Mg based metallic glass film, its preparation method and application

A magnesium-based metallic glass, magnesium-based metal technology, applied in metal material coating process, vacuum evaporation coating, coating and other directions, can solve problems such as difficult adjustment, achieve easy plastic forming, low preparation cost, annealing temperature range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

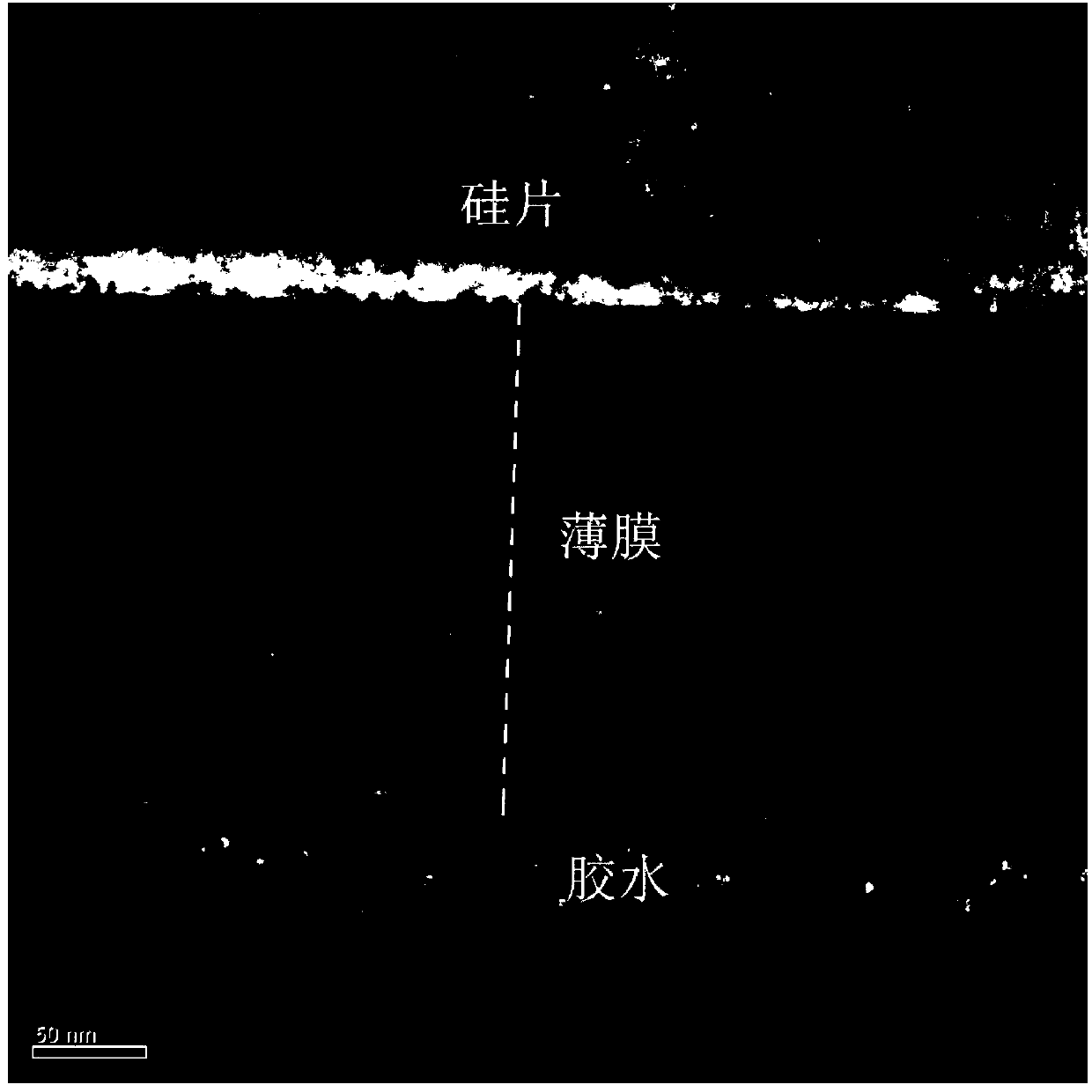

[0045] The general chemical formula of the magnesium-based metallic glass film of the present embodiment is Mg 58.01 Cu 28.81 Y 13.18 , the thickness of the film is 221nm, and the film substrate is a single crystal silicon wafer or an ordinary glass wafer.

[0046] The magnesium-based metallic glass film described in this embodiment is prepared by the following steps:

[0047] 1) The alloy target is prepared by using Mg, Cu and Y with a purity of 99.98% as the raw material according to the atomic ratio of 65:25:10. The preparation method of the alloy target is melting and smelting. The target is placed in the target position of the sputtering table as a target for sputtering. The ratio of Mg, Cu, and Y is not limited to 65:25:10, and other ratios may also be adopted.

[0048] 2) Put monocrystalline silicon wafers and ordinary glass wafers into ethanol for ultrasonic cleaning for a certain period of time (for example, 10 minutes), then put them in acetone for ultrasonic cle...

Embodiment 2

[0059] The average chemical composition of the magnesium-based nanocrystalline film of the present embodiment is Mg 58.01 Cu 28.81 Y 13.18 , the thickness of the film is 221nm, and the film substrate is a single crystal silicon wafer or an ordinary glass wafer.

