Preparation method of platinum-palladium alloy nanocrystalline

A technology of platinum-palladium alloy and nanocrystal, which is applied in the field of preparation of precious metal nanomaterials, can solve the problems of complex process, high cost and low output, and achieve the effect of simple preparation method, simple reagent and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

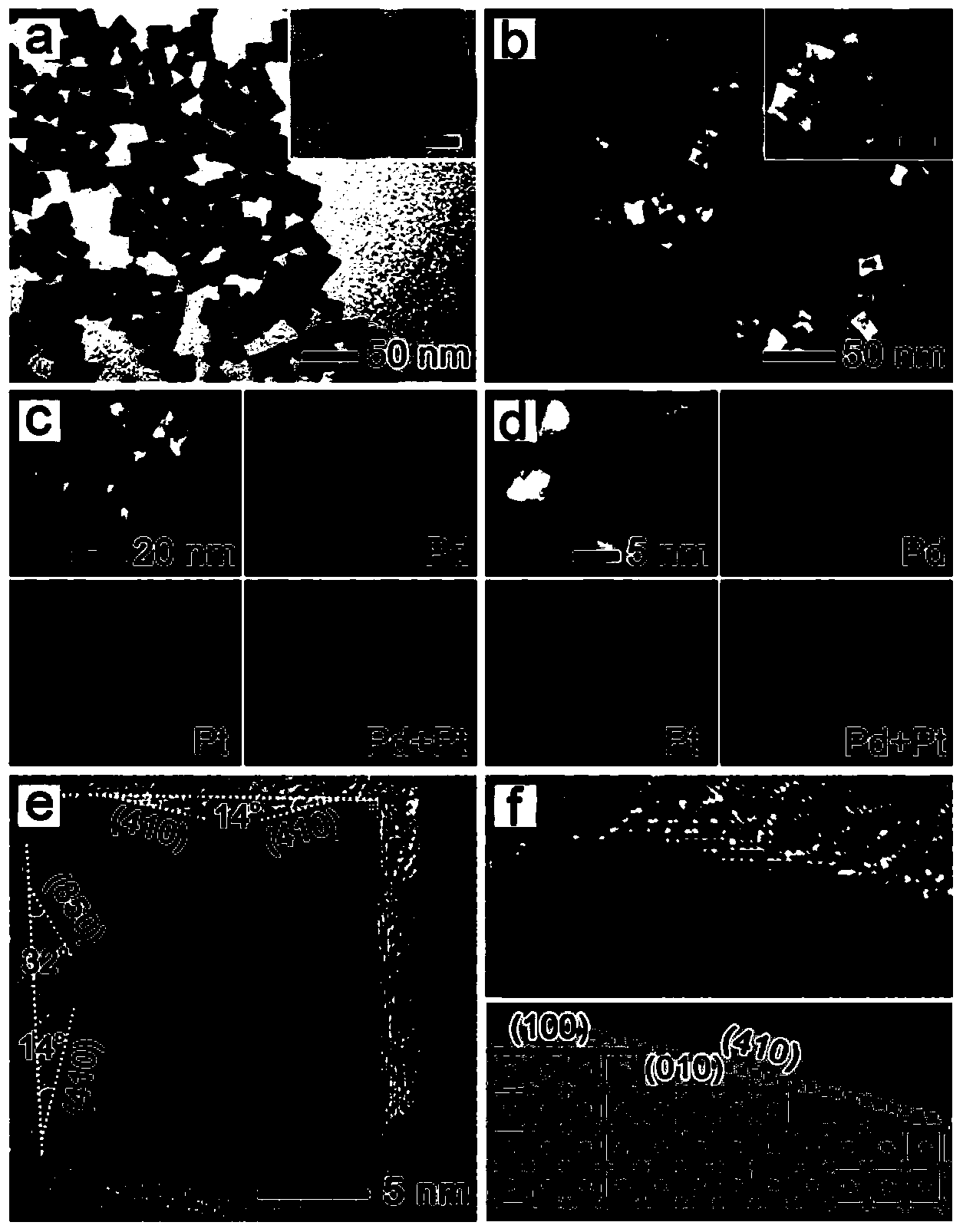

Image

Examples

Embodiment 1

[0027] Dissolve 99 mg of chloroplatinic acid and 72 mg of sodium tetrachloropalladate in 4 mL of ethylene glycol (the concentration of chloroplatinic acid is 0.06 mol / L, and that of sodium tetrachloropalladate is 0.06 mol / L), while 199 mg of polyvinylpyrrolidone, 200 mg Add ascorbic acid and 150mg potassium bromide to 6ml of ethylene glycol (polyvinylpyrrolidone concentration is 0.3mol / L, ascorbic acid concentration is 0.19mol / L, potassium bromide concentration is 0.21mol / L). Then place 6mL mixed solution of polyvinylpyrrolidone, ascorbic acid, potassium bromide and ethylene glycol in a heater, heat to 130°C while stirring, and inject chloroplatinic acid, tetrachloromethane at a rate of 2mL / h with a syringe pump. 3 mL of a mixed solution of sodium palladium and ethylene glycol was injected into a mixed solution of polyvinylpyrrolidone, ascorbic acid, potassium bromide, and ethylene glycol. When the mixed solution is completely injected, the reaction ends, and platinum-palladiu...

Embodiment 2

[0030] Dissolve 66 mg of chloroplatinic acid and 48 mg of sodium tetrachloropalladate in 4 mL of ethylene glycol (the concentration of chloroplatinic acid is 0.04 mol / L, and that of sodium tetrachloropalladate is 0.04 mol / L), while 199 mg of polyvinylpyrrolidone, 300 mg of Ascorbic acid and 100 mg of potassium bromide were added to 6 ml of ethylene glycol (the concentration of polyvinylpyrrolidone was 0.3 mol / L, the concentration of ascorbic acid was 0.28 mol / L, and the concentration of potassium bromide was 0.14 mol / L). Then place 6mL mixed solution of polyvinylpyrrolidone, ascorbic acid, potassium bromide and ethylene glycol in a heater, heat to 130°C while stirring, and inject chloroplatinic acid, tetrachloromethane at a rate of 3mL / h with a syringe pump. 3 mL of a mixed solution of sodium palladium and ethylene glycol was injected into a mixed solution of polyvinylpyrrolidone, ascorbic acid, potassium bromide, and ethylene glycol. When the mixed solution was fully injected...

Embodiment 3

[0032] Dissolve 132mg of chloroplatinic acid and 24mg of sodium tetrachloropalladate in 4mL of ethylene glycol (the concentration of chloroplatinic acid is 0.08mol / L, and the concentration of sodium tetrachloropalladate is 0.02mol / L), while 199mg of polyvinylpyrrolidone, 400mg Ascorbic acid and 100 mg of potassium bromide were added to 6 ml of ethylene glycol (the concentration of polyvinylpyrrolidone was 0.3 mol / L, the concentration of ascorbic acid was 0.38 mol / L, and the concentration of potassium bromide was 0.14 mol / L). Then place 6mL mixed solution of polyvinylpyrrolidone, ascorbic acid, potassium bromide and ethylene glycol in a heater, heat to 120°C while stirring, and inject chloroplatinic acid, tetrachloromethane at a speed of 4mL / h with a syringe pump 3 mL of a mixed solution of sodium palladium and ethylene glycol was injected into a mixed solution of polyvinylpyrrolidone, ascorbic acid, potassium bromide, and ethylene glycol. When the mixed solution was completely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com