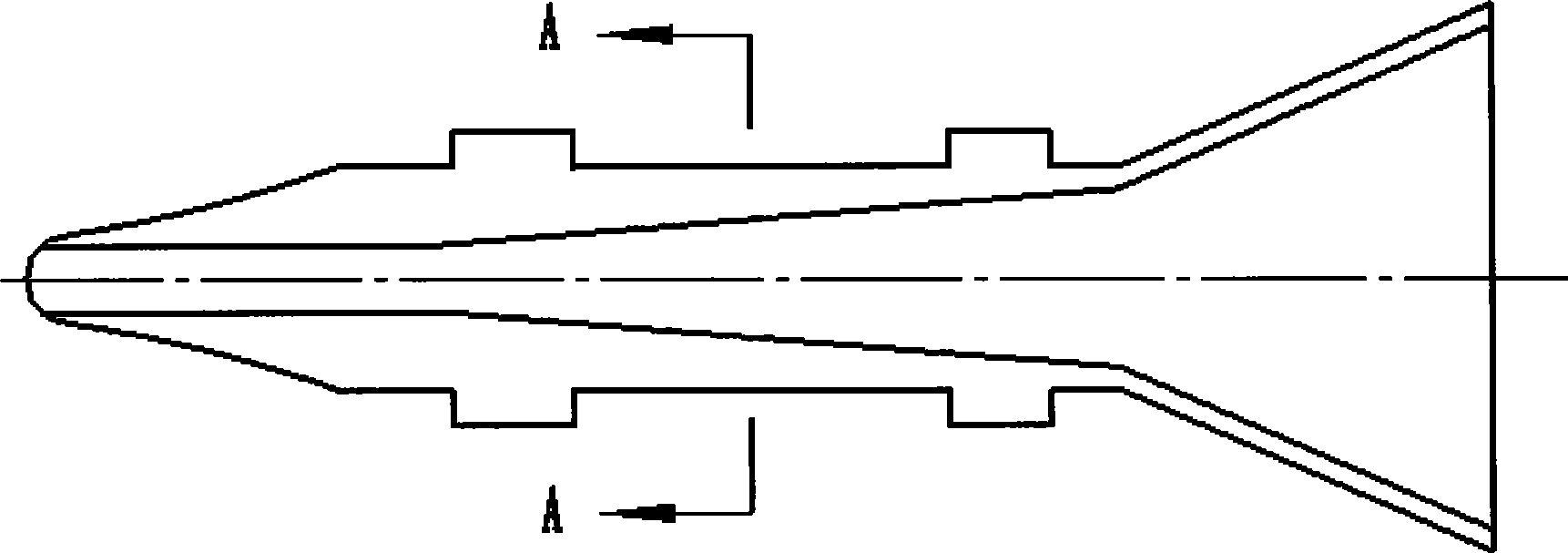

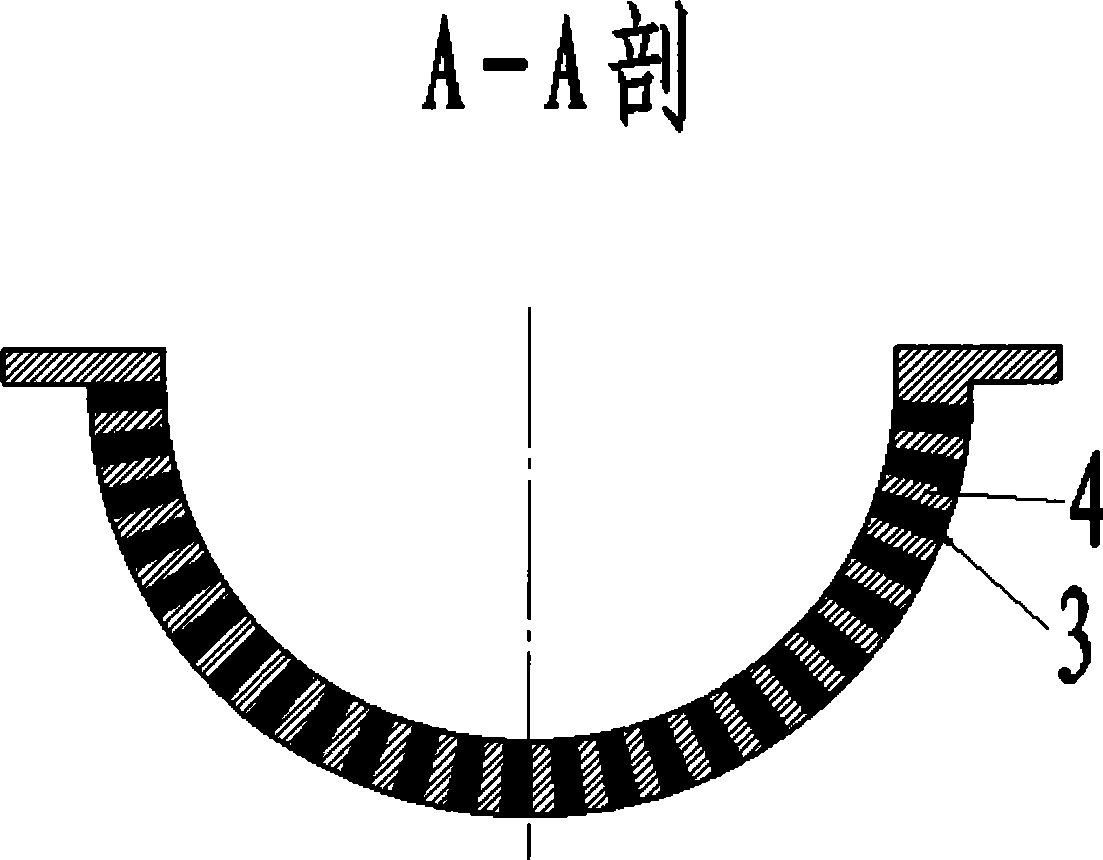

Method for preparing composite wear-resistant foreplate

InactiveCN101412095AInhibited DiffusionReduce the temperatureGuiding/positioning/aligning arrangementsWear resistantHardness

The invention discloses a method for preparing a composite antiwear guide plate, which comprises the following steps: alloy dust core bars are bound into bundles and arranged in a guide plate casting mould cavity, and the volume of the alloy dust core bars accounts for 20 to 60 percent of the total volume of the guide plate; molten matrix metal is cast into the guide plate casting mould cavity, the alloy dust core bars are melted and dissolved under the heat effect of the matrix metal, a great number of alloy elements and the molten matrix metal generate metallurgical combination reaction so as to generate a highly dispersed alloy structure on the original position; and finally the alloy structure is cooled and solidified, and the bar-shaped hard phase is metallurgically and transitionally combined into a whole with the matrix metal, thereby preparing the composite guide plate which takes the high-strength and high-ductility metal as the matrix and contains a certain number of metallurgically combined bar-shaped hard points. The composite anti-wear guide plate has high strength and high ductility of the matrix metal and high hardness and high wear resistance of the hard phase, can simultaneously bear high pressure and strong wear, and has the characteristics of long service life, low price, simple preparation and so on.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

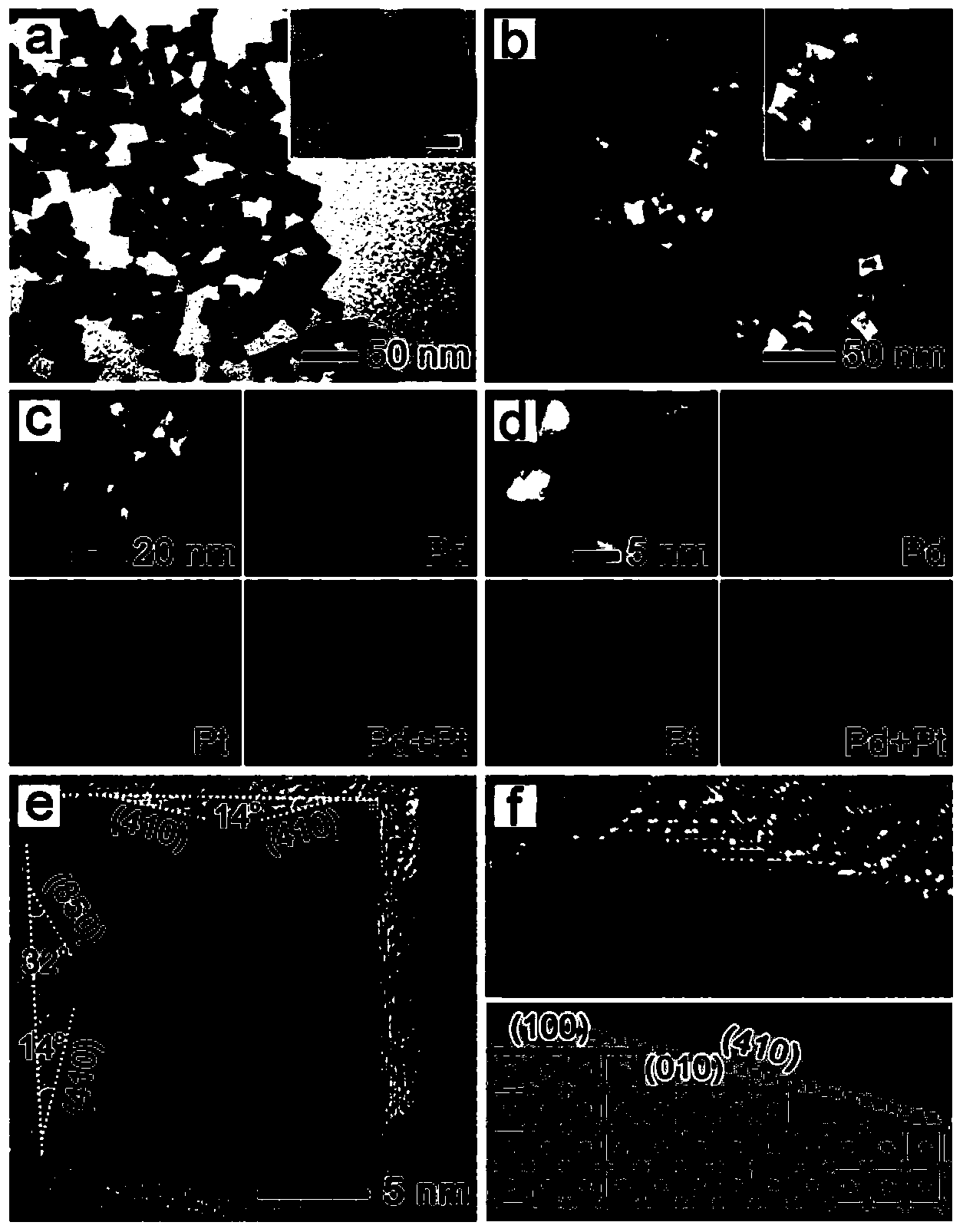

Preparation method of platinum-palladium alloy nanocrystalline

ActiveCN103668462AUniform sizeGood dispersionPolycrystalline material growthFrom normal temperature solutionsPotassium bromideSodium tetrachloropalladate

The invention discloses a preparation method of platinum-palladium alloy nanocrystalline. The preparation method comprises the following steps: dissolving chloroplatinic acid and sodium tetrachloropalladate into ethylene glycol to obtain a mixed solution I; dissolving polyvinylpyrrolidone, ascorbic acid and potassium bromide into ethylene glycol to obtain a mixed solution II; heating the mixed solution II to 100-150 DEG C while continuously stirring, and adding the mixed solution I into the mixed solution II to obtain the platinum-palladium alloy nanocrystalline, wherein the molar concentration of the potassium bromide is 0.1-0.4 mol / L. By the preparation method, the platinum-palladium alloy nanocrystalline with a concave hexahedral shape can be prepared by one step; reagents used in the preparation method are relatively simple and non-toxic and harmless; the preparation method is simple, and easy to implement; the prepared platinum-palladium alloy nanocrystalline has the concave hexahedral shape and has the characteristics of high-index crystal surface exposure, uniform particle size, and controllable components.

Owner:ZHEJIANG UNIV

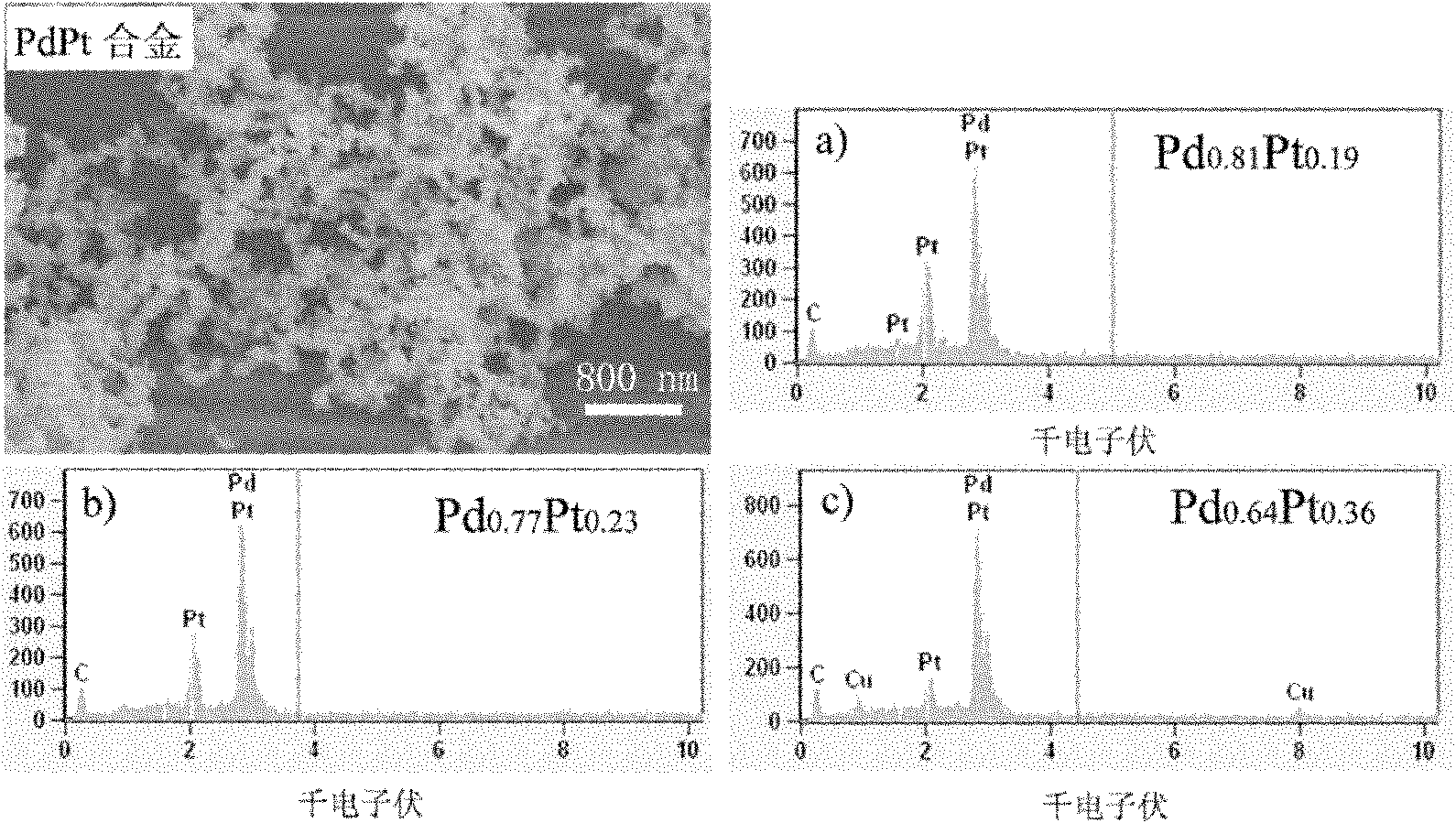

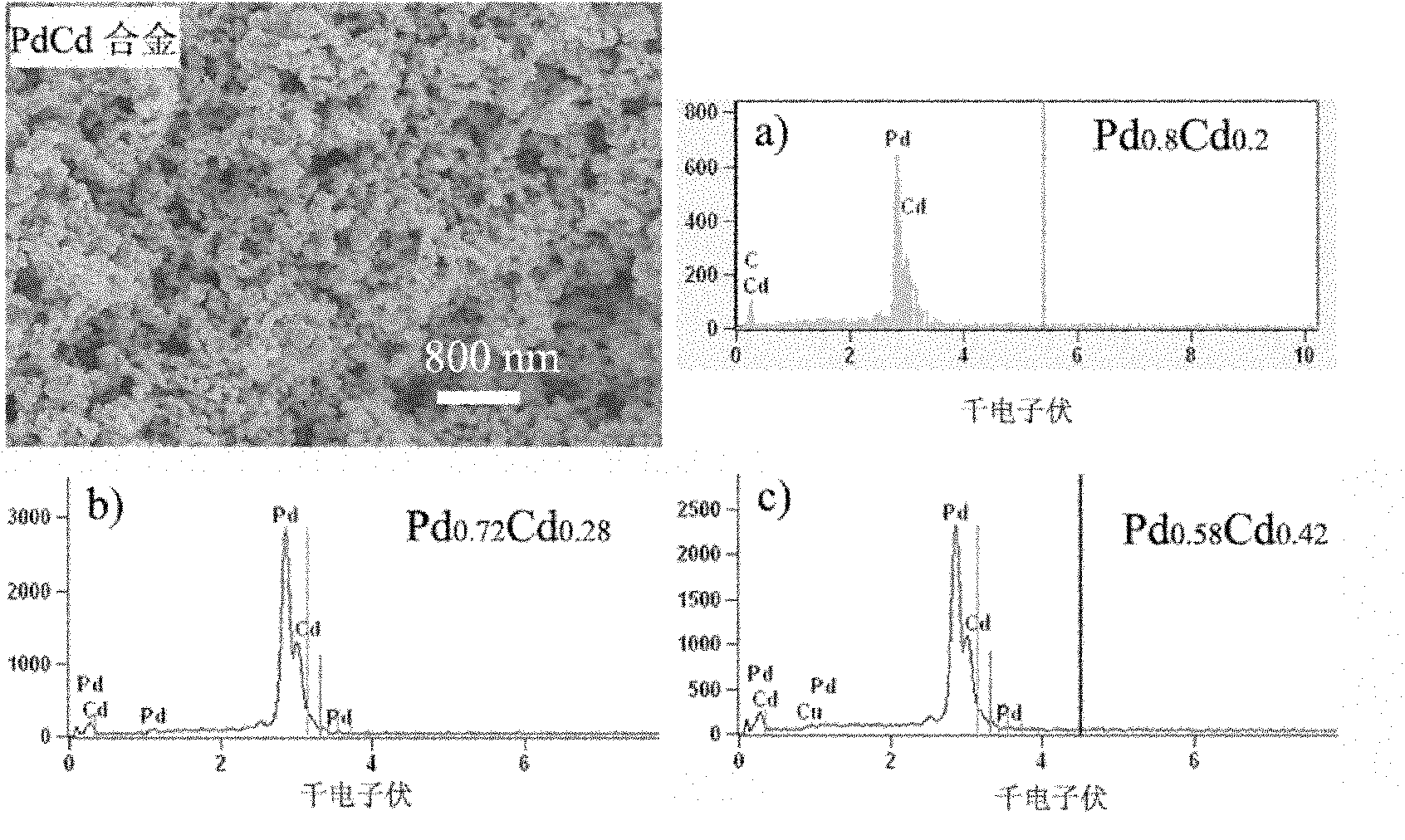

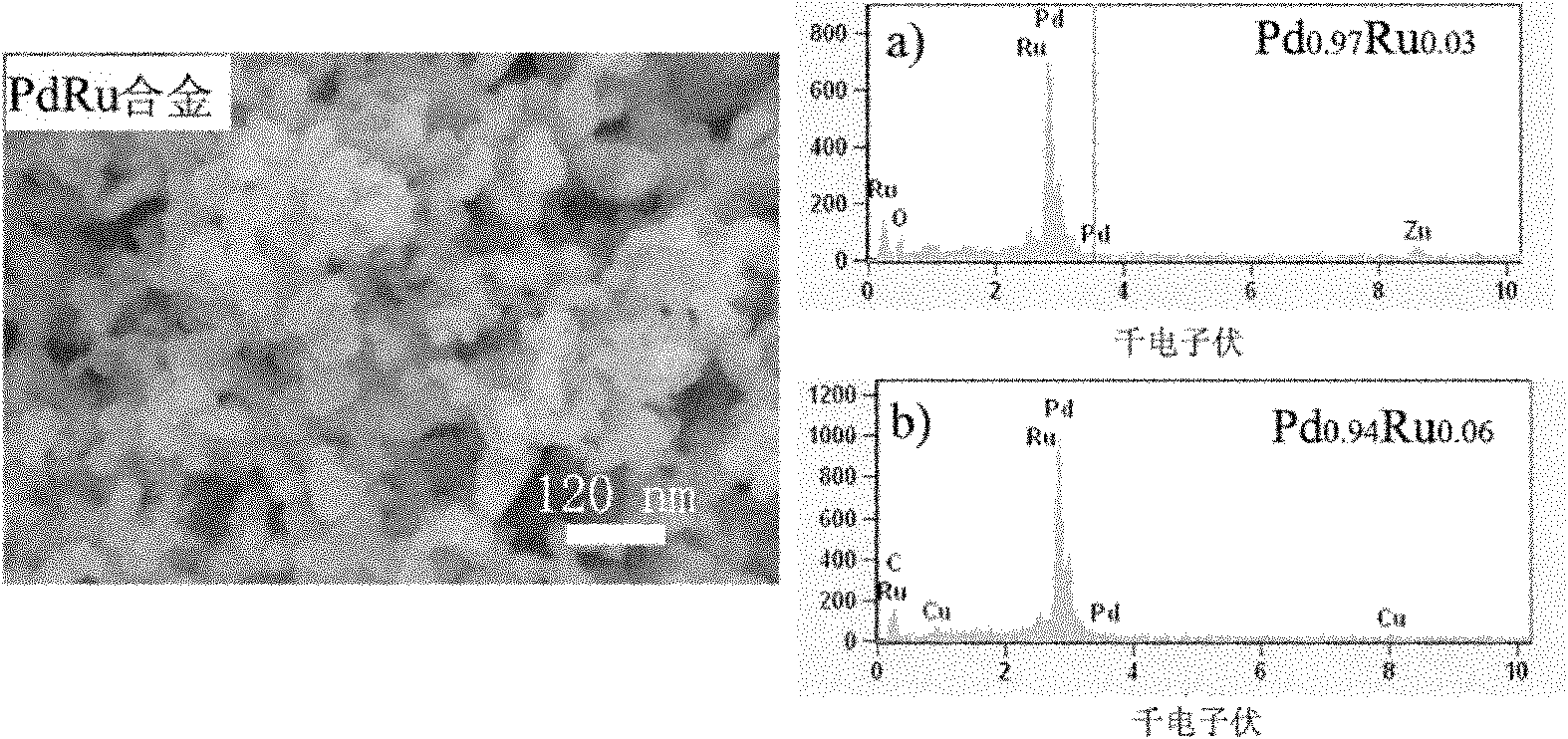

Method for preparing noble metal alloy nano material with three-dimensional porous network structure