[0060] The magnesium-based nanocrystalline film in the present embodiment is prepared by the following steps: the Mg in the embodiment 1 58.01 Cu 28.81 Y 13.18 The amorphous film was annealed in high vacuum with a vacuum degree of 1.1×10 -4 Pa, the annealing temperature is 623K, and the annealing time is 30min.

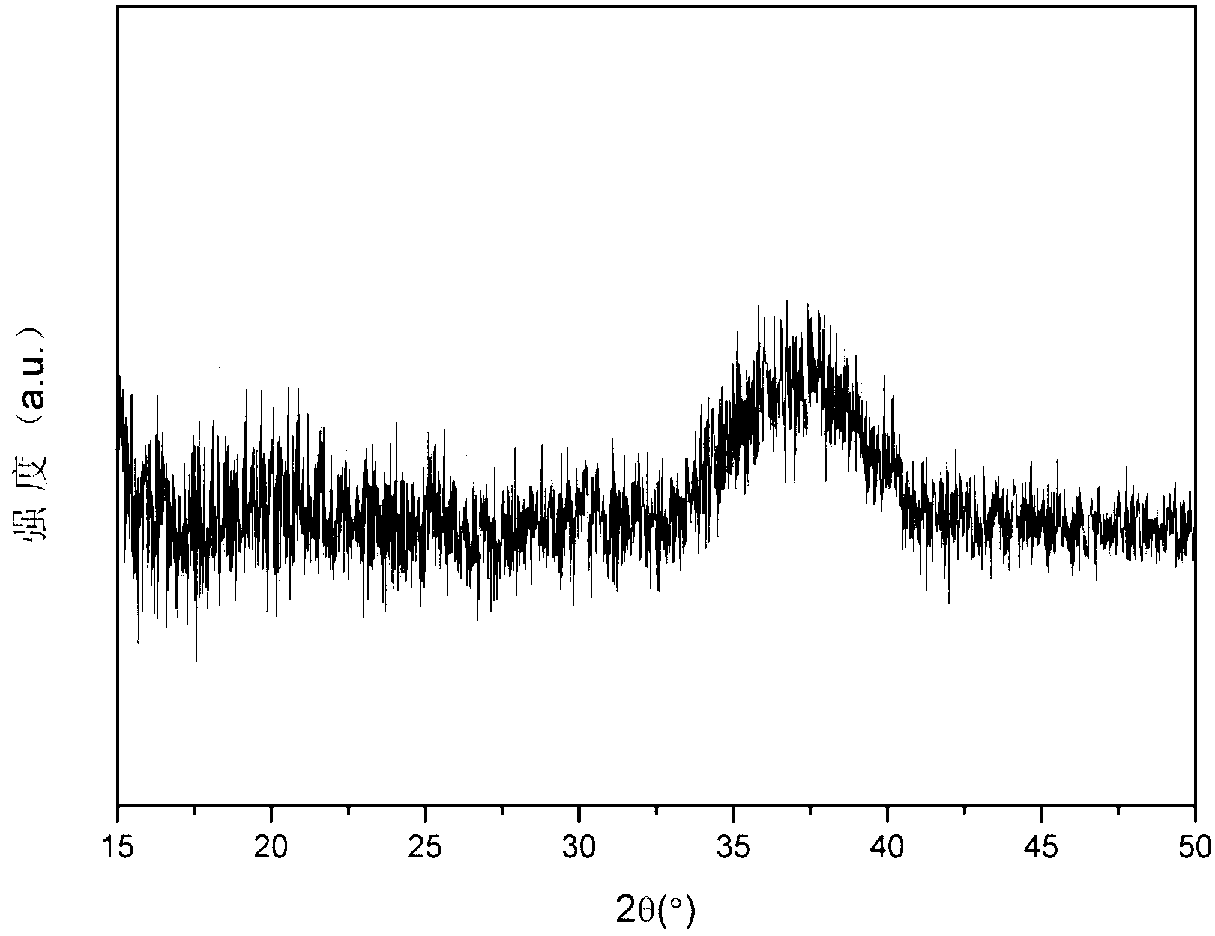

[0061] The above-mentioned magnesium-based nanocrystalline film was tested using the same method and equipment as in Example 1.

[0062] The test results are as follows:

[0063] (1) Figure 7 It is a scanning electron microscope on the surface of the sample, and the figure shows that uniformly distributed nanocrystal grains appear on the surface of the sample, and the roughness increases.

[0064] (...

Embodiment 3~6

[0069] The preparation method of the magnesium-based metallic glass films in Examples 3 to 6 is basically the same as in Example 1, except that the sputtering parameters are changed, and the sputtering parameters and the general chemical formula of the prepared films are shown in Table 1. :

[0070] Table 1: Composition and sputtering parameters of magnesium-based metallic glass films in Examples 3-6

[0071] Example

Sputtering power

target base distance

Sputtering argon pressure

3

Mg 46.30 Cu 28.96 Y 24.74

60W

120mm

0.3Pa

4

Mg 54.96 Cu 24.61 Y 20.43

60W

120mm

0.4Pa

5

Mg 51.73 Cu 25.87 Y 22.46

60W

120mm

0.6Pa

6

Mg 48.36 Cu 28.52 Y 23.06

60W

120mm

0.7Pa

[0072] Using the same annealing process as in Example 2, Examples 1 and 3-6 were respectively annealed to crystallize.

[0073] Embodiment 1 and 3~6 and corr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com