Preparation method of Co-Pt / Fe-Pt nanoparticle with adjustable composition

A nanoparticle, co-pt technology, applied in the field of preparation of Co-Pt/Fe-Pt nanoparticles, can solve problems such as difficulty in uniform deposition, and achieve the effects of simple process, excellent three-dimensional adhesion, and simple film thickness control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

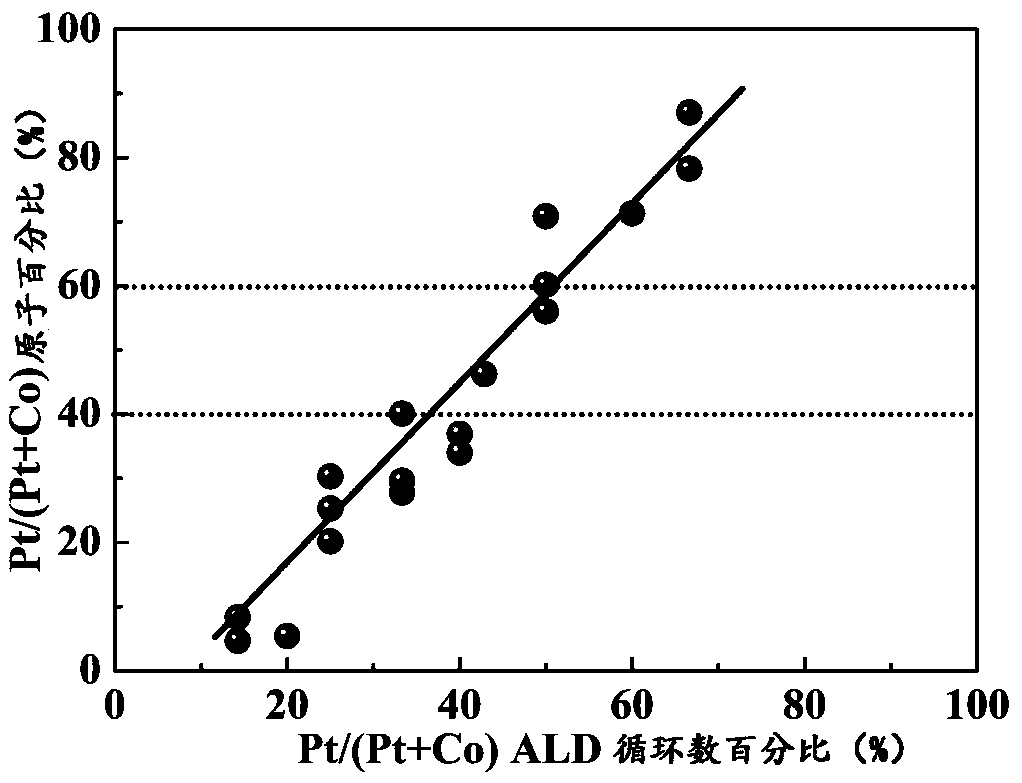

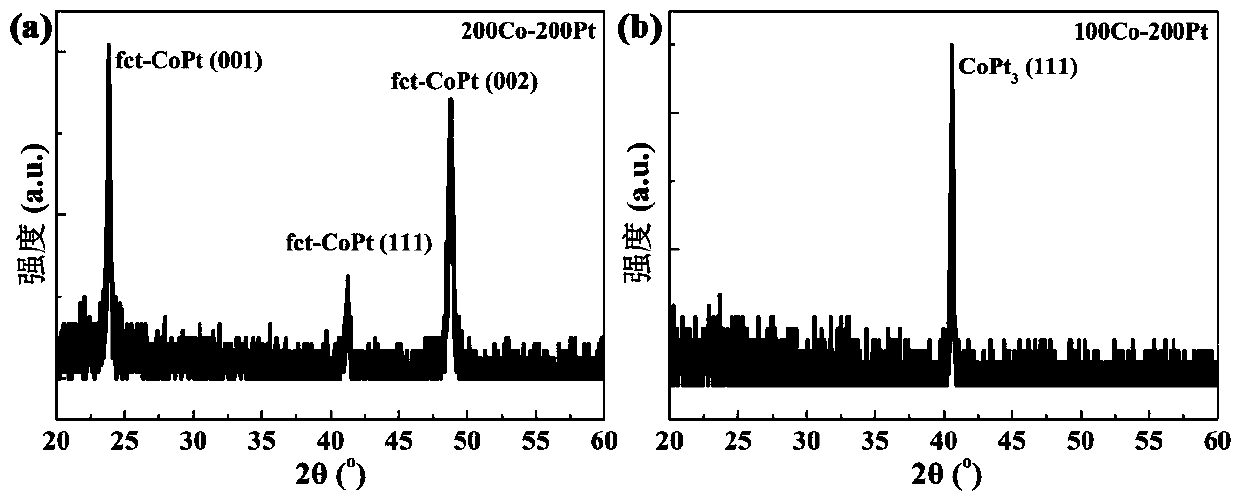

[0025] A method for preparing Co-Pt nanoparticles with adjustable composition, comprising the following steps:

[0026] (1) ALD deposition of cobalt oxide film: using surface growth of 300 nm SiO 2 The silicon wafer was used as the substrate, and cobalt oxide was grown for 100, 200, and 300 cycles respectively, and the growth parameters were as follows:

[0027] Reaction chamber temperature: 250 o C;

[0028] Reaction source: cobaltocene (Co(Cp) 2 ) as the metal source, the source temperature is 85 o C, ozone as an oxygen source;

[0029] Pulse and cleaning time: metal source pulse is 1 s, high-purity nitrogen gas cleaning is 5 s; ozone pulse is 1.5 s; followed by high-purity nitrogen gas cleaning for 10 s to wash away reaction by-products and residual reaction sources;

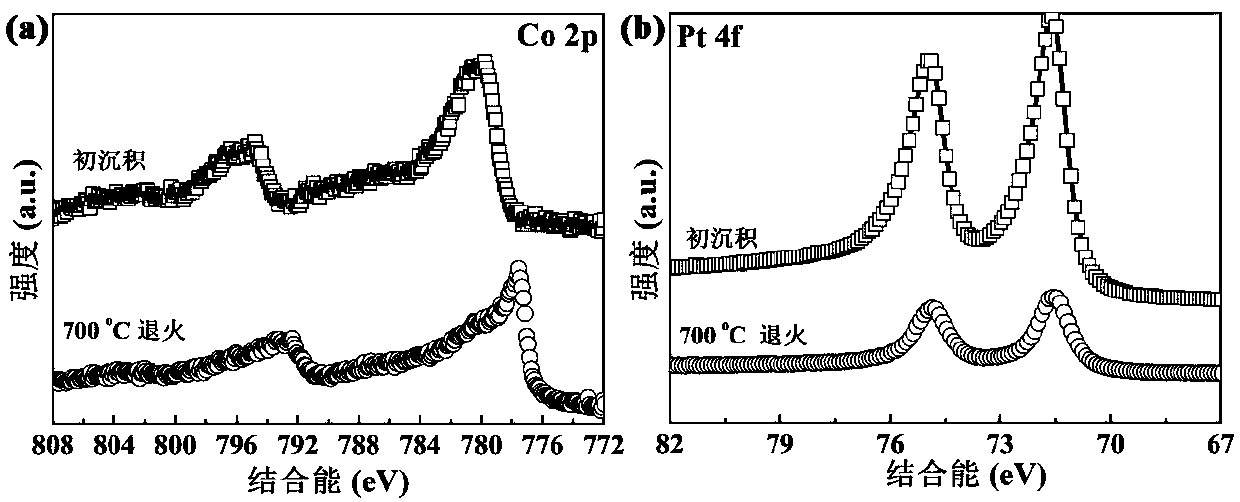

[0030] (2) ALD deposition of metal platinum: continue ALD deposition of metal platinum on the substrate obtained in step (1) with cobalt oxide, and grow 50, 100, 150, 200 cycles of metal platinum. The AL...

Embodiment 2

[0039] A method for preparing Co-Pt nanoparticles with adjustable composition, comprising the following steps:

[0040] (1) ALD deposition of cobalt oxide thin film: use cleaned carbon fiber paper as the substrate, and grow cobalt oxide for 100 cycles. The growth parameters are as follows:

[0041] Reaction chamber temperature: 250 o C;

[0042] Reaction source: cobaltocene (Co(Cp) 2 ) as the metal source, the source temperature is 85 o C, ozone as an oxygen source;

[0043] Pulse and cleaning time: metal source pulse is 5 s, high-purity nitrogen gas cleaning is 20 s; ozone pulse is 5 s; followed by high-purity nitrogen gas cleaning for 20 s to wash away reaction by-products and residual reaction sources.

[0044] (2) ALD deposition of metal platinum: continue ALD deposition of metal platinum on the substrate obtained in step (1) with cobalt oxide, and grow 100 cycles of metal platinum. The ALD growth parameters of platinum are as follows:

[0045] Reaction chamber temper...

Embodiment 3

[0052] A method for preparing Co-Pt nanoparticles with adjustable composition, comprising the following steps:

[0053] (1) ALD deposition of cobalt oxide film: use the cleaned AAO template as the substrate, and grow cobalt oxide for 50 cycles. The growth parameters are as follows:

[0054] Reaction chamber temperature: 400 o C;

[0055] Reaction source: cobaltocene (Co(Cp) 2 ) as the metal source, the source temperature is 85 o C, ozone as an oxygen source;

[0056] Pulse and cleaning time: metal source pulse is 3 s, high-purity nitrogen cleaning is 15 s; ozone pulse is 3 s; followed by high-purity nitrogen cleaning for 15 s, flushing away reaction by-products and residual reaction sources.

[0057] (2) ALD deposition of metal platinum: continue ALD deposition of metal platinum on the substrate obtained in step (1) with cobalt oxide, and grow 50 cycles of metal platinum. The ALD growth parameters of platinum are as follows:

[0058] Reaction chamber temperature: 400 o C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com