Patents

Literature

147results about How to "Avoid over-regulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

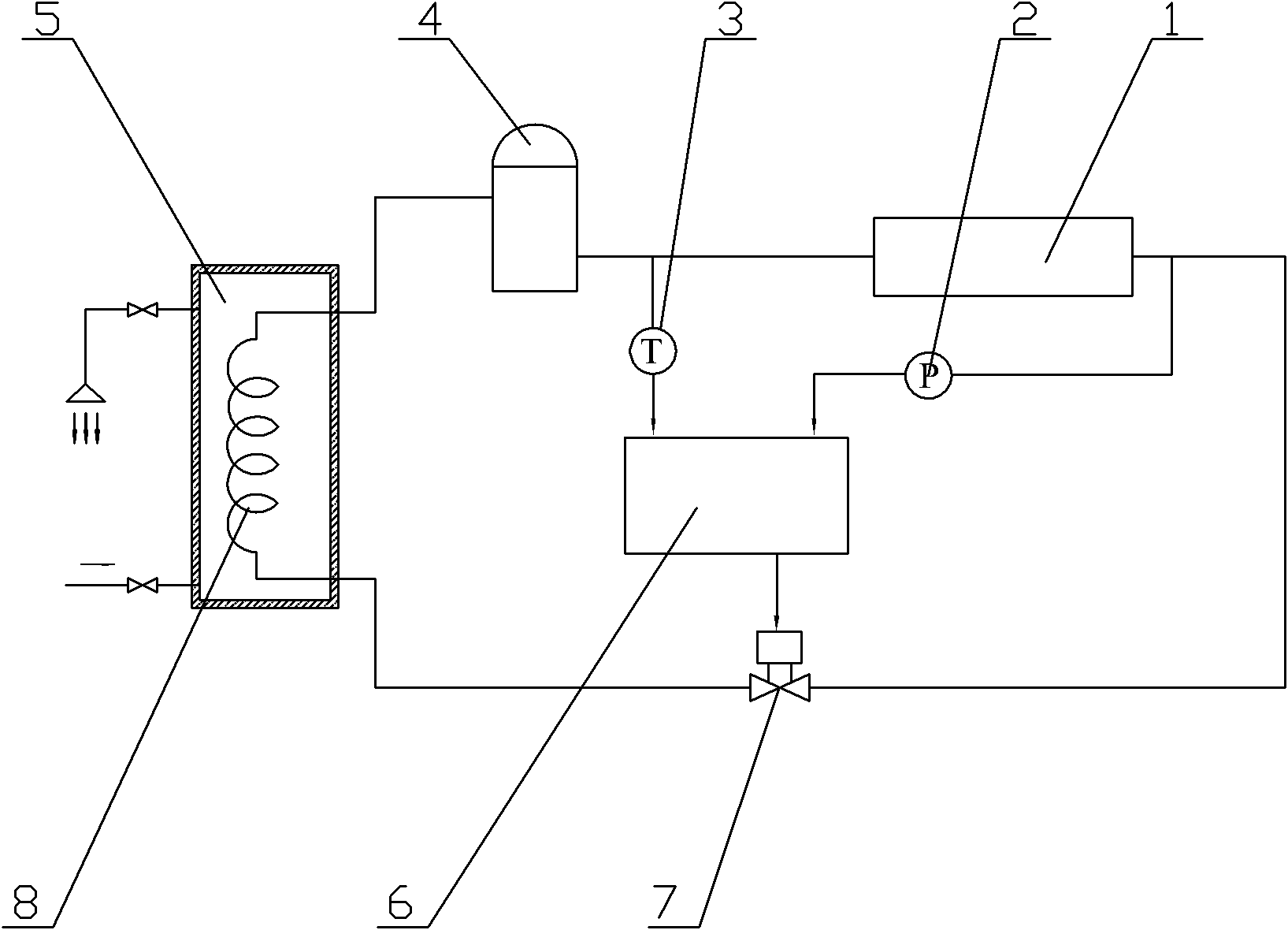

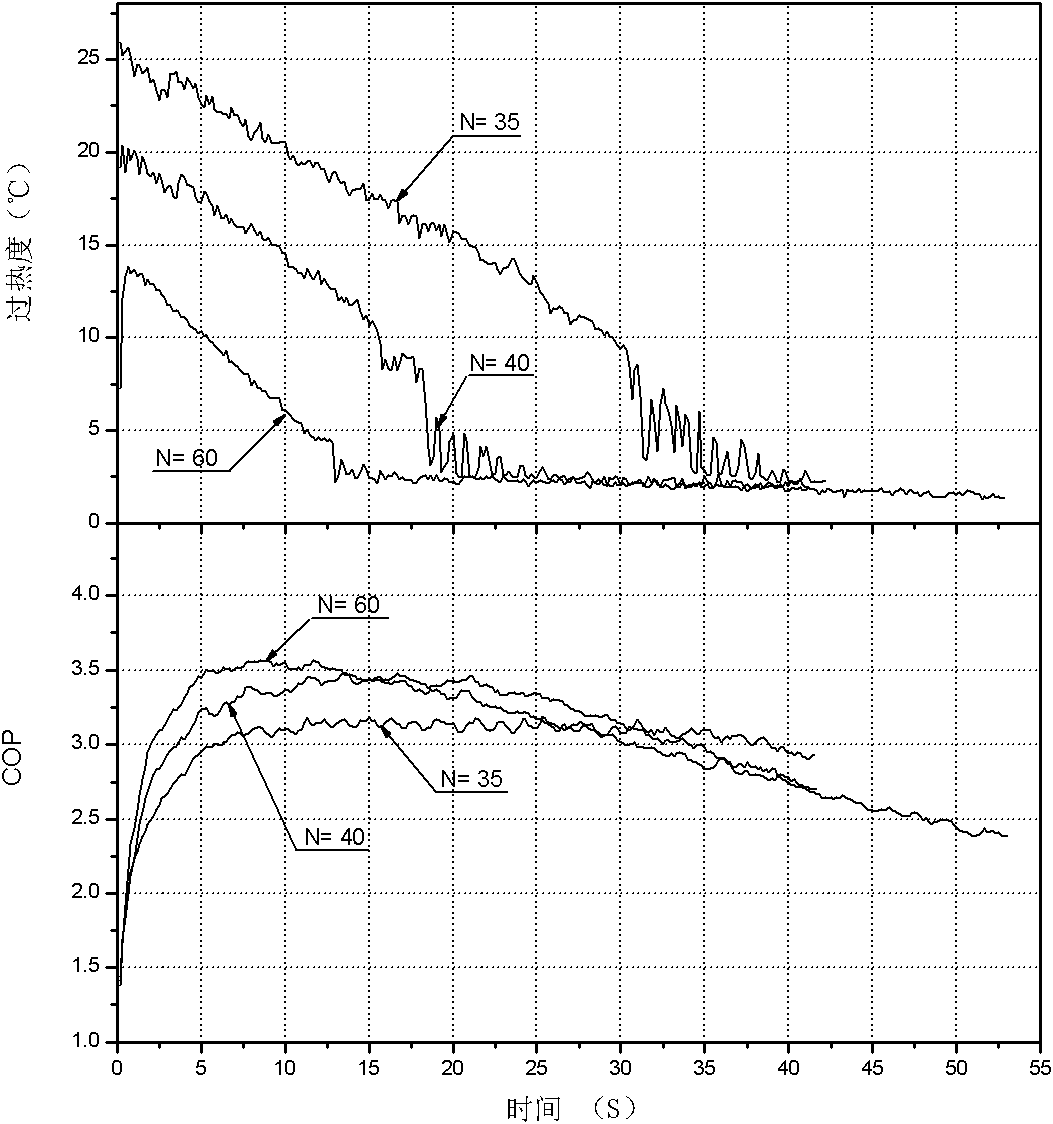

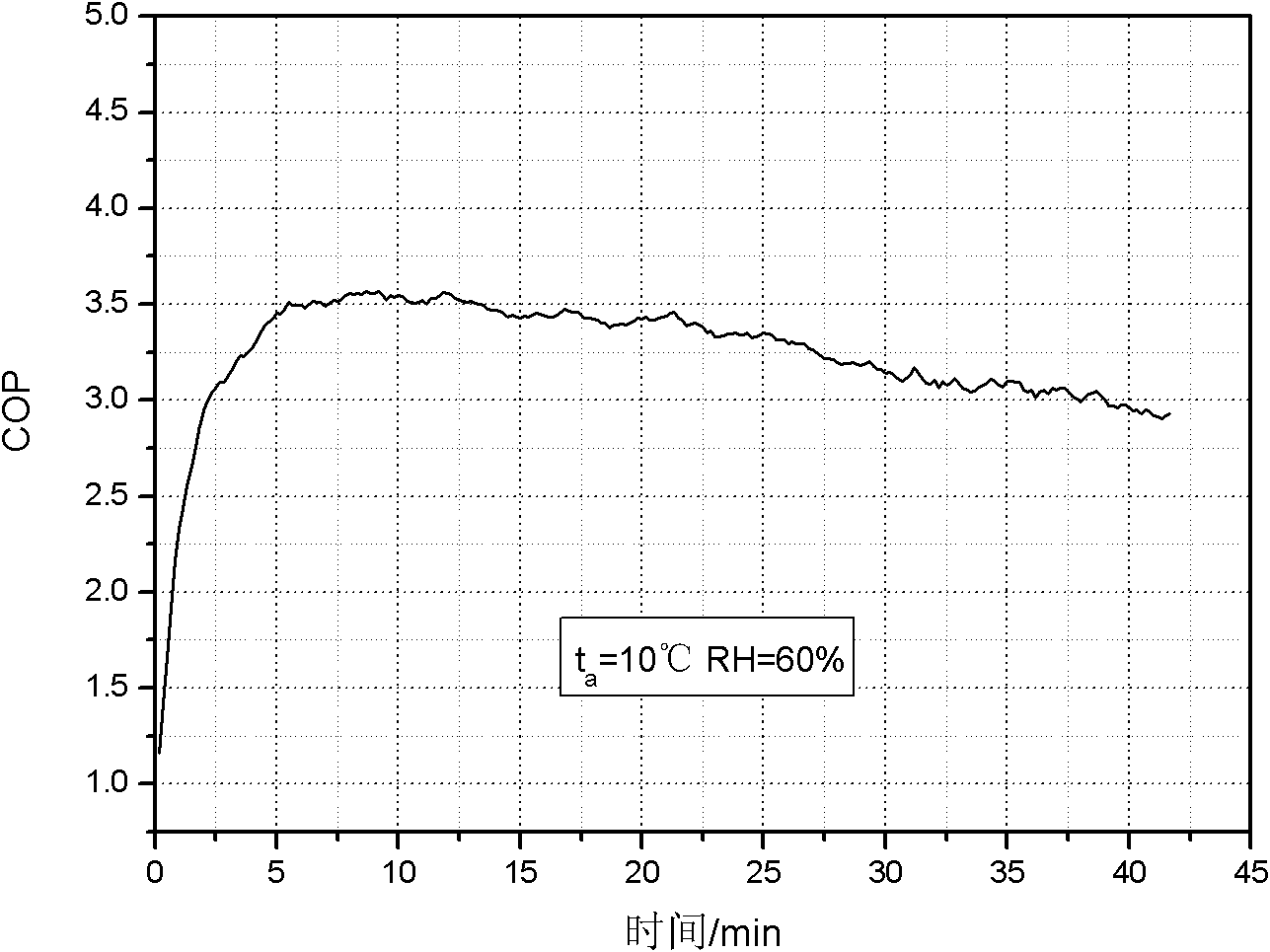

Method for controlling opening of electronic expansion valve in heat pump water heater system

InactiveCN102384618AReduce openingPrecise control of refrigerant flowRefrigeration safety arrangementElectronic expansion valveIndustrial engineering

The invention discloses a method for controlling the opening of an electronic expansion valve in a heat pump water heater system, and aims to provide a control method for allowing a system to avoid an area in which the air suction degree of superheat drops suddenly in the running process and allowing the coefficient of performance (COP) of the system to keep a high level. The method comprises thefollowing steps of: setting the optimum value of the change rate delta T / delta t of the air suction degree of superheat, and setting the initial opening of the expansion valve as 80 percent of total opening; taking a temperature difference between an average temperature value at an air suction port of a compressor and the saturated evaporating temperature as the air suction degree of superheat when the compressor runs to the state of the stable running of the system; measuring and calculating the air suction degree of superheat at the interval time delta t; calculating the change rate of the actual air suction degree of superheat according to the adjacent two-time air suction degree of superheat, comparing with the set optimum value of the change rate of the air suction degree of superheat, and when the change rate of the actual air suction degree of superheat is less than or equal to A, reducing the opening of the expansion valve; when the change rate of the actual air suction degreeof superheat is more than 0, increasing the opening of the expansion valve; and when the change rate of the actual air suction degree of superheat is more than A and is less than or equal to 0, maintaining the current running state.

Owner:TIANJIN UNIV OF COMMERCE

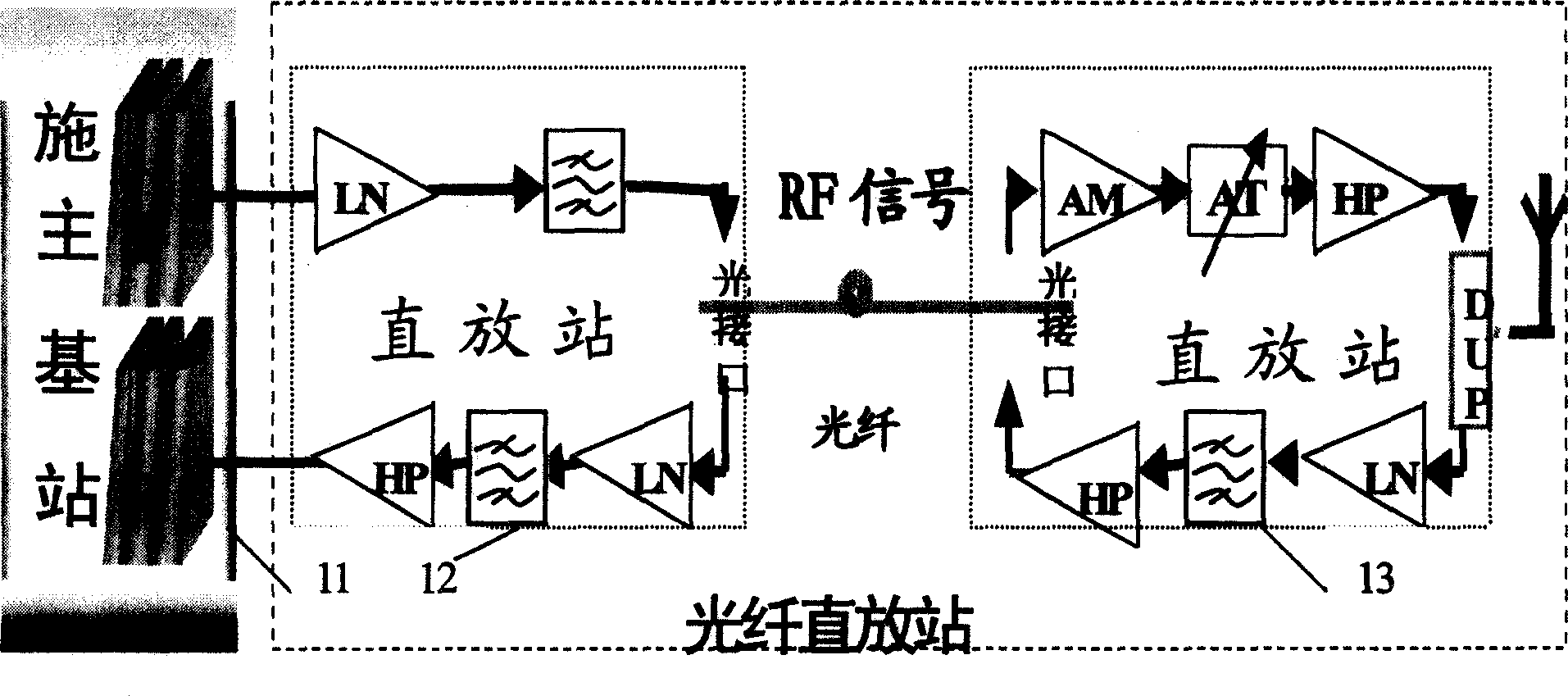

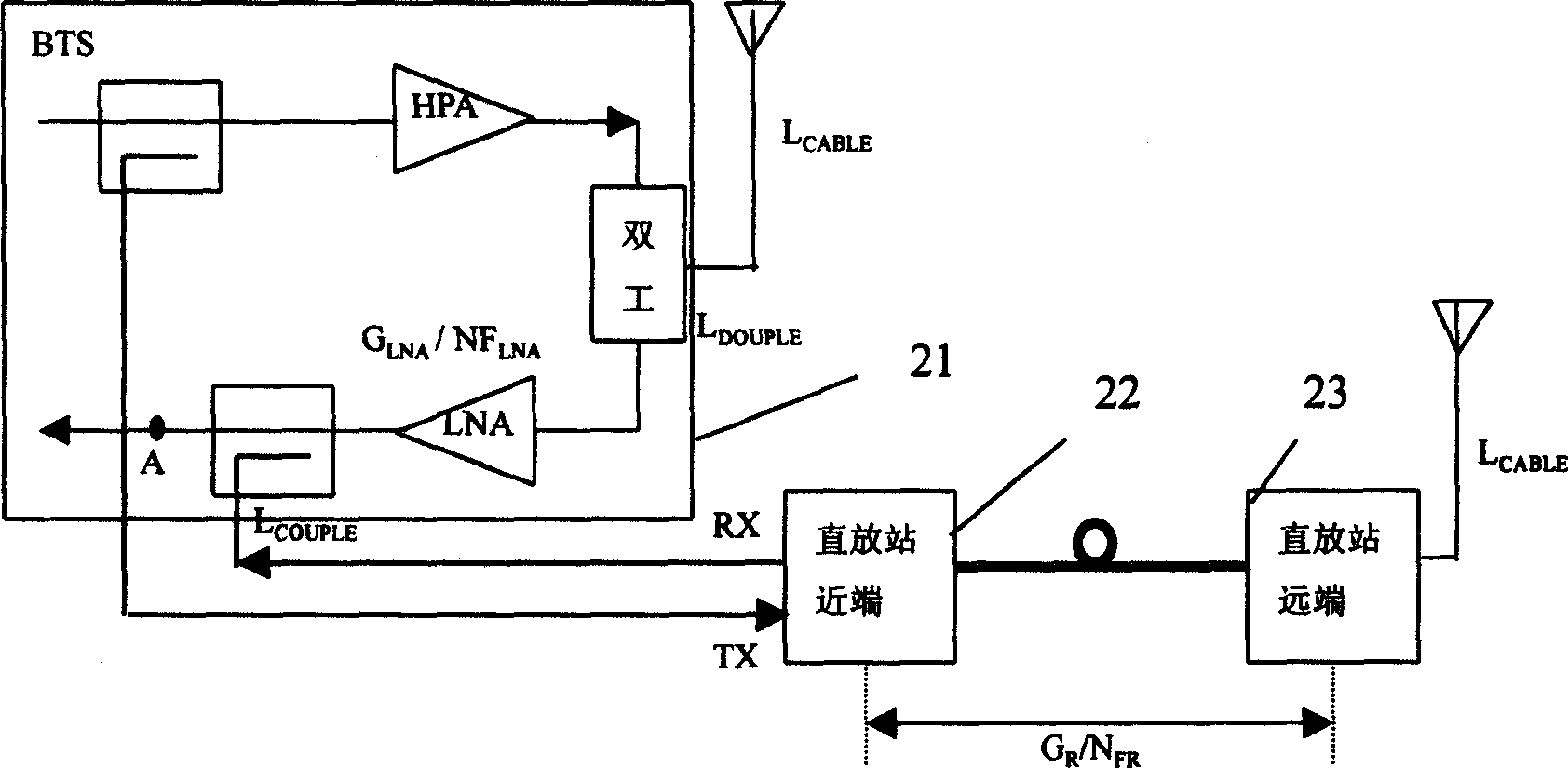

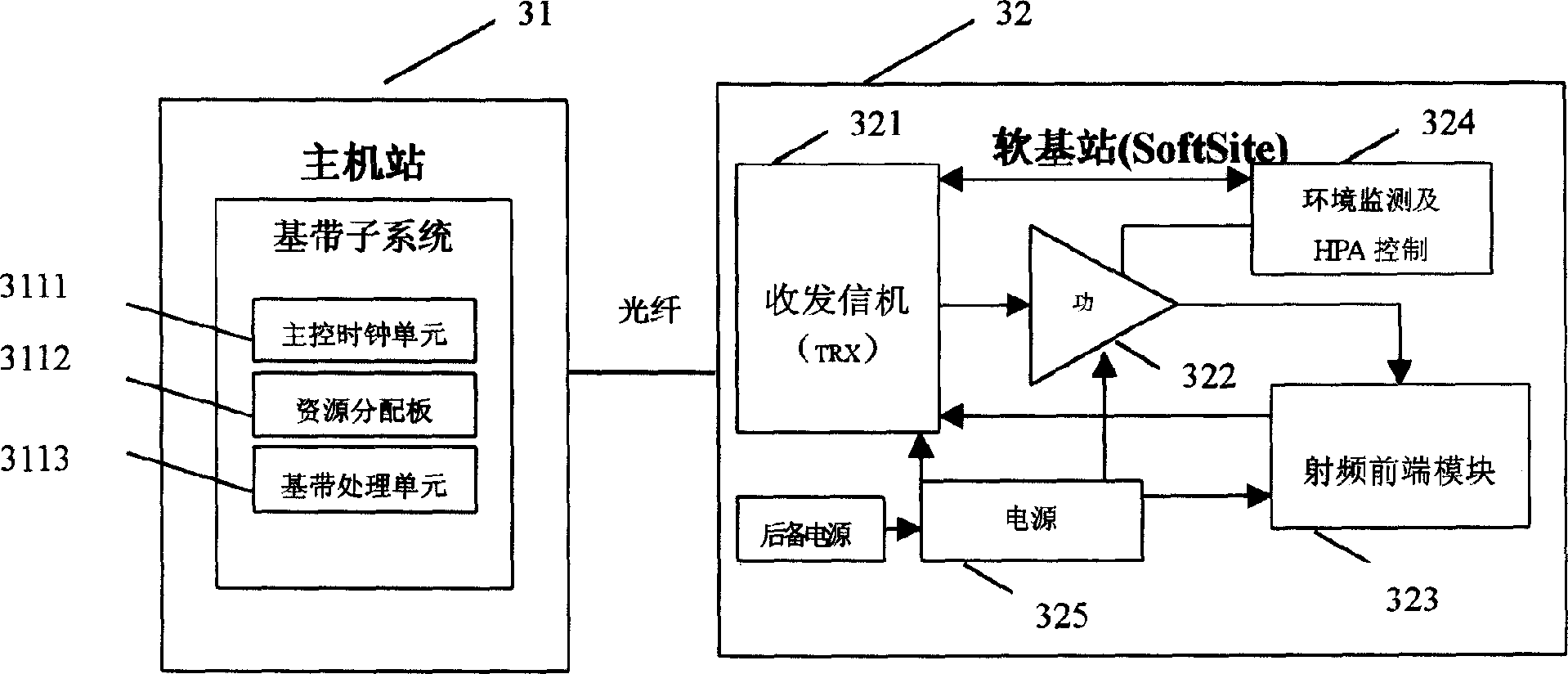

Soft base station system based on fiber optic stretch and synchronous method thereof

InactiveCN1464666AAvoid over-regulationFew linksCode division multiplexRadio/inductive link selection arrangementsFiber optic transmissionSystem capacity

The invention discloses a soft base station system and process of synchronizing based on optical fiber zooming out. Presently, direct sending stations are used to expand the signal coverage in the mobile communication network, but noise level and low sensitivity are also brought in. The soft base station system based on optical fiber will transform the radio frequency signal directly coupled from the large capacity base station into optical signal through analog optical modulation, which will be transmitted to the soft base station via. the optical fiber, the soft base station will transform the optical signal into the electrical signal, which will radiate to the needed coverage via the service antenna. Apart from all the advantages resulted from using digital transmission and receiving machine, the soft base station has bee proved to increase system capacity, improve the network quality and reduce the occurrence of disconnection.