The invention discloses a method for preparing a noble metal alloy nano material with a three-dimensional porous network structure. By adopting a one-step hydrothermal method, the method comprises the following steps of: firstly adding glycol, a metal precursor and a surfactant into a reaction kettle, stirring uniformly, then adding formaldehyde into the reaction kettle and stirring uniformly; sealing the reaction kettle, and then putting the reaction kettle in an oven with the temperature of 130-200 DEG C, and reacting for 6-10 hours; and finally, cooling the reaction kettle to room temperature naturally, cleaning centrifugally to finally obtain the noble metal alloy nano material with the three-dimensional porous network structure. In the method, the attributive advantages of noble metal and the three-dimensional porous network structure are combined, and the one-step hydrothermal method is adopted. Compared with the traditional methods, the method has the characteristics of simple operation method, strong universality, high yield and high repeatability and the like, and the prepared noble metal alloy has uniform appearance, strong stability, high purity and is adjustable in size and component.

Owner:苏州科昂泰材料科技有限公司

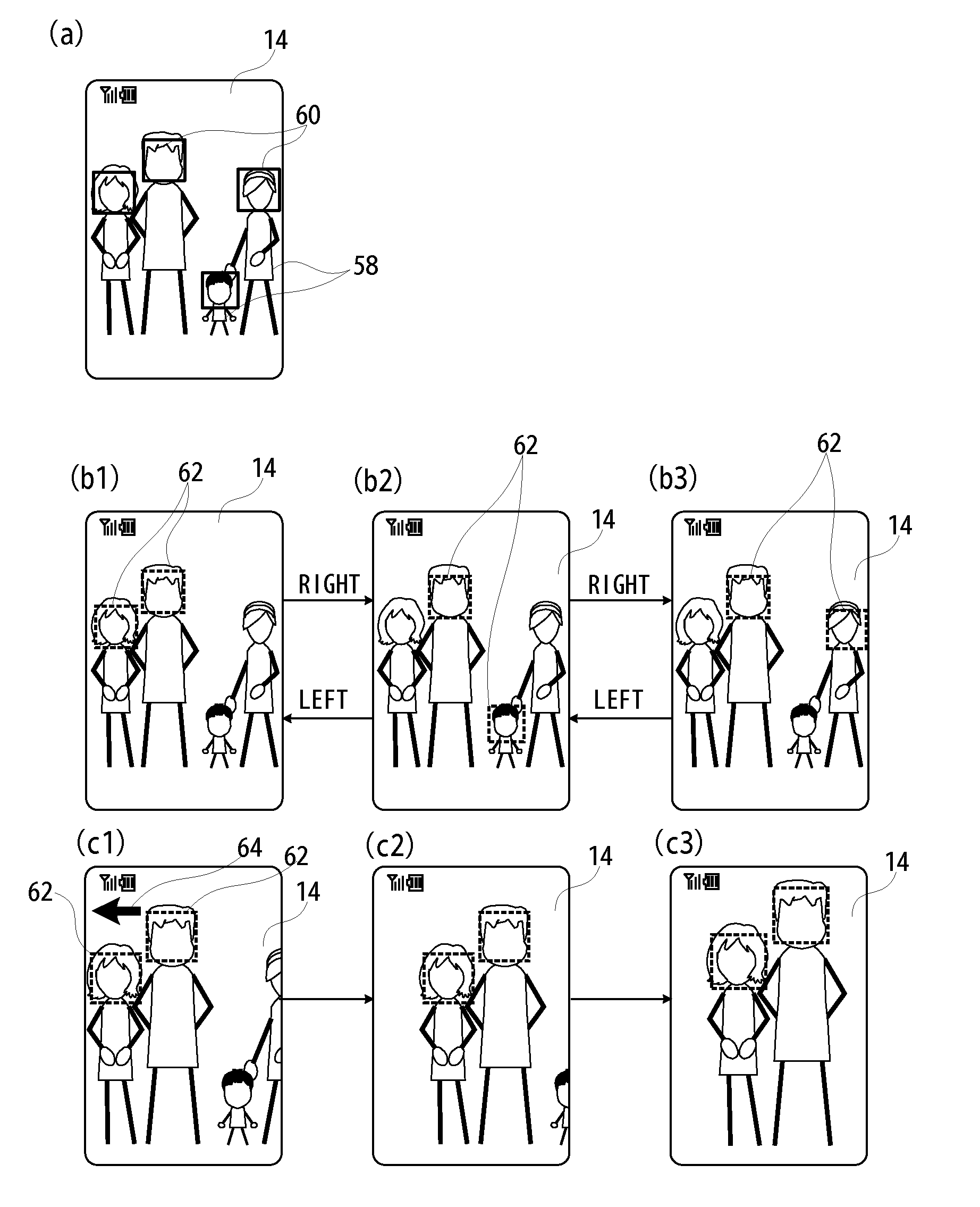

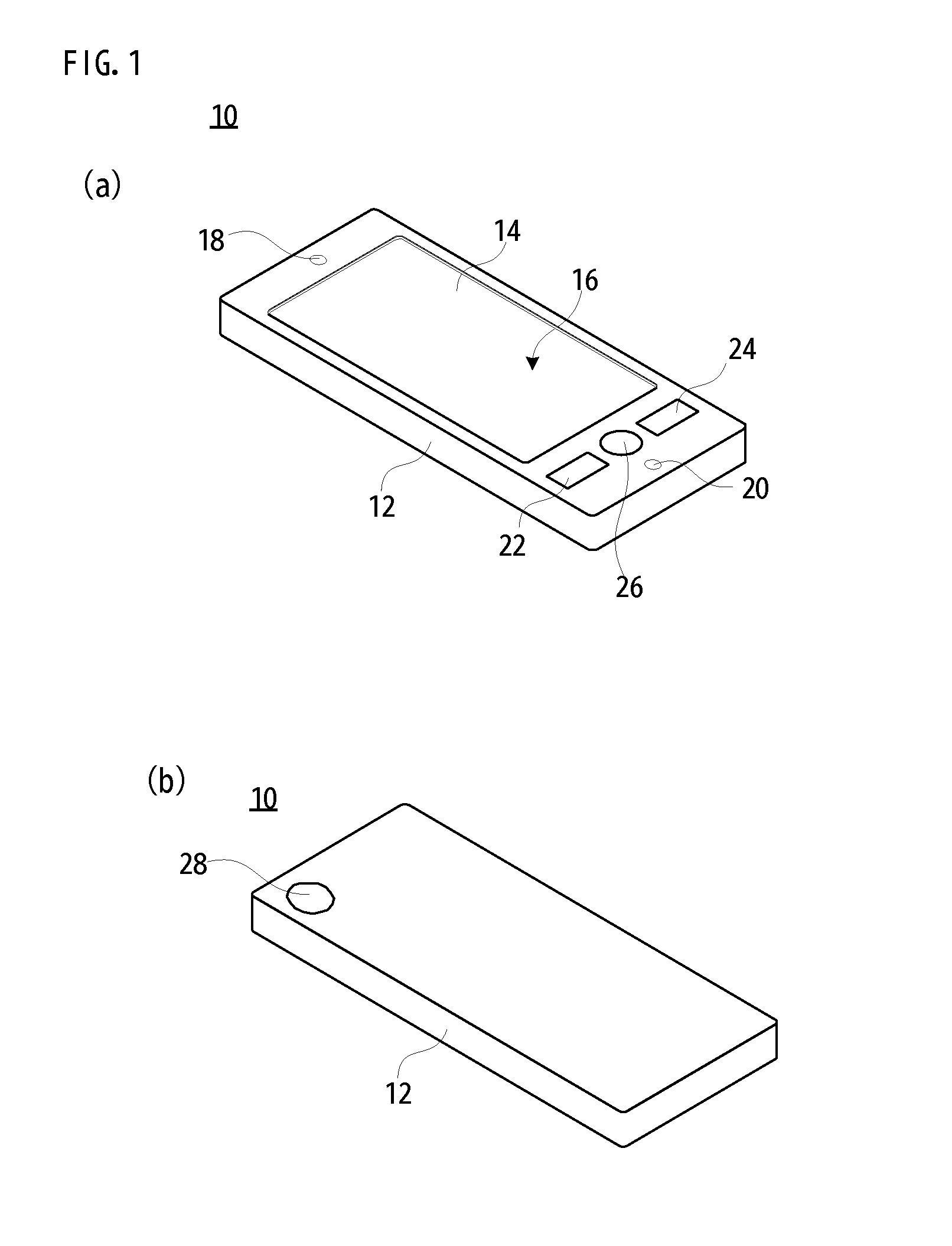

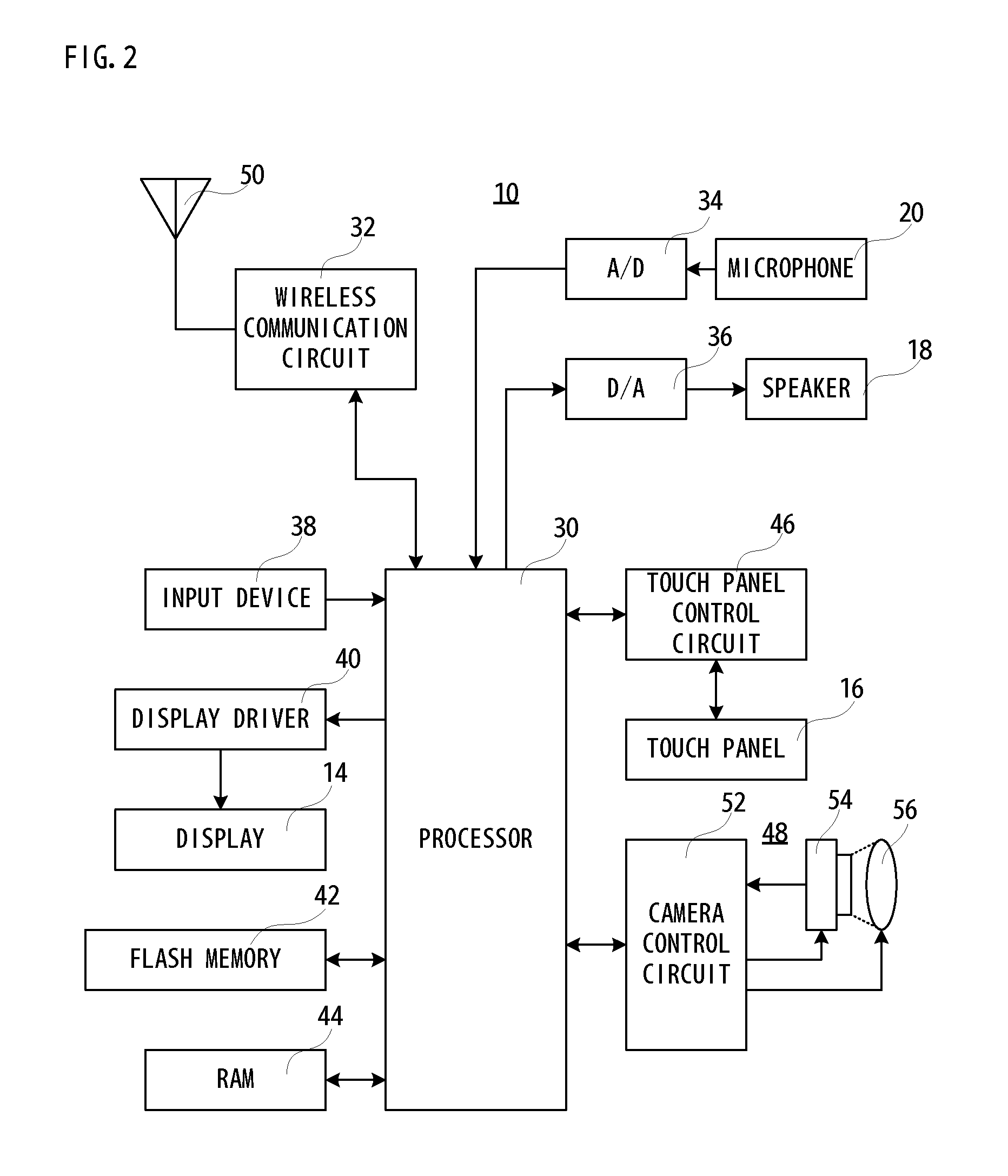

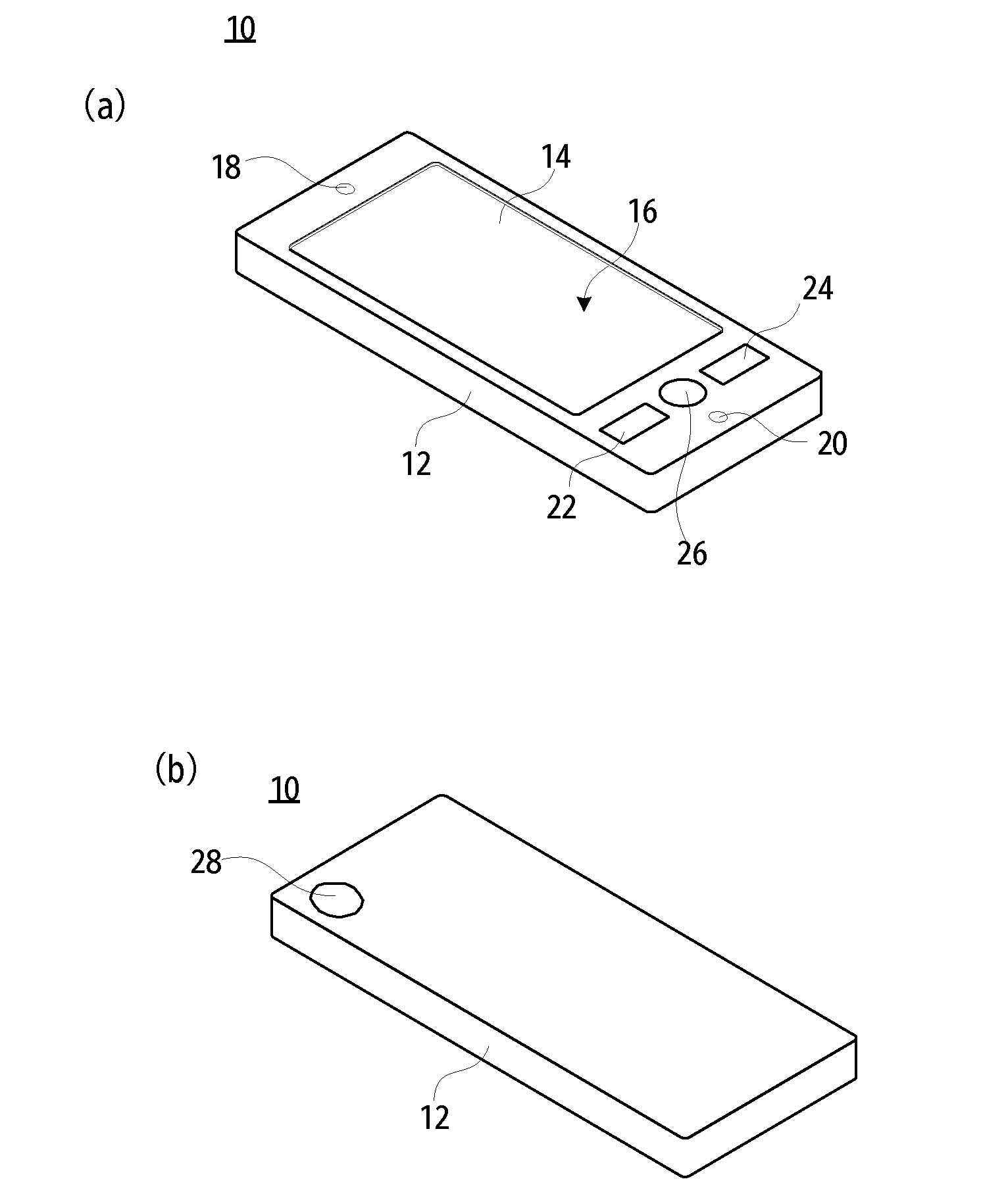

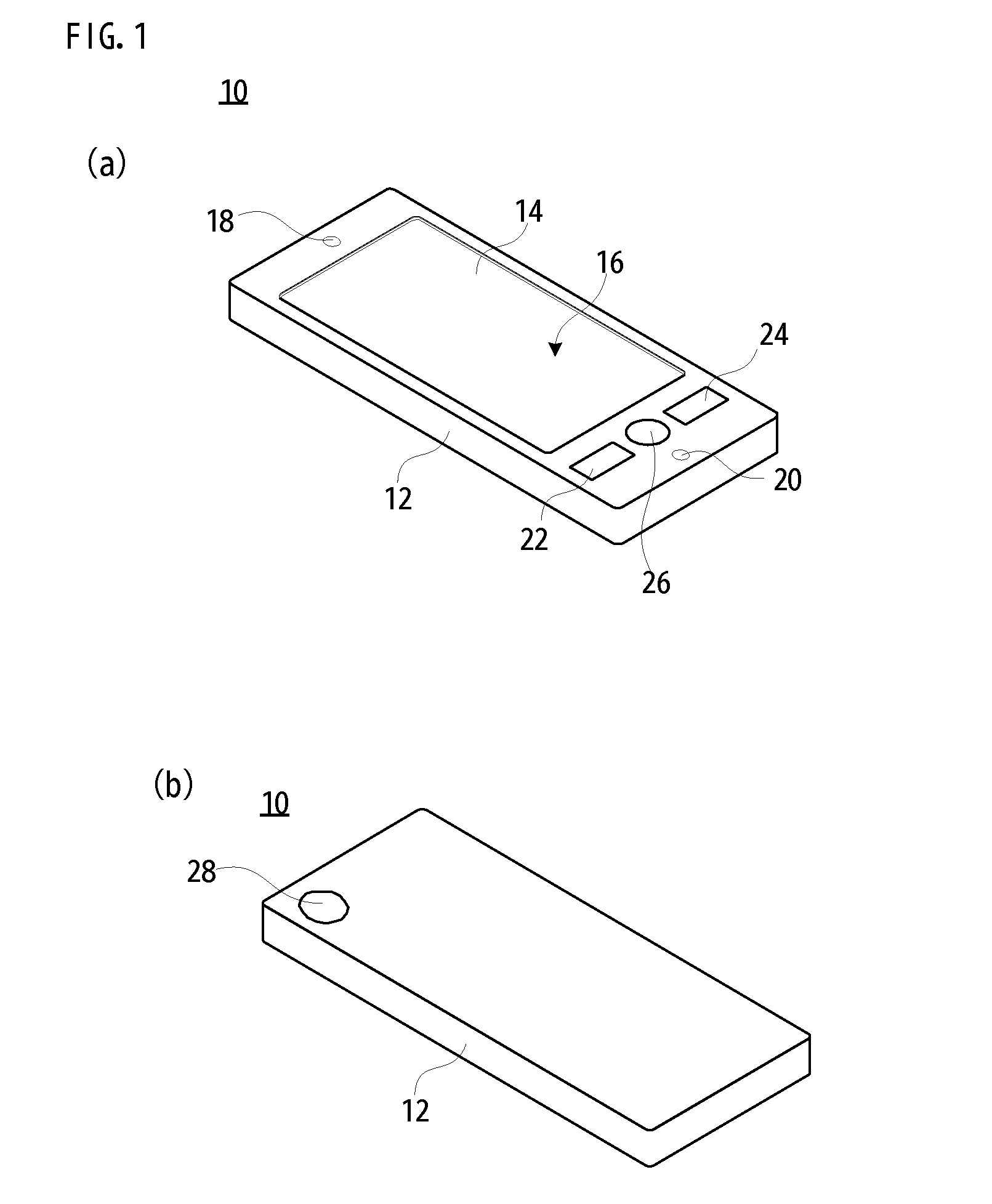

Camera apparatus and mobile terminal

InactiveUS20130076945A1Ingredients adjustableTelevision system detailsColor television detailsComputer graphics (images)Radiology

A processor (30) of a mobile terminal (10) that is one example of a camera apparatus detects a face image of a person image (58) in an object image displayed on a display (14) prior to an imaging key (26) is operated, and displays a face mark (60) at a portion of the face of each person image. A user selects arbitrary one or more person image out of the person images onto each of which the face mark is displayed as a zoom processing target by operating an operating portion such as a GUI. A selection mark (62) is applied to a person image that the user selects. A zooming-up and / or down (zoom processing) is performed such that the object image including the person image onto which the selection mark is applied is rendered to a predetermined composition.

