Fe-Pd-based nano-porous material and preparation method thereof

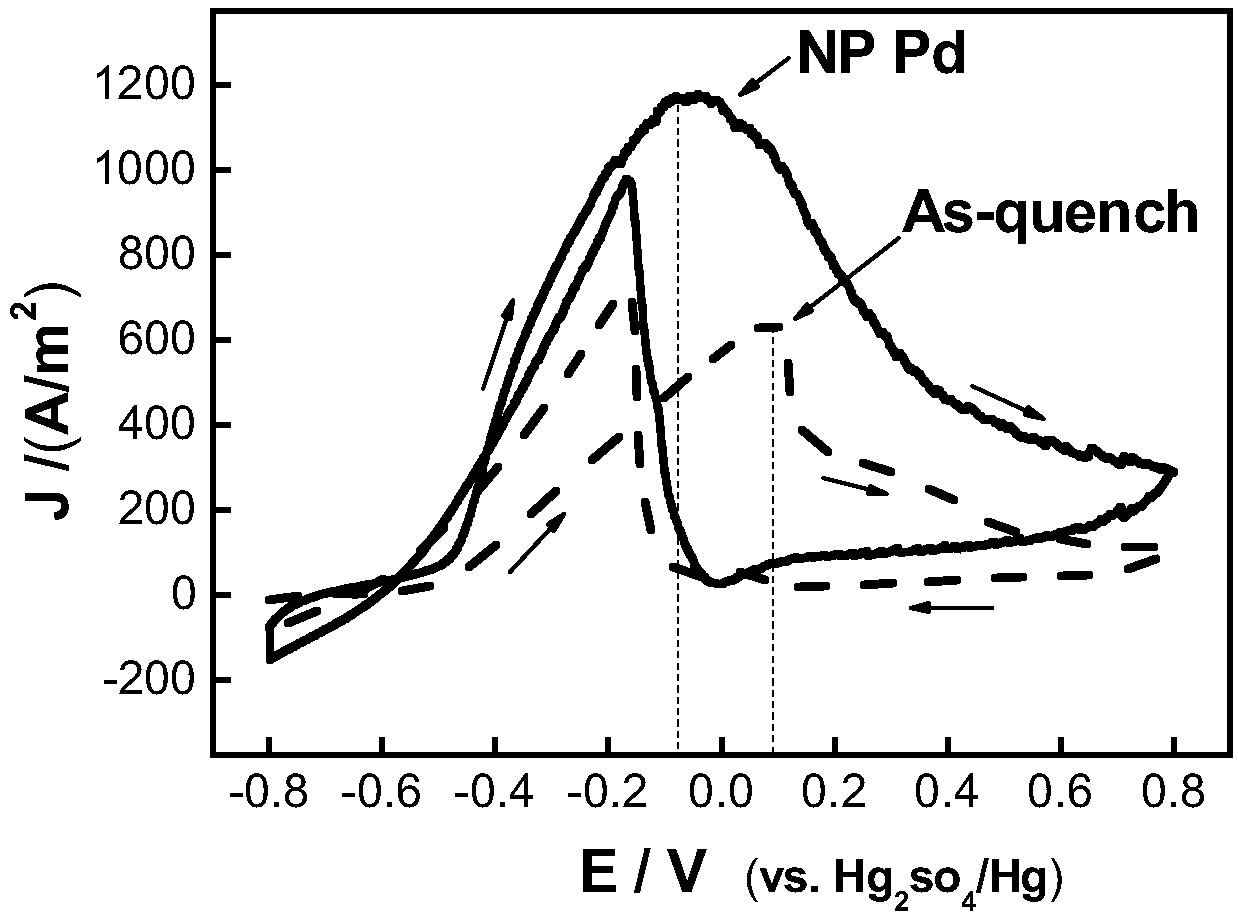

A nanoporous, fe-pd technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem that it is difficult to efficiently prepare nanoporous materials in alloy systems, and achieve excellent electrocatalytic performance, Short production cycle, simple and efficient preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Fe 70 PD 20 P 10 Preparation of Nanoporous Materials by Chemical Dealloying of Amorphous Alloys.

[0029] Step 1: Ingredients

[0030] According to Fe 70 PD 20 P 10 The atomic percentage of the alloy composition is converted into a weight percentage, using high-purity Fe (99.9mass%), Fe 3 P (99.5mass%), Pd (99.9mass%) elements and compounds are weighed according to the composition of the alloy.

[0031] Step 2: Melting the master alloy ingot.

[0032] Place the prepared metal raw materials in the Nisshin Giken NEV-SM04 vacuum induction melting device, and vacuumize to 8×10 -3 Pa below, and under the protection of high-purity argon (purity 99.99%) fully smelted to obtain the master alloy ingot.

[0033] Step 3: Preparation and Characterization of Amorphous Alloy Ribbon.

[0034] Using Japan's Nisshin Giken NEV-SM04 vacuum quenching belt device, the vacuum degree is lower than 2.0×10 -3 Below Pa, and filled with high-purity argon protection (purity...

Embodiment 2

[0039] Example 2: Fe 70 PD 20 P 10 Amorphous alloy increases the chemical dealloying time to 5h to prepare nanoporous materials

[0040] Method is with embodiment 1, and difference is:

[0041] (1) Fe 70 PD 20 P 10 Nanoporous materials were prepared by dealloying amorphous alloy strips in 0.1 L of concentrated nitric acid solution with a mass fraction of 65% at 25 °C for 5 h.

[0042] (2) After chemical dealloying for 5 hours, a nanoporous material with a three-dimensional uniform network structure was prepared with a pore size of 55-90 nm and a pore wall size of 10-30 nm; Figure 4 shown.

[0043] (3) Increase the chemical dealloying time to 5h, which promotes Fe 70 PD 20 P 10 With the chemical dealloying of the amorphous alloy thin strip, the Fe element continues to corrode and dissolve, and the pore size of the nanoporous material continues to corrode and become larger. It shows that in the acidic solution, increasing the chemical dealloying time promotes the cor...

Embodiment 3

[0044] Example 3: Fe 60 PD 20 P 20 Preparation of nanoporous materials by chemical dealloying of amorphous alloys for 5 hours

[0045] Method is with embodiment 1, and difference is:

[0046] (1) Press Fe 60 PD 20 P 20 Nominal composition batch melting and vacuum quenching strip alloy prepared into 2 mm wide × 30 μm thick Fe 60 PD 20 P 20 Amorphous alloy thin strip;

[0047] (2) Fe with a width of 2 mm × thickness of 30 μm 60 PD 20 P 20 After chemical dealloying of the amorphous alloy ribbon in 0.1 L of concentrated nitric acid solution with a mass fraction of 65% at 25 °C for 5 h, the sample formed a large number of corrosion crack structures with a width of 50-180 nm, as shown in the attached Figure 5 shown.

[0048] (3) Fe 60 PD 20 P 20 Amorphous alloy ribbon with Fe 70 PD 20 P 10 Compared with amorphous alloys, due to the decrease of Fe element, Fe 70 PD 20 P 10 Amorphous alloys are more prone to corrosion and dissolution of Fe elements, and diffusio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com