Owner:HUAWEI TECH CO LTD

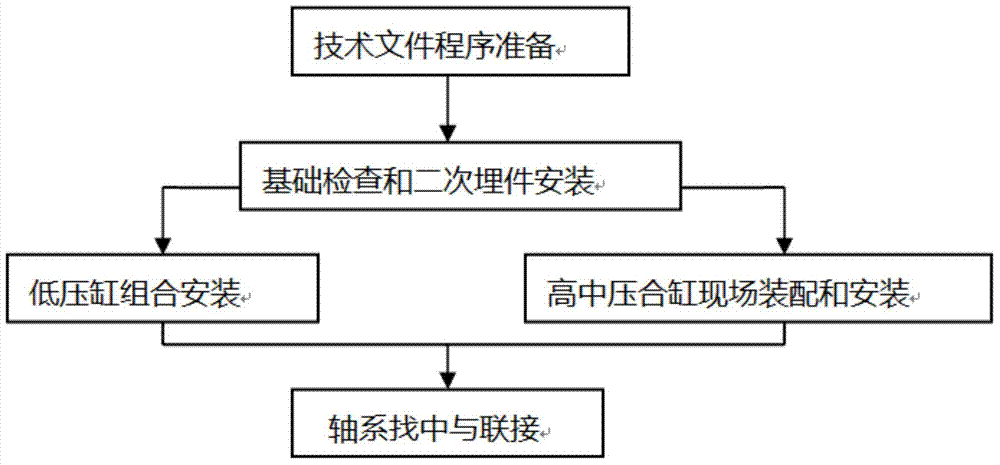

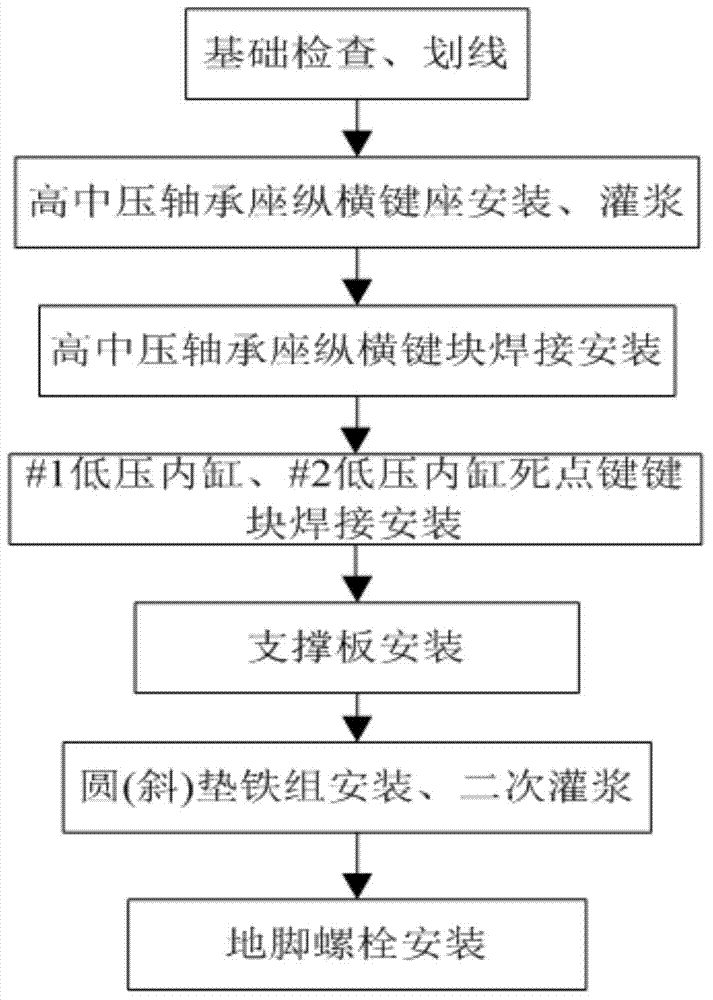

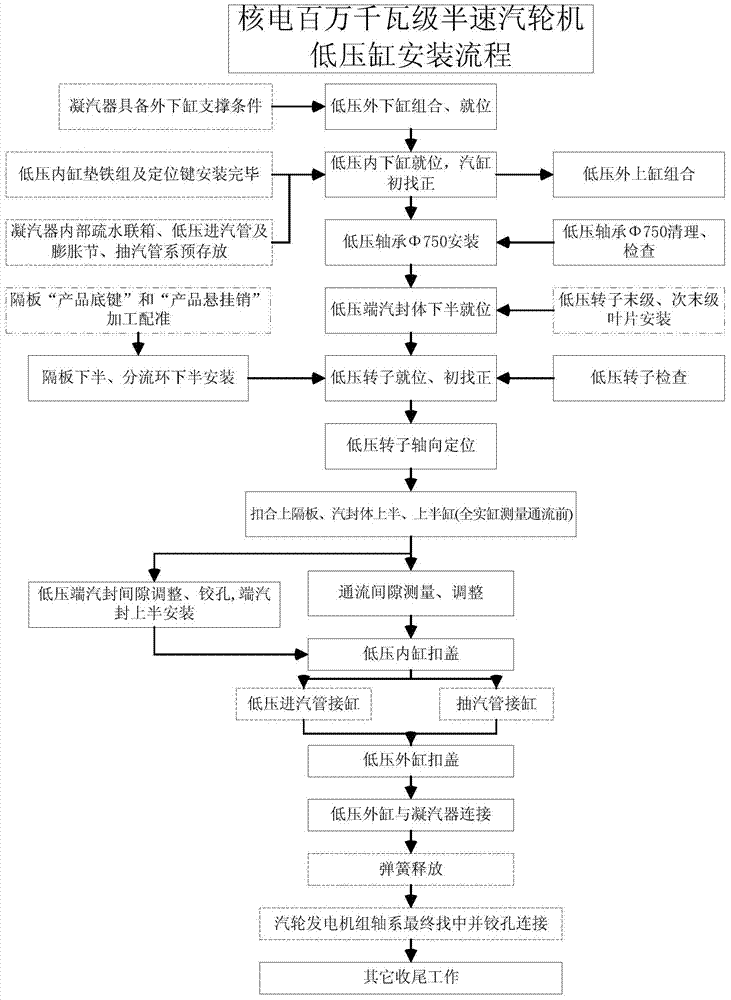

Method for installing nuclear power half-speed steam turbine

ActiveCN103939156AHigh precisionGuaranteed accuracyMachines/enginesEngine componentsNuclear powerThrust bearing

The invention discloses a method for installing a nuclear power half-speed steam turbine. The method comprises the steps of I, foundation inspection and secondary embedded installation; II, assembly and installation of a low-pressure cylinder; III, assembly and installation of a high and middle-pressure cylinder; IV, axis alignment and connection installation. The assembly and installation of a high and middle-pressure cylinder comprise the steps of (1), overhaul and installation of a thrust bearing; (2) measurement and regulation of a middle gland casing; (3) load distribution of the high and middle-pressure cylinder. The method has the advantages that load measurement is performed on a claw of the high and middle-pressure cylinder through a hydraulic jacking method, the method is simple in operation and high in measurement accuracy, jacking oil is injected during axis alignment, and accuracy of axis alignment is ensured.

Owner:SEPCOIII ELECTRIC POWER CONSTR CO LTD

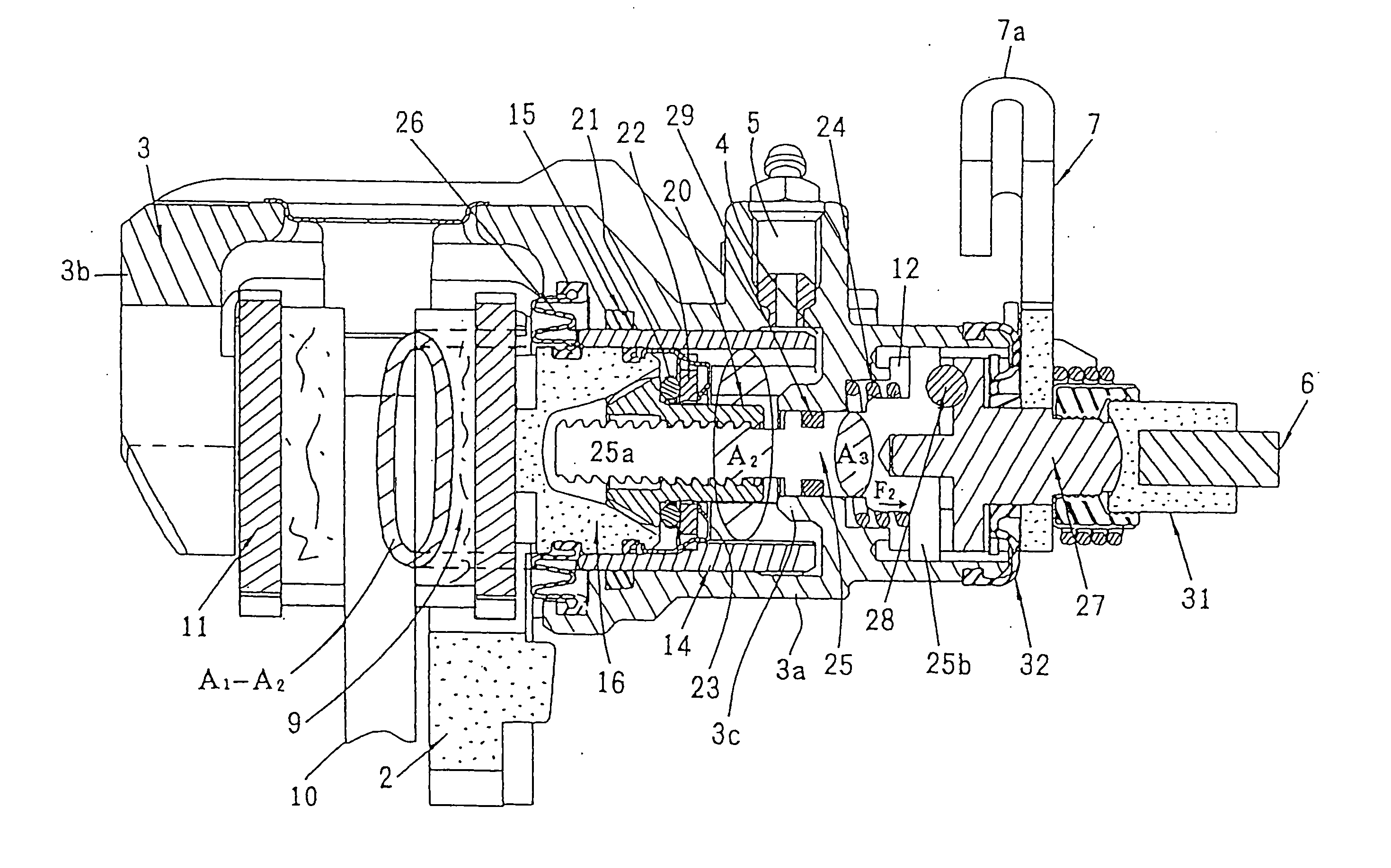

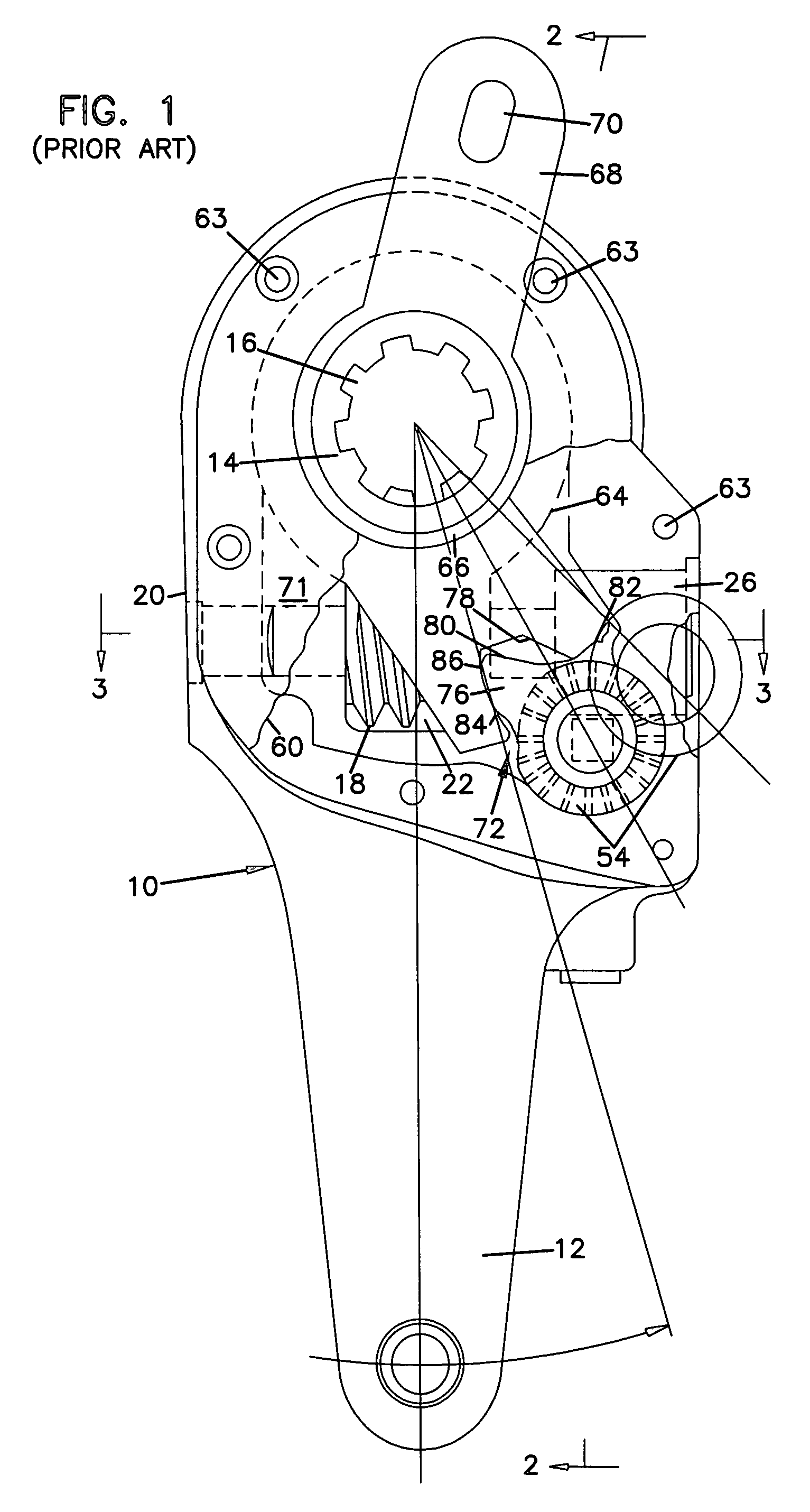

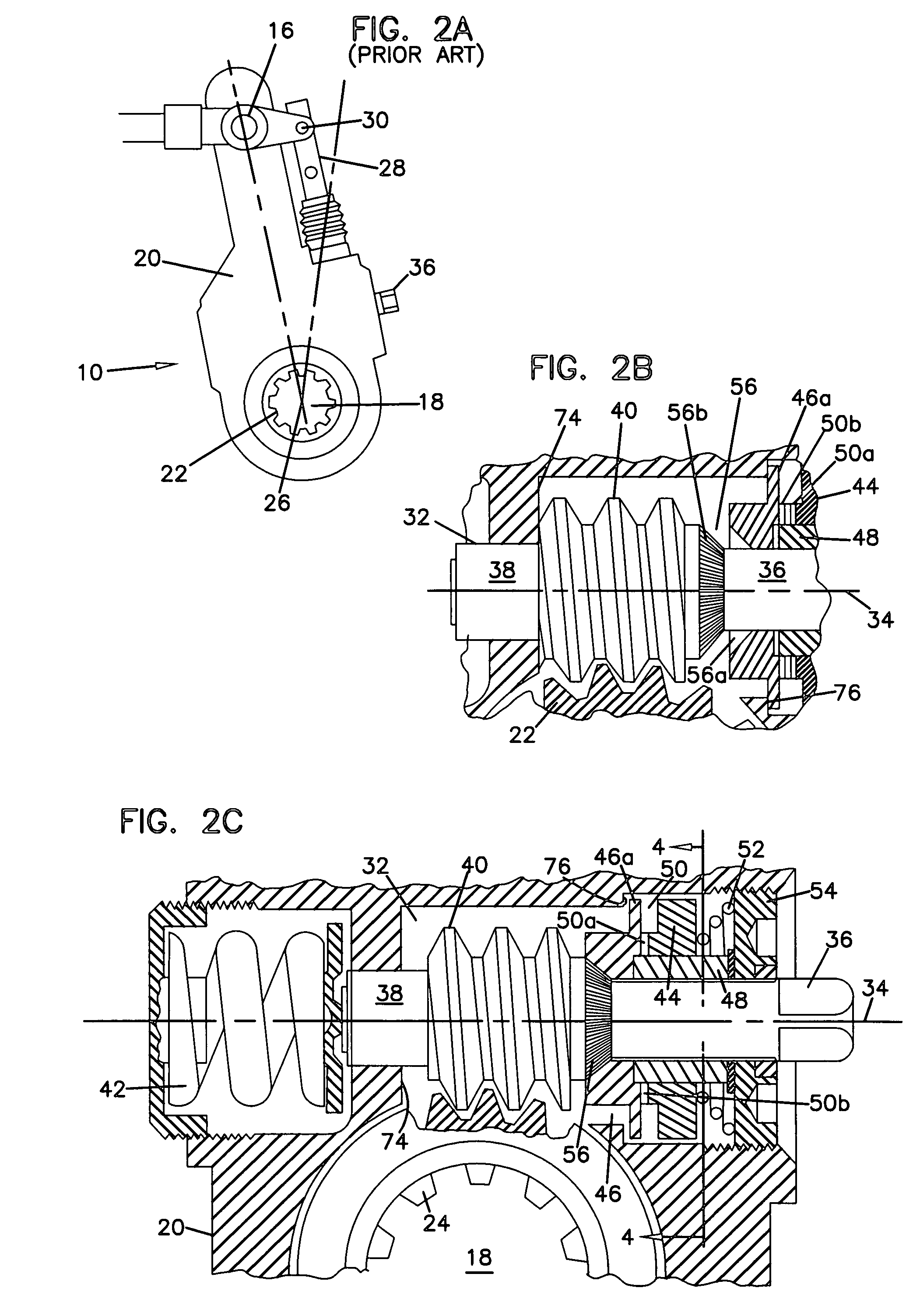

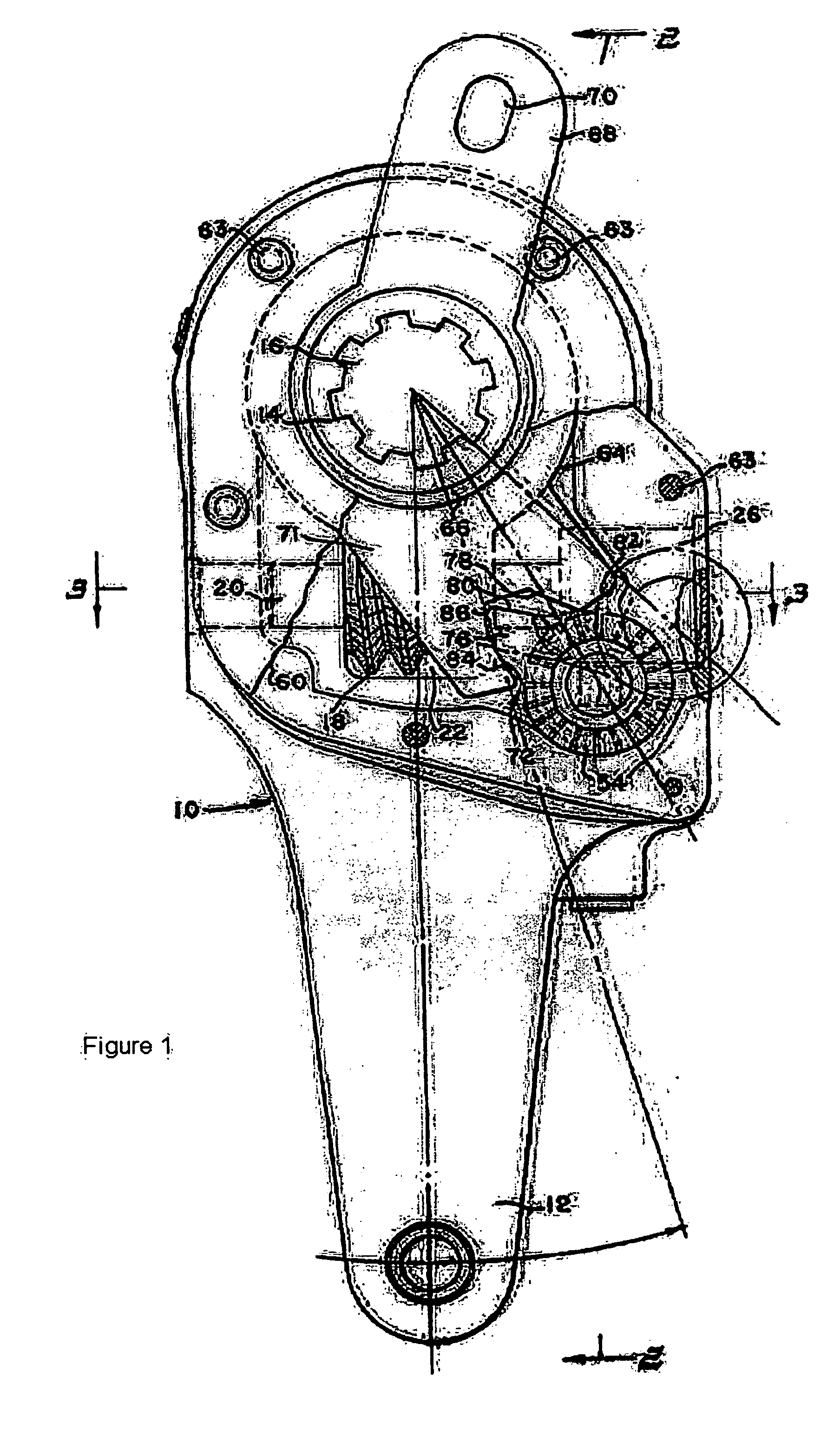

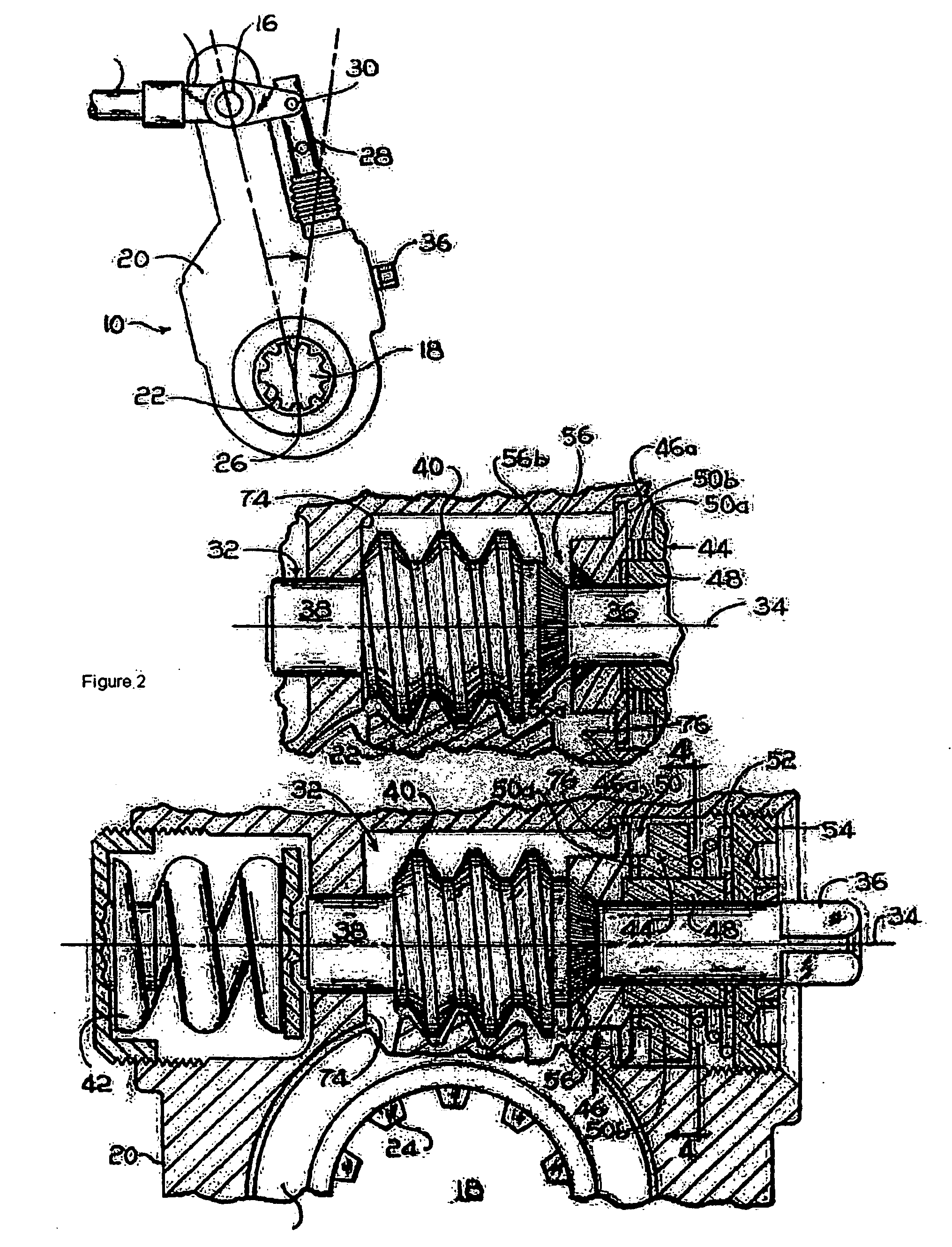

Brake apparatus having automatic clearance adjusting mechanism with overadjustment preventer

InactiveUS20050034935A1Reduce the number of partsSimple structureAxially engaging brakesBrake actuating mechanismsEngineeringMechanical engineering

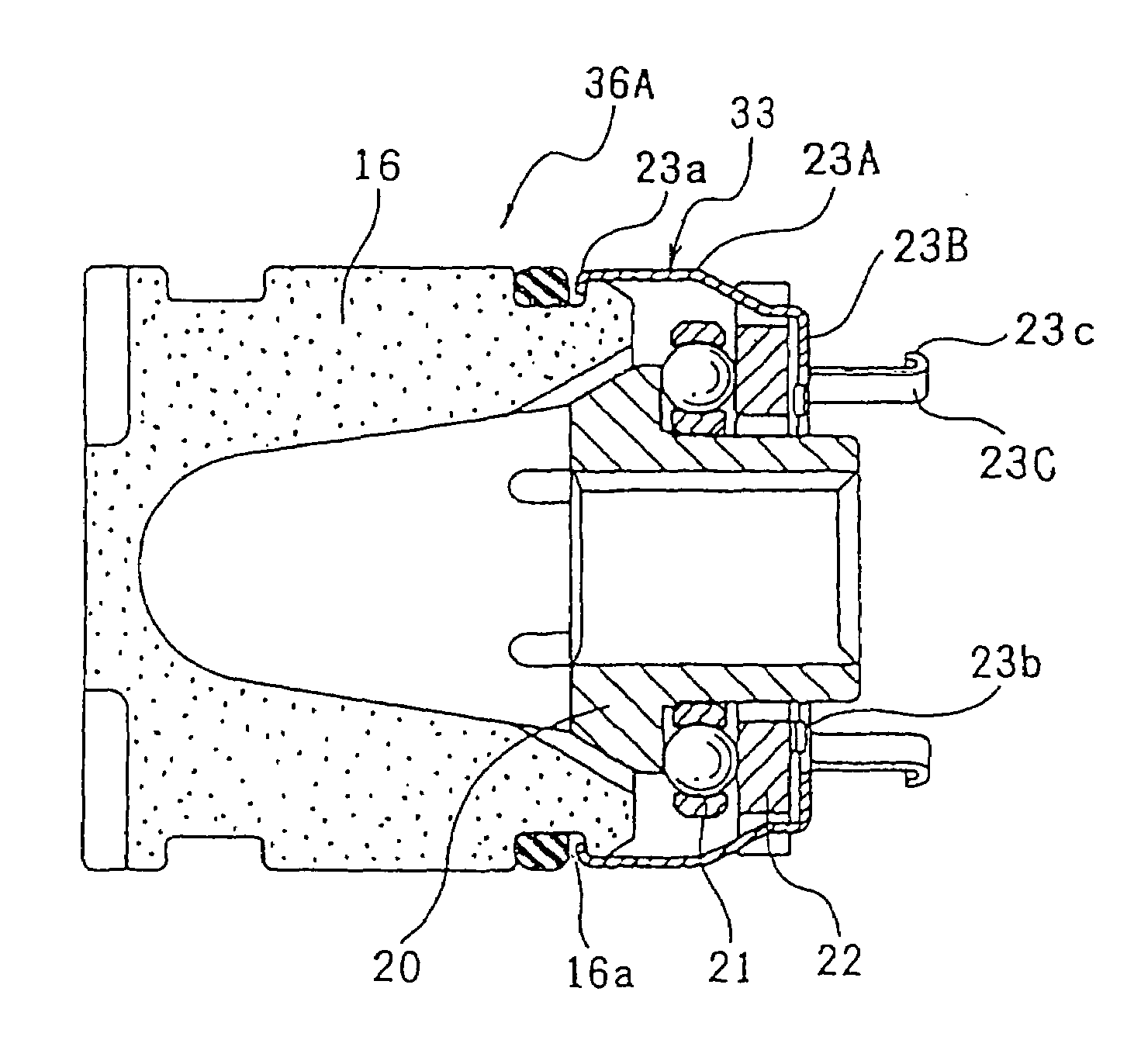

A brake apparatus having an automatic clearance adjusting mechanism with an overadjustment preventer constituted such that a piston is constituted by a structure of being divided in a plug piston 16 and a ring piston 14. The plug piston 16 is integrated with an adjusting nut 20, a bearing 21, a bearing support plate 22 and a spring holder 23. An outer side claw portion 23a of the holder is locked by an outer side groove 16 of the plug piston. The plug piston 16 integrated with the respective parts is inserted to fit to the ring piston 14 to thereby prevent the outer side claw portion 23a of the holder from being detached.

Owner:AKEBONO BRAKE IND CO LTD

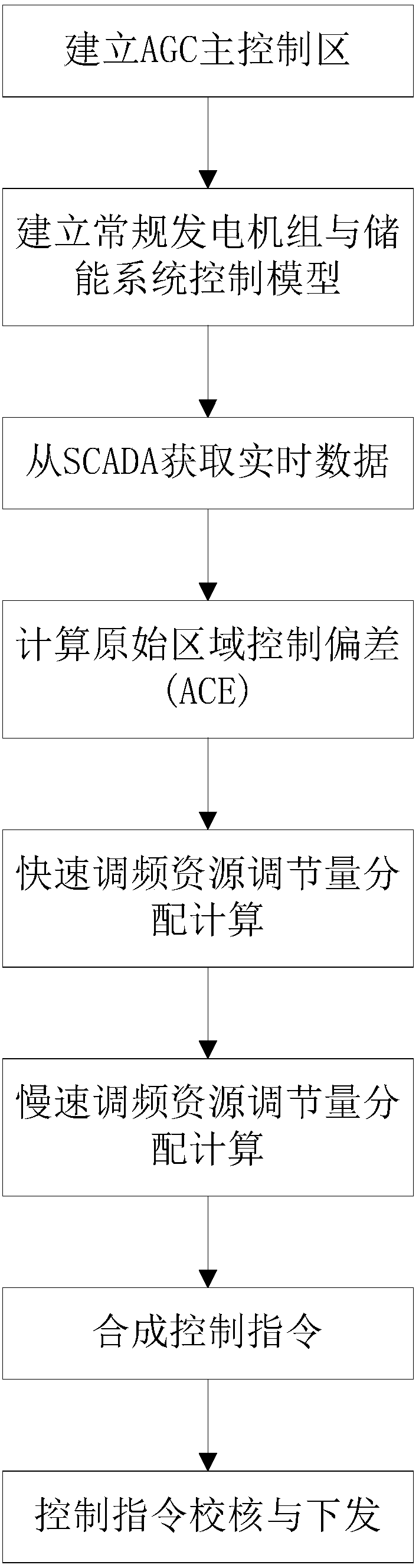

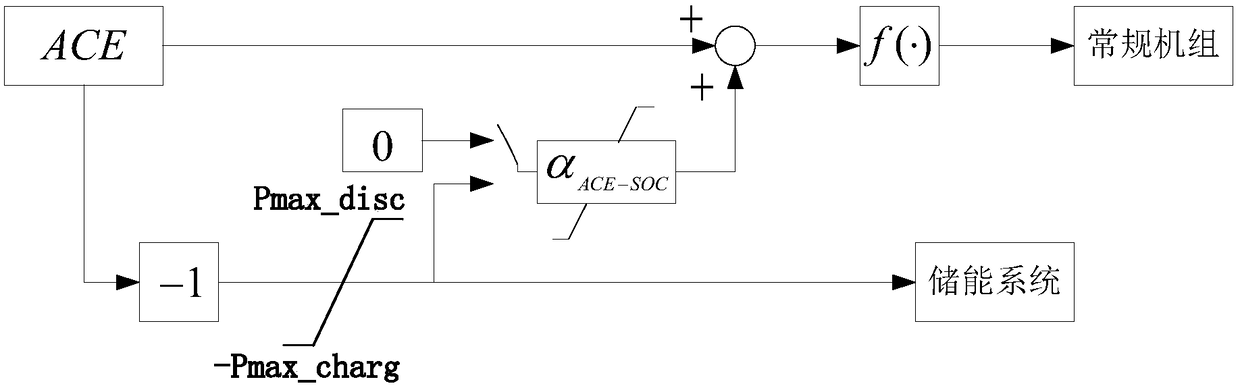

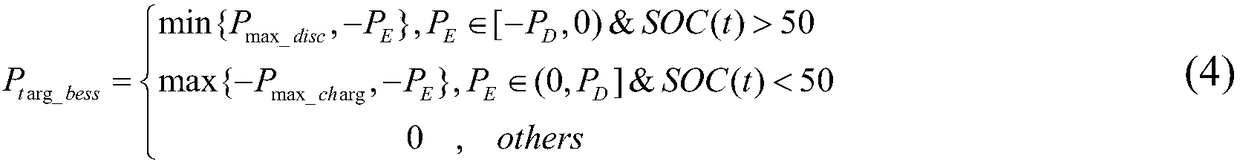

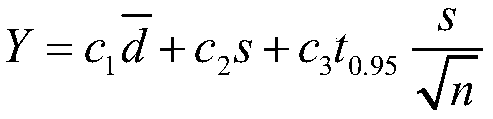

High-speed and low-speed frequency modulation resource coordination control method considering energy storage system SOC

ActiveCN108390405AReasonable operating rangeAvoid over-regulationElectric power transfer ac networkAc network load balancingLow speedResource coordination

The invention discloses a high-speed and low-speed frequency modulation resource coordination control method considering energy storage system SOC. The control method comprises the steps of establishing a main control region in an AGC system; establishing a generator set and an energy storage system control model in the main control region, and dividing a high-speed frequency modulation group anda low-speed frequency modulation group; obtaining real-time measurement data from an SCADA system; calculating control deviation of an original region; calculating a high-speed frequency modulation resource energy storage system control instruction according to the original ACE and by considering the energy storage system SOC and the maximum allowable charging / discharging power; performing correction and filtering processing on an ACE control signal in the low-speed frequency modulation group, and calculating the regulation requirement of the low-speed frequency modulation group; generating control instructions of respective control objects; and performing verification and correction on the control instructions of respective control objects and issuing to a station terminal. By increasingchances and depth of the energy storage system in power grid frequency modulation participation, the regulation actions of the conventional low-speed generator set can be reduced, the mechanical lossof the conventional generator set is lowered, and power generation economic efficiency is improved.

Owner:NARI TECH CO LTD +5

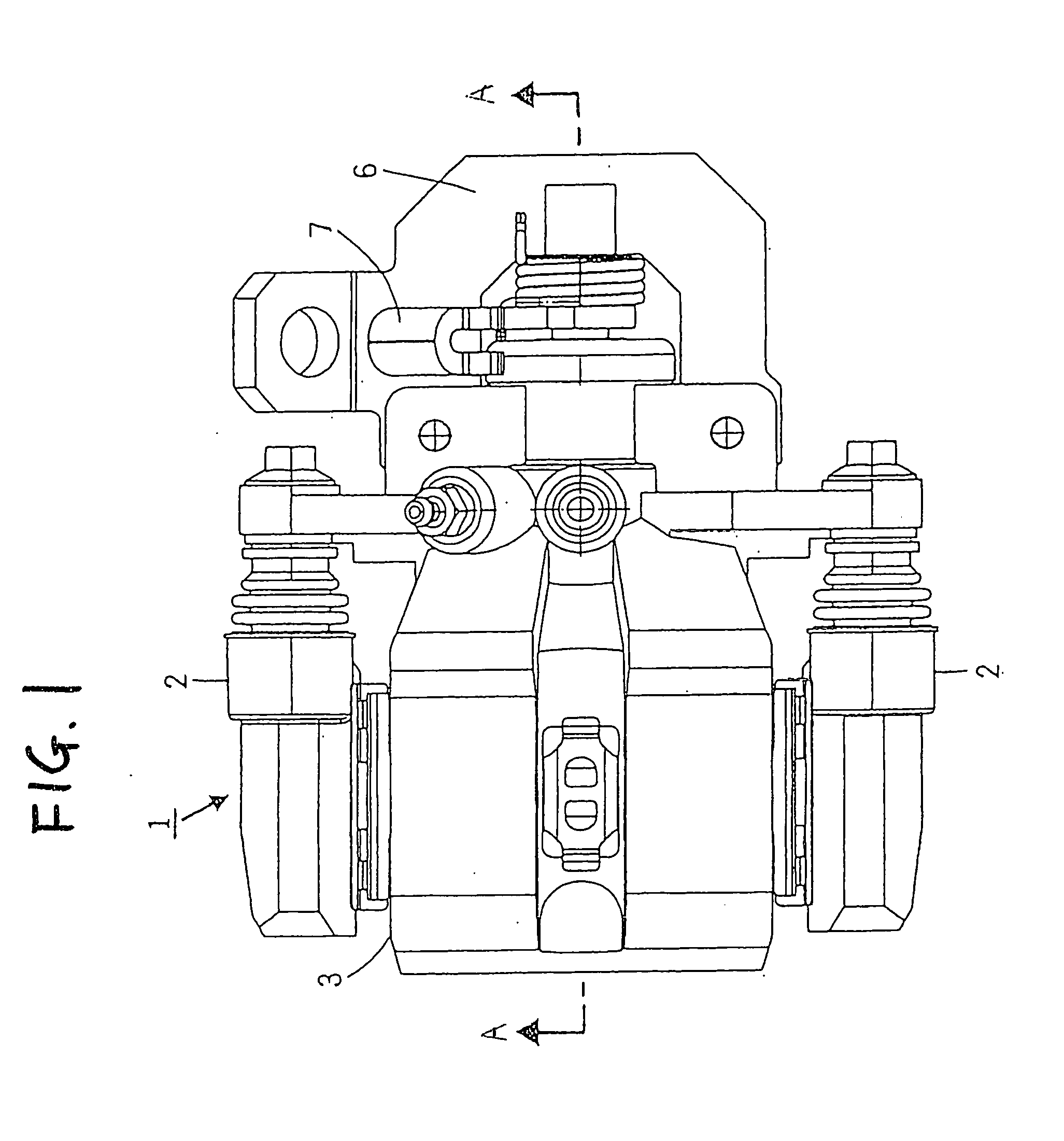

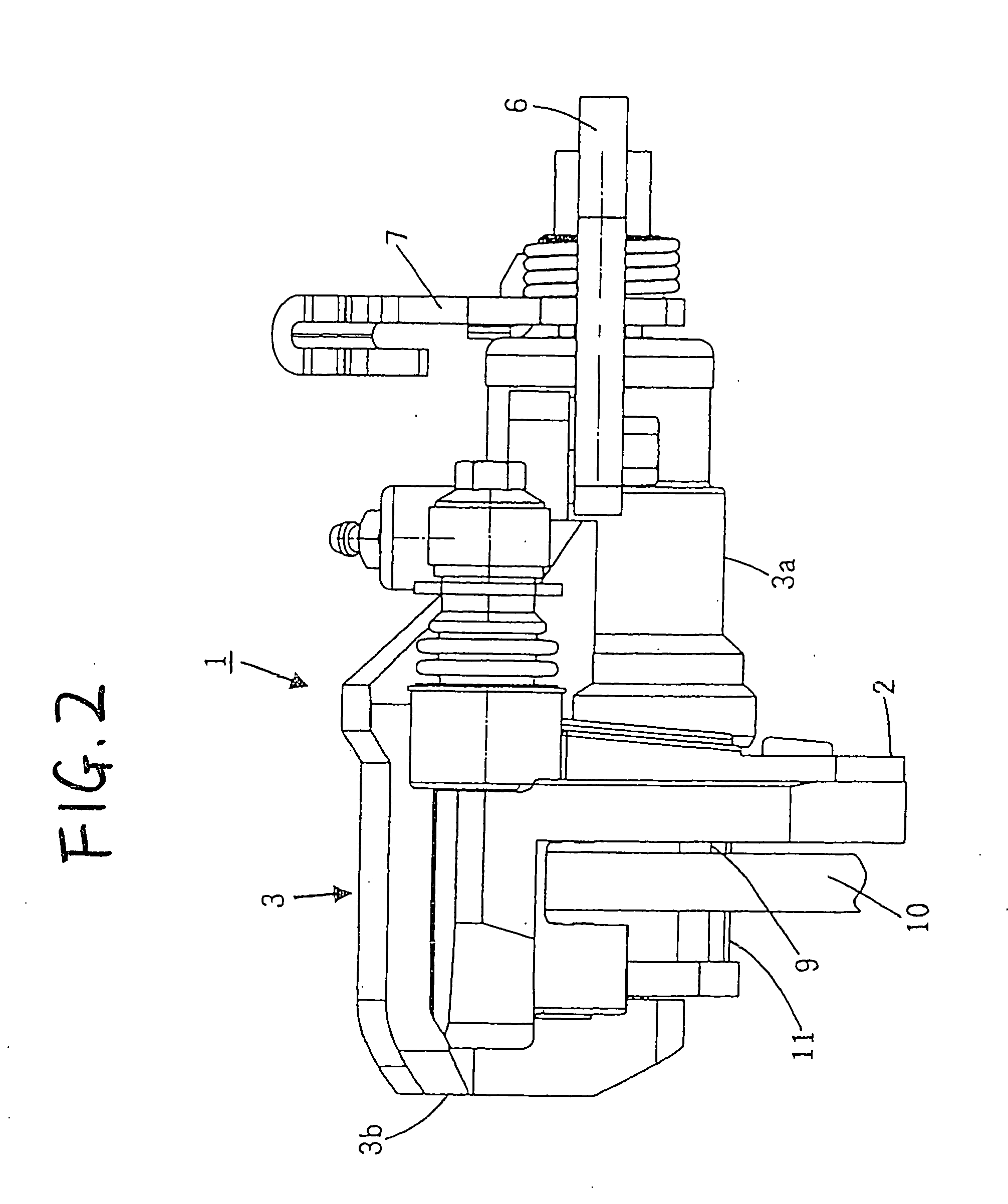

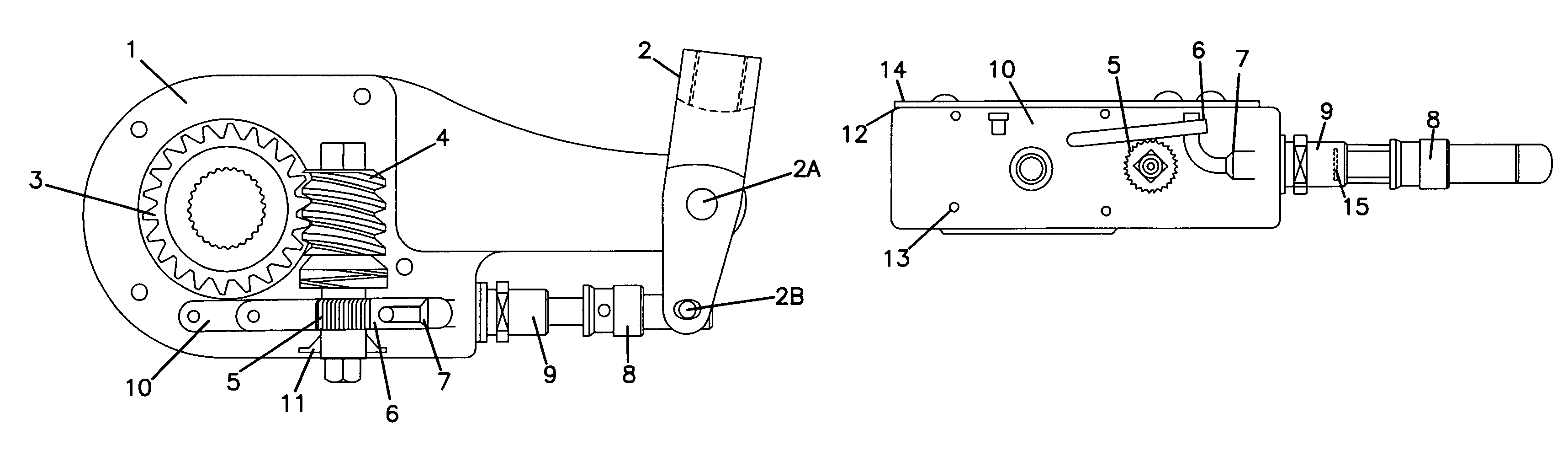

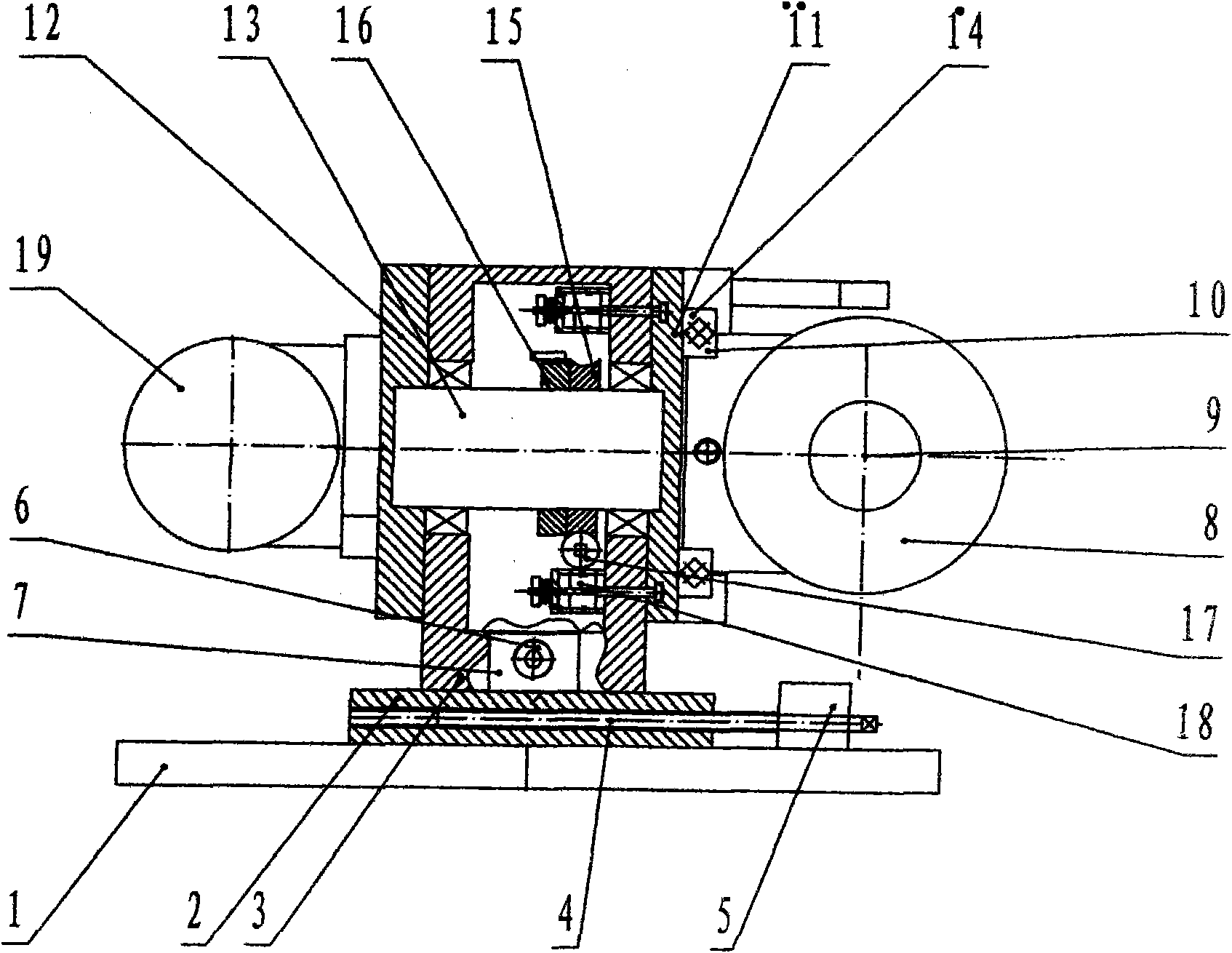

Automatic slack adjuster assembly for vehicle braking system

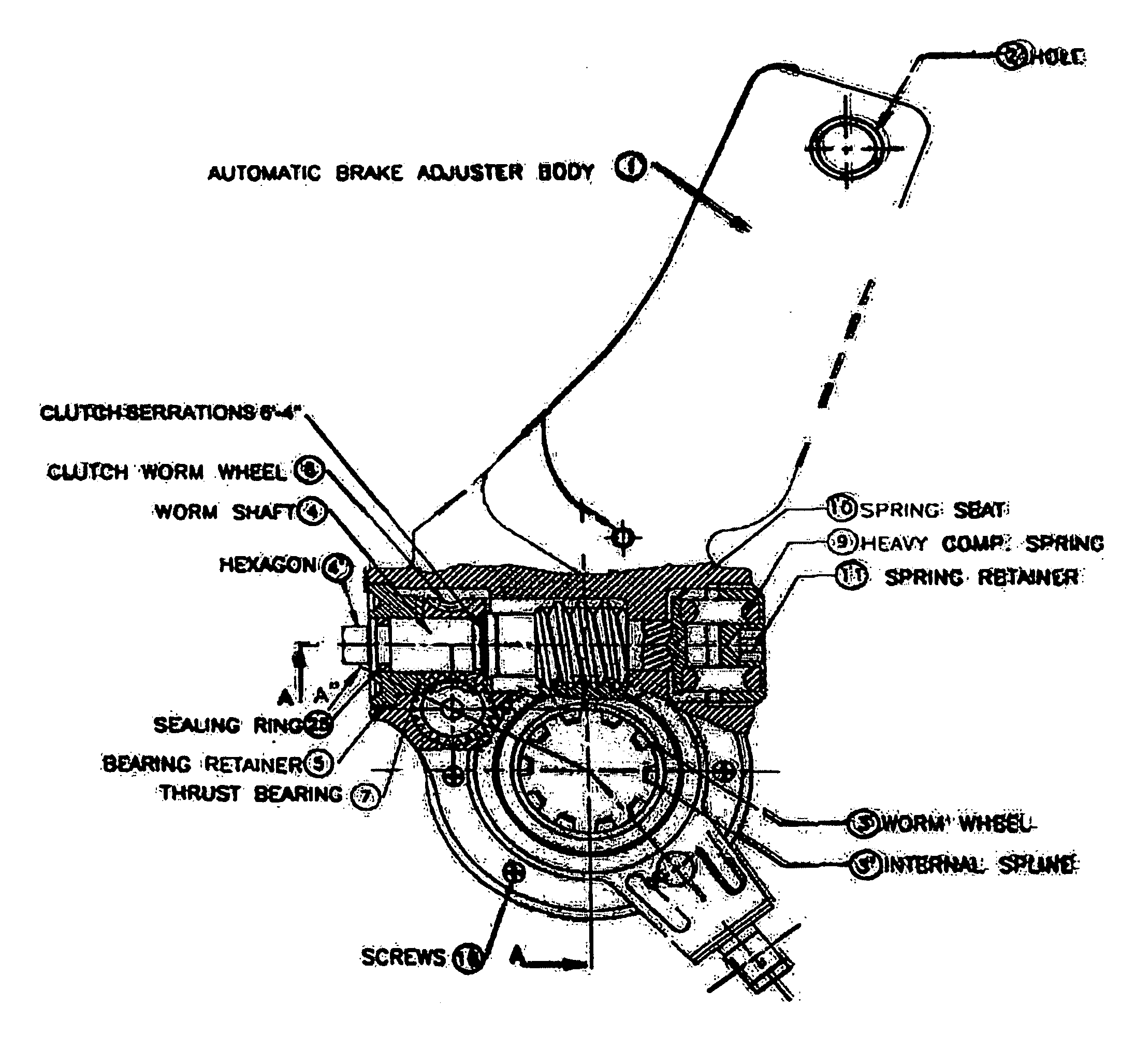

InactiveUS7198138B2Avoid over-regulationBig gapAxially engaging brakesDrum brakesEngineeringActuator

The invention pertains to the fluid powered brake systems of vehicles using brake drum and lined brake shoes internally expanded by cam. The invented device automatically adjusts the slack, which develops due to the wearing of brake liners and the drum. When the angular movement of the Lever Housing (1) exceeds the desired limit due to the wear, the internal device adjusts the excess clearance of slack automatically. The parts consist of a Worm Wheel (3); an enmeshing Worm Shaft (4); a Paul (6); a Leaf Spring (1); a Ratchet cylinder (5); an Acuator Rod (7); a Guide (9); an End Connector (8); a Clevis (2); and Clevis Pins (2A) and 2(B). When brakes are applied, the Actuator Rod (7) gets pulled out and engages the Paul (6) with the Ratchet cylinder (5). On the return stroke the Paul (6) rotates the worm shaft (4) which in turn rotates the worm wheel (3) and the attached cam thereby removing the slack.

Owner:ANG AUTOMOTIVE IND

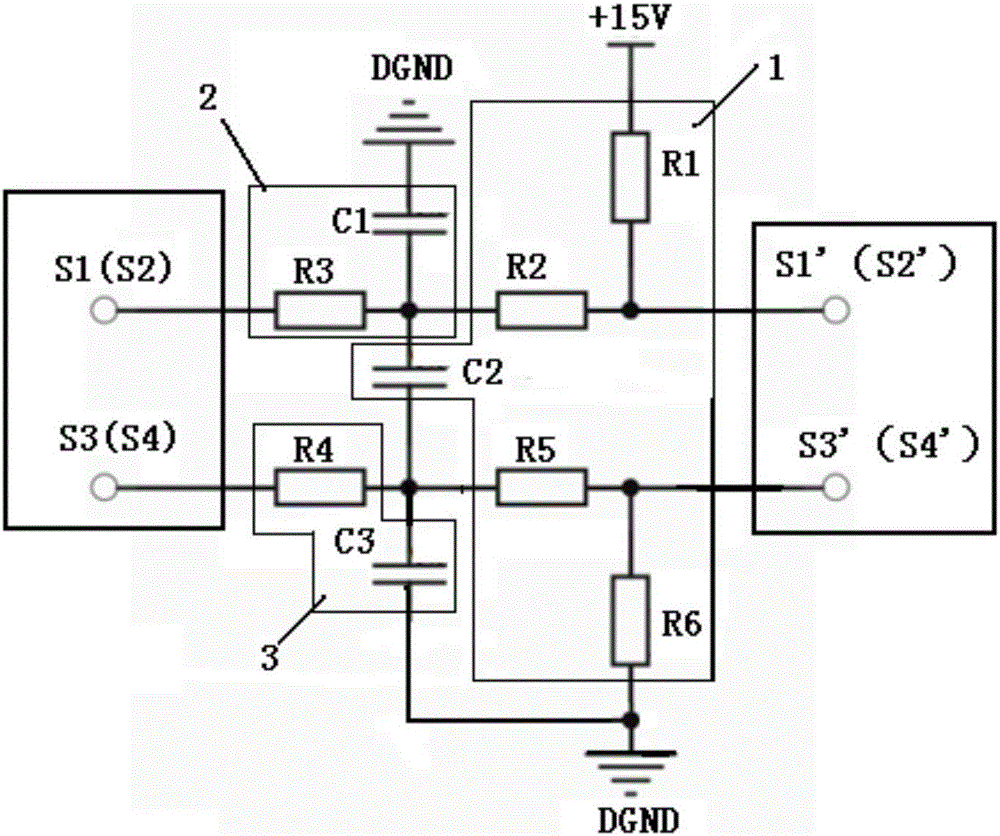

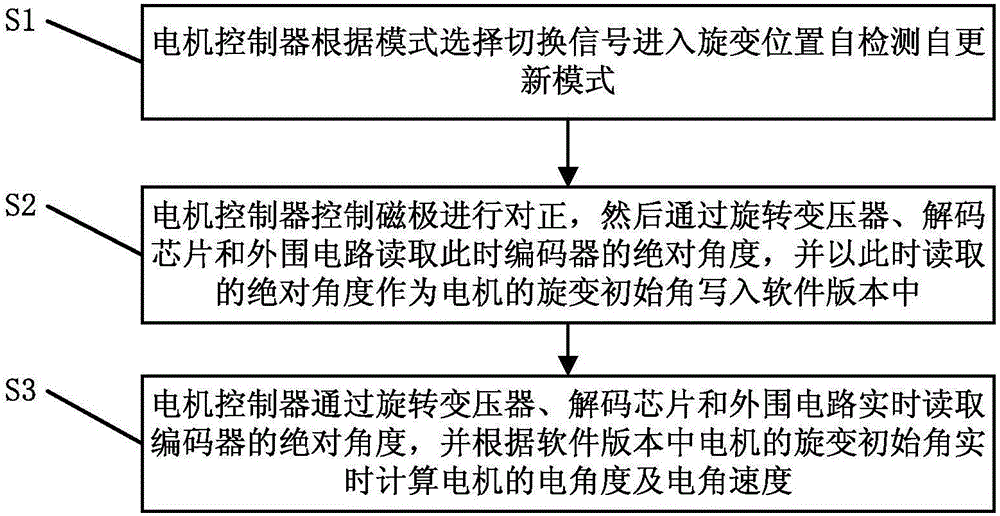

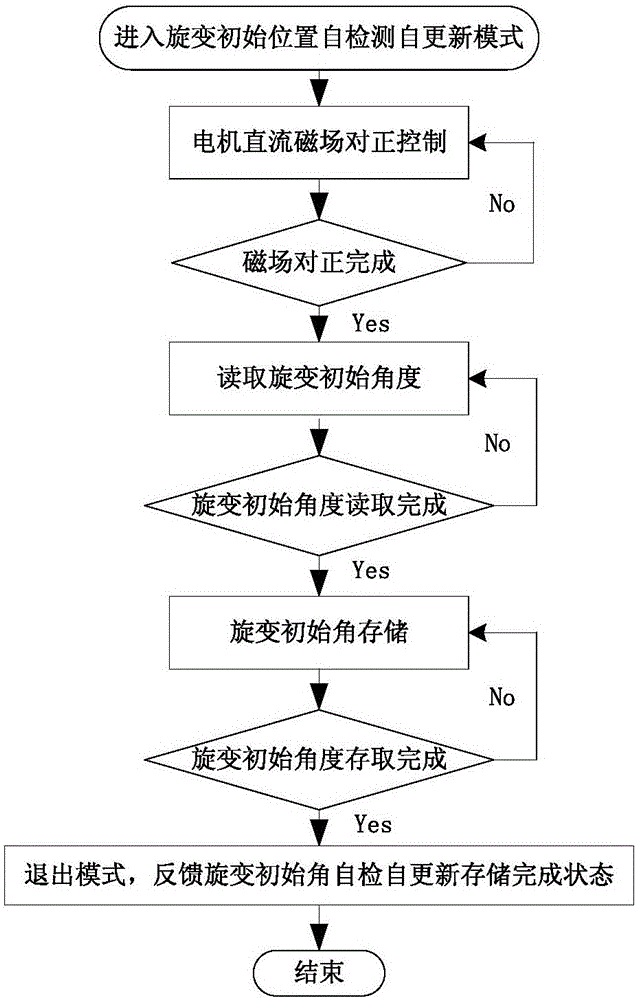

Motor resolver detection and conditioning circuit and resolver initial position self-detection and self-updating method

ActiveCN105897105ALess damageHigh precisionElectronic commutation motor controlVector control systemsSwitching signalMotor controller

The invention discloses a motor resolver detection and conditioning circuit and a resolver initial position self-detection and self-updating method. The method comprises the steps that a motor controller enters a resolver position self-detection and self-updating mode according to a mode selection switching signal; the motor controller controls the alignment of magnetic electrodes, then reads out the absolute angle of an encoder at the moment through a rotary transformer, an encoder chip and a peripheral circuit, uses the absolute angle read out at the moment as the resolver initial angle of the motor, and writes into a software version; and the motor controller reads out the absolute angle of the encoder in real time through the rotary transformer, the encoder chip and the peripheral circuit, and calculates the electrical angle and electrical angle speed of the motor in real time according to the resolver initial angle of the motor in the software version. By adding the resolver position self-detection and self-updating mode, the invention can effectively reduce the resolver position adjustment link in the motor factory test under the premise of the same software version, and can automatically and accurate detect and update the resolver initial angle. The invention can be widely applied to the field of frequency control.

Owner:GUANGZHOU CHENGXING ZHIDONG AUTOMOTIVE TECH CO LTD

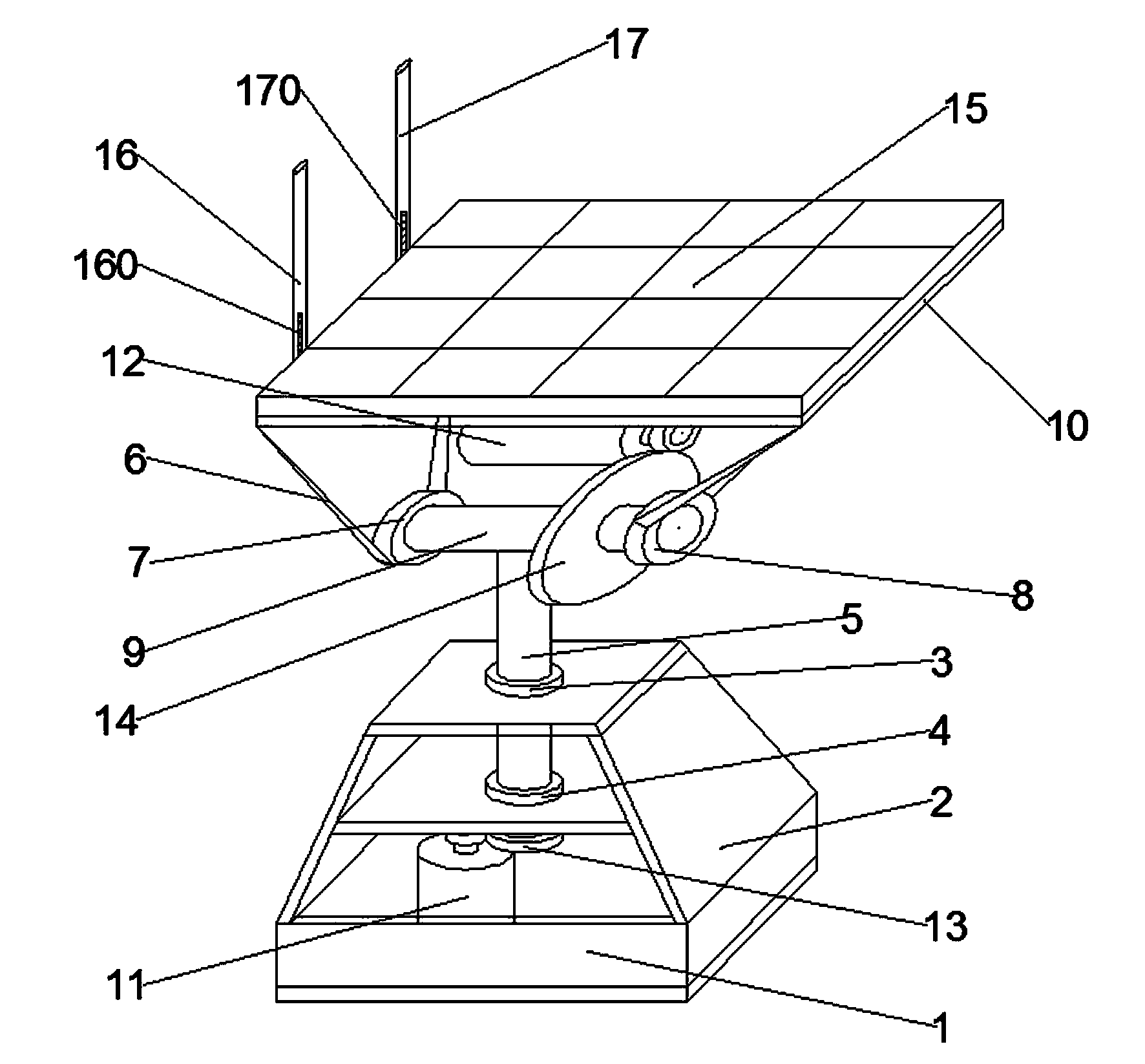

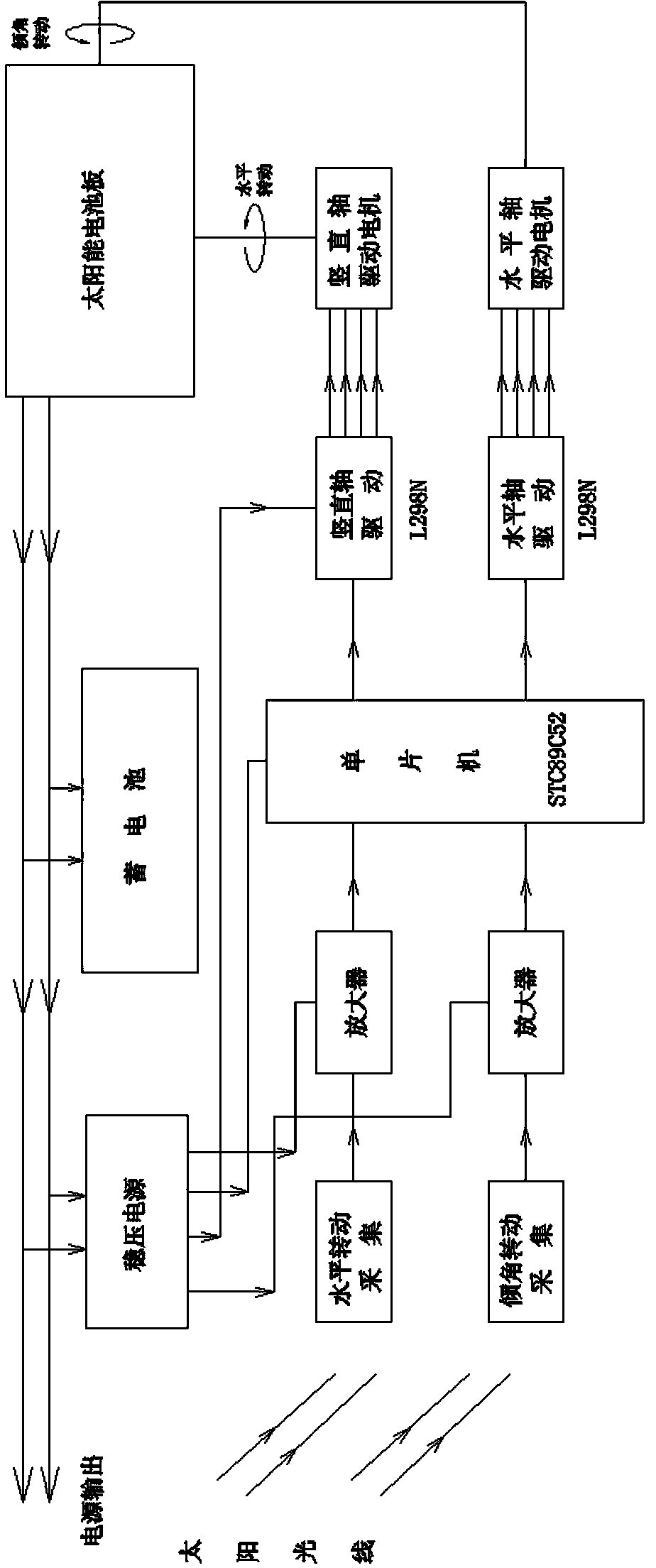

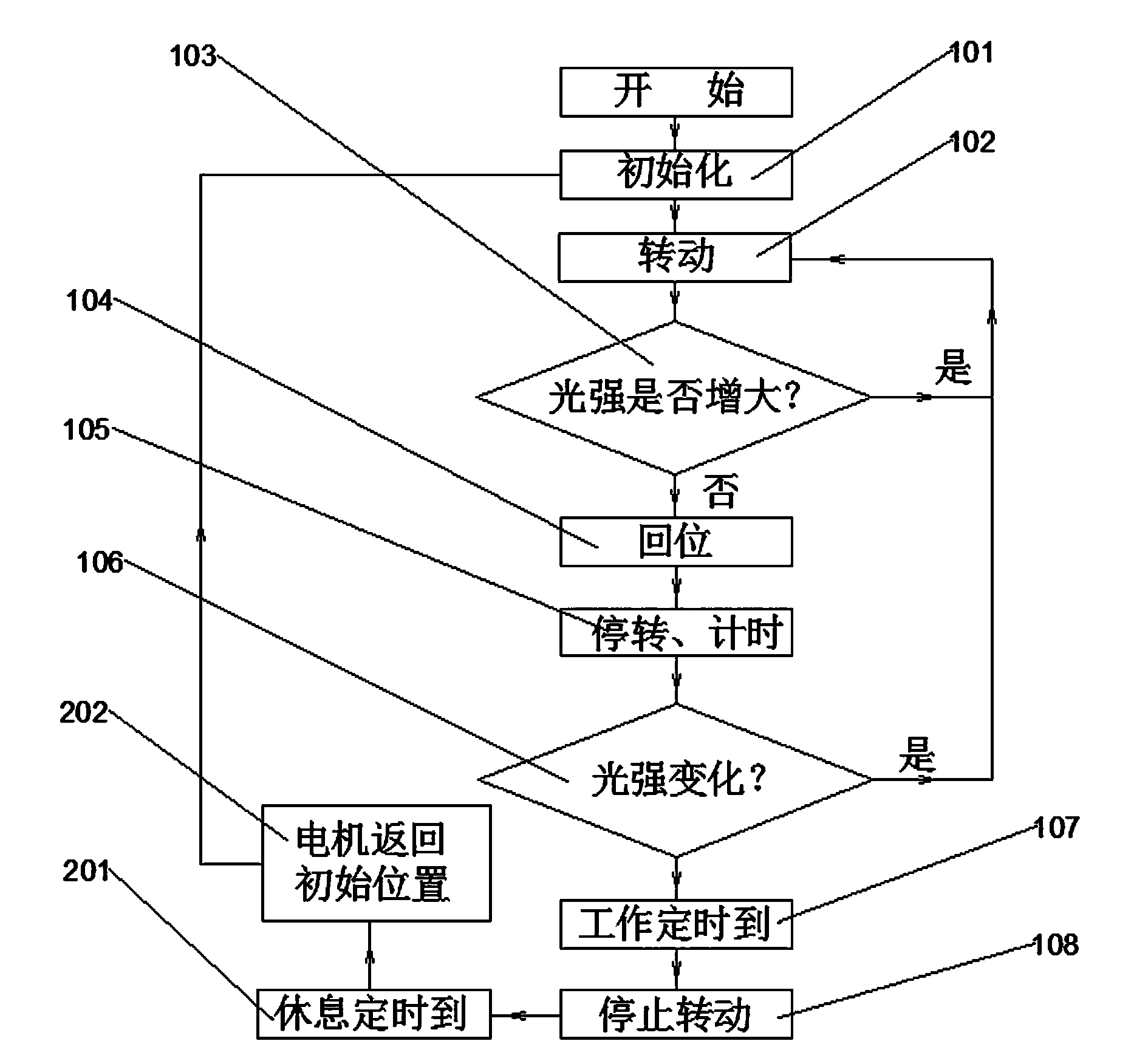

Light source automatic tracking type solar collecting device and control method thereof

InactiveCN103869832AGuaranteed to be verticalGuaranteed parallelControl using feedbackLight energyEngineering

The invention provides a light source automatic tracking type solar collecting device. The light source automatic tracking type solar collecting device can automatically track a sun light source, a solar cell panel can be irradiated by sun light vertically and continuously, and therefore the light energy conversion efficiency is improved. The light source automatic tracking type solar collecting device comprises a base, a solar cell panel base is movably connected to the base through a horizontal steering device and a dip angle pitching device, the solar cell panel is flatly laid on the solar cell panel base, a horizontal steering collecting pipe and a dip angle pitching collecting pipe which are perpendicular to the solar cell panel are arranged on one side of the solar cell panel base, and photoelectric sensors are arranged in the horizontal steering collecting pipe and the dip angle pitching collecting pipe. A control device is further included. The invention further provides a control method of the device.

Owner:ANQING NORMAL UNIV

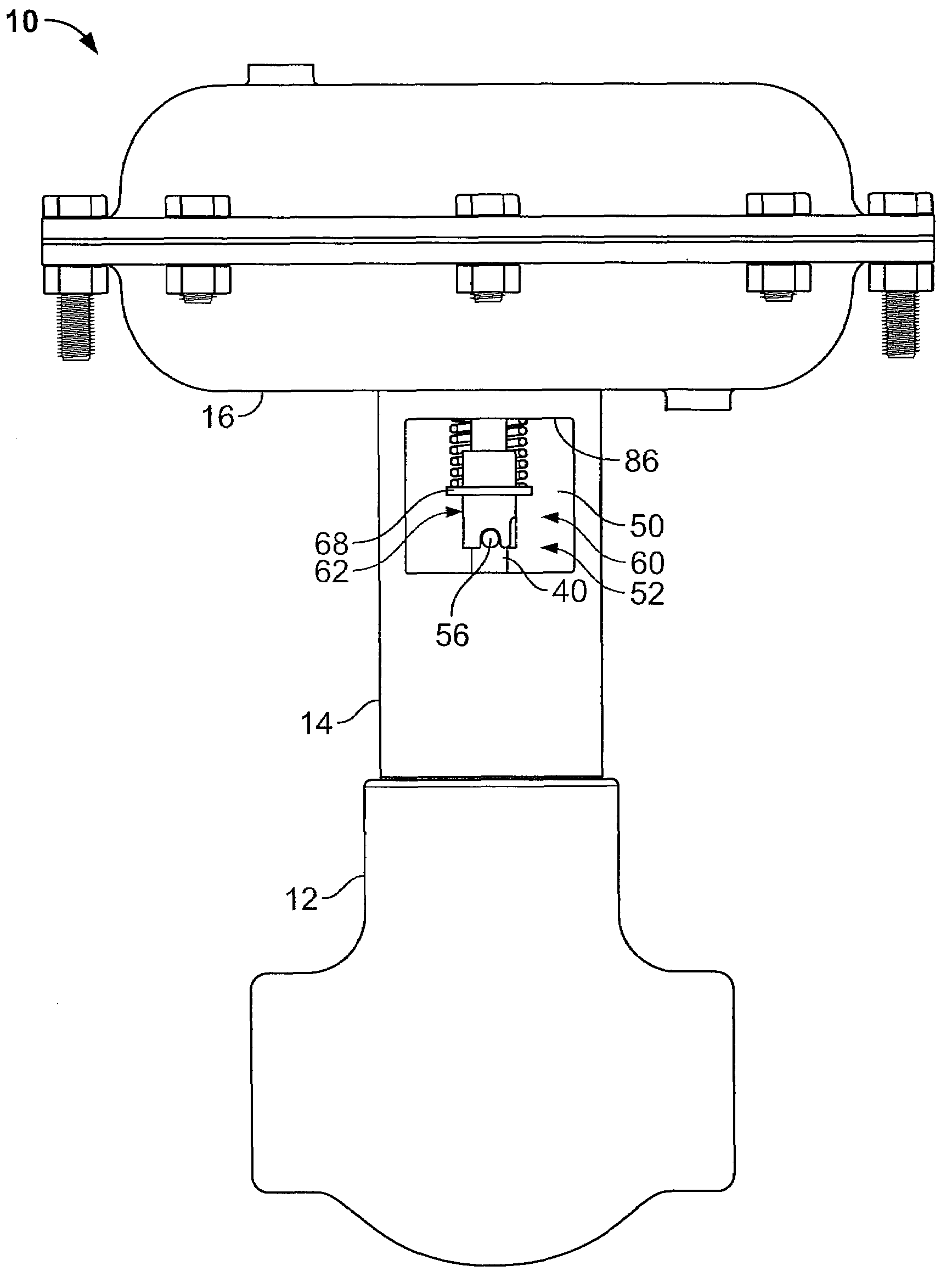

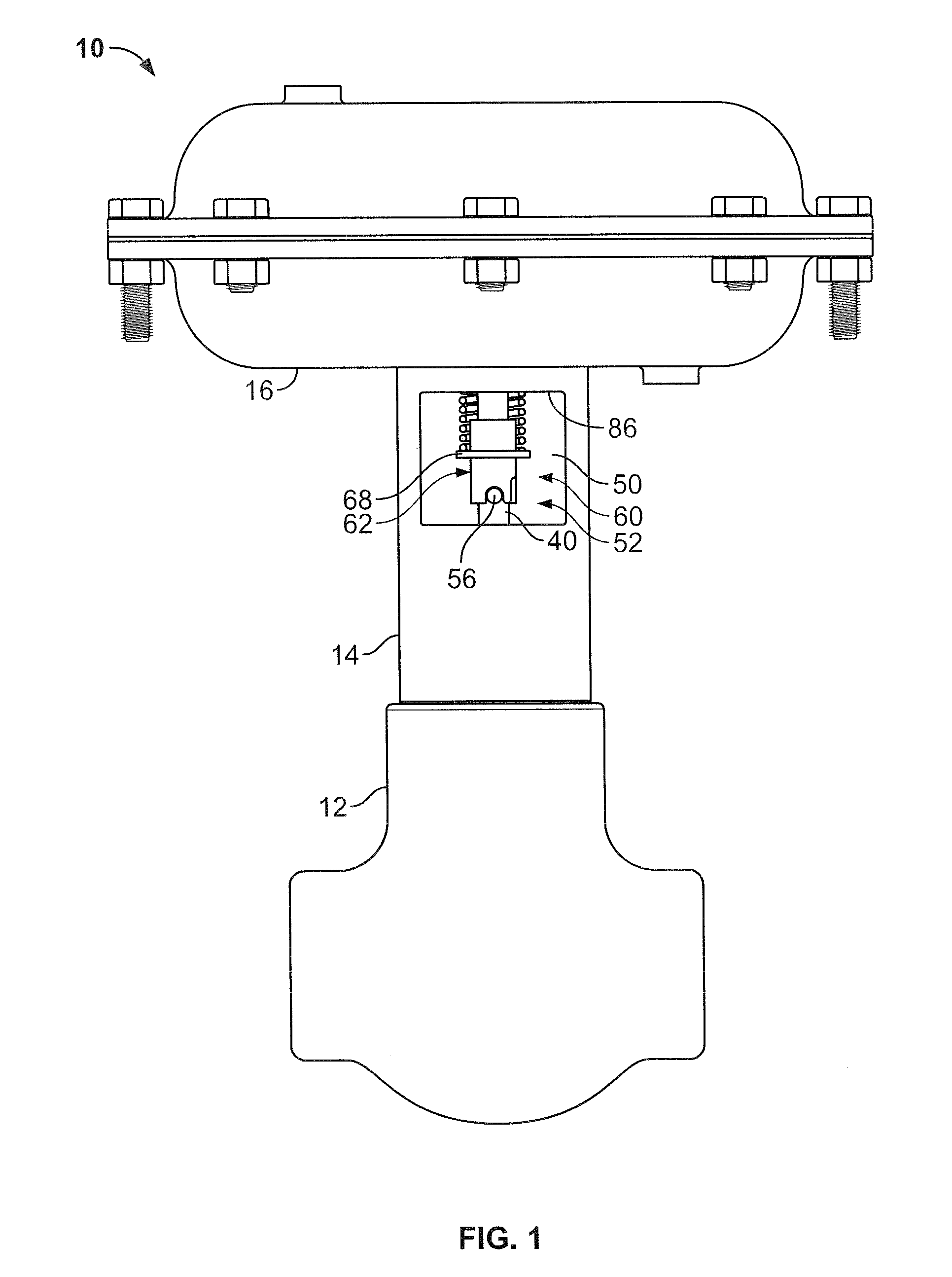

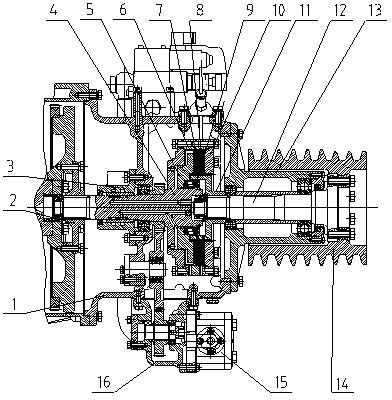

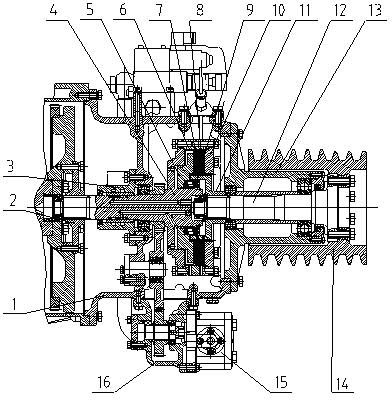

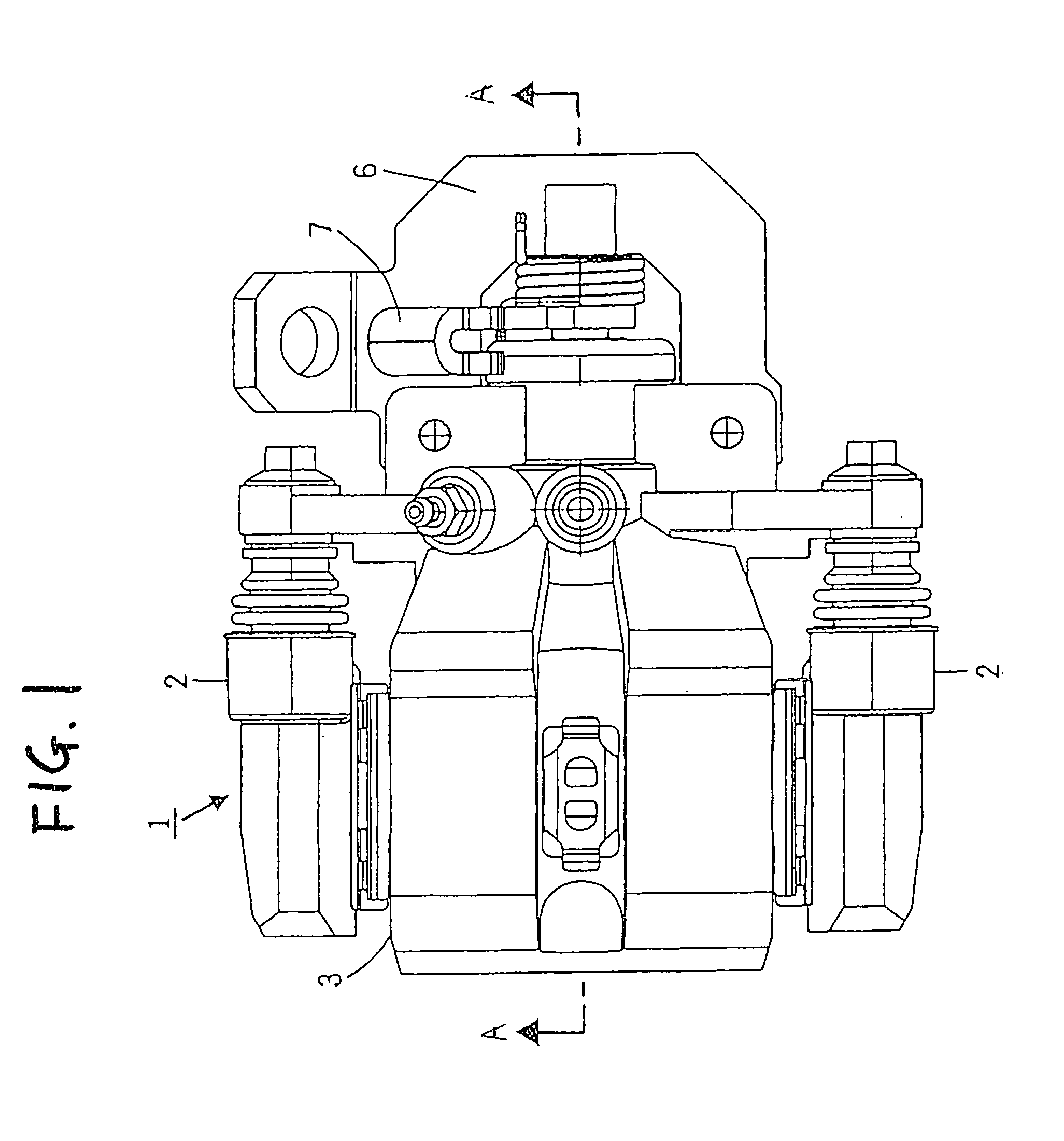

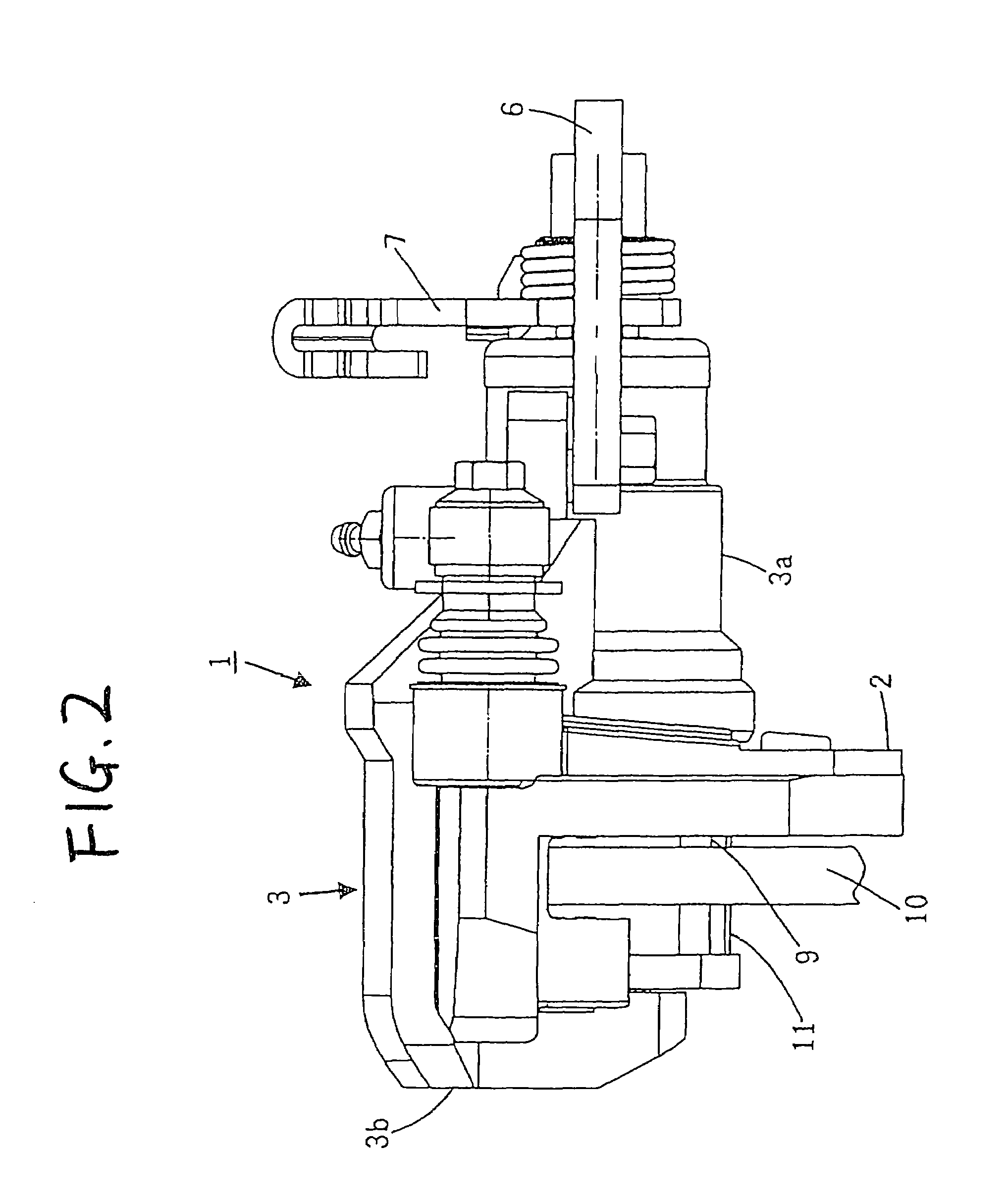

Automatic slack adjuster assembly for vehicle braking system

The invention pertains to the fluid powered brake systems of vehicles using brake drum and lined brake shoes internally expanded by cam. The invented device automatically adjusts the slack, which develops due to the wearing of brake liners and the drum. The device is depicted in FIG. 1 when the angular movement of the Lever Housing (1) exceeds the desired limit due to the wear, the internal device adjusts the excess clearance of slack automatically. The parts consist of Worm Wheel (3); an enmeshing Worm Shaft (4); a Paul (6); a Leaf Spring (1); a Ratchet cylinder (5); an Acuator Rod (7); a Guide (9); an End Connector (8); a Clevis (2); and Clevis Pins (2A) and 2(B). When brakes are applied the Actuator Rod (7) gets pulled out and brings the Paul (6) in engagement with Ratchet cylinder (5). On the return stroke the Paul (4) rotates the worm shaft (4) which in turn rotates the worm wheel (3) and the attached cam thereby removing the slack.

Owner:ANG AUTOMOTIVE IND

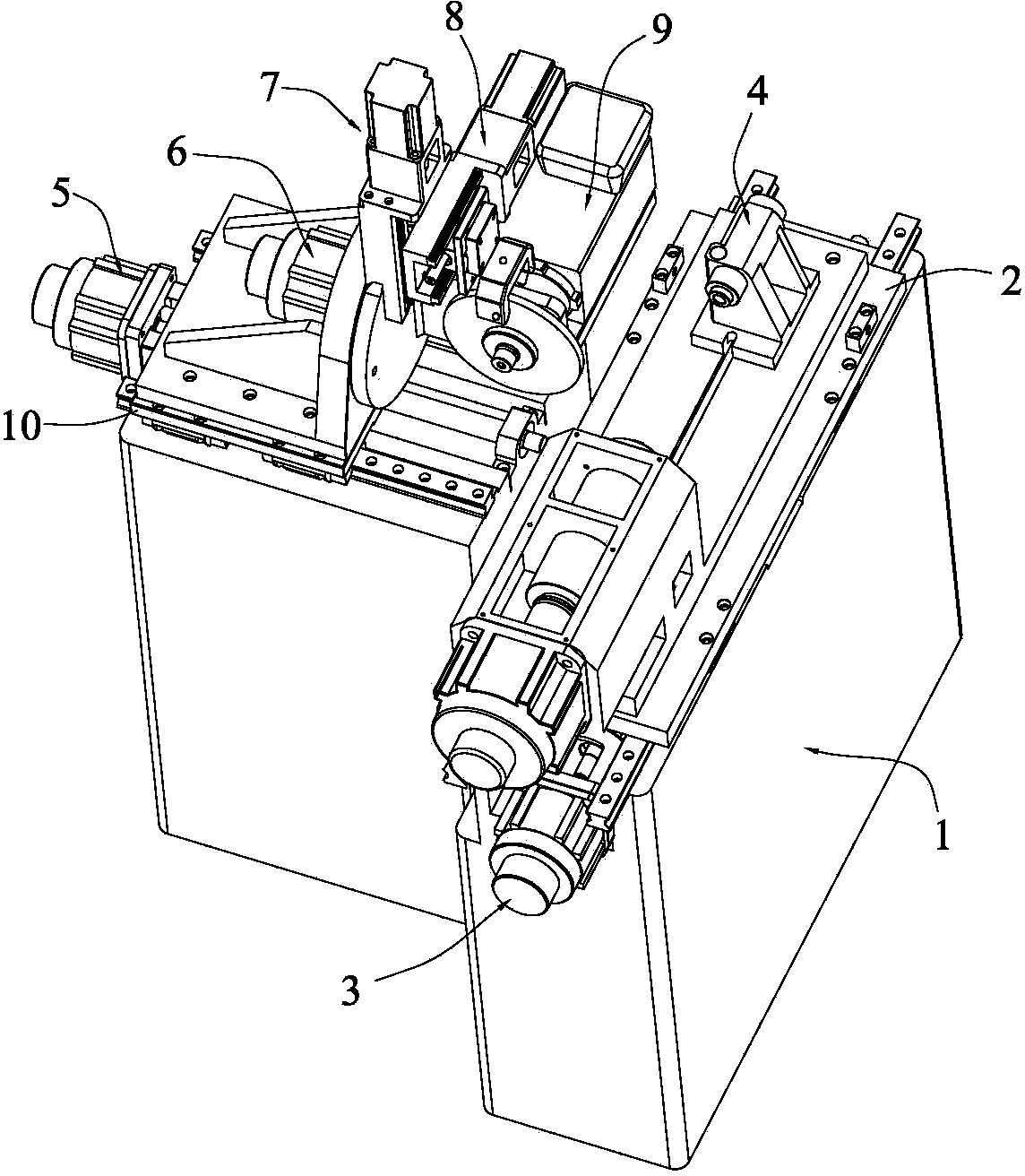

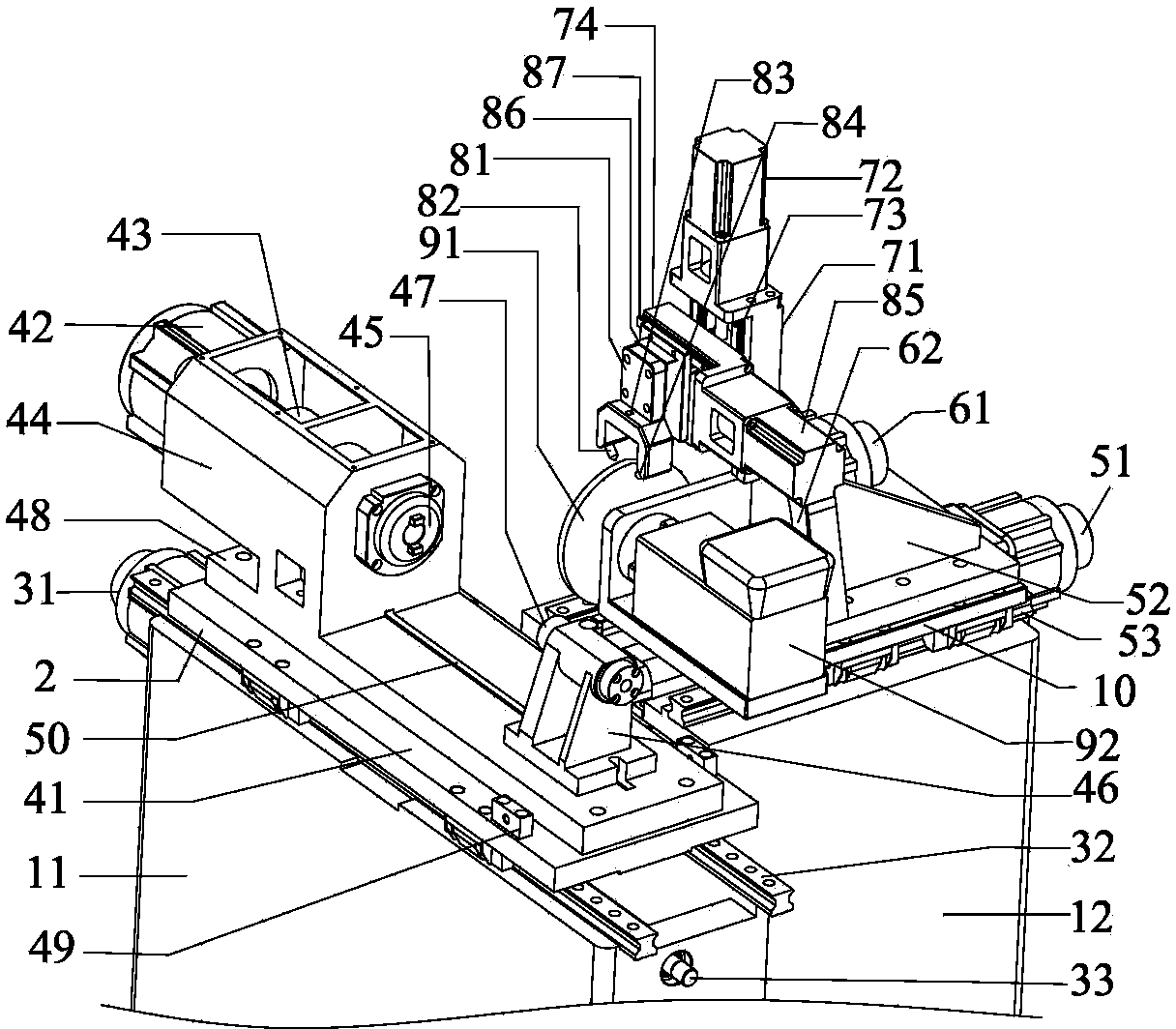

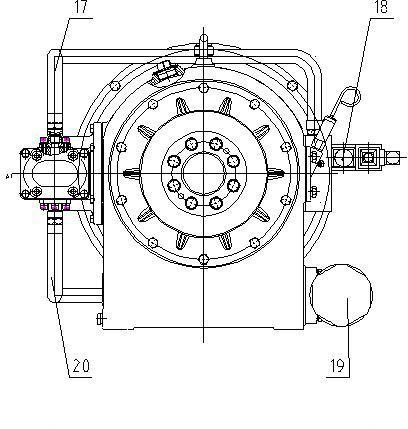

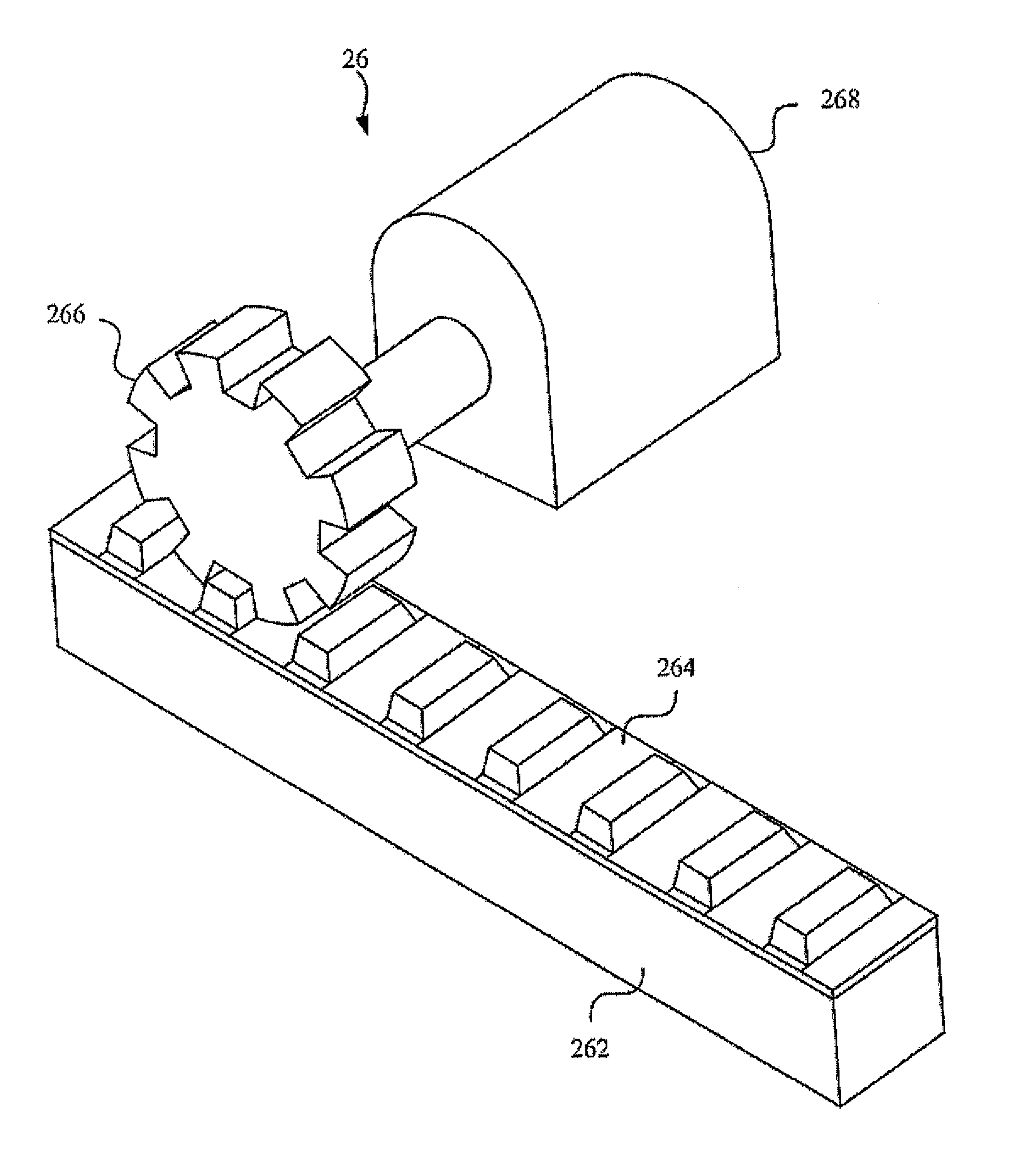

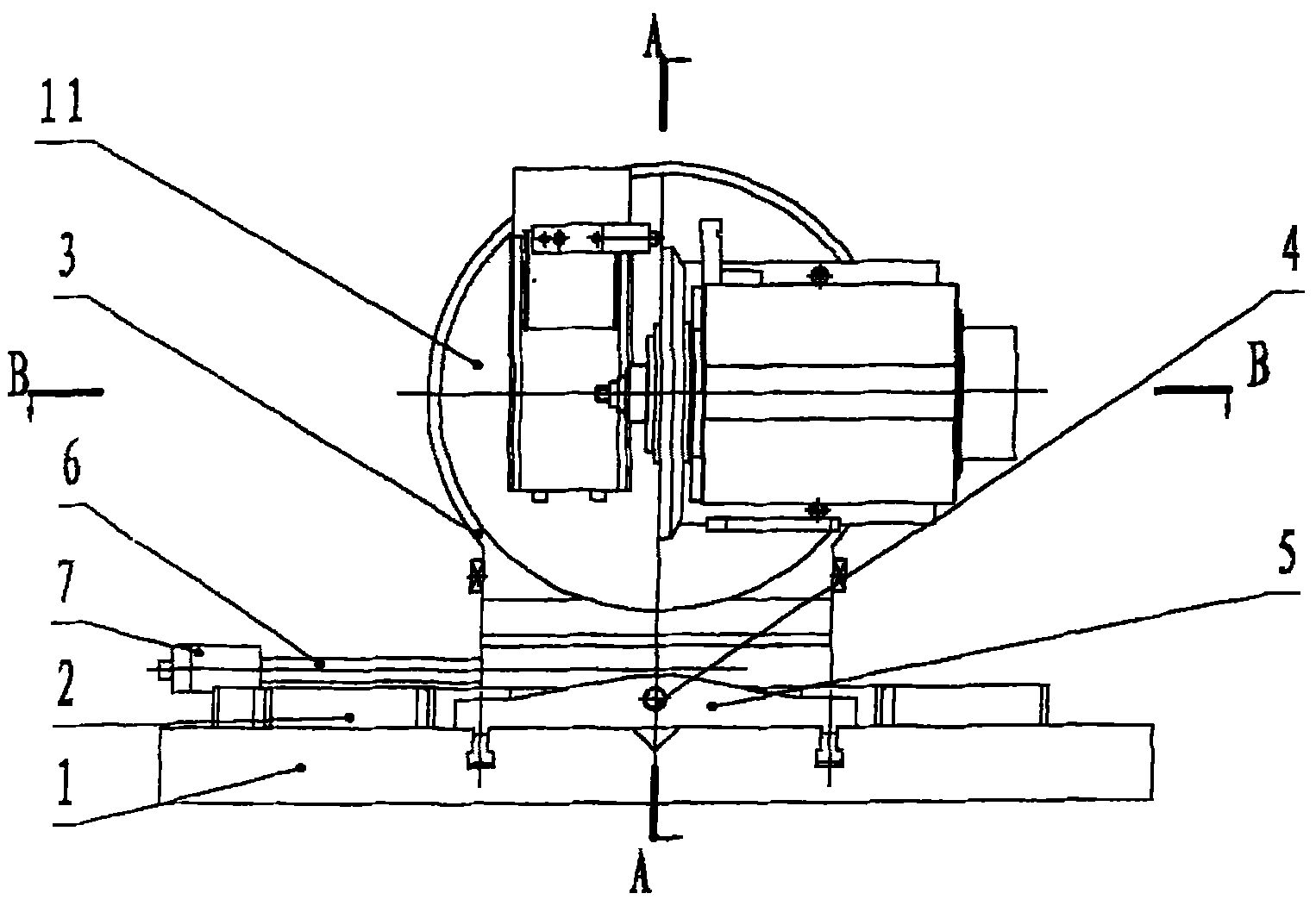

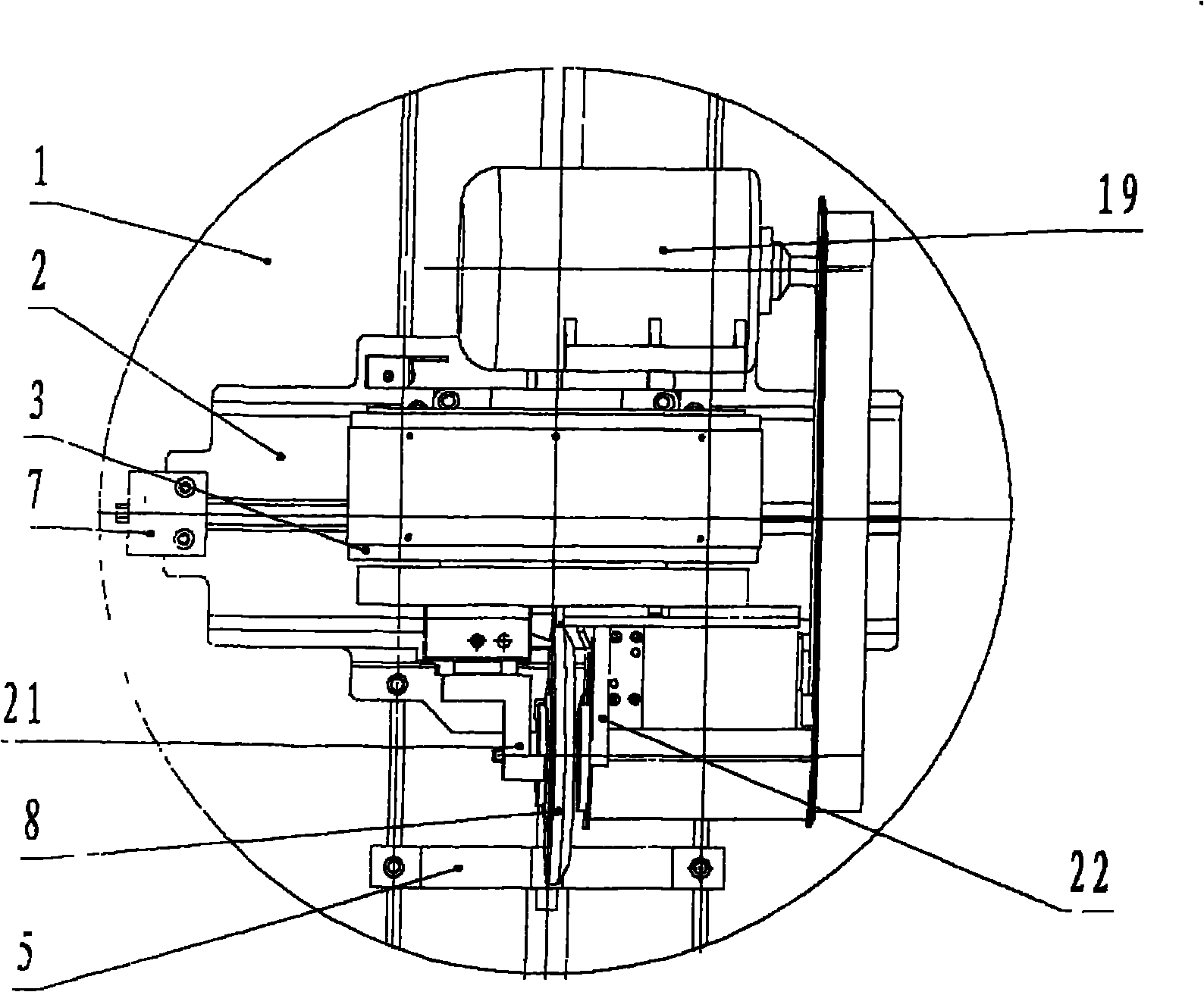

Novel efficient numerical control gear grinding machine

ActiveCN103418852AWith trimming functionEfficient trimmingLarge fixed membersGear-cutting machinesNumerical controlGear grinding

The invention discloses a novel efficient numerical control gear grinding machine which comprises a machine frame, a left-right workbench, a front-rear workbench, a Z-axis sliding mechanism, a C-axis workpiece clamping and holding mechanism, an X-axis sliding mechanism, a B-axis rotating mechanism, a V-axis trimming mechanism, a U-axis trimming mechanism and a grinding head mechanism. The left-right workbench is horizontally arranged at the front portion of the machine frame; the C-axis workpiece clamping and holding mechanism is arranged on the left-right workbench; the front-rear workbench is longitudinally arranged at the tail portion of the machine frame; the grinding head mechanism is arranged on the front-rear workbench. The novel efficient numerical control gear grinding machine is ingenious and reasonable in design, easy to operate, multifunctional, capable of grinding ordinary spur gears, bevel gears, screw rods, worms and ring surface worms efficiently, multipurpose and wide in application range, has the function of trimming grinding heads, can efficiently trim the grinding heads of any contour, greatly improves rigidity of the grinding heads, effectively improves machining accuracy, and is simple in overall structure, easy to manufacture and produce, and beneficial to being popularized and applied widely.

Owner:ZHONGSHAN MLTOR CNC TECH CO LTD

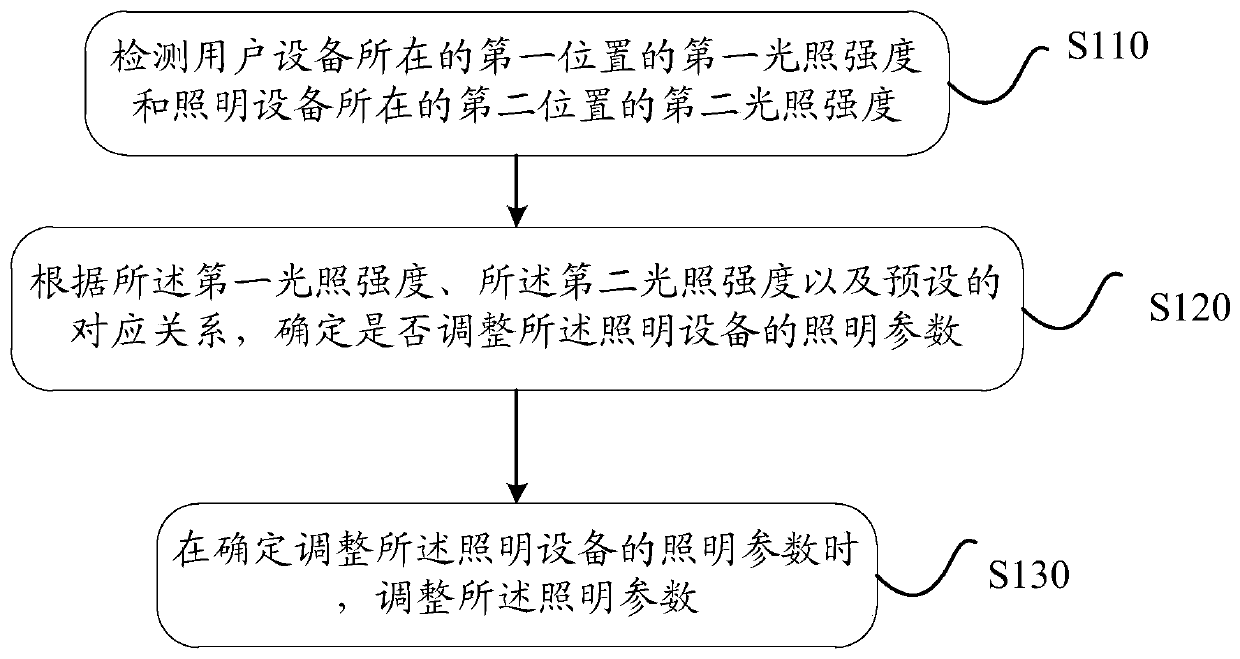

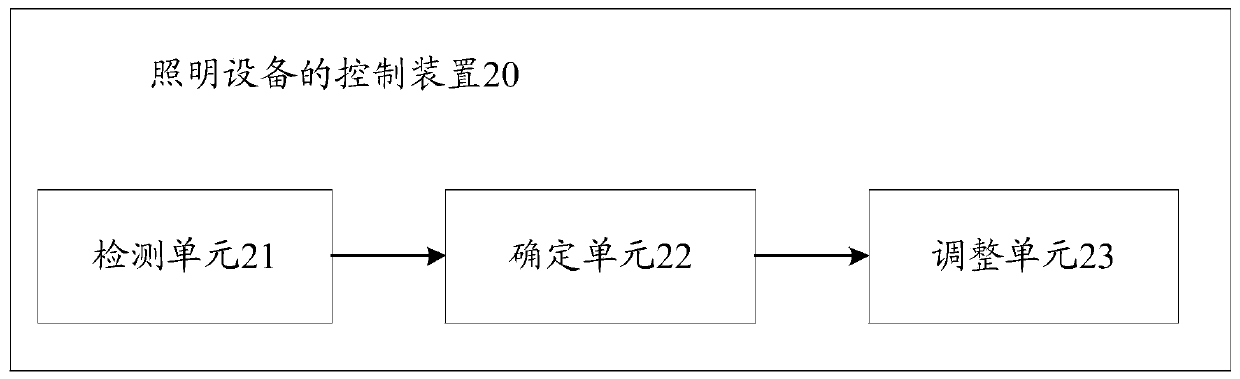

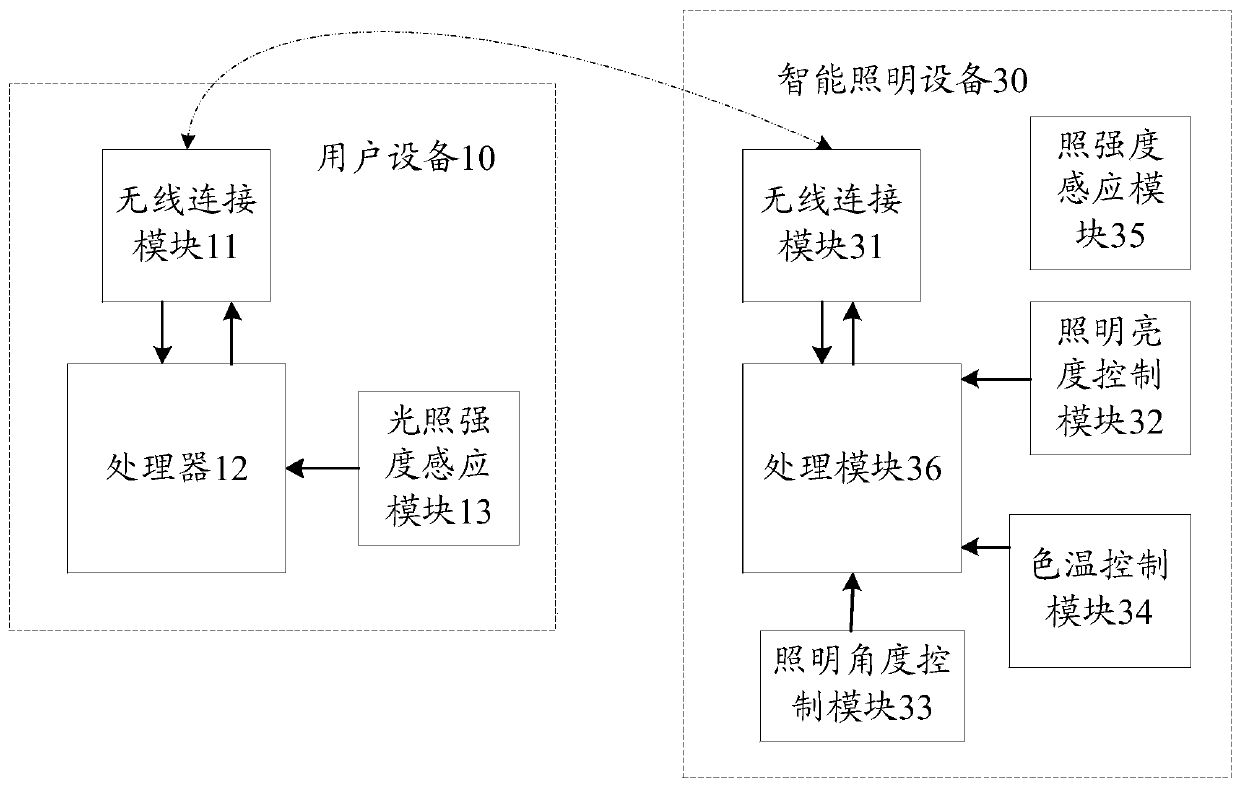

Control method and control device for lighting equipment

ActiveCN110267416AImprove the intelligence of adjustment methodsHigh degree of intelligenceElectrical apparatusElectric light circuit arrangementState of artLight equipment

The invention discloses a control method and a control device for lighting equipment. The control method comprises the following steps: detecting the illumination intensity at positions where user equipment and the lighting equipment are; according to the illumination intensity and a preset corresponding relation, determining whether lighting parameter of the lighting equipment is adjusted; and if the definitive result is yes, adjusting the lighting parameter. Through the preset corresponding relation, whether the lighting parameter is adjusted is determined by comprehensively considering the illumination intensity at two positions of the user equipment and the lighting equipment, and more factors are considered relative to a single adjusting way, so that the adjusting way intelligence degree of the lighting equipment is improved, excessive adjustment of the lighting parameter is prevented by setting preset illumination intensity interval and adjusting way, and the technical problem that the adjusting way intelligence degree of the lighting equipment is low in the prior art is solved.

Owner:GREE ELECTRIC APPLIANCES INC

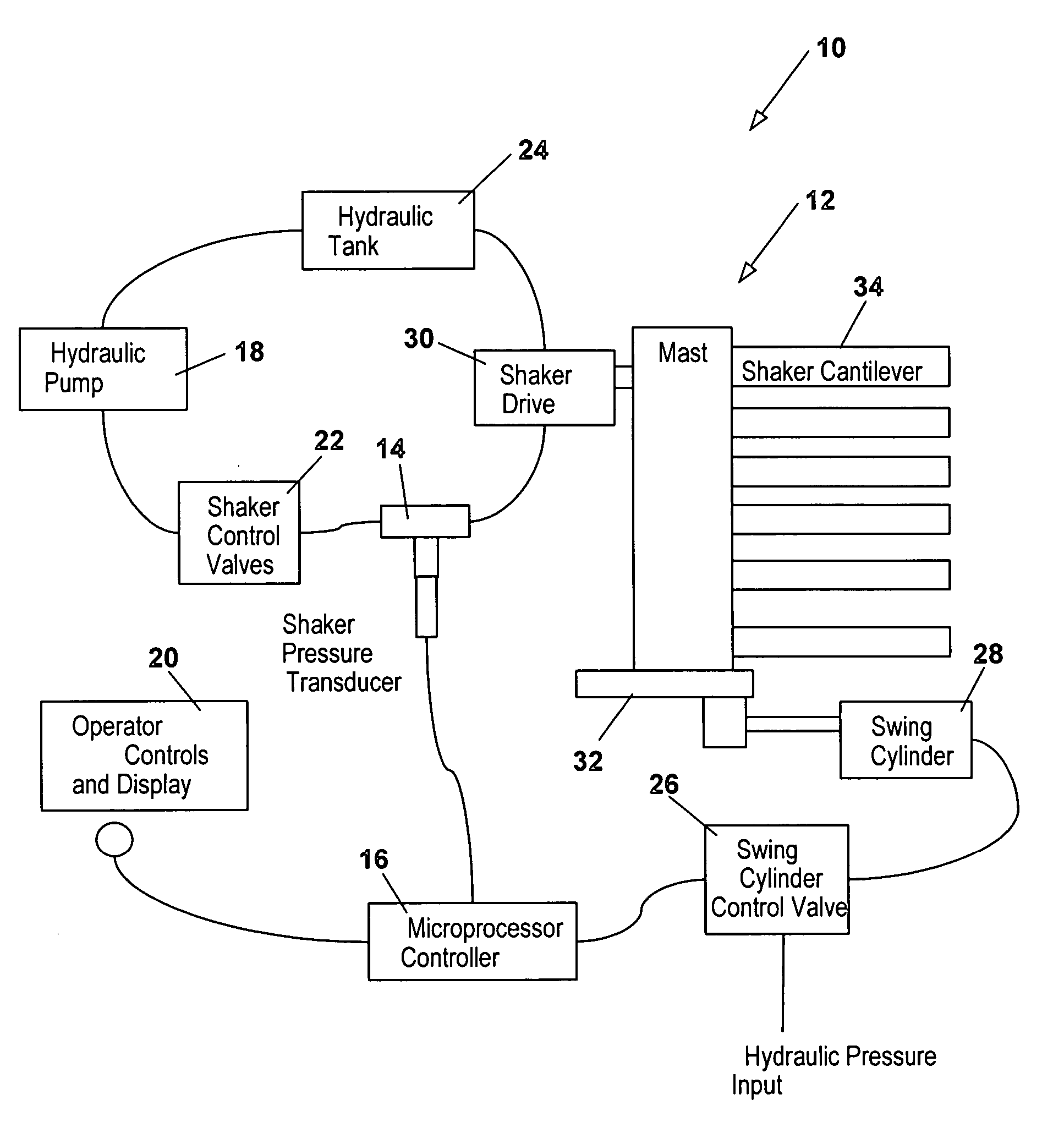

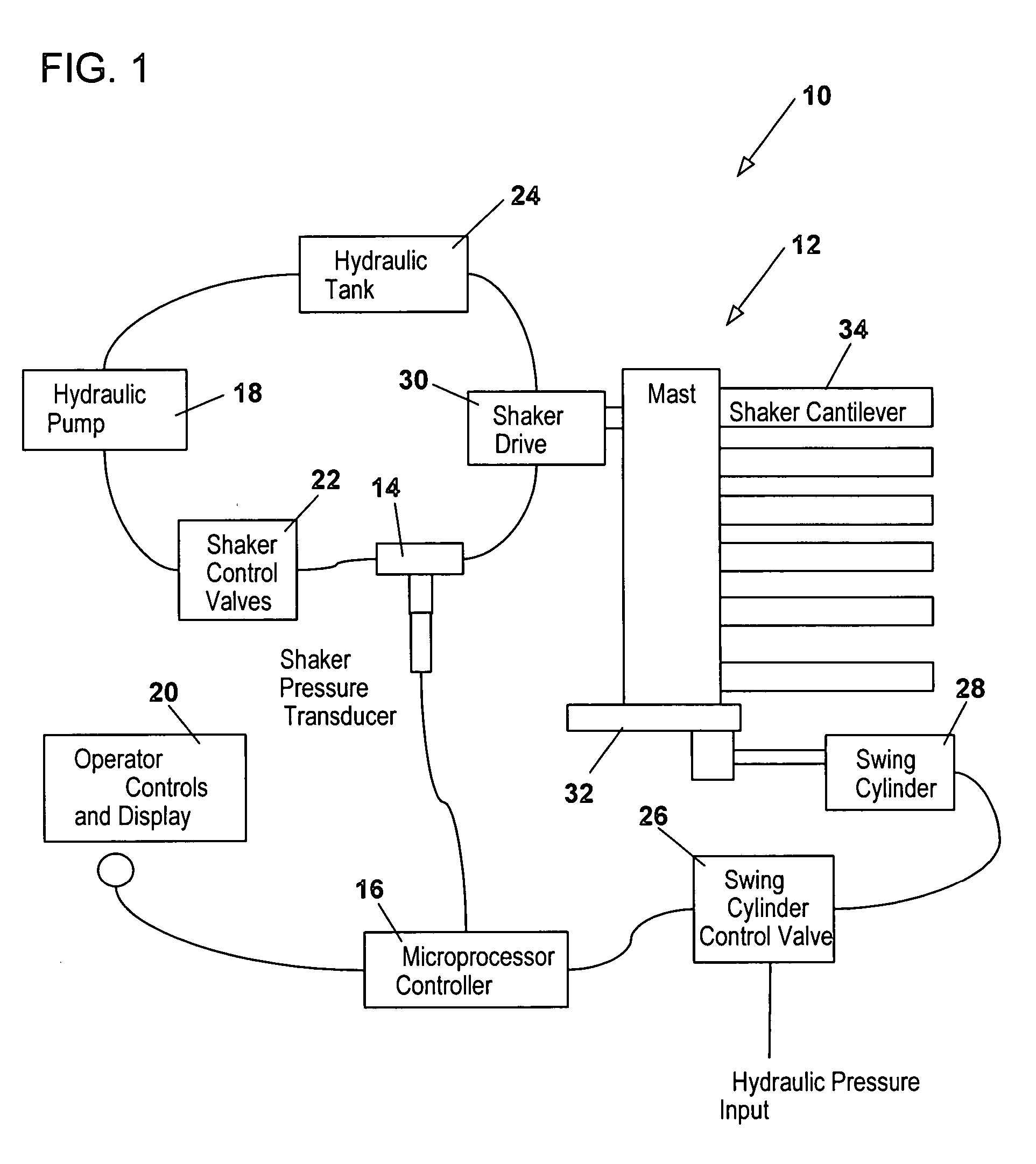

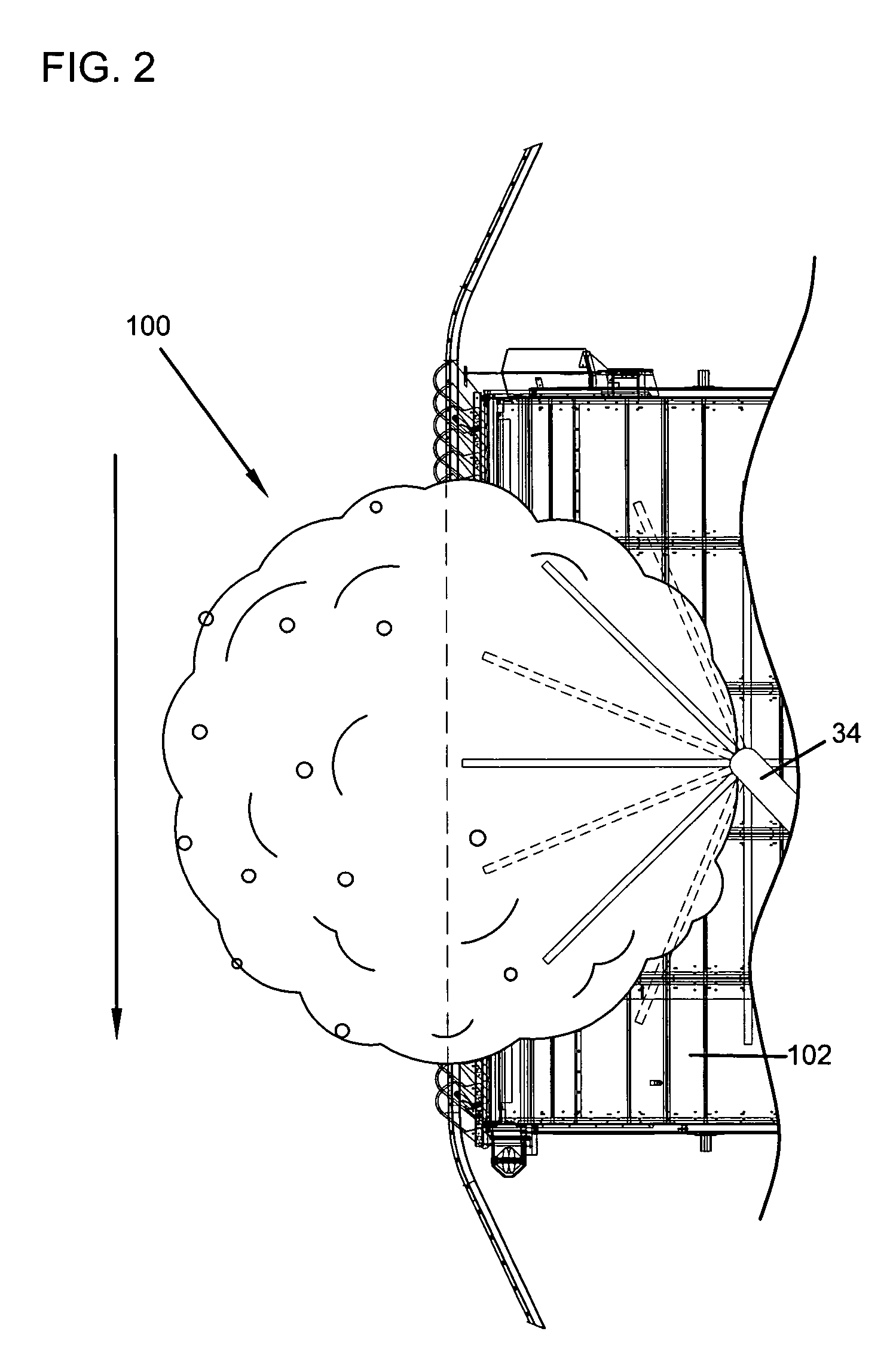

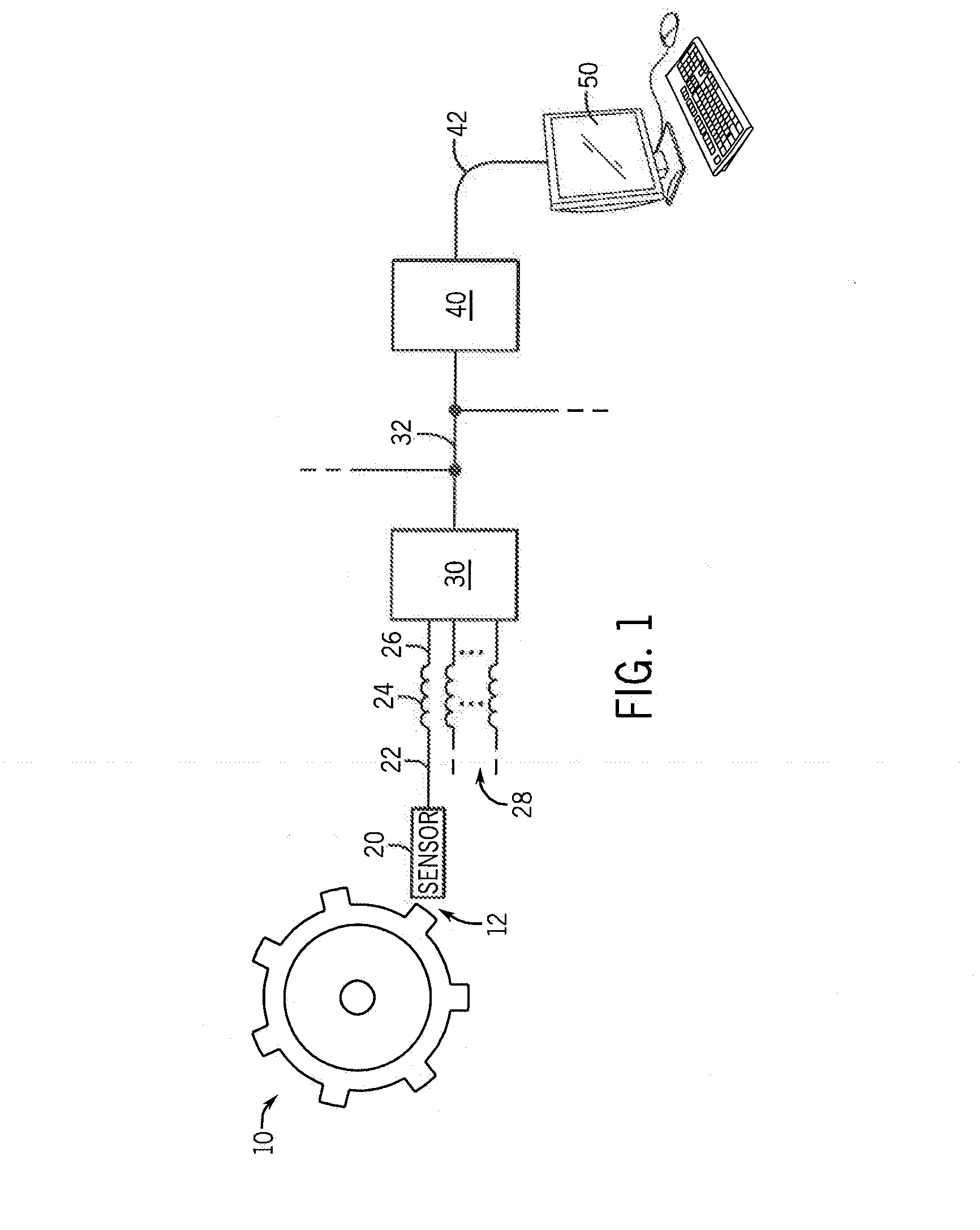

Tree follower

The present invention is directed to a tree follower device. The tree follower device includes an engagement assembly that penetrates into and shakes the branches of fruit trees to dislodge the fruit. A pressure transducer in communication with a controller measures the pressure resistance from engagement with the branches and moves the tree follower device further into and out of the branches depending upon the resistance. The present invention allows for programming various upper and lower limits and for operating in different modes for different types of trees. The present invention also provides for varying the sensitivity and the speed at which the engagement devices moves into or out of the tree.

Owner:OXBO INT CORP

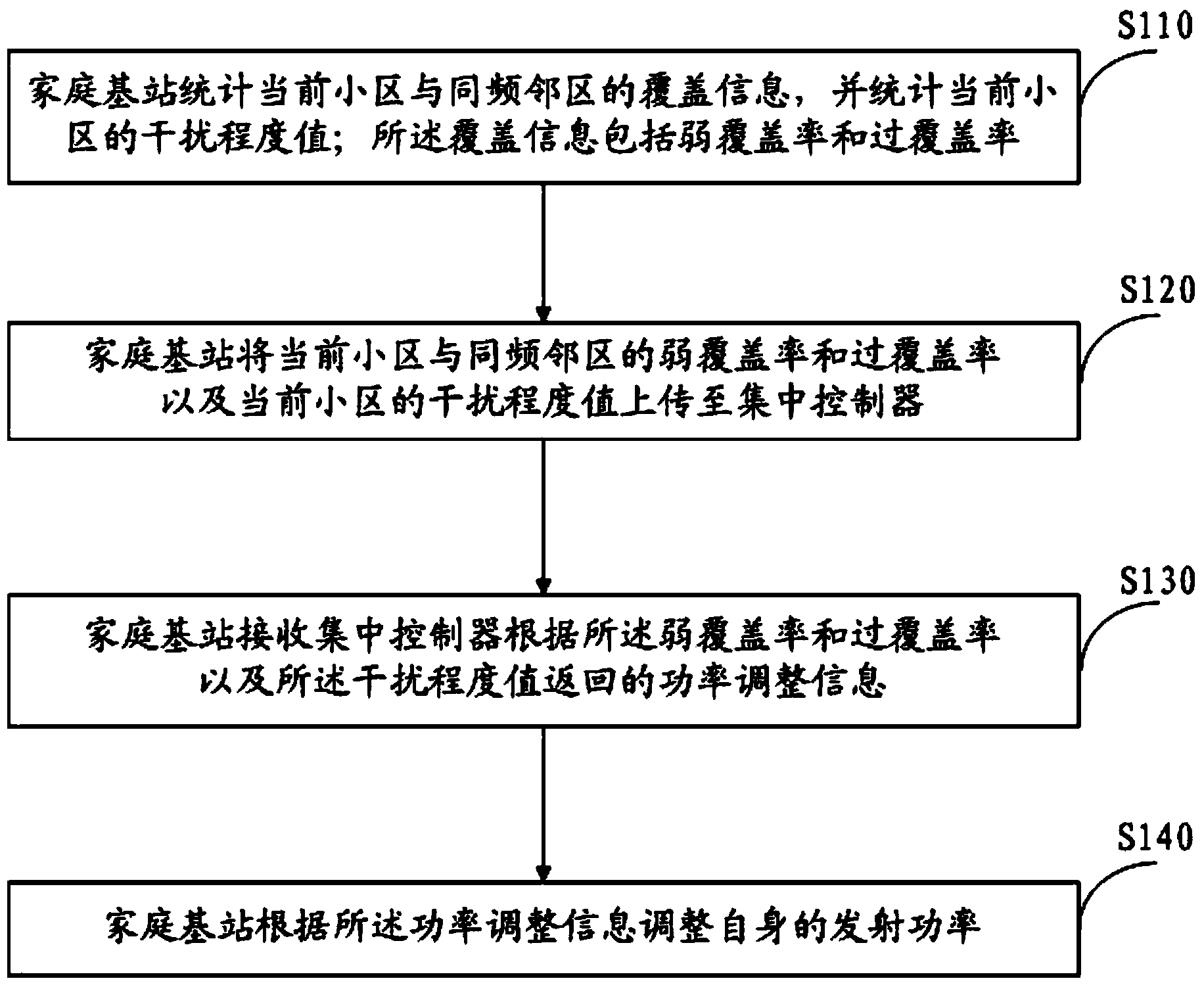

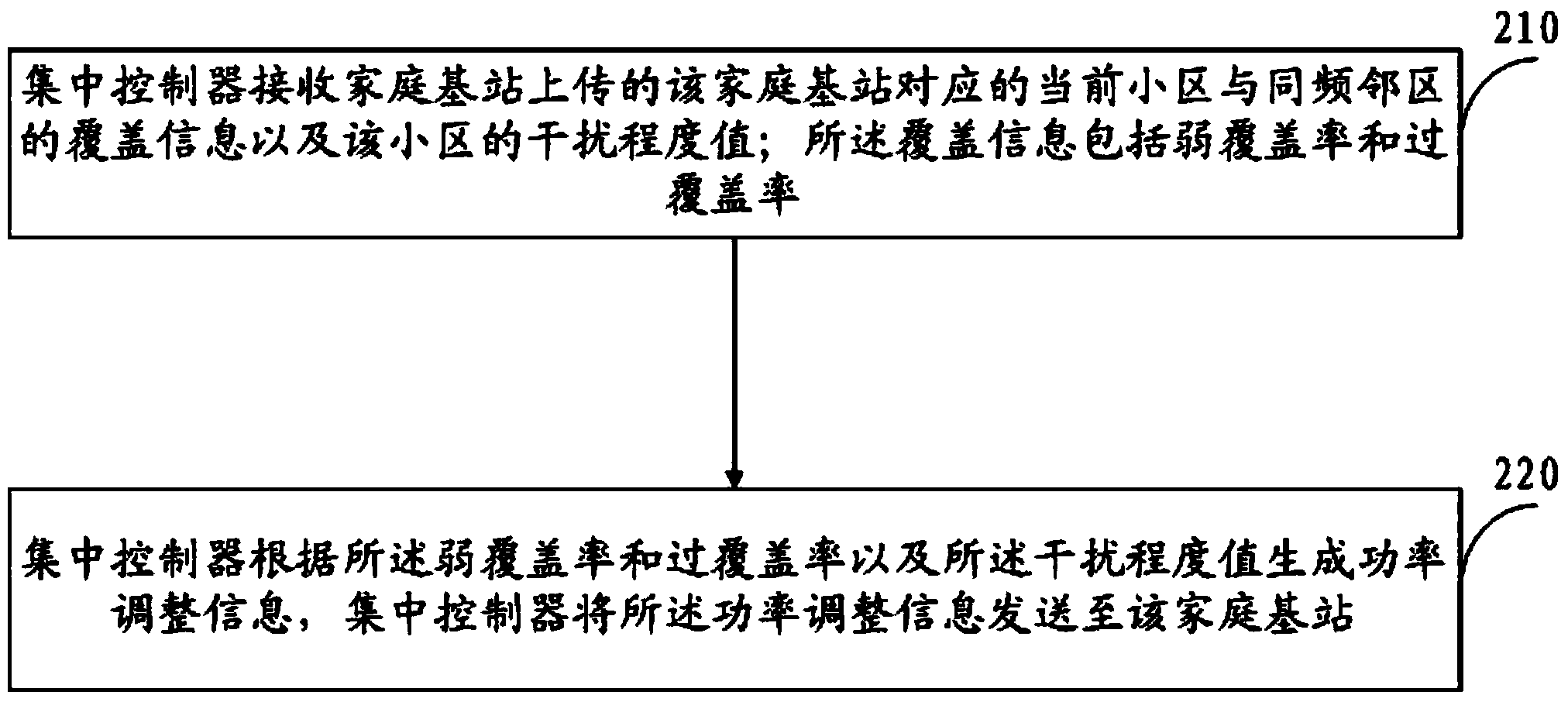

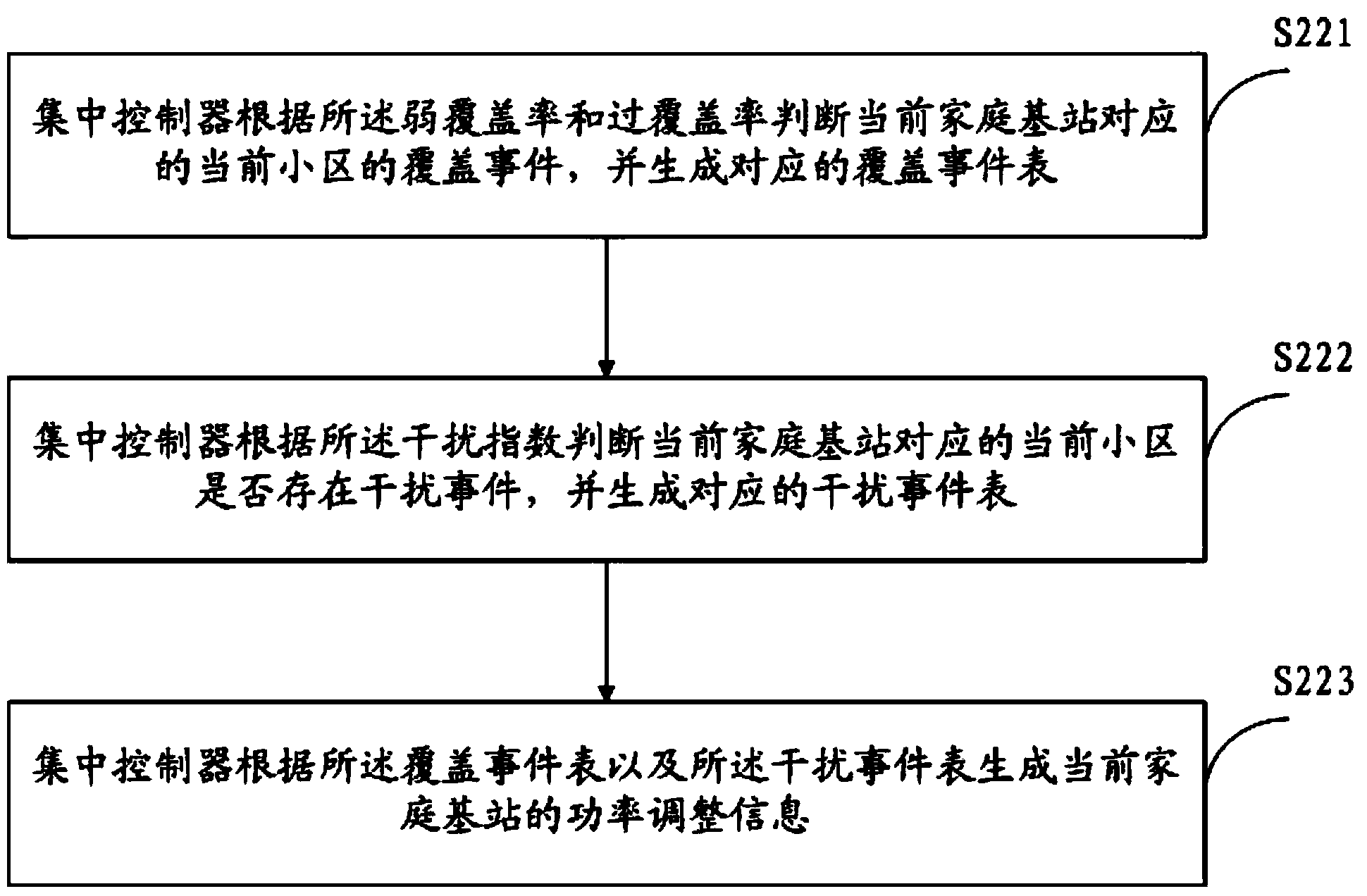

Power adjustment method, device and system

The invention discloses a power adjustment method, device and system. The method comprises the following steps that femtocells count coverage information of a current cell and a same-frequency adjacent cell and count interference indexes of the current cell, wherein the coverage information comprises the weak-coverage rate and the over-coverage rate; the femtocells upload the weak-coverage rate and the over-coverage rate of the current cell and the same-frequency adjacent cell and the interference indexes of the current cell to an integrated controller; the femtocells receive power adjustment information returned by the integrated controller according to the weak-coverage rate, the over-coverage rate and the interference indexes and adjust transmission power of itself according to the power adjustment information. According to the power adjustment method, device and system, comprehensive consideration is given to the coverage information and the interference information of the femtocells, the adjustment of the transmission power of all the femtocells is determined in an integrated mode through the integrated controller, in this way, networks of the femtocells can achieve a compromise between coverage and interference, and the overall performance of the networks is effectively improved.

Owner:COMBA TELECOM SYST CHINA LTD

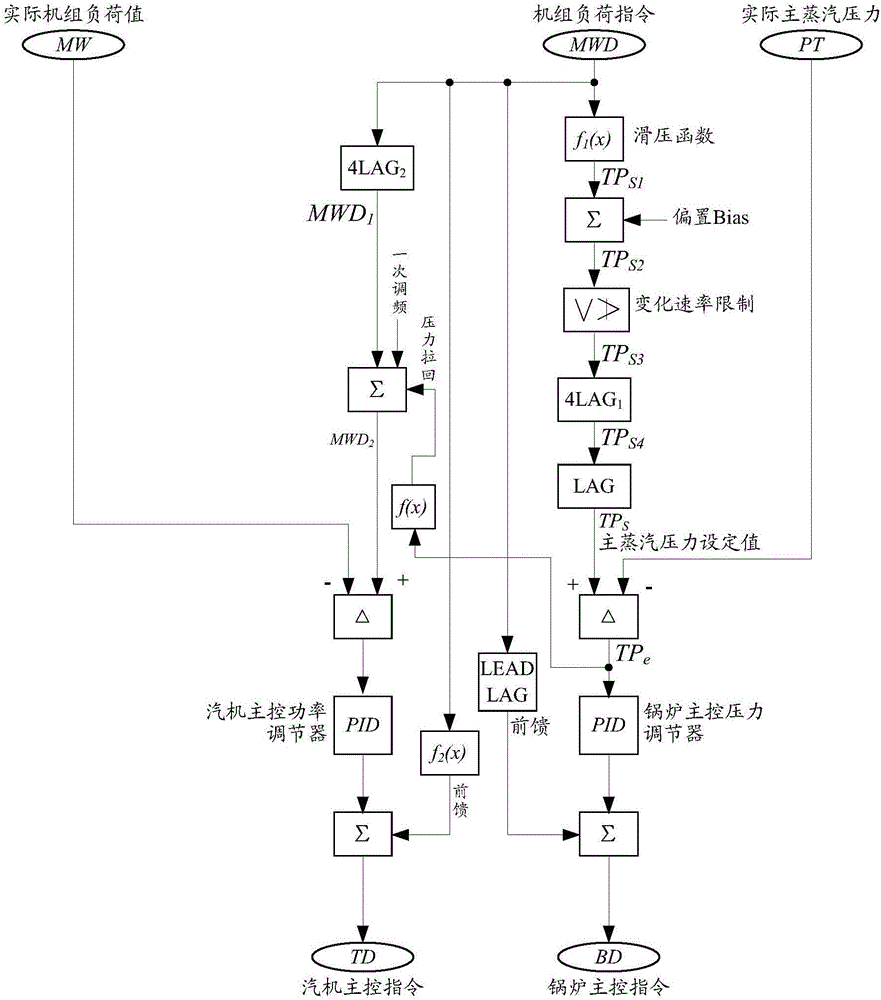

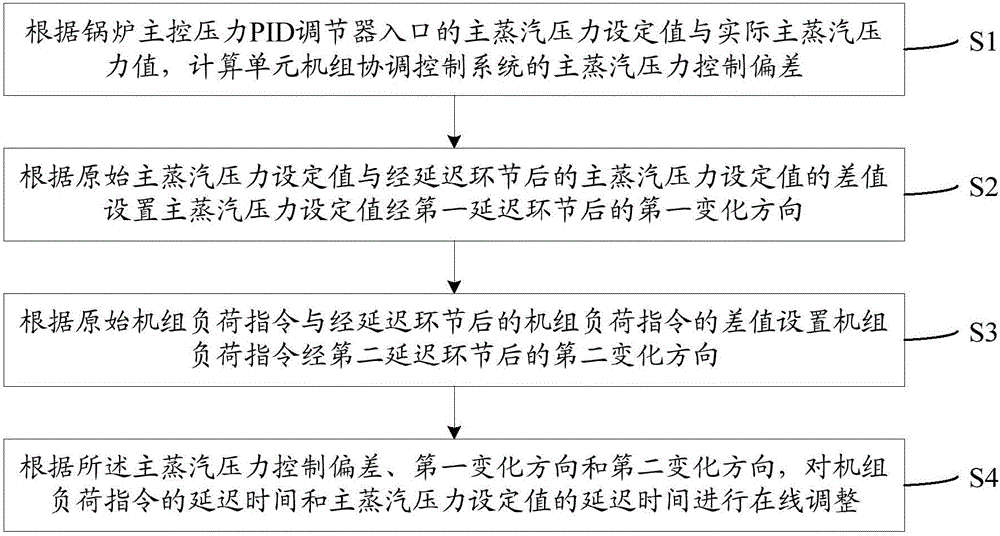

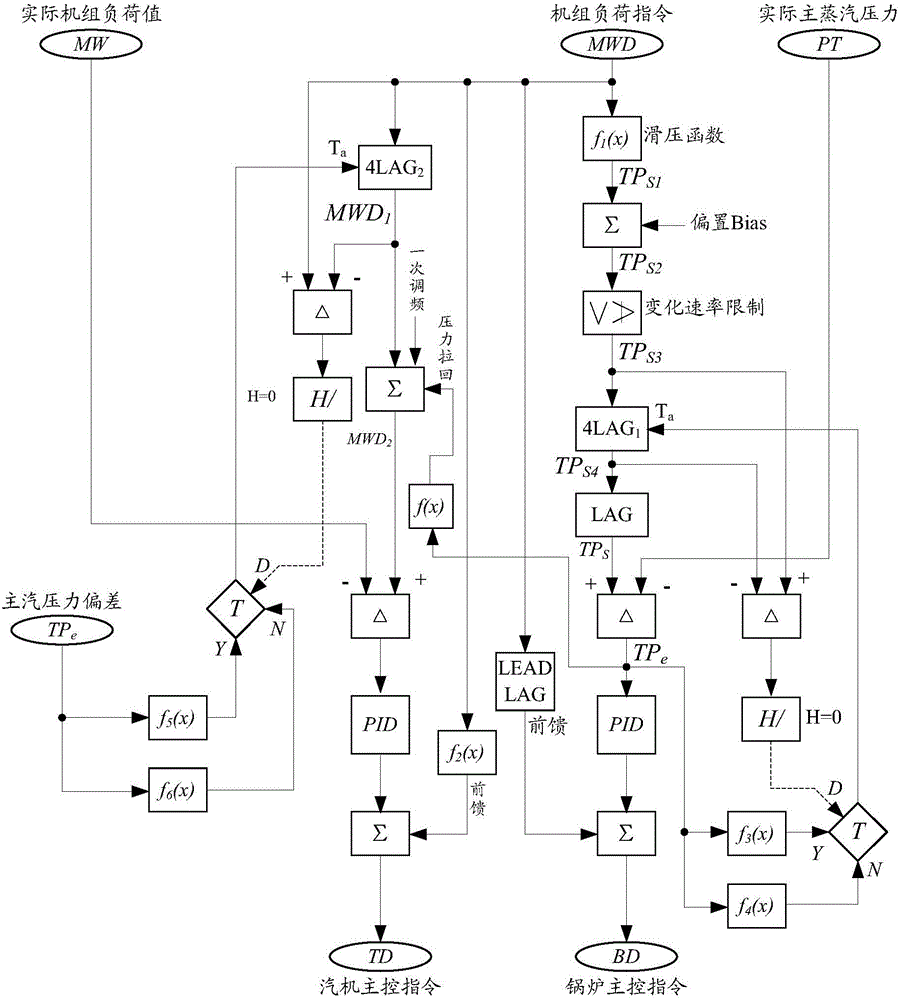

Unit plant coordinative control method and system

ActiveCN105114141AAvoid over-regulationMain steam pressure control deviation reducedSteam engine plantsLoad instructionSteam pressure

The invention relates to a unit plant coordinative control method and system. The method includes the steps of calculating the main steam pressure control deviation of the unit plant coordinative control system according to a main steam pressure set value and an actual main steam pressure value at the inlet of a boiler main control pressure PID adjustor, setting the first change direction, obtained after a first delay link, of the main steam pressure set value according to the difference value between an original main steam pressure set value and the main steam pressure set value obtained after the delay link, setting the second change direction, obtained after a second delay link, of a plant load instruction according to the difference value between an original plant load instruction and the unit load instruction obtained after the delay link, and online adjusting the delay time of the plant load instruction and the delay time of the main steam pressure set value according to the main steam pressure control deviation, the first change direction and the second change direction.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

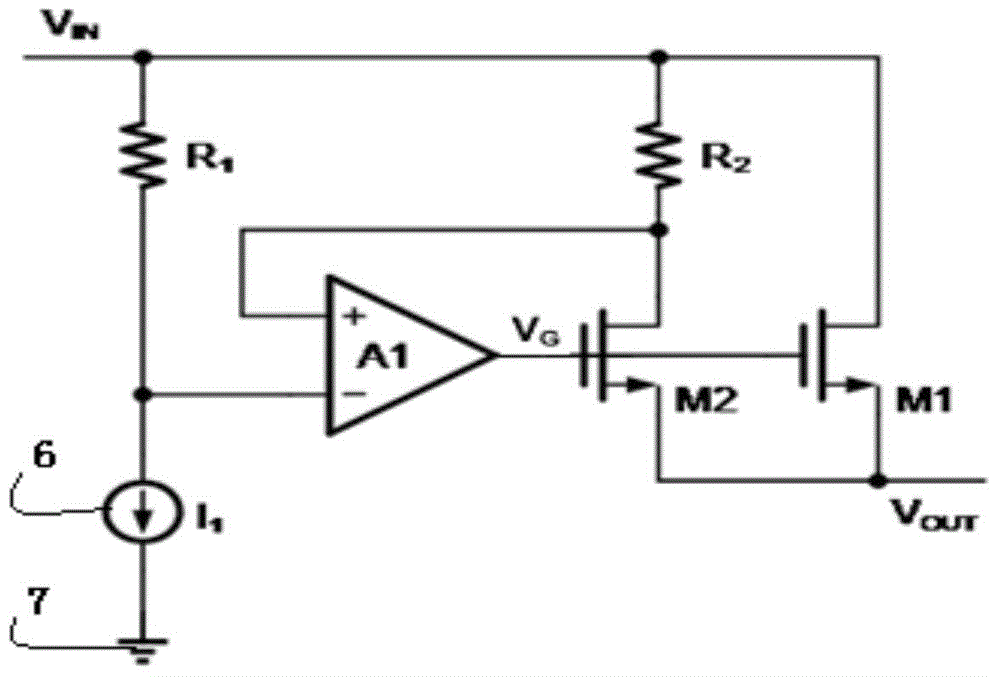

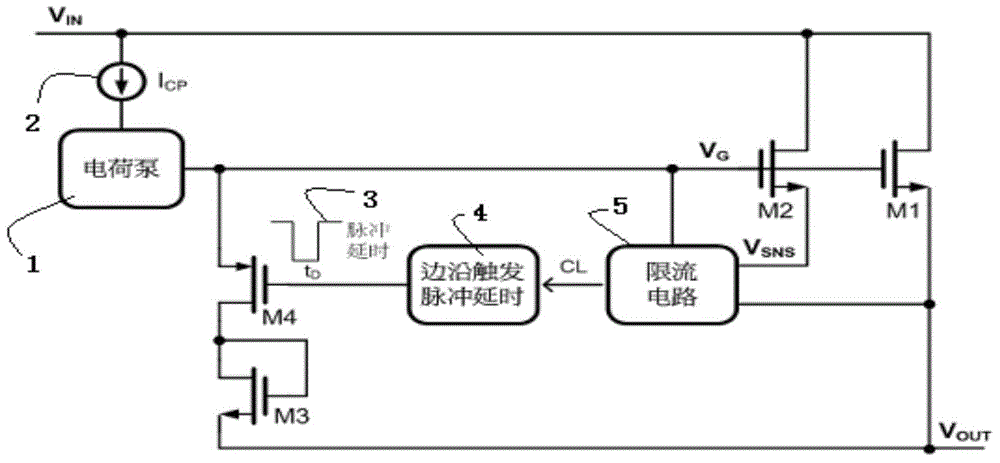

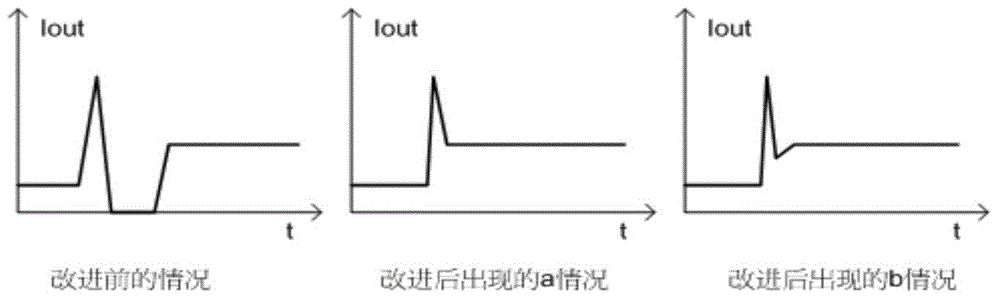

Device for preventing current limiting circuit from being adjusted excessively

ActiveCN104143818AImprove protectionAvoid over-regulationEmergency protective arrangements for limiting excess voltage/currentCurrent limitingEngineering

The invention provides a device for preventing a current limiting circuit from being adjusted excessively. The device can well protect the safety of an upstream power source by preventing output current from being zero in short time during current limitation. The device comprises a double-MOS-tube structure formed by combining a power MOS tube and an induction MOS tube. A grid of the power MOS tube and a grid of the induction MOS tube are connected. The current output end of the power MOS tube is connected with the voltage output end. The source drain current input end of the power MOS tube and the source drain current input end of the induction MOS tube are connected with the voltage input end. The source drain current output end of the induction MOS tube is connected with a current limiting circuit module. The source drain current output end of the power MOS tube is directly connected with the voltage output end. The current limiting circuit module is connected with the voltage output end, a grid voltage node and an edge trigger pulse delay circuit module. The current limiting circuit module and the edge trigger pulse delay circuit module are connected with the grid voltage node through a selection conducting MOS tube. The selection conducting MOS tube is connected with the voltage output end or the voltage input end through a transition MOS tube.

Owner:SG MICRO

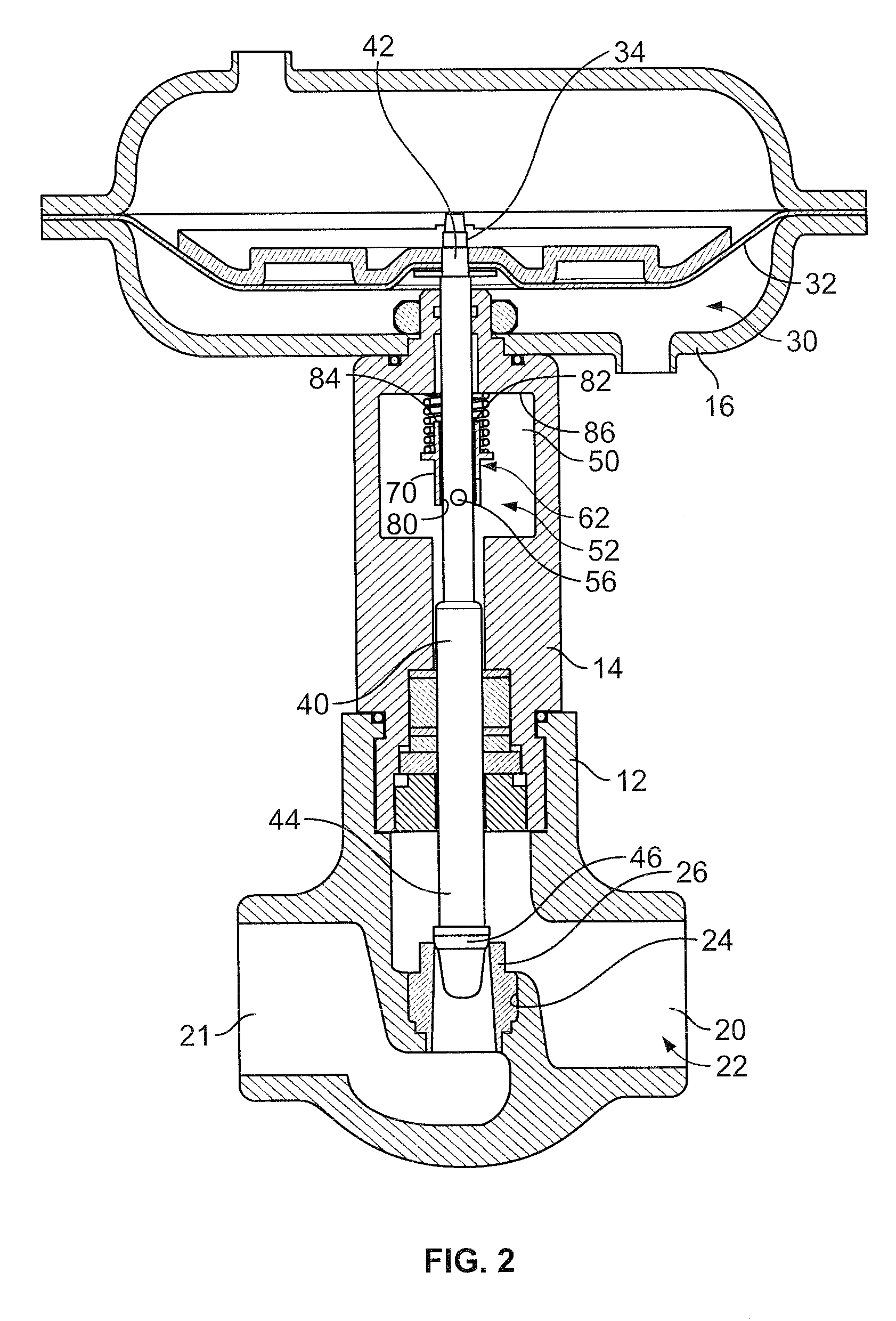

Valve flow adjustment device

ActiveUS20080197310A1Travel can be limitedEasy to adjustOperating means/releasing devices for valvesLift valveEngineeringValve stem

A valve with a flow adjustment device in the form of a valve stem travel limiter includes a collar having a passage therethrough to receive a valve stem having a projection, the collar further includes a plurality of grooves having different depths. The flow adjustment device may be assembled to a valve stem to permit a plurality of different predetermined valve stem travel limits corresponding to respective different maximum flow capacities of the valve.

Owner:FISHER CONTROLS INT LLC

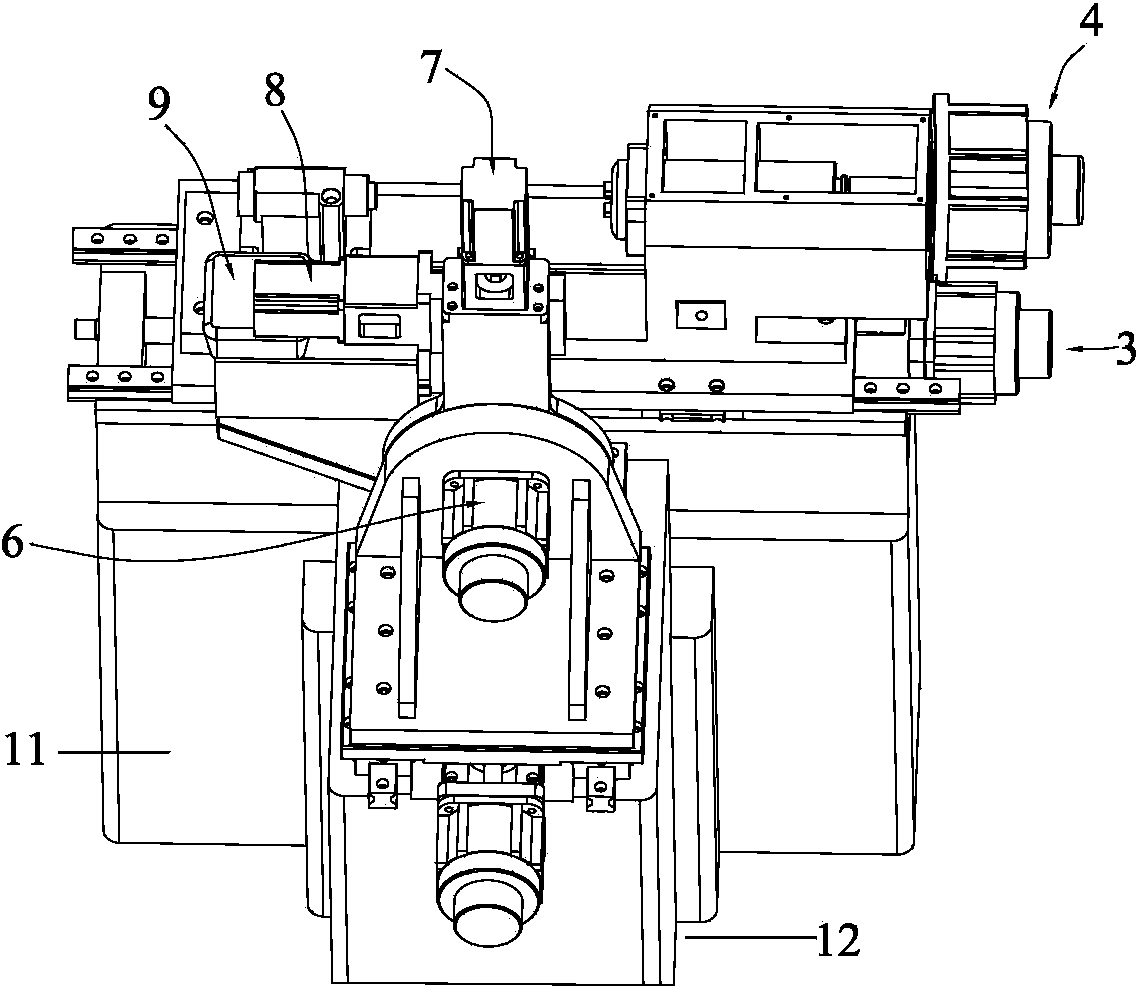

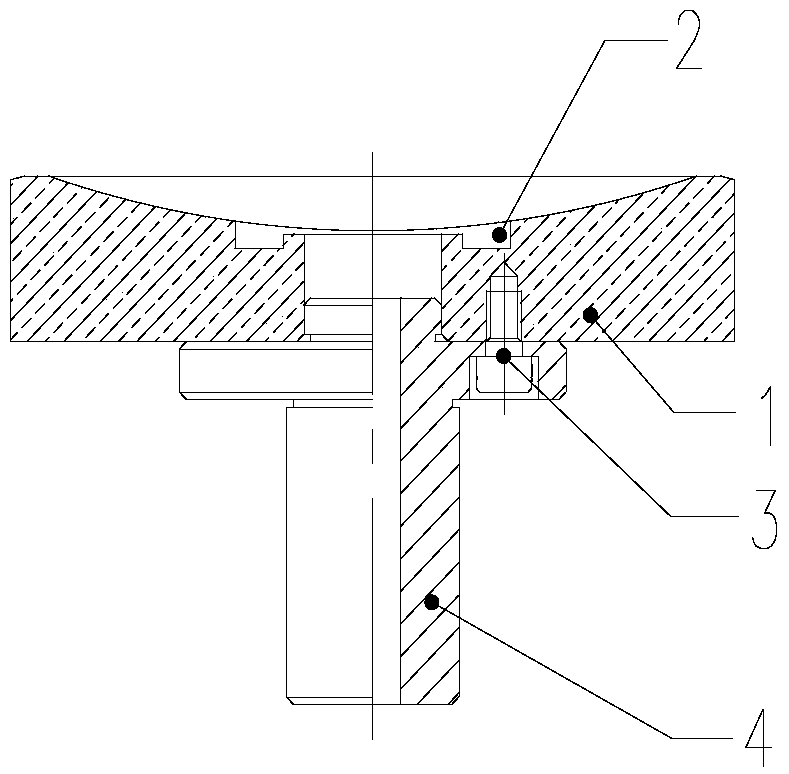

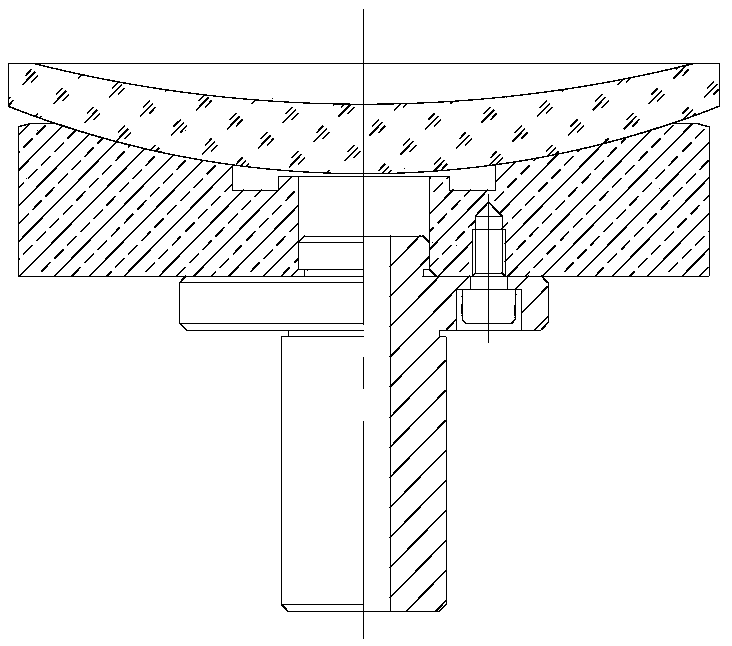

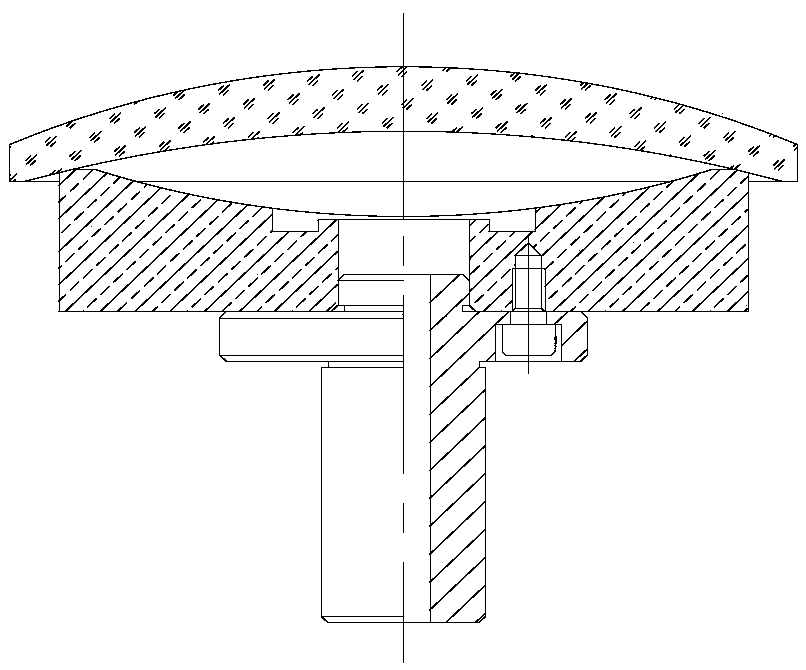

Multifunctional numerical-control spherical optical element milling and grinding tool

InactiveCN105538087AAvoid over-regulationFew linksOptical surface grinding machinesLensNumerical controlEngineering

The invention discloses a multifunctional numerical-control spherical optical element milling and grinding tool. The multifunctional numerical-control spherical optical element milling and grinding tool comprises a clamp main body and a connector. The clamp main body comprises a body, an inward-concave spherical surface formed on the upper portion of the body, an annular platform formed on the periphery of the inward-concave spherical surface, and an outward-convex spherical surface formed on the periphery of the annular platform. The radius of the inward-concave spherical surface is consistent with that of a convex surface of an optical element to be machined, and the inward-concave spherical surface is used for supporting and placing the convex surface of the optical element to be machined. The width of the annular platform is not smaller than 4 mm, and the annular platform is used for supporting and placing a plane of the optical element to be machined. The radius of the outward-convex spherical surface is consistent with that of a concave surface of the optical element to be machined, and the outward-convex spherical surface is used for supporting and placing a concave surface of the optical element to be machined. The connector is connected with the bottom of the clamp main body in a matched mode and used for being connected with machine tool equipment for machining the optical element in a matched and positioned mode. According to the multifunctional numerical-control spherical optical element milling and grinding tool, through one tool clamp, the inner surface and the outer surface of the element can be machined, the number of tool adjustment links is reduced, and the machining efficiency is improved; the multifunctional numerical-control spherical optical element milling and grinding tool is suitable for small-batch and multi-variety machining in the development process.

Owner:TIANJIN JINHANG INST OF TECH PHYSICS

Electro-hydraulic control engine power output device

ActiveCN102656994AAvoid over-regulationManipulation level requirements are reducedHarvestersFreewheelGear pump

The invention discloses an electro-hydraulic control engine power output device. The electro-hydraulic control engine power output device comprises a shell, a splined hub, an oil distribution base assembly, an input shaft, a piston, a driven gear hub, an output shaft, an output shaft shell, a belt pulley, a gear pump, a transfer case assembly, an oil pump oil outlet tube, an electromagnetic valve assembly, a filter assembly, an oil pump oil inlet tube and the like, wherein the shell is connected to an engine flywheel shell; the output shaft shell is connected with the rear end of the shell; the splined hub is fixed on an engine flywheel; the oil distribution base assembly is arranged at the front end of a central hole of the shell; a spline at the front end of the input shaft is inserted into the splined hub; the rear end of the input shaft is supported on the shell; a driving gear ring is fixed on the input shaft; the other end of the driving gear ring is provided with a fixed pressure plate; a driving friction plate is meshed with the driving gear ring; a driven friction plate is meshed with the driven gear hub; the driven gear hub is fixed on the output shaft through the spline and a nut; the transfer case assembly is arranged on the left side of the shell through a flange; the gear pump is arranged on the transfer case assembly; the electromagnetic valve assembly is arranged on the right side of the shell; and the filter assembly is arranged on the lower right side of the shell.

Owner:YTO LUOYANG DIESEL ENGINE CO LTD

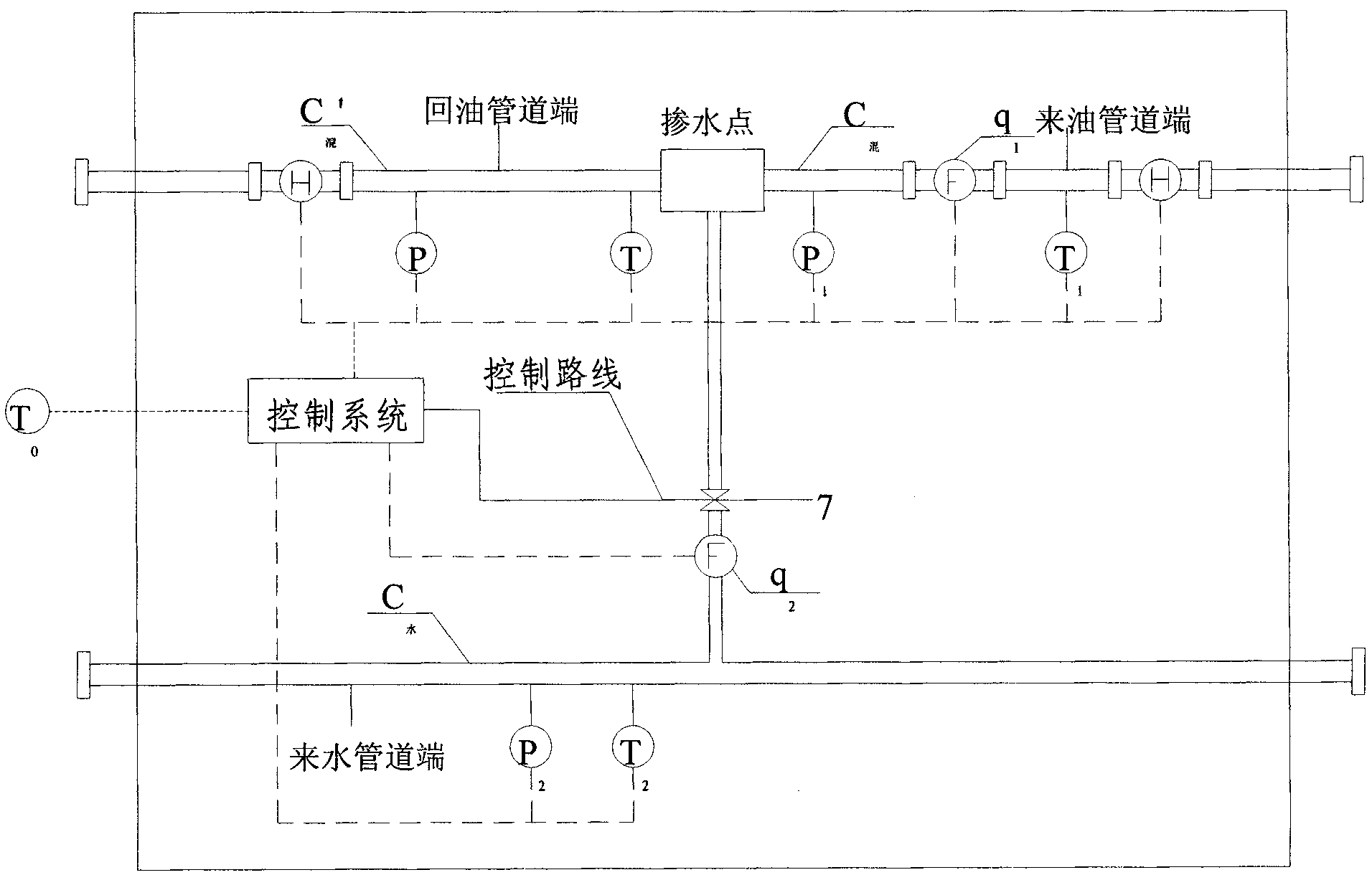

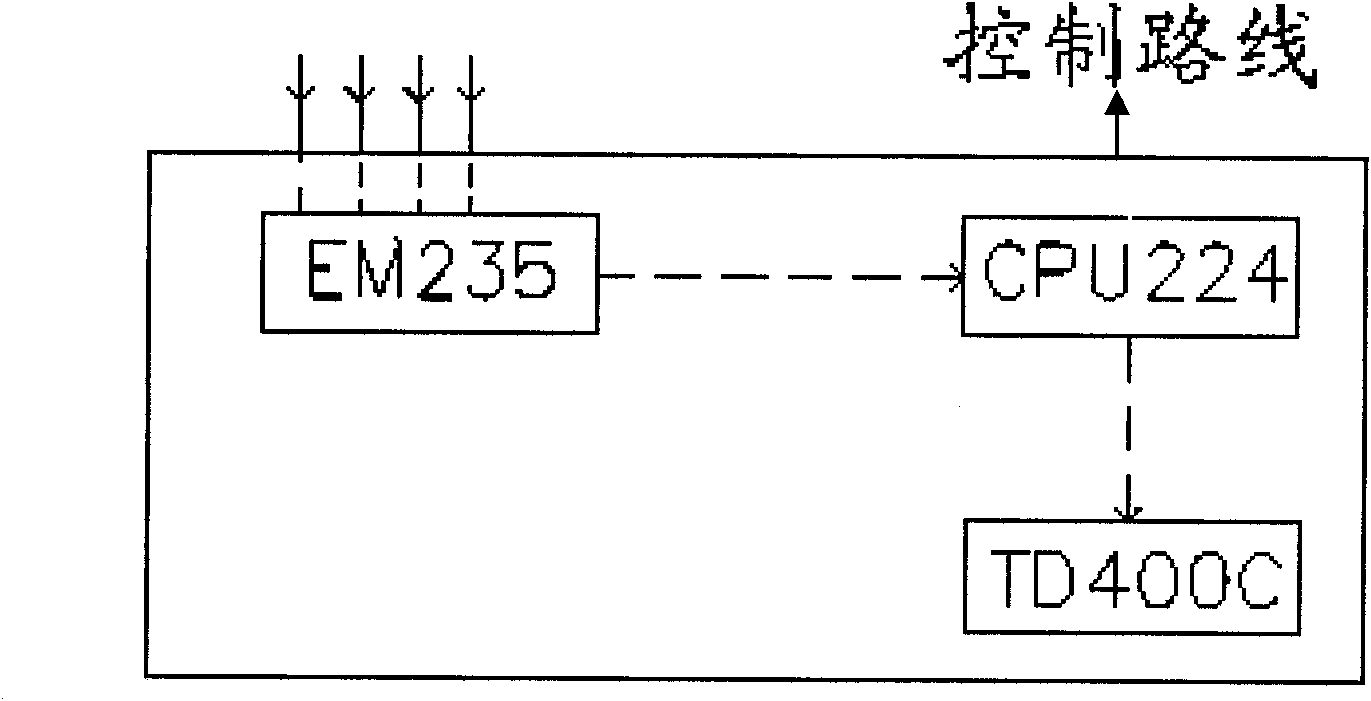