Owner:KYOCERA CORP

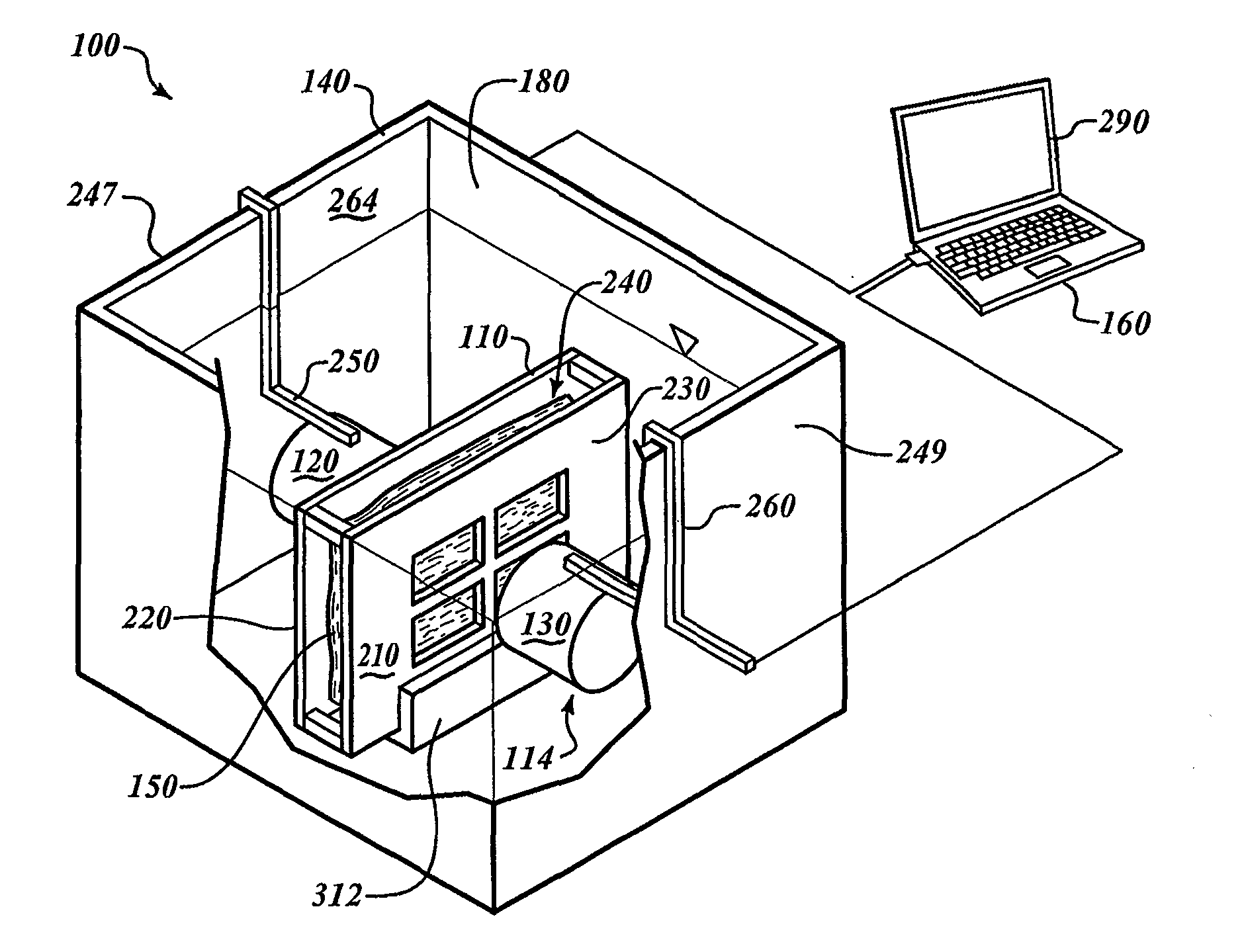

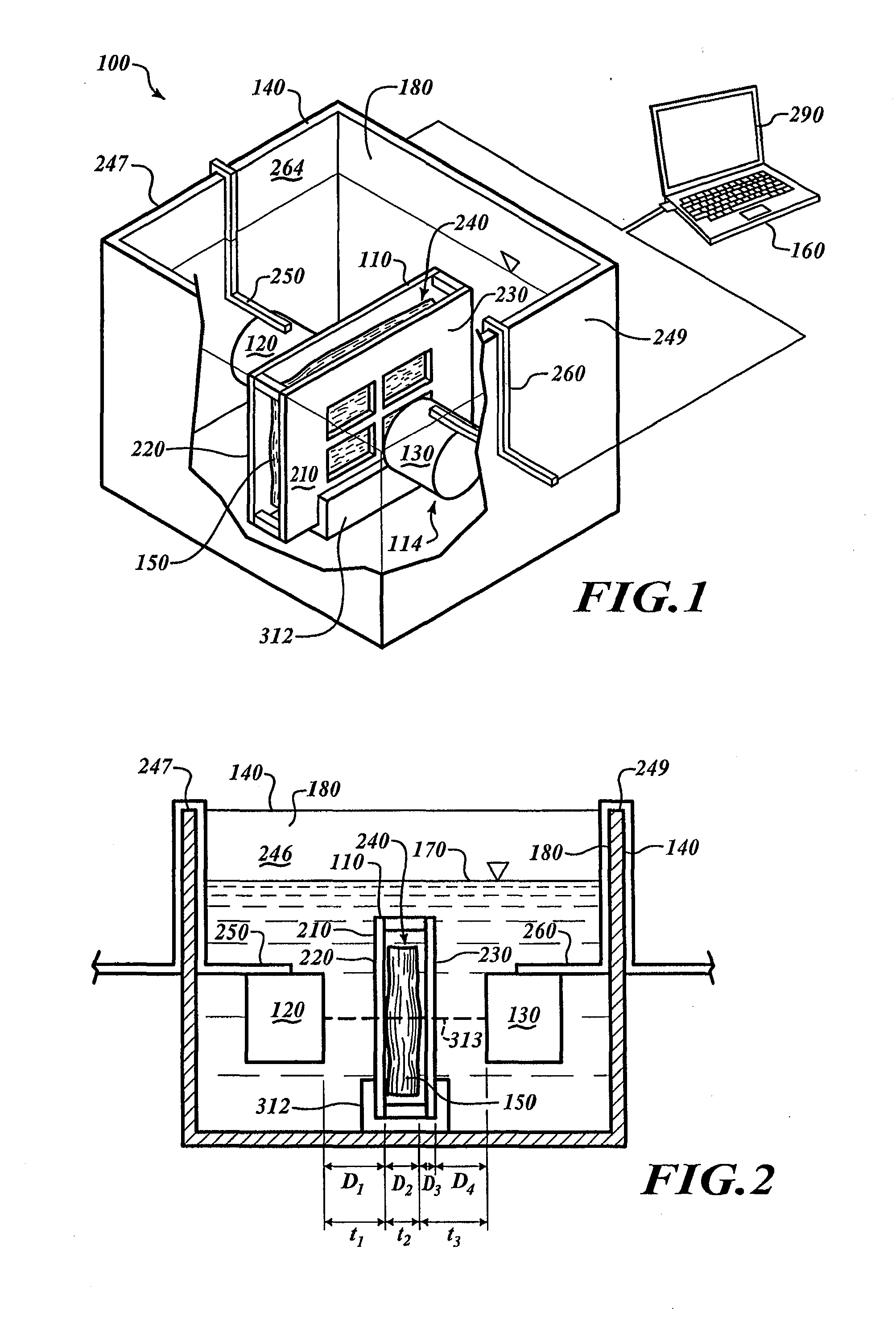

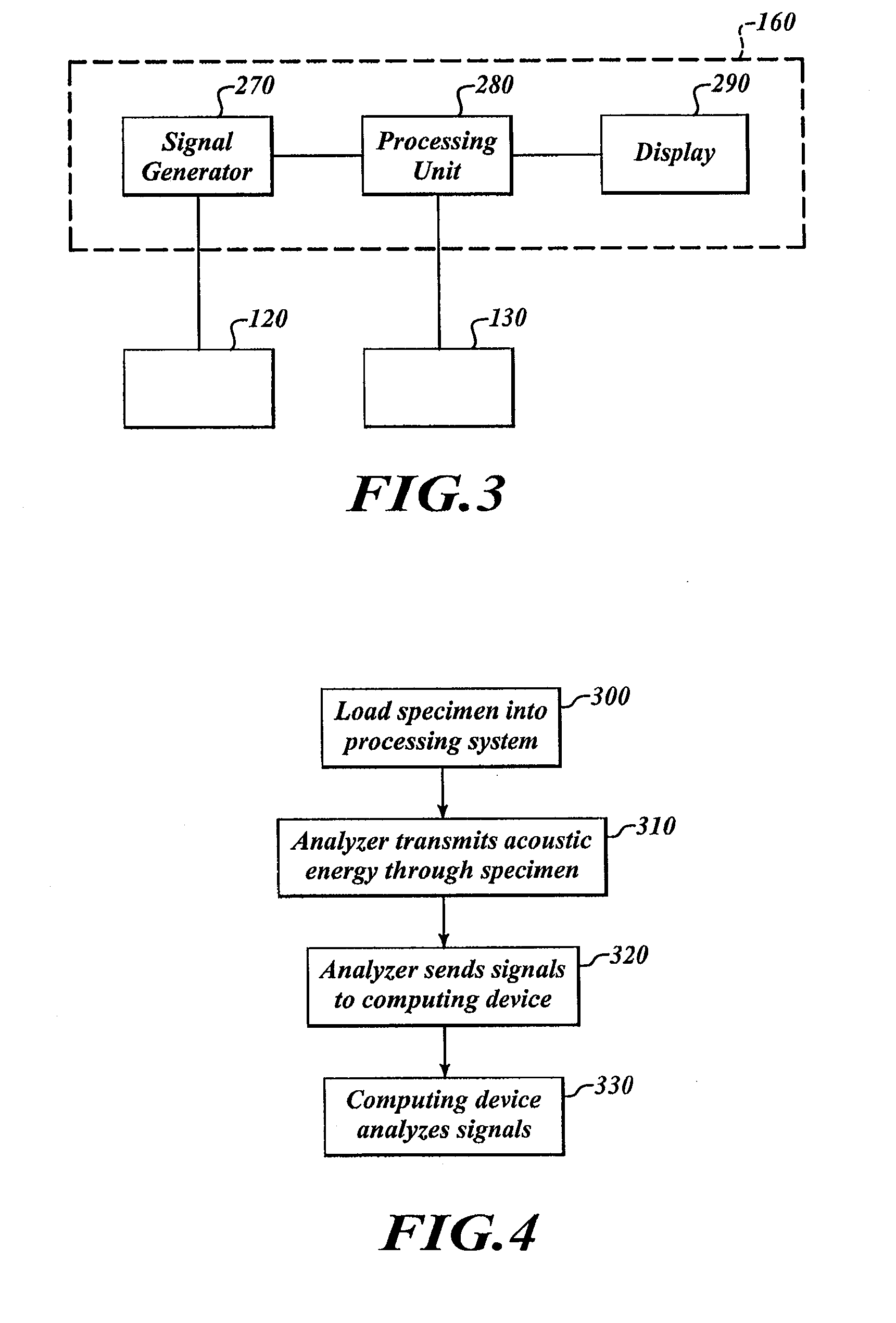

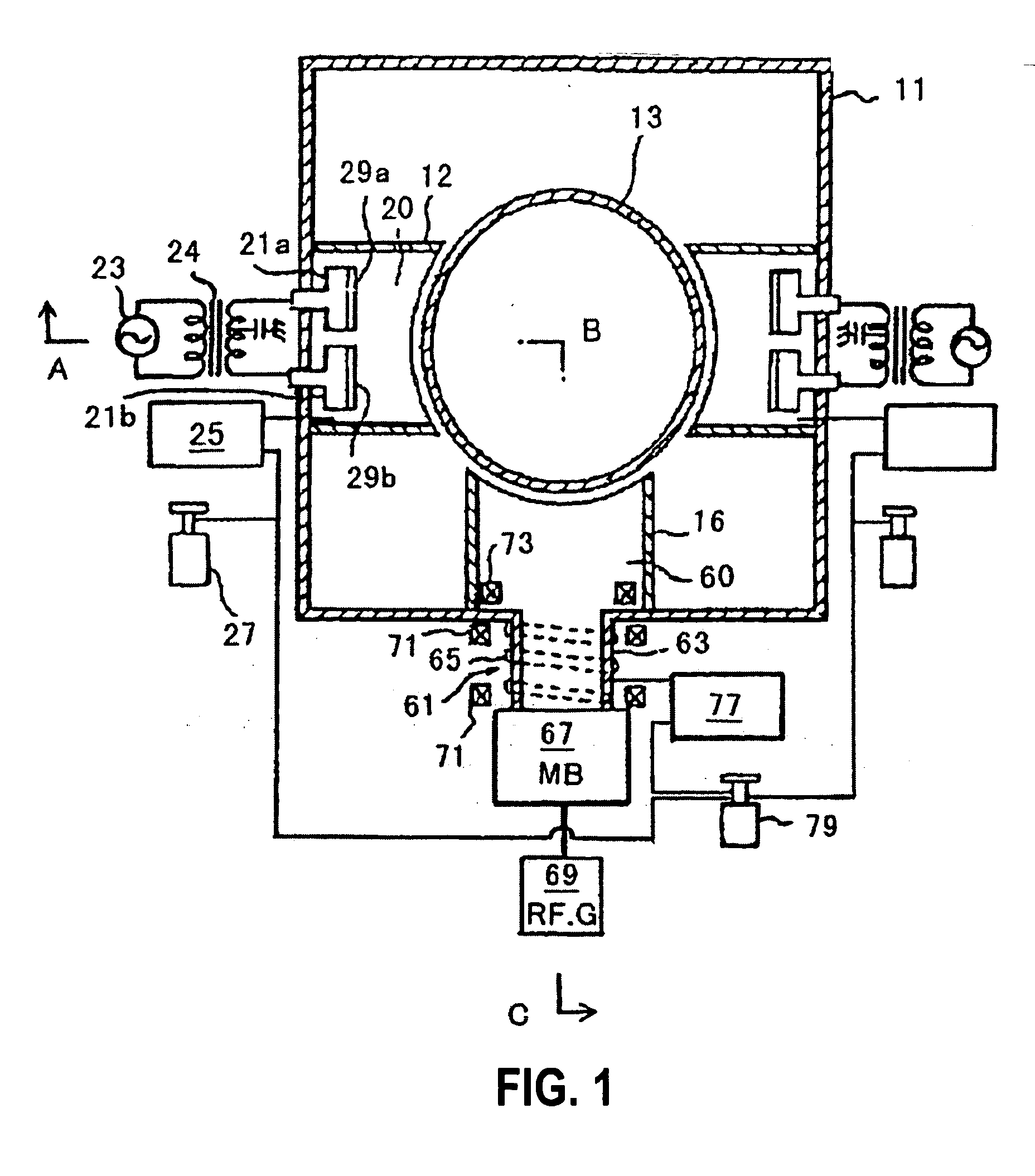

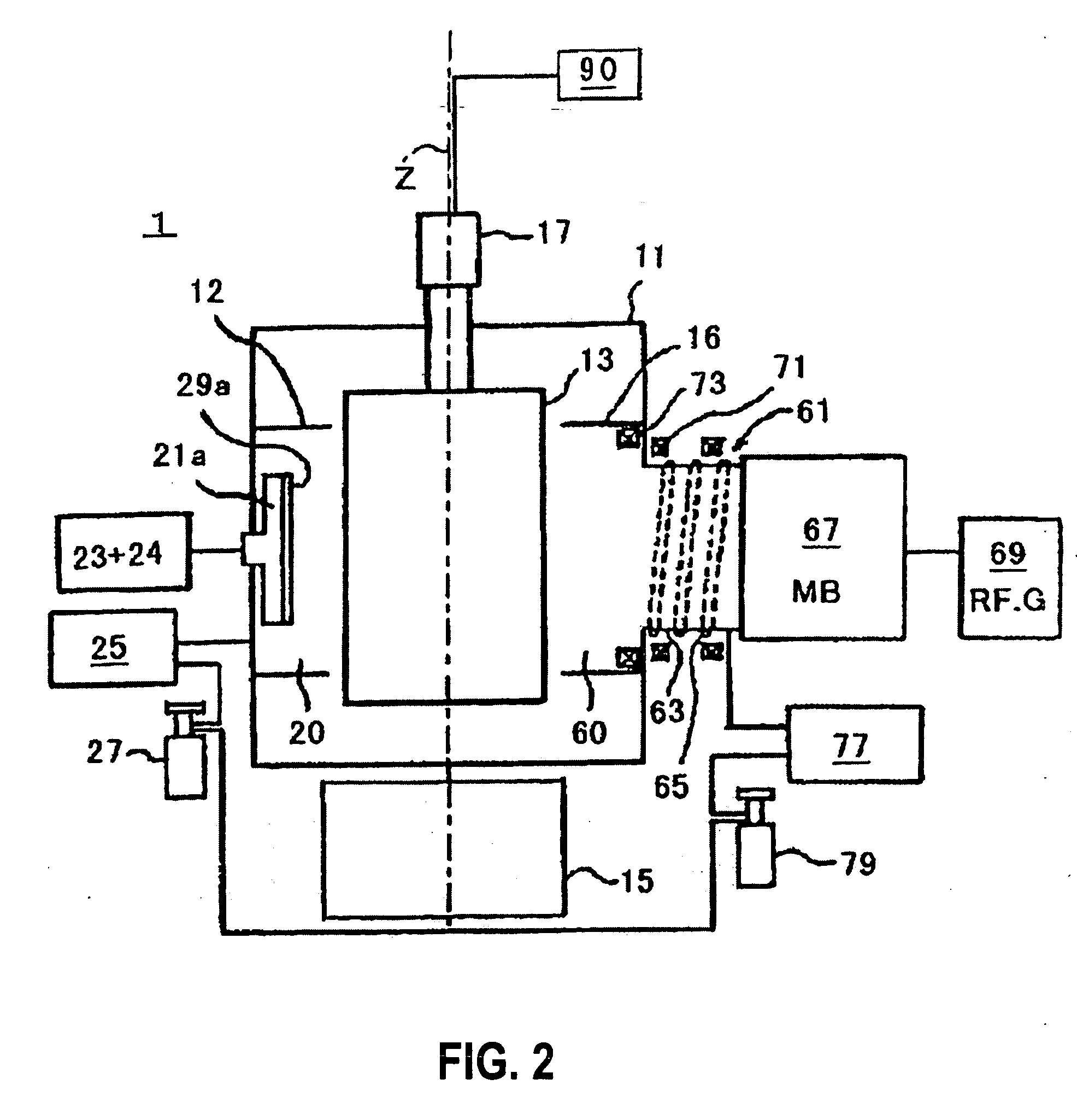

Processing system for processing specimens using acoustic energy

ActiveUS20120329088A1Improve consistencyReduce processing timeBioreactor/fermenter combinationsAnalysing solids using sonic/ultrasonic/infrasonic wavesAcoustic energyEnergy based

A method for fixing a biological sample includes delivering energy through a biological sample that has been removed from a subject, while fixing the biological sample. A change in speed of the energy traveling through the biological sample is evaluated to monitor the progress of the fixation. A system for performing the method can include a transmitter that outputs the energy and a receiver configured to detect the transmitted energy. A computing device can evaluate the speed of the energy based on signals from the receiver.

Owner:VENTANA MEDICAL SYST INC

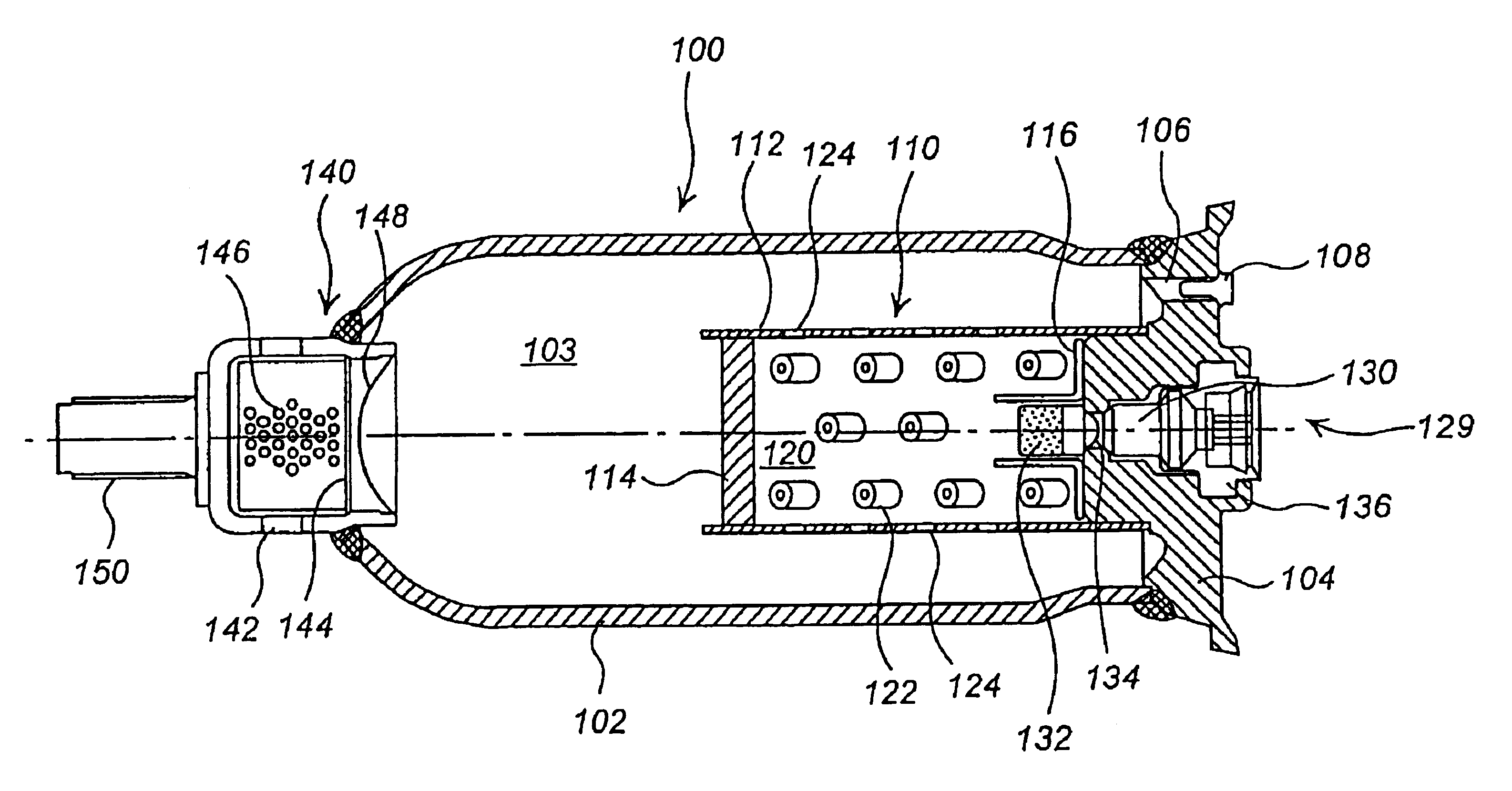

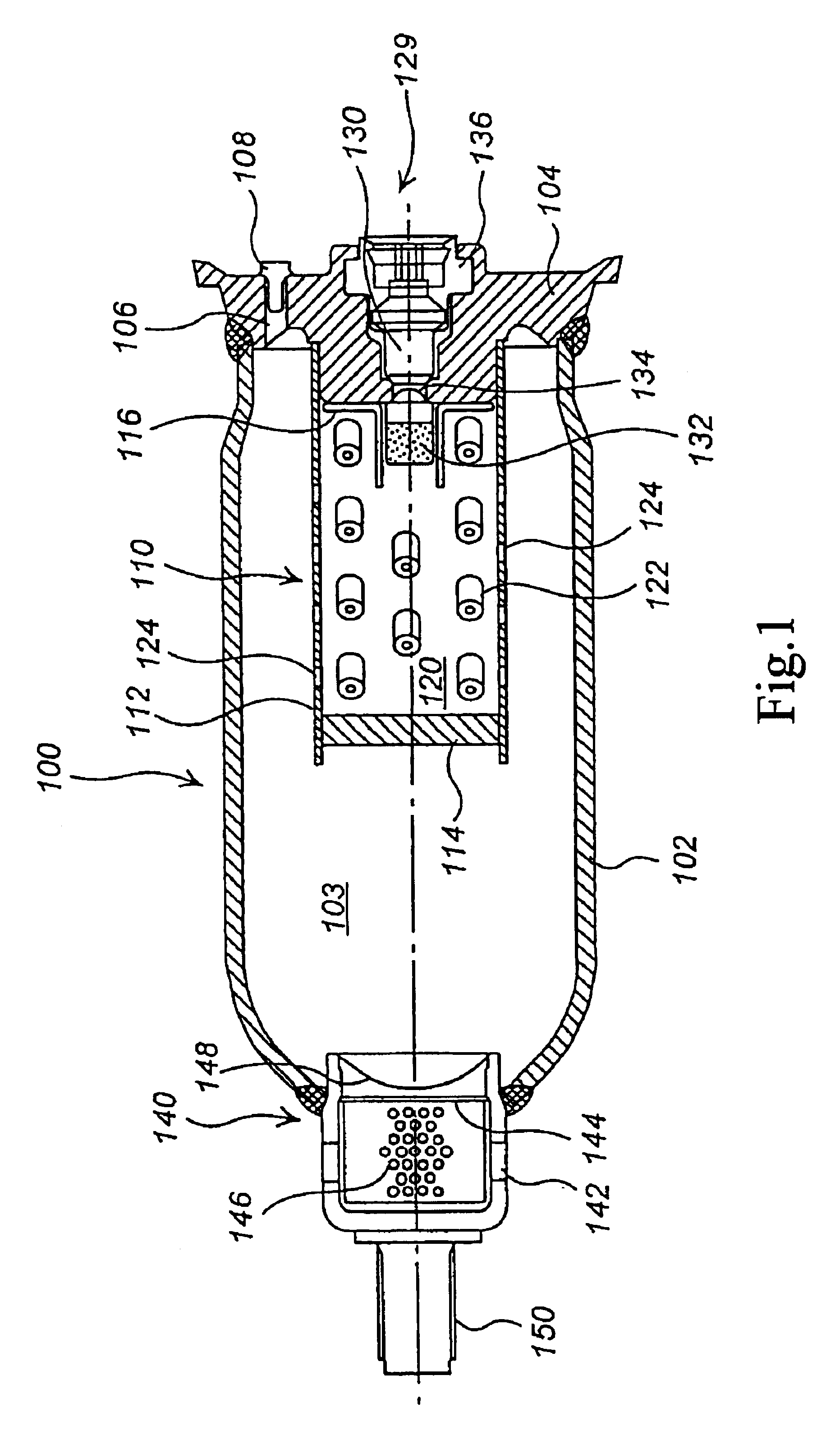

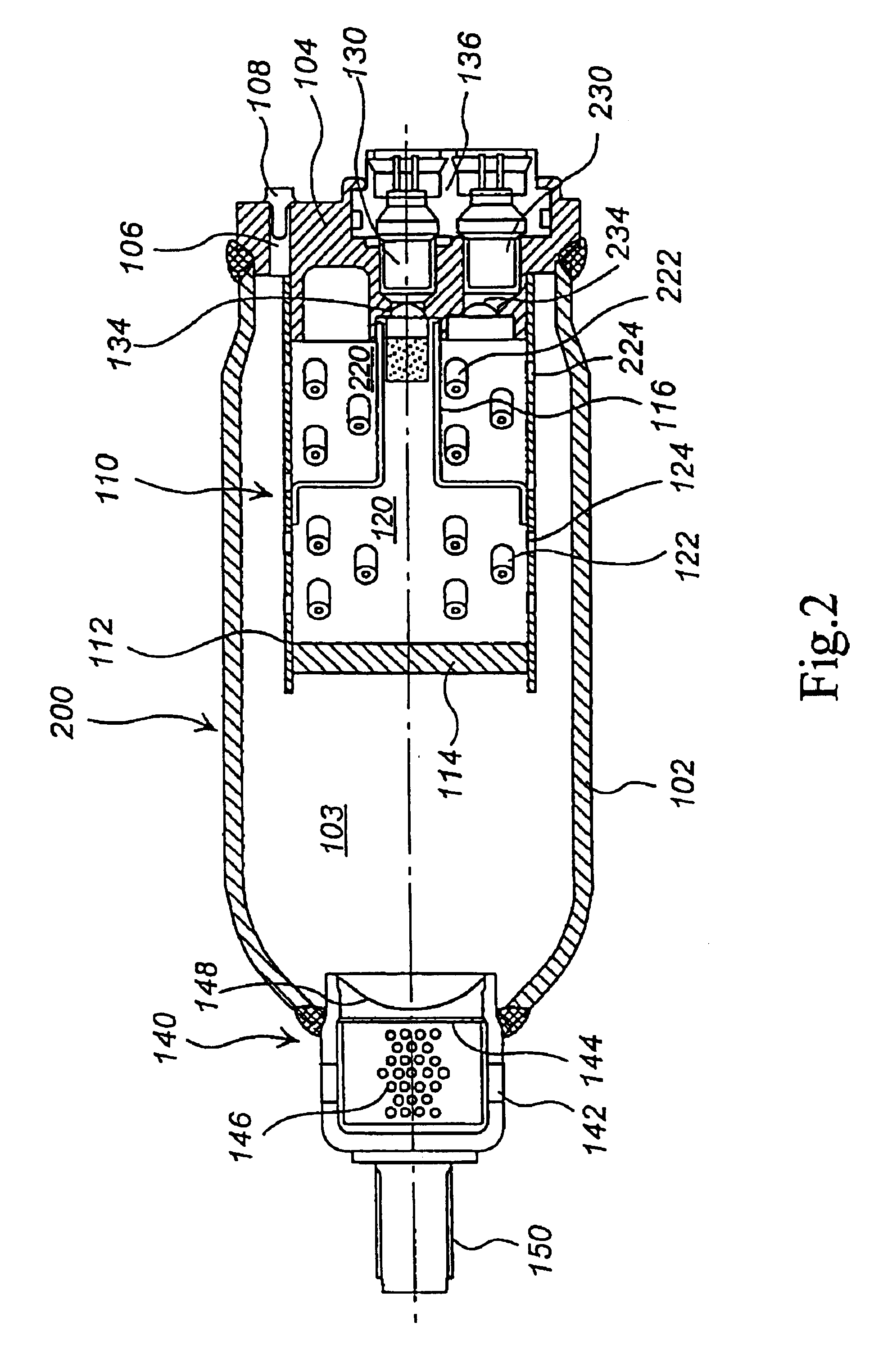

Hybrid inflator

InactiveUS6808204B1Improve securityMuch of lightPedestrian/occupant safety arrangementExplosivesInternal pressureCombustion

A hybrid inflator which is made more compact and lighter is provided. An excessive internal pressure increase at a time of activation is prevented by setting a molar ratio (A / B) between a pressurized medium (A moles) charged in a housing 102 and an amount of a gas (B moles) generated due to combustion of a gas generating agent 122 to 8 / 2 to 1 / 9.

Owner:DAICEL CHEM IND LTD

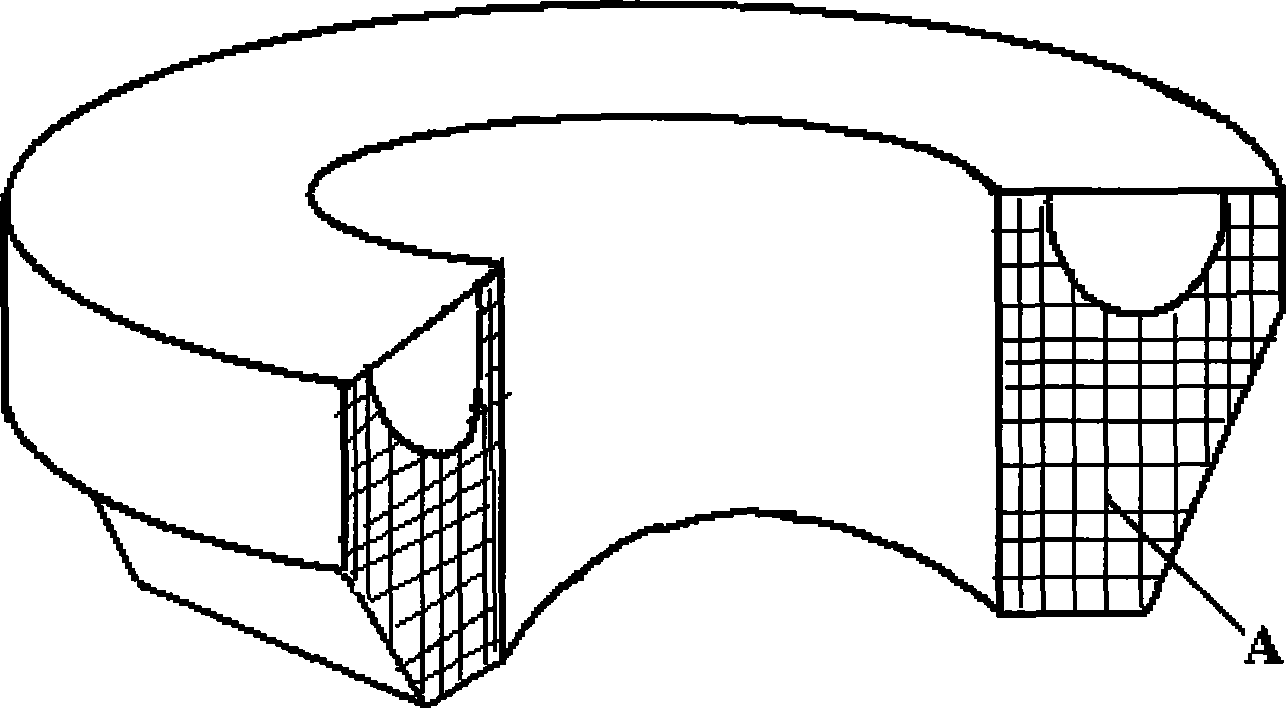

Method for preparing primary column shaped horniness phase composite wear-resistant grinder dish

The invention discloses a method for preparing a composite wear resistant abrasive disk with a protogenous columnar hard phase. The wear resistant abrasive disk prepared by the method is formed by pouring and compounding a high hardness columnar alloy hard phase and a high tenacity base metal. The method comprises the following steps: weaving an alloy powder core wire material into a framework similar to the shape of the abrasive disk, and pouring smelted high temperature base material molten steel into a die cavity of an abrasive disk casting mould; putting the woven framework similar to the shape of the abrasive disk into the casting die cavity filled with the high temperature base metal molten steel quickly, performing cast-infiltration, sintering or melting on the woven alloy powder core wire material framework by using the heat of the high temperature base metal molten steel so as to generate a highly-dispersed high hardness columnar alloy hard phase in situ; and cooling the phase at room temperature to produce the composite wear resistant abrasive disk using high-tenacity and high-strength metal as a base and containing the metallurgically-combined protogenous columnar hard phase. The composite wear resistant abrasive disk with the protogenous columnar hard phase has ultra wear resistance and good impact resistant toughness, and the service life of the abrasive disk is close to or exceeds the imported products of the same type.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

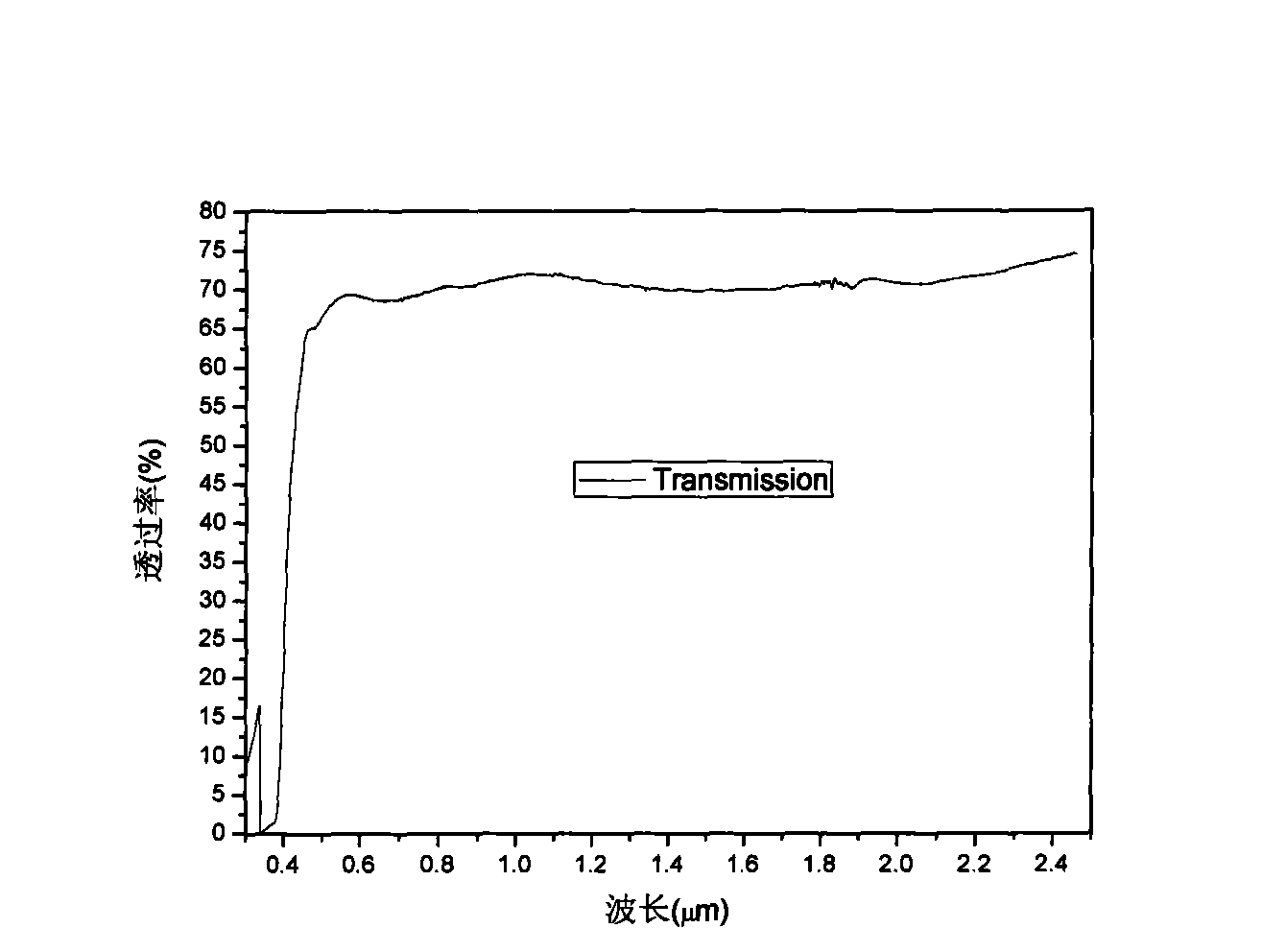

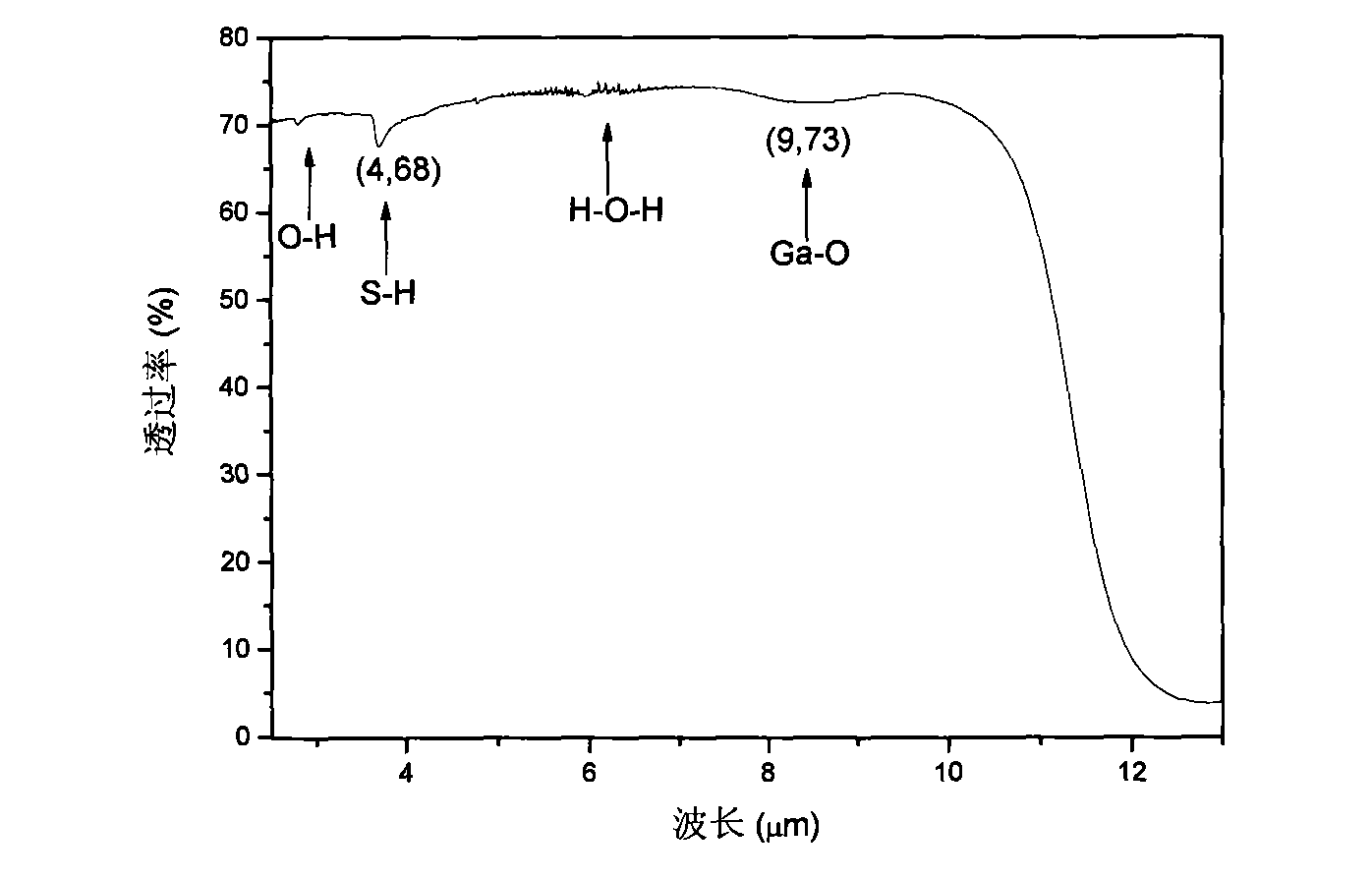

Broadband-spectrum optical glass and method of producing the same

ActiveCN101492249ALight transmission is easyEasy to manufactureGlass furnace apparatusDouble tubeMetallurgy

The invention relates to broad-spectrum optical glass and a preparation method thereof, which is characterized in that: (1) the glass comprises the following components in percentage by mol: 20 to 33 percent of Ga2S3, 5 to 40 percent of GeS, 38 to 67 percent of CsX, and 2 to 5 percent of YS2; the preparation method comprises the following steps: mixing elementary substances such as Ga, Ge and S and compounds such as CsX and YS2 to obtain a mixture, and putting 0.01 weight percent of magnesium ribbon as deoxidizer into the mixture, wherein X is Cl or I or Br; and Y is Ti or Zr or Hf; (2) filling the mixture into one quartz tube in an H-shaped double-tube quartz ampoule subjected to dehydroxylation pretreatment, vacuumizing the quartz tube, and sealing the quartz ampoule by hydrogen flame when the pressure is less than or equal to 1*10Pa; (3) putting the sealed quartz ampoule filled with the mixture into a double-tube distilling furnace, distilling and purifying the mixture to obtain extract of Ge, Ga and S in the other quartz tube of the H-shaped double-tube quartz ampoule; and (4) putting the purified quartz ampoule into a rocking furnace, slowly heating the quartz ampoule to between 800 and 950 DEG C, smelting the mixture for 8 to 12 hours by rocking, then taking out and cooling the mixture, preserving heat at a temperature of between 150 and 330 DEG C, and then carrying out related annealing treatment to obtain a broad-spectrum optical glass product.

Owner:宁波阳光和谱光电科技有限公司

Electrocatalyst and preparation method thereof

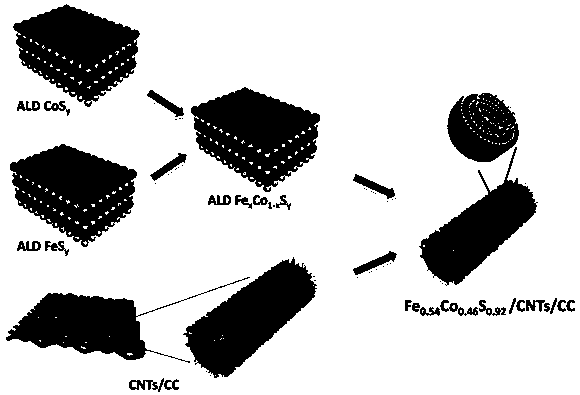

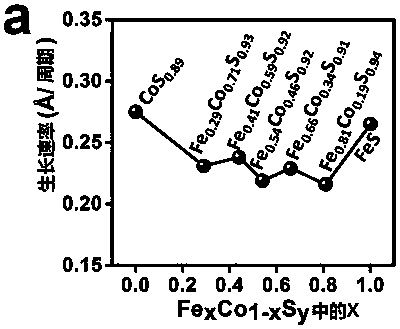

ActiveCN107597148AIngredients adjustableImprove electrocatalytic activityCatalyst activation/preparationElectrodesNanostructureAtomic layer deposition

The invention discloses an electrocatalyst and a preparation method thereof. The preparation method of the electrocatalyst comprises the steps as follows: a new substrate is formed by growing a nanostructure on a substrate with a CVD method; a FeSy film is deposited on the new substrate with an atomic layer deposition technology, and the FeSy film is obtained through deposition of one or more circular FeSy; a CoSy film is deposited on the FeSy film, and the CoSy film is obtained through deposition of one or more circular CoSy, the FeSy film and the CoSy film are deposited alternately multipletimes, and a FexCo(1-x)Sy film is prepared, wherein x ranges from 0 to 1 while y ranges from 0 to 2. The prepared electrocatalyst has the characteristics of component adjustability, high electrocatalytic activity and stable performance; besides, the process of the preparation method is simple and industrial mass production can be realized.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

Silicon-aluminium alloy target material with high silicon content for sputtering and coating film, and method of producing the same

InactiveCN101403088AAlloy with high purityThe size of the silicon phase is fine and uniformVacuum evaporation coatingSputtering coatingSilica fumeHot press

The invention relates to a Si-Al alloy target with 25-95 percent of silicon used in vacuum sputtering coating, which adopts the processes of pre-press molding sintering and direct hot press molding. As the aluminum in the Si-Al alloy has low melting point, the silicon powder can be bonded together by the aluminum under high temperature sintering bonding, so as to obtain the required Si-Al alloy target stock of various components, and then the stock is mechanically processed to reach the required specification and size. The Si-Al alloy target of the invention has the advantages of adjustable Si-Al alloy target components, high alloy purification, fine and uniform silicon phrase in the alloy and high density of the Si-Al target. Moreover, the process of the invention with short process flow and lower cost can obtain the high-quality Si-Al alloy target, and the prepared Si-Al alloy target can be applied to both functional films and decorative films.

Owner:CENT SOUTH UNIV

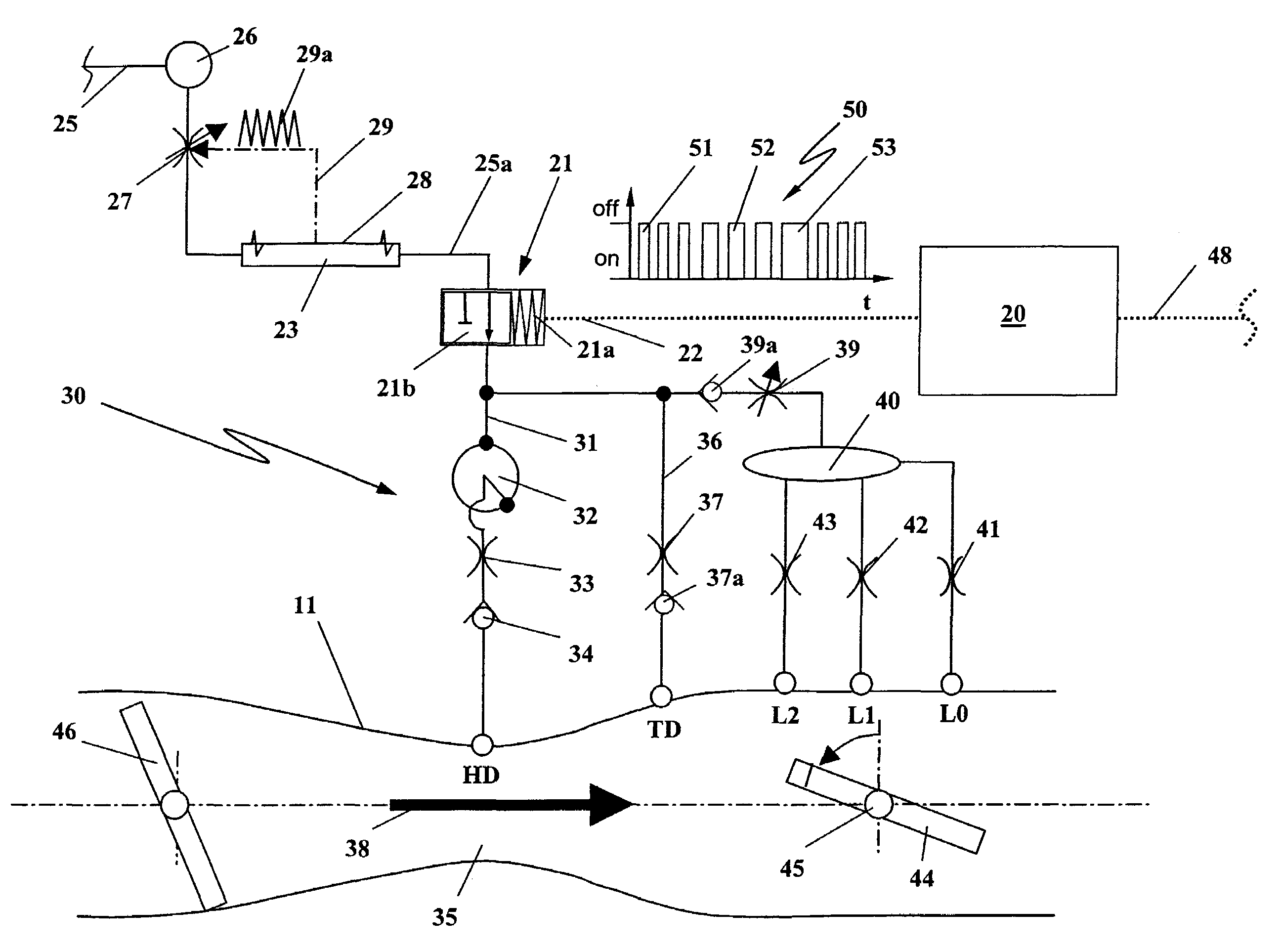

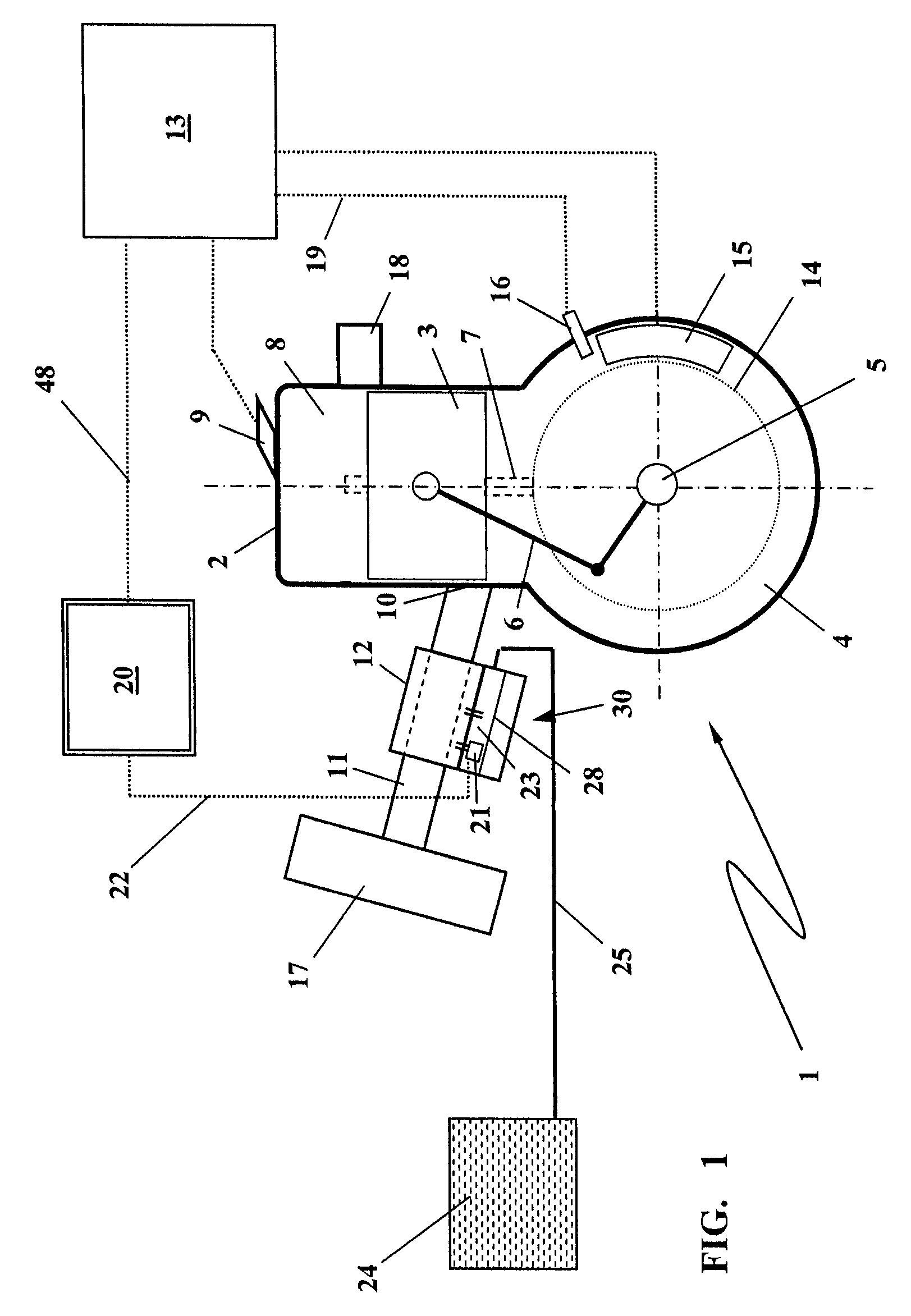

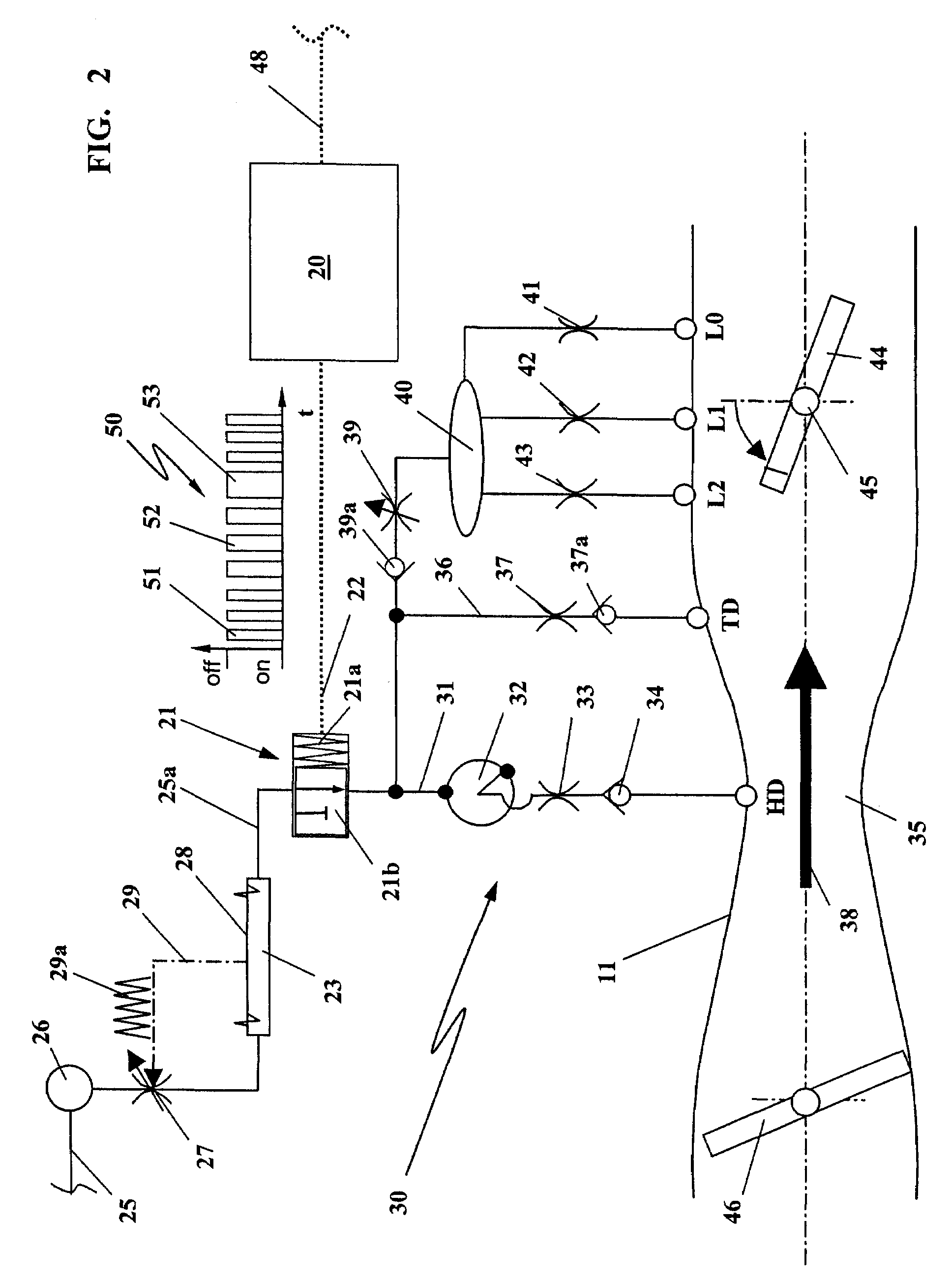

Method for controlling the composition of a fuel/air mixture for an internal combustion engine

ActiveUS7493889B2Ingredients adjustableInhibition rangeElectrical controlMachines/enginesEvaluation resultExternal combustion engine

In a method for controlling a composition of a fuel / air mixture supplied to an internal combustion engine, which engine has a speed control circuit maintaining an actual rotary speed of the crankshaft within preset limits and a controllable metering device for at least one component of the fuel / air mixture, a disruptive variable is introduced into the valve control circuit at a predeterminable point in time, the activity of an engine speed control circuit is monitored and evaluated immediately after introducing the disruptive variable, and, depending on the evaluation result, at least one parameter having an effect on the operation of the internal combustion engine is adjusted.

Owner:ANDREAS STIHL AG & CO KG

Method for preparing composite wear-resistant hammerhead

The invention discloses a method for preparing a high-ductility and high-abrasion composite hammerhead, which comprises the following steps: alloy dust core bars are bound into bundles and arranged in a hammerhead casting mould cavity, and the volume of the alloy dust core bars accounts for 20 to 60 percent of the total volume of the hammerhead; molten matrix metal is cast into the casting mould cavity, the alloy dust core bars are melted and dissolved under the heat effect of the matrix metal, a great number of alloy elements and the molten matrix metal generate metallurgical combination reaction so as to generate a highly dispersed alloy structure on the original position; and finally the alloy structure is cooled and solidified, and the bar-shaped hard phase is metallurgically and transitionally combined into a whole with the matrix metal, thereby preparing the composite hammerhead which takes the high-strength and high-ductility metal as the matrix and contains a certain number of metallurgically combined bar-shaped hard points. The composite hammerhead has high strength and high ductility of the matrix metal and high hardness and high wear resistance of the hard phase, can simultaneously bear high pressure and strong wear, and has the characteristics of long service life, low price and so on.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Production process of composite steel pipe with cermet lining

The present invention provides the production process of composite steel pipe with cermet lining, and belongs to the field of steel surface coating technology. The production process includes mixing ferric oxide powder, aluminum powder, WO3 powder and graphite powder in the proportioning of reaction expression of Fe2O3+2(1+x)Al+xWO3+xC=(x+1)Al2O3+2Fe+xWC, where x is 0.5-3; reaction at high temperature to produce alumina, Fe in molten state and W and C dissolved in molten Fe; applying centrifugal force for alumina to distribute in the inner surface of steel pipe and Fe to combine with mother pipe metallurgically; lowering temperature for W and C to combine into WC separated from the molten Fe and distributed inside the metal layer and for the molten Fe to combine with mother pipe metallurgically; and eliminate surface oxide scale after cooling to obtain composite steel pipe with cermet lining. Different kinds of cermet lined steel pipe with adjustable components may be produced.

Owner:UNIV OF SCI & TECH BEIJING

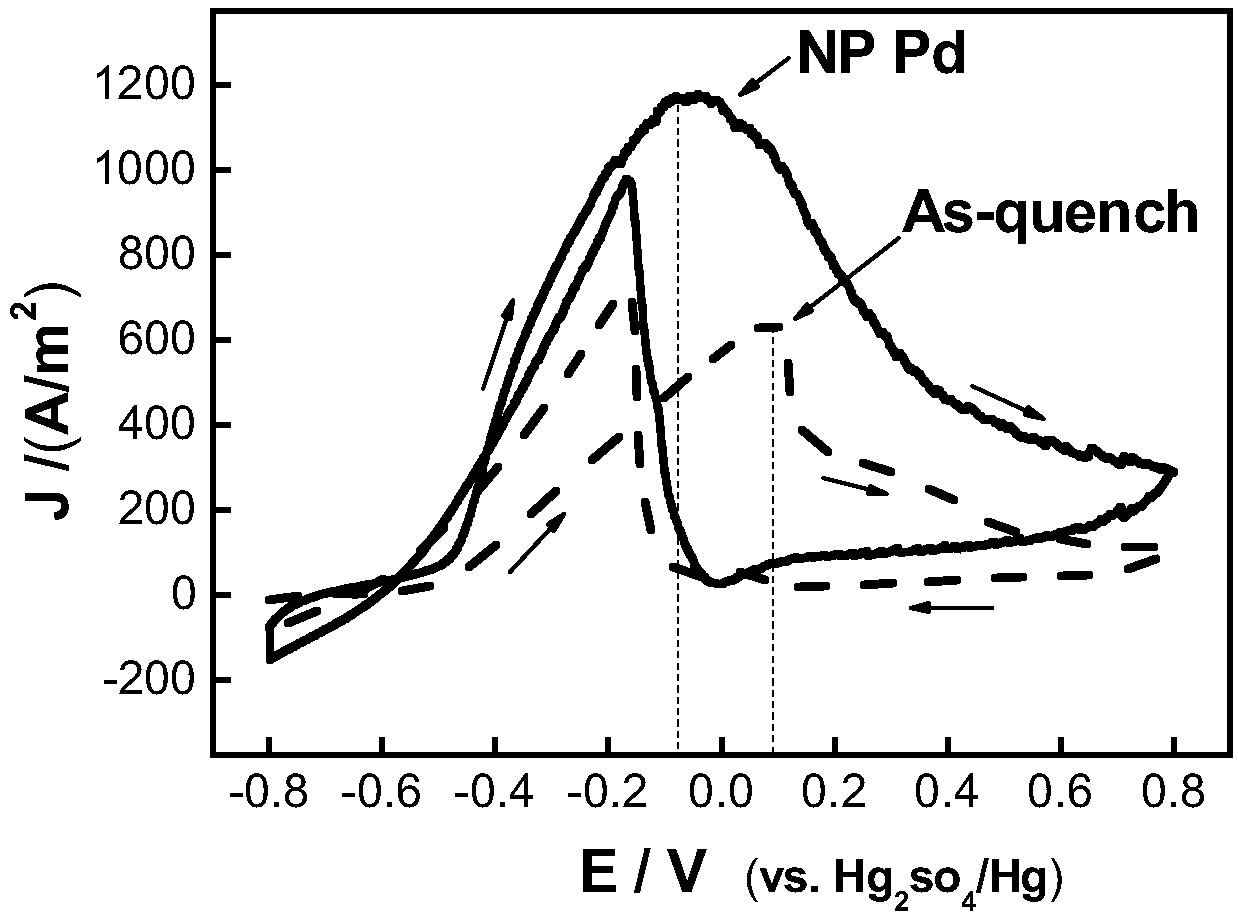

Fe-Pd-based nano-porous material and preparation method thereof

ActiveCN108767277ALow costSimple manufacturing processMaterial nanotechnologyCell electrodesNew energyCO poisoning

The invention provides a nanoporous material and a preparation method thereof, and belongs to the technical field of new materials. The nanoporous material, namely a catalytic material, with a uniformnet structure is prepared by adopting Fe-Pd-P amorphous alloy as precursor alloy and adopting a chemical dealloying process under the acid environment at room temperature, and the prepared Fe-Pd-based nanoporous material has a high electro-catalytic property on methanoic acid and the like. The prepared nanoporous material is used as an electrode material, so that the electro-catalytic property onmethanoic acid is obviously improved. Compared with traditional metal material, the prepared nanoporous material is uniform in structure, high in specific surface area and high in stability, and hasno CO poisoning phenomenon in the electro-catalytic process of methanoic acid; the chemical dealloying method is low in cost, simple and efficient, and easy to realize industrial production; and the prepared nanoporous material is widely applied in the field of new energy electrode materials such as fuel cells.

Owner:UNIV OF SCI & TECH LIAONING

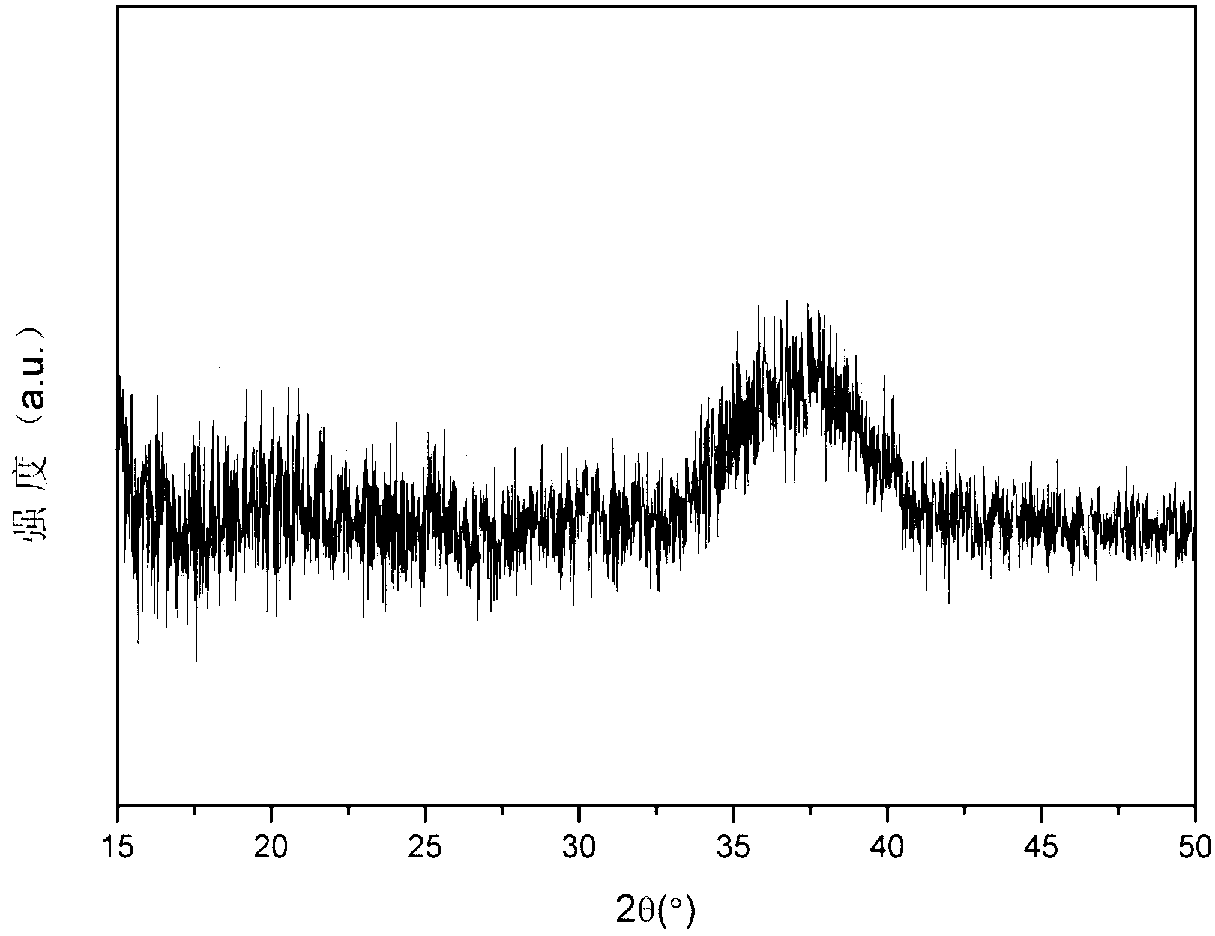

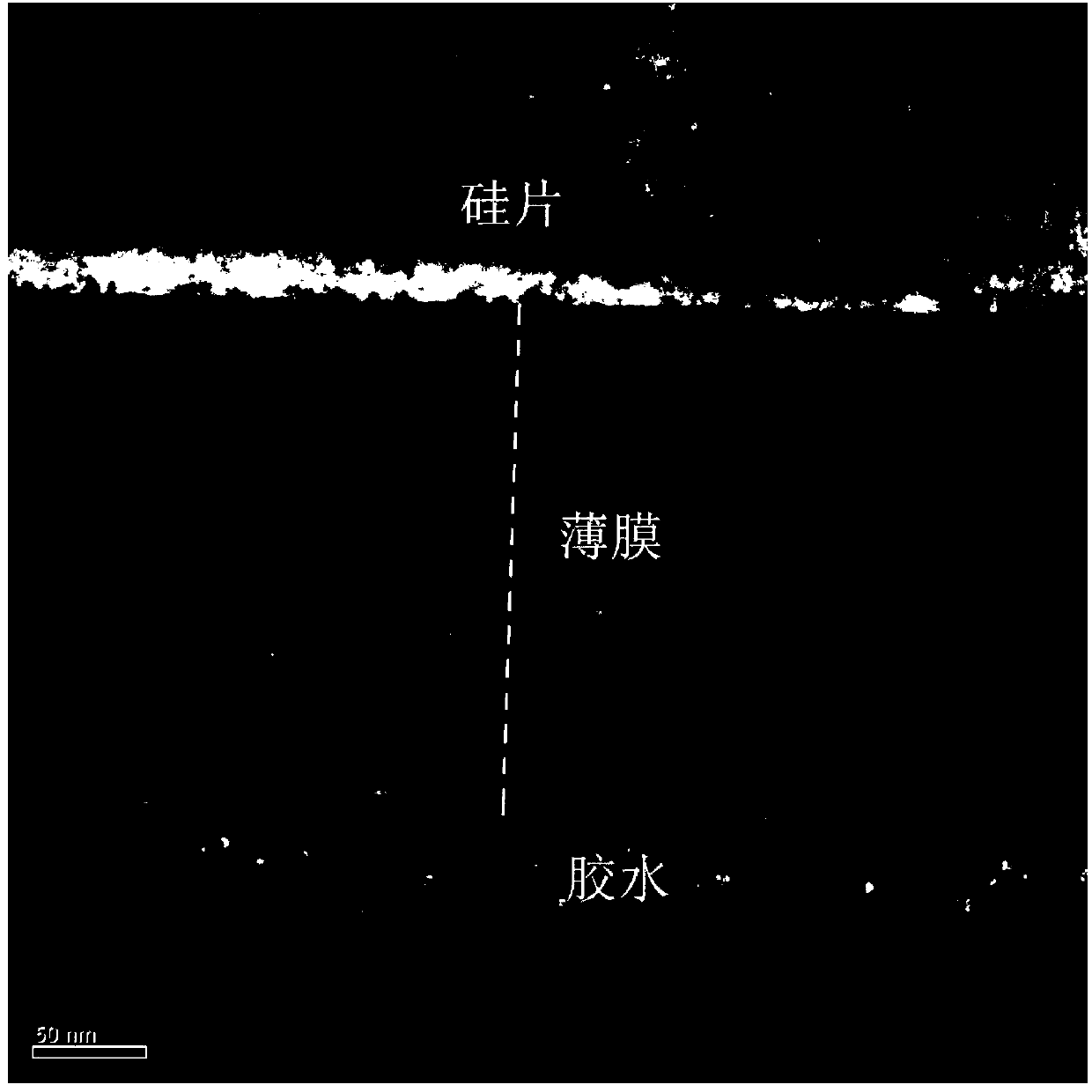

Mg based metallic glass film, its preparation method and application

ActiveCN103215528AAmorphous formation is easyFilm composition and thickness adjustableVacuum evaporation coatingSputtering coatingReflectivityMagnesium

The invention discloses an Mg based metallic glass film and its preparation method. The chemical general formula of the film is MgaCubYc, wherein a, b, and c are atomic percentage, a is greater than or equal to 46.30 and smaller than or equal to 58.01, b is greater than or equal to 24.61 and smaller than or equal to 28.96, c is greater than or equal to 13.18 and smaller than or equal to 24.74, and the sum of a, b and c is 100. The invention also discloses a preparation method of the Mg based metallic glass film, which is obtained by magnetron sputtering. And the method includes: preparing Mg, Cu and Y into an alloy target according to certain proportion; using a monocrystalline silicon wafer and an ordinary glass sheet as the film substrate; putting the alloy target and the film substrate into a sputtering chamber, and performing magnetron sputtering, thus obtaining the Mg based metallic glass film. The method of preparing the metallic glass film by magnetron sputtering only needs ordinary water cooling to obtain an ultrahigh cooling rate, the amorphous is easy to form, and by means of single target sputtering, the film components and thickness are adjustable, and the preparation cost is low. With large differences in amorphous and crystalline resistivity as well as reflectivity, the Mg based metallic glass film has great application prospects in phase-change optical disks and phase change memory.

Owner:HUAZHONG UNIV OF SCI & TECH

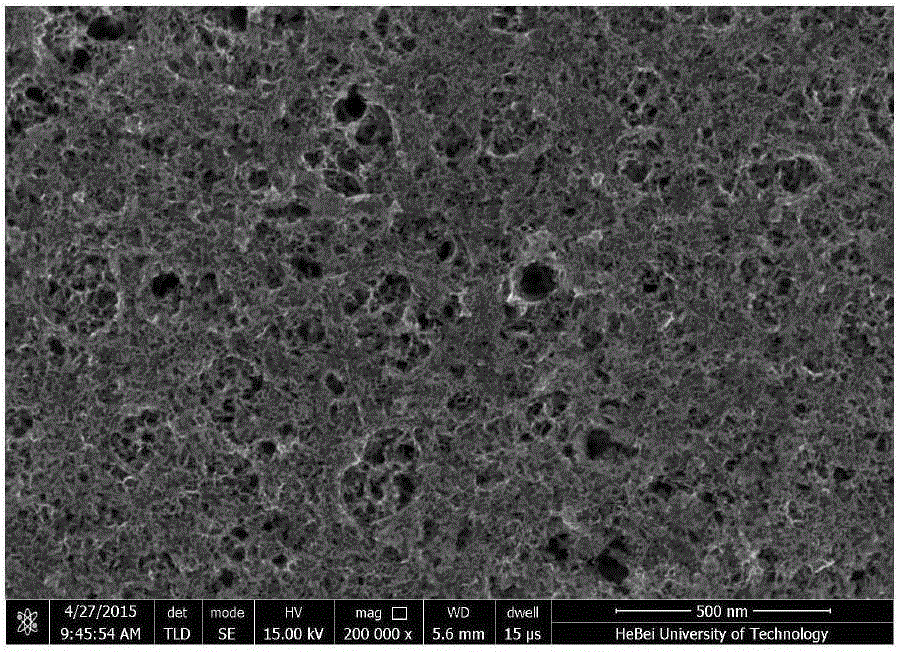

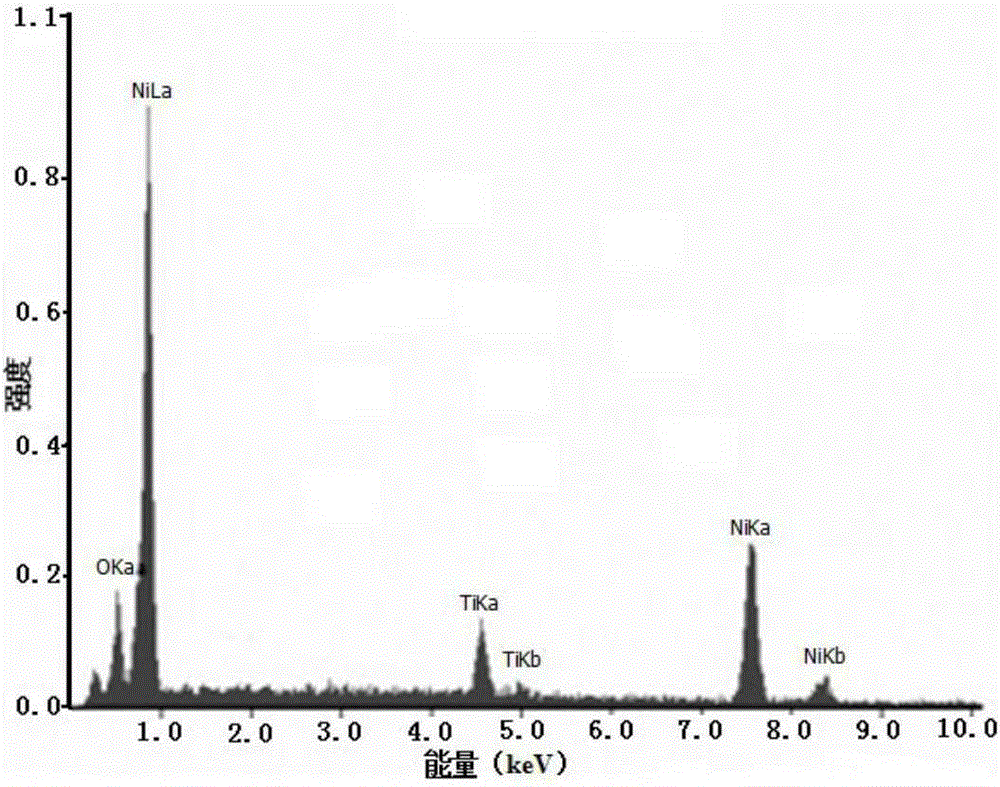

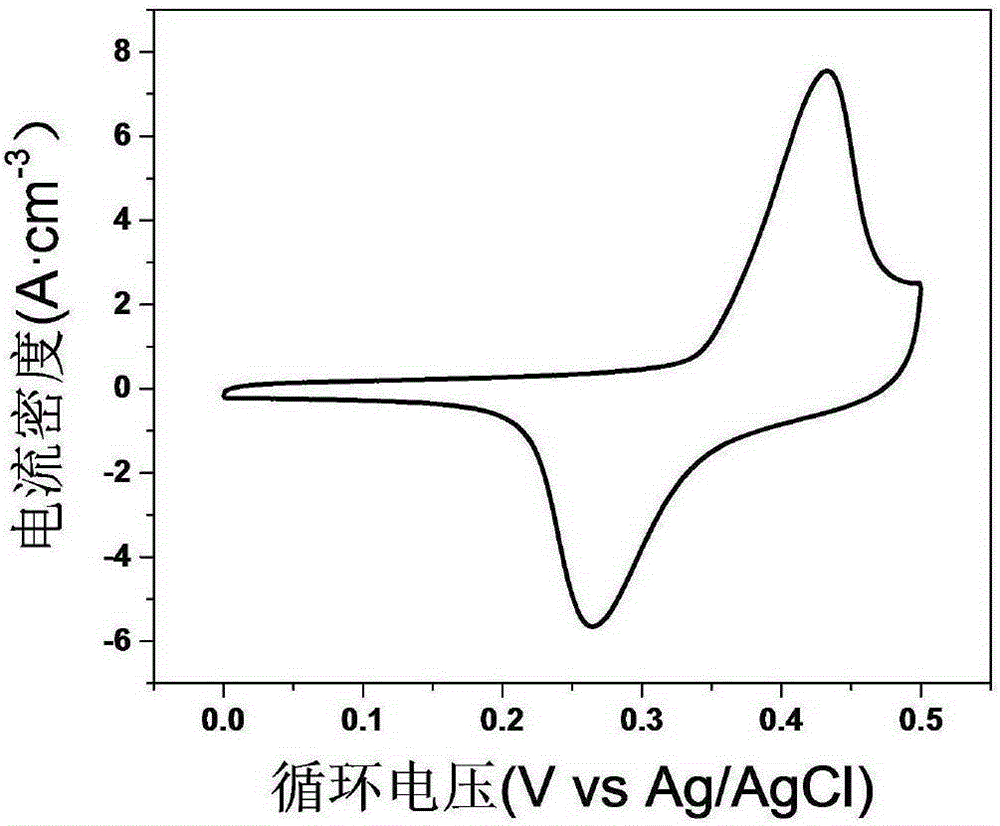

Preparation method of flexible nano porous nickel/nickel oxide composite electrode plate

ActiveCN105261491AHighlight substantive featuresGood flexibilityHybrid capacitor electrodesHybrid/EDL manufactureAcid etchingComposite electrode

The invention discloses a preparation method of a flexible nano porous nickel / nickel oxide composite electrode plate. The method comprises the following steps: (1) preparing a Ni-Ti precursor amorphous alloy ribbon, selecting high-purity Ni and Ti metals according to the atomic percentage ratio of Ni to Ti being (35+x):(65-x), wherein x is 0 to 10, carrying out melting by an arc-melting furnace to prepare a Ni-Ti alloy ingot, removing a surface scale cinder of the Ni-Ti alloy ingot, and preparing the Ni-Ti amorphous alloy ribbon by vacuum melt-spinning equipment, so as to prepare the Ni-Ti amorphous alloy ribbon with the thickness of 25-30 microns; and (2) carrying out a free dealloying treatment on the Ni-Ti amorphous alloy ribbon obtained in the previous step in an acid etching solution at a room temperature for 40-100 minutes, and washing the obtained nano porous ribbon with deionized water, so as to obtain the nano porous nickel / nickel oxide composite electrode plate. The composite electrode material prepared by the method shows excellent flexibility and simultaneously has good electrochemical properties.

Owner:HEBEI UNIV OF TECH

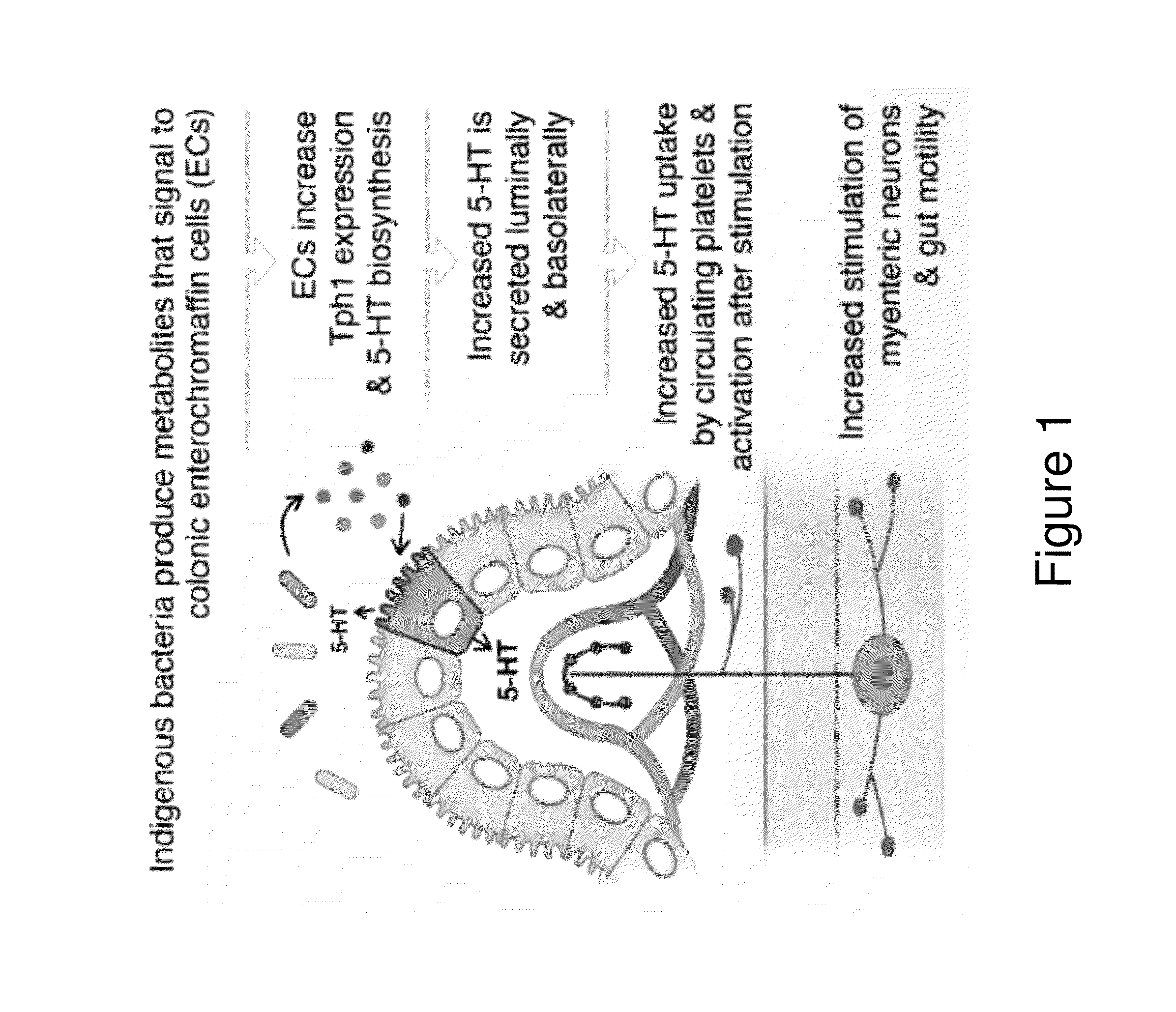

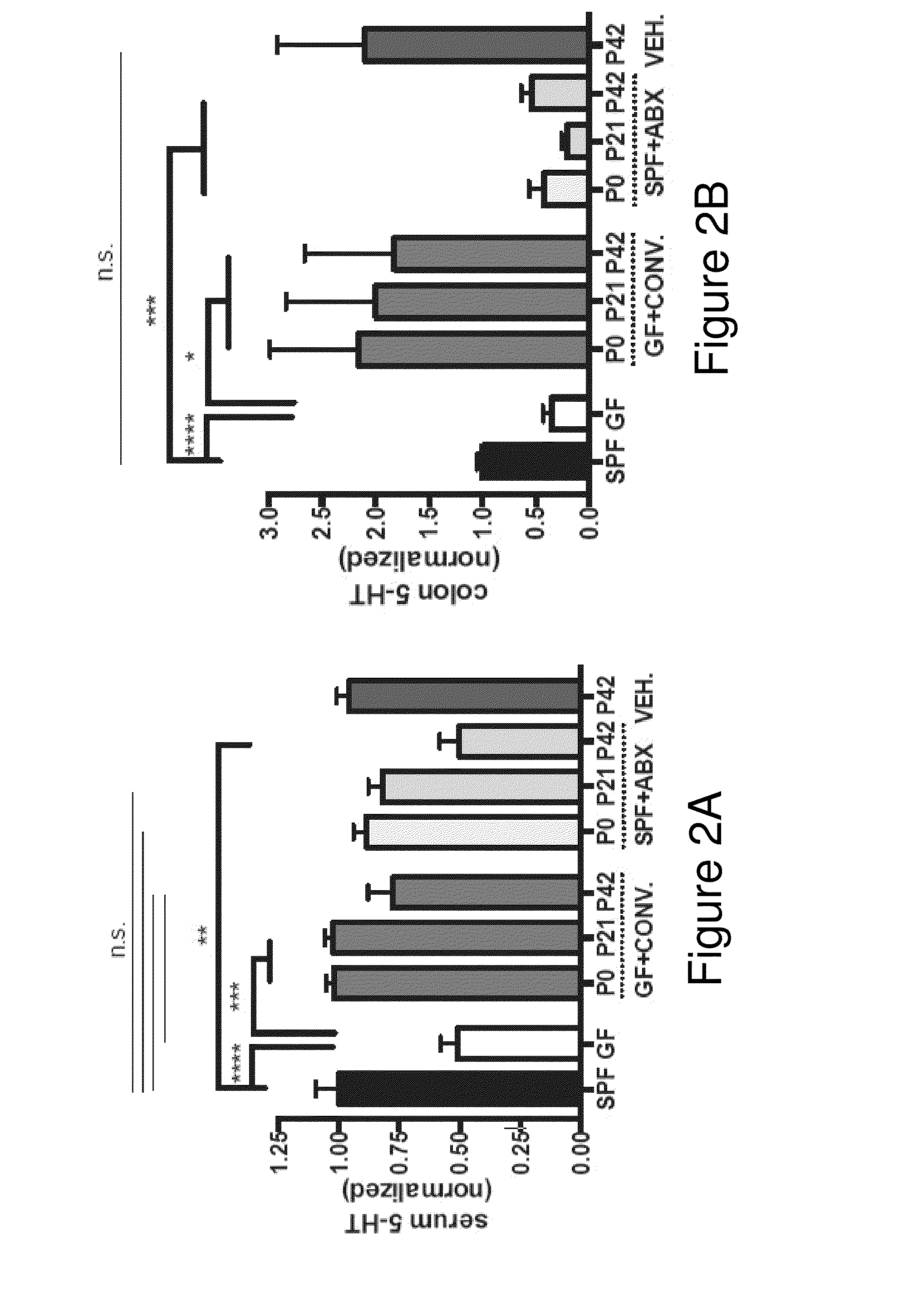

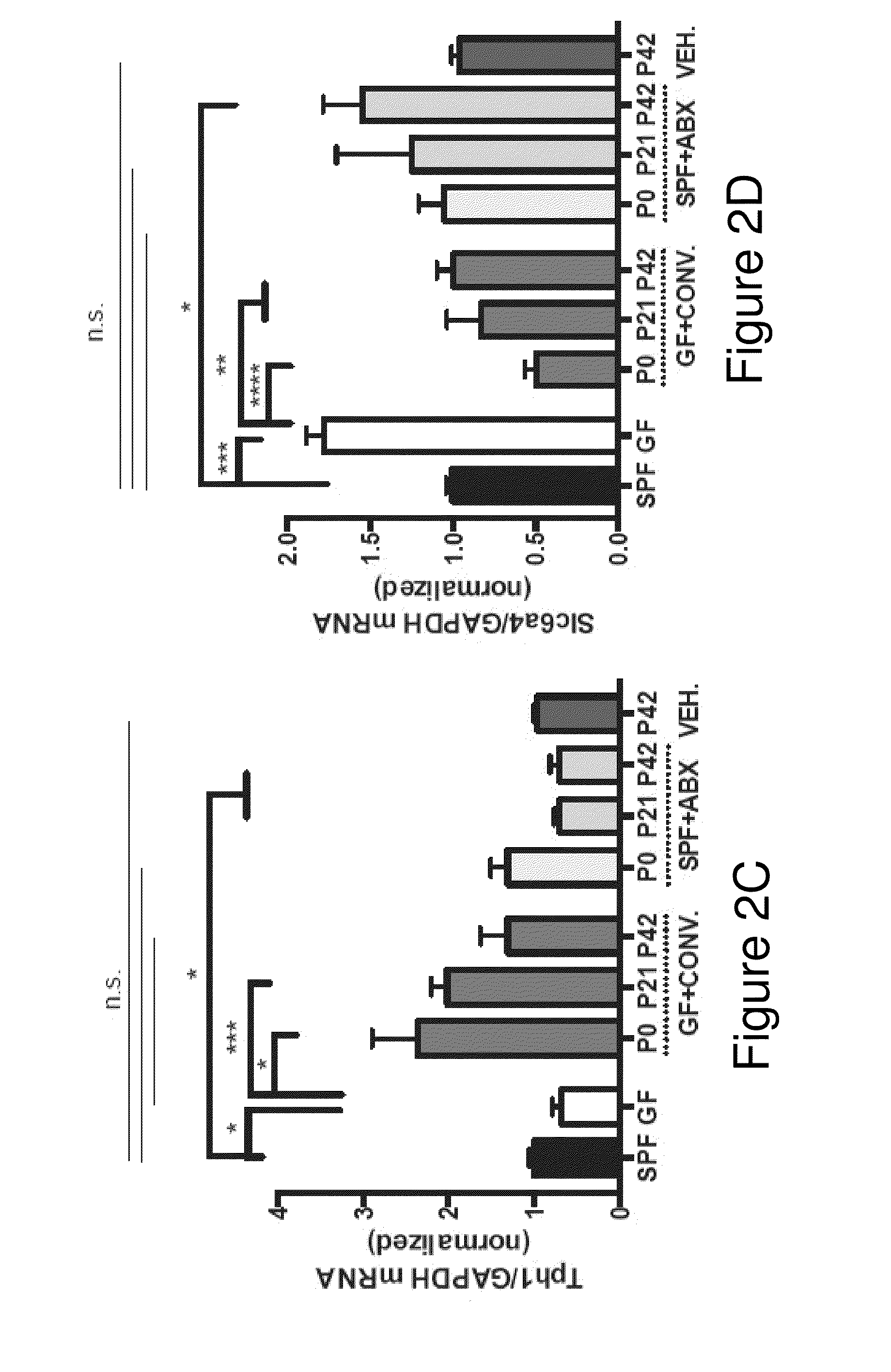

Microbe-based modulation of serotonin biosynthesis

InactiveUS20160058808A1Increase gastrointestinal motilityIncreasing colonic and blood level of serotoninBiocideUnknown materialsMicroorganismDisease

Methods and compositions that can be used to modulate serotonin level in a subject are disclosed herein. In some embodiments, the methods include adjusting the composition of gut microbiota in the subject. Also disclosed are methods of adjusting the level of one or more serotonin-related metabolites to modulate serotonin biosynthesis in a subject, and methods for treating serotonin-related diseases, for example disorders caused by serotonin deficiency.

Owner:RGT UNIV OF CALIFORNIA

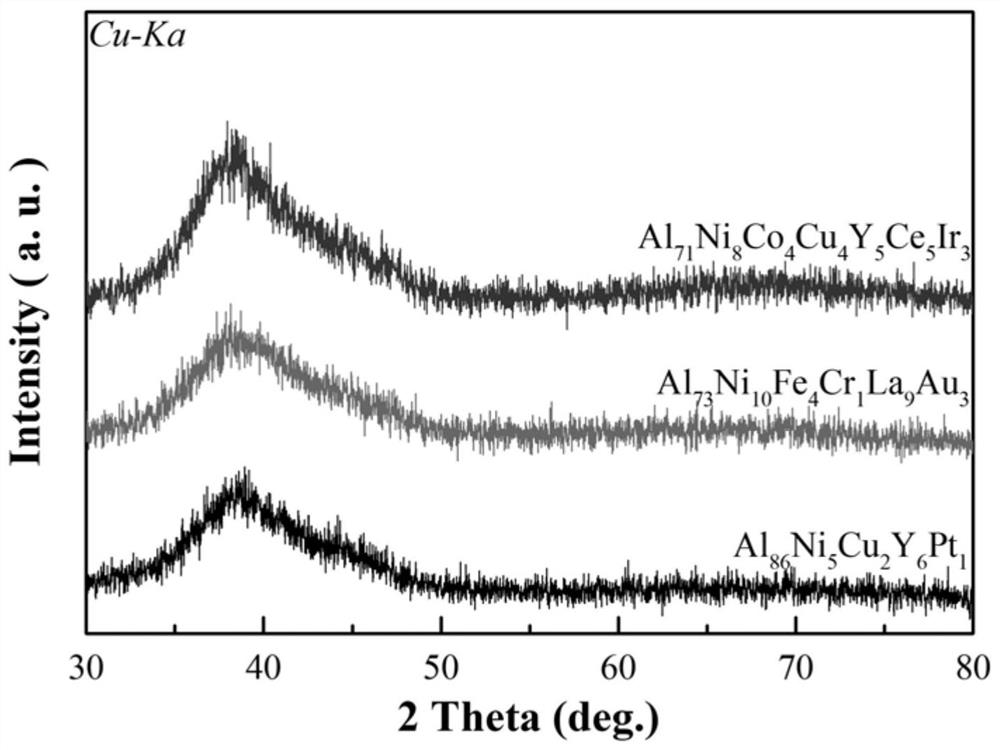

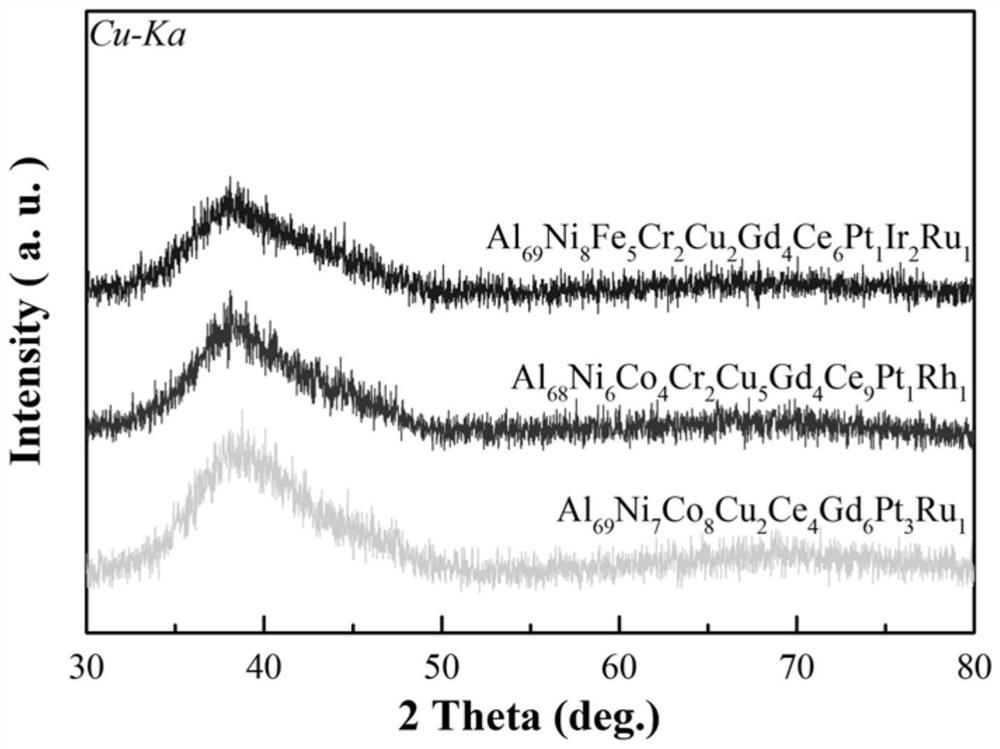

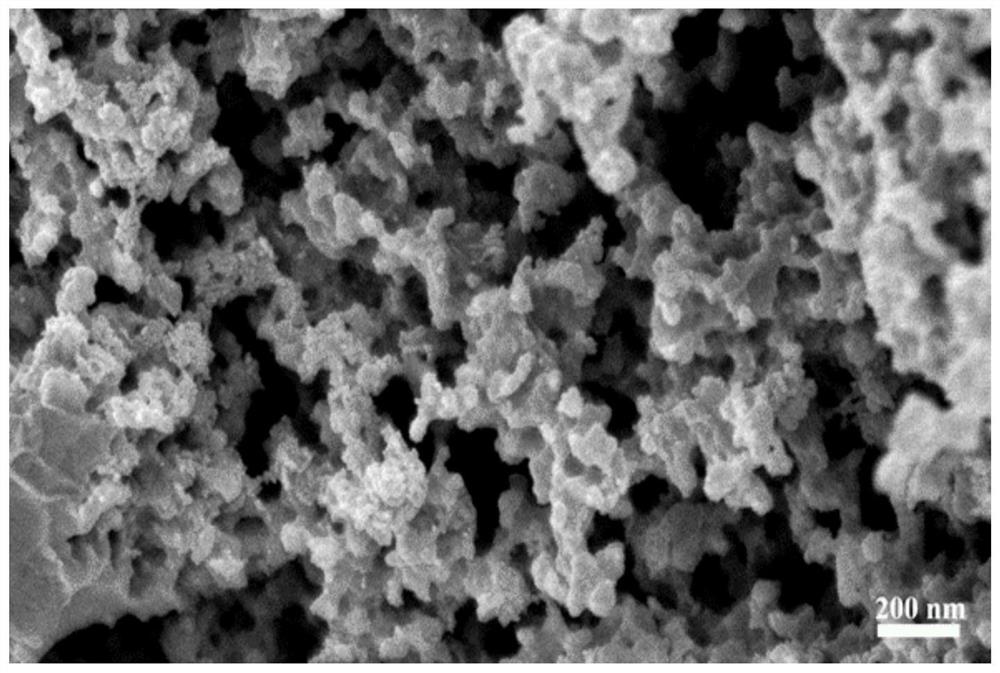

Nano-porous Al-Ni-M-RE-R amorphous alloy used as hydrogen evolution catalytic electrode, and preparation method thereof

ActiveCN112064058AWide range of ingredientsSolve the problem of difficult preparation of nanoporous structuresElectrode shape/formsRare-earth elementElectrolysis

The invention discloses a nano-porous Al-Ni-M-RE-R amorphous alloy used as a hydrogen evolution catalytic electrode, wherein a transition metal element M is Fe, Co, Cr and Cu, a rare earth element REis Y, La, Gd and Ce, a precious metal R is Pt, Ru, Pd, Rh, Au and Ir, and a hydrogen evolution catalytic electrode comprises the following components in percentage by mass: Al, 2-12% of Ni, 1-13% of M, 2-13% of RE, and 0.2-7% of R, and is treated by adopting a constant current method, a corrosion method or a pulse corrosion current method, so that the prepared nano porous amorphous alloy is stablein structure, large in specific surface area, adjustable in component, structure and morphology and high in catalytic activity. According to the invention, when the nano-porous amorphous alloy hydrogen evolution electrode is used as a water electrolysis hydrogen evolution catalytic electrode, the hydrogen evolution overpotential is 40-65 mV and the Tafel slope is 10-60 mV / dec under the current density of 10 mA.cm<-2>, so that the nano-porous amorphous alloy hydrogen evolution electrode has excellent hydrogen evolution catalytic activity.

Owner:BEIHANG UNIV

Method for preparing plate-like structure WC-Co composite powder by utilizing waste cemented carbide

The invention discloses a method for preparing plate-like structure WC-Co composite powder by utilizing waste cemented carbide. The method comprises the steps that (1) the waste cemented carbide is placed in a muffle furnace for oxidizing roasting in order to obtain a tungsten cobalt oxidation product; (2) the tungsten cobalt oxidation product is crushed in order to obtain tungsten cobalt composite oxide powder; (3) at least one of a tungsten oxide, a cobalt oxide and carbon is added into the tungsten cobalt composite oxide powder in order to regulate the content ratio between tungsten, cobaltand the carbon to reach a predetermined value; (4) inorganic salt is added into a mixture obtained from the step (3), and a molten salt reaction is conducted under inert gas protection in order to obtain a synthesized product; and (5) the synthesized product is rinsed in order to remove molten salt particles and obtain the plate-like structure WC-Co composite powder. The method has the advantagesof being simple in technological process and easy to operate, the prepared and obtained plate-like structure WC-Co composite powder is good in plate-like effect, high in purity and adjustable in composition and granularity, and the method can be used for preparing of high-performance plate-like grain cemented carbide.

Owner:CHONGYI ZHANGYUAN TUNGSTEN

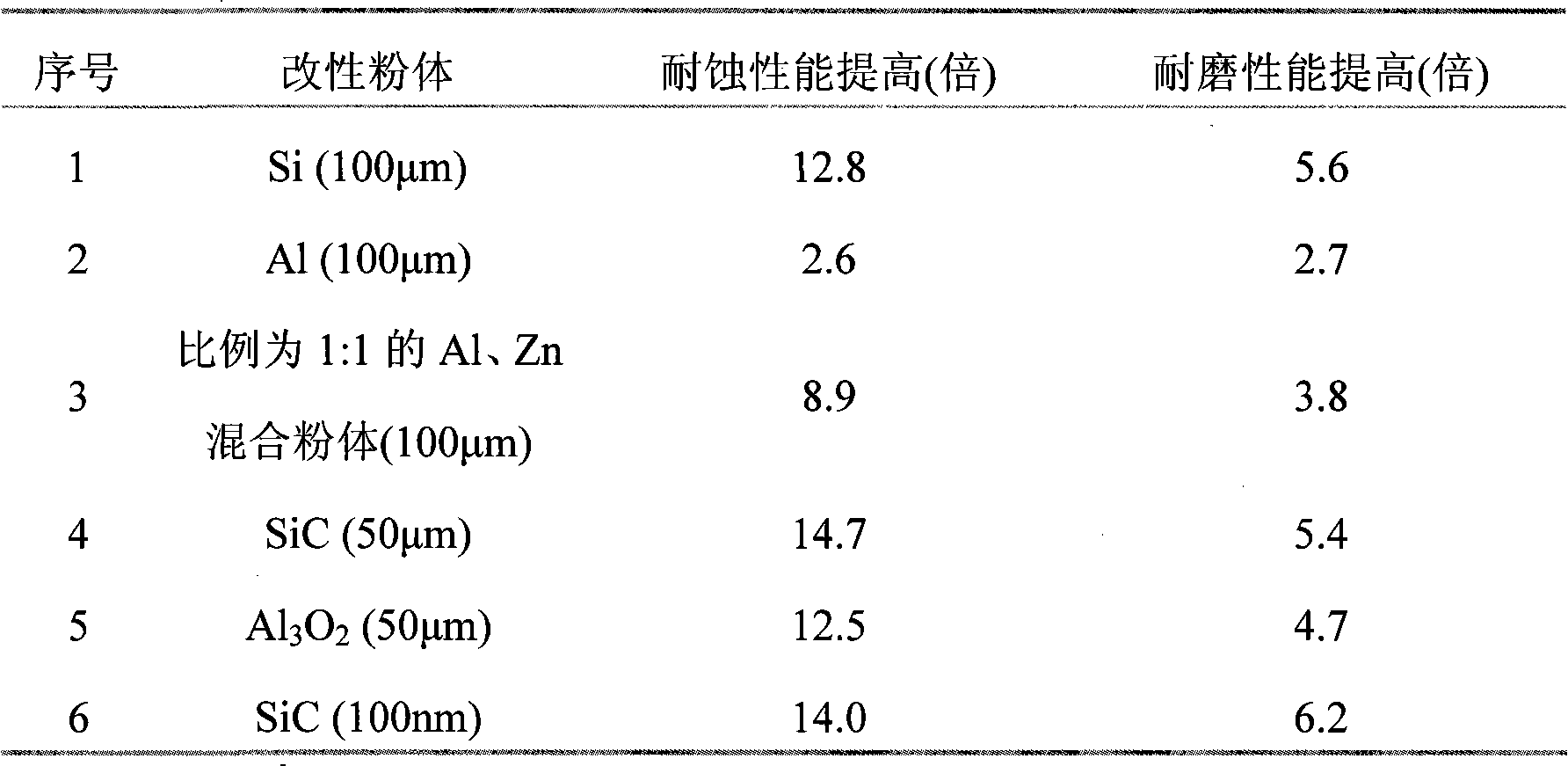

Die-casting magnesium alloy surface modified powder infiltration process

InactiveCN101402136AThe technical effect is obviousChange the physical and chemical properties of the surfaceHigh rateFiltration

The invention relates to a modified powder body filtration process for the surface of die casting magnesium alloy, which forms the gradient of alloy concentration on a surface layer of a die casting magnesium alloy part through an infiltration technology. The adopted technical proposal is as follows: different modified powder bodies without adding any adhesive are directly sprayed on the surface of a parting agent of a die casting mold, and a modification layer can be formed on the surface of the magnesium alloy part by casting liquid magnesium alloy in the metal casting mold by die casting and cooling. The process substantially changes the physicochemical property and the mechanical property of the surface of the magnesium alloy; the formed surface modification layer is continuous and compact, does not contain organic substances, and has good corrosion resistance and wear resistance; and the process simplifies the prior surface modification technology of the magnesium alloy, and realizes green, environment-friendly and pollution-free production. The process is simple, has easily controlled parameters and high rate of finished products, and can be widely used for industrial production.

Owner:DALIAN JIAOTONG UNIVERSITY

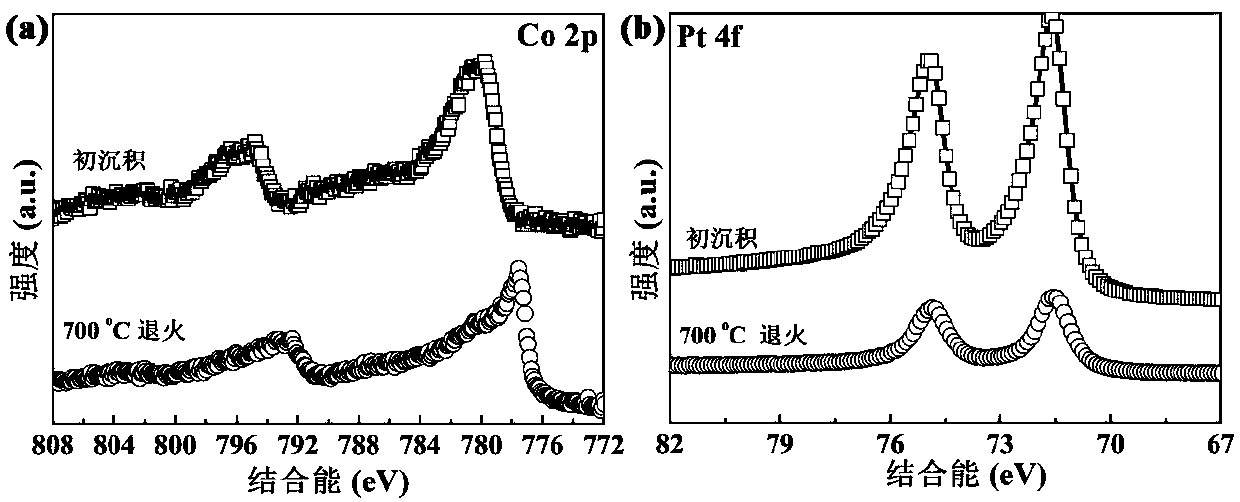

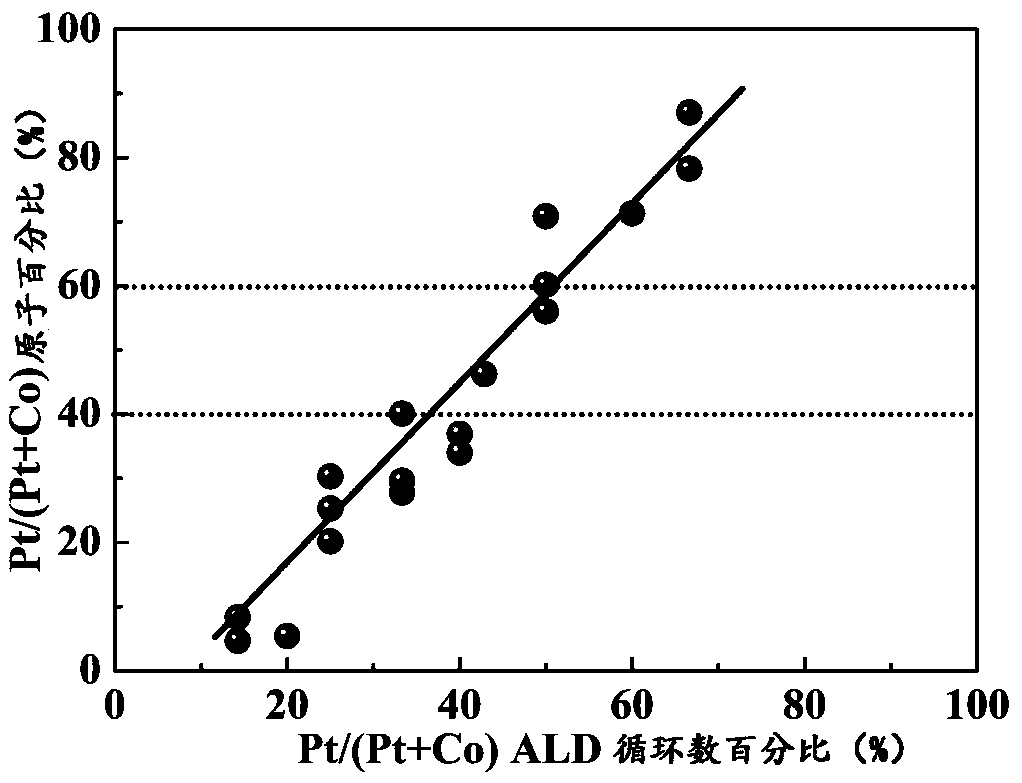

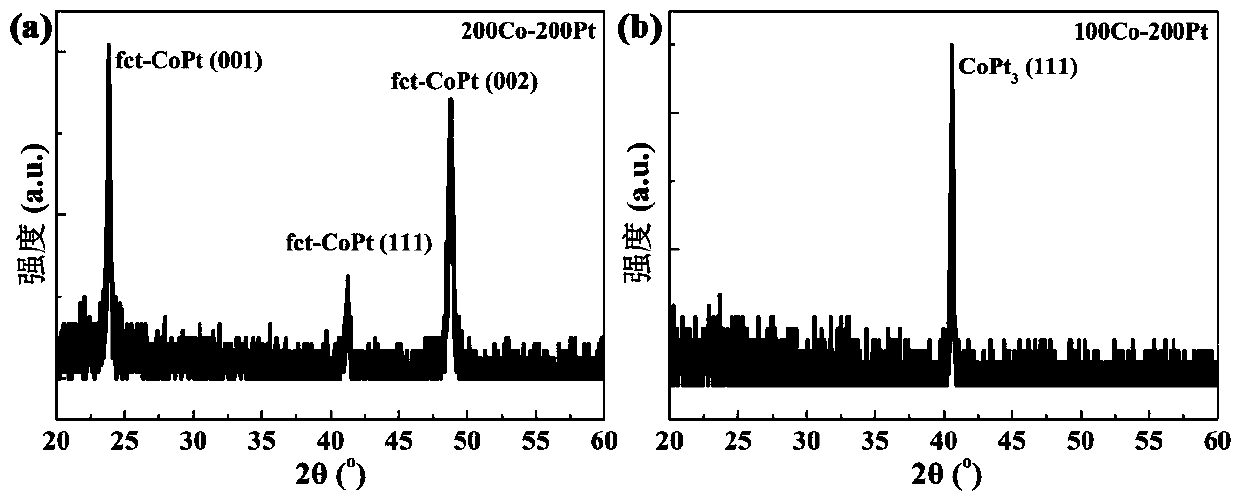

Preparation method of Co-Pt / Fe-Pt nanoparticle with adjustable composition

ActiveCN110284121ASimple processPrecise control of compositionMaterial nanotechnologyChemical vapor deposition coatingMagnetic storagePt element

The invention discloses a preparation method of a Co-Pt / Fe-Pt nanoparticle with adjustable composition, and belongs to the field of preparation of nano materials. The composition of a material can be accurately regulated and controlled by utilizing a film thickness control method which is simple in atomic layer deposition technology and changing the cycle number of ALD deposited cobalt oxide or ferric oxide and Pt; and the three-dimensional fitting property of the ALD is combined, so that uniform coating can be realized on a three-dimensional structural matrix; and the preparation method is simple in process and accurate and controllable in composition; and the obtained Co-Pt / Fe-Pt nanoparticle can be applied to the fields of high-density magnetic storage, electrocatalysis and the like. According to the preparation method of the Co-Pt / Fe-Pt nanoparticle with the adjustable composition, the cobalt oxide or the ferric oxide is firstly deposited on a substrate; then ALD deposition of platinum is carried out; zirconium oxide or the ferric oxide and the platinum are repeatedly deposited to obtain cobalt oxide or ferric oxide / platinum nano-laminated layer; and finally annealing treatment is carried out to obtain the Fe-Pt / Co-Pt nanoparticle with the adjustable composition.

Owner:NANJING UNIV

Camera apparatus and control method for selecting a target for zoom processing in an image

InactiveUS9077895B2Ingredients adjustableTelevision system detailsColor television detailsComputer terminalImage display

A processor (30) of a mobile terminal (10) that is one example of a camera apparatus detects a face image of a person image (58) in an object image displayed on a display (14) prior to an imaging key (26) is operated, and displays a face mark (60) at a portion of the face of each person image. A user selects arbitrary one or more person image out of the person images onto each of which the face mark is displayed as a zoom processing target by operating an operating portion such as a GUI. A selection mark (62) is applied to a person image that the user selects. A zooming-up and / or down (zoom processing) is performed such that the object image including the person image onto which the selection mark is applied is rendered to a predetermined composition.

Owner:KYOCERA CORP

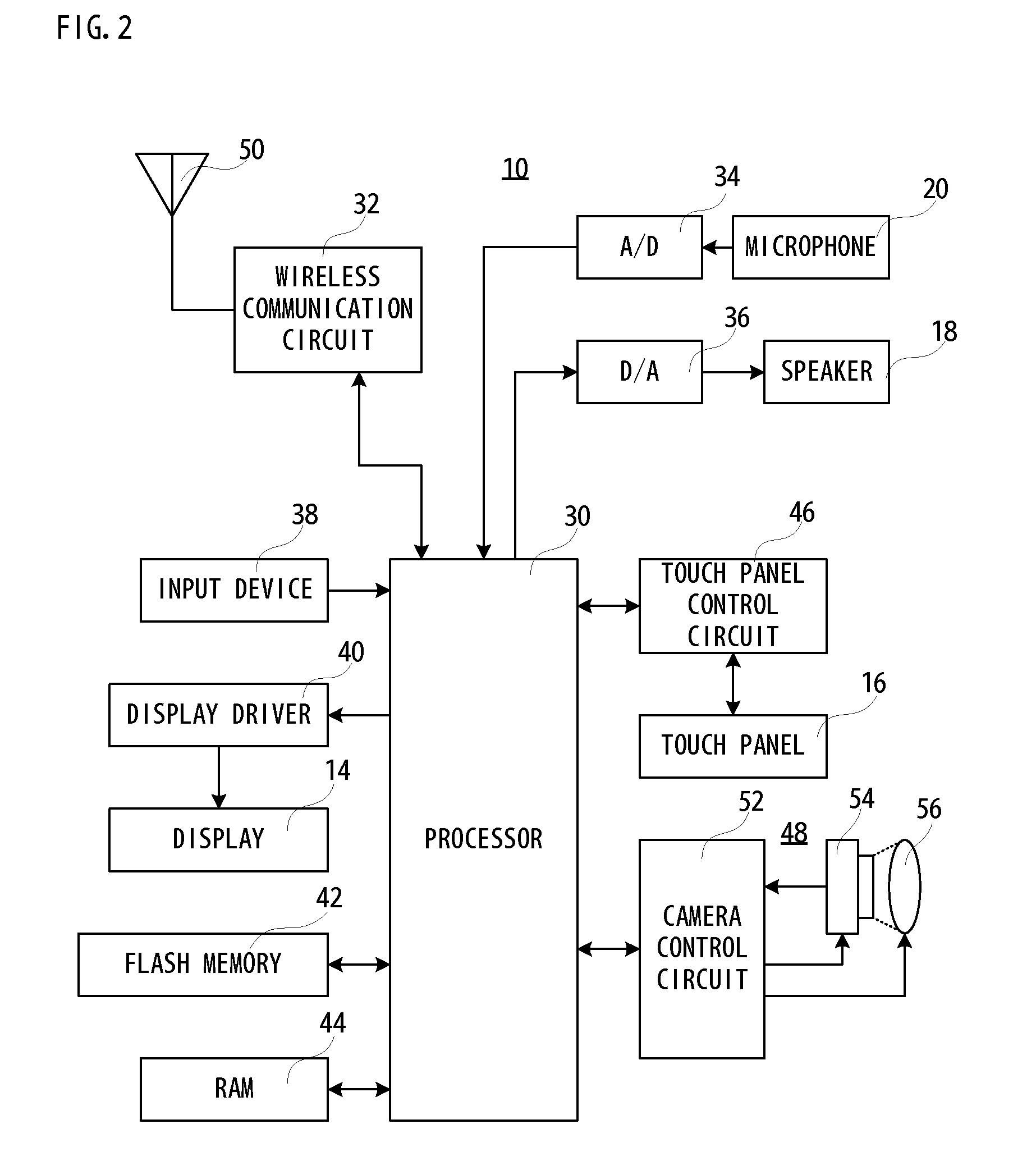

Thin film forming method and forming device therefor

InactiveUS20060189046A1Good reproducibilityLimit on characteristicSolid-state devicesVacuum evaporation coatingOptoelectronicsHysteresis phenomenon

A method of forming a thin film of the present invention comprises: an optical characteristic adjusting step of repeatedly conveying a substrate holder between a zone to perform an intermediate thin film forming step and a zone to perform a film composition converting step while controlling a conveying speed of the substrate holder for holding a substrate, and adjusting a film composition of a finally formed thin film to form the thin film having an optical characteristic value of a region where a hysteresis phenomenon occurs.

Owner:SHINCRON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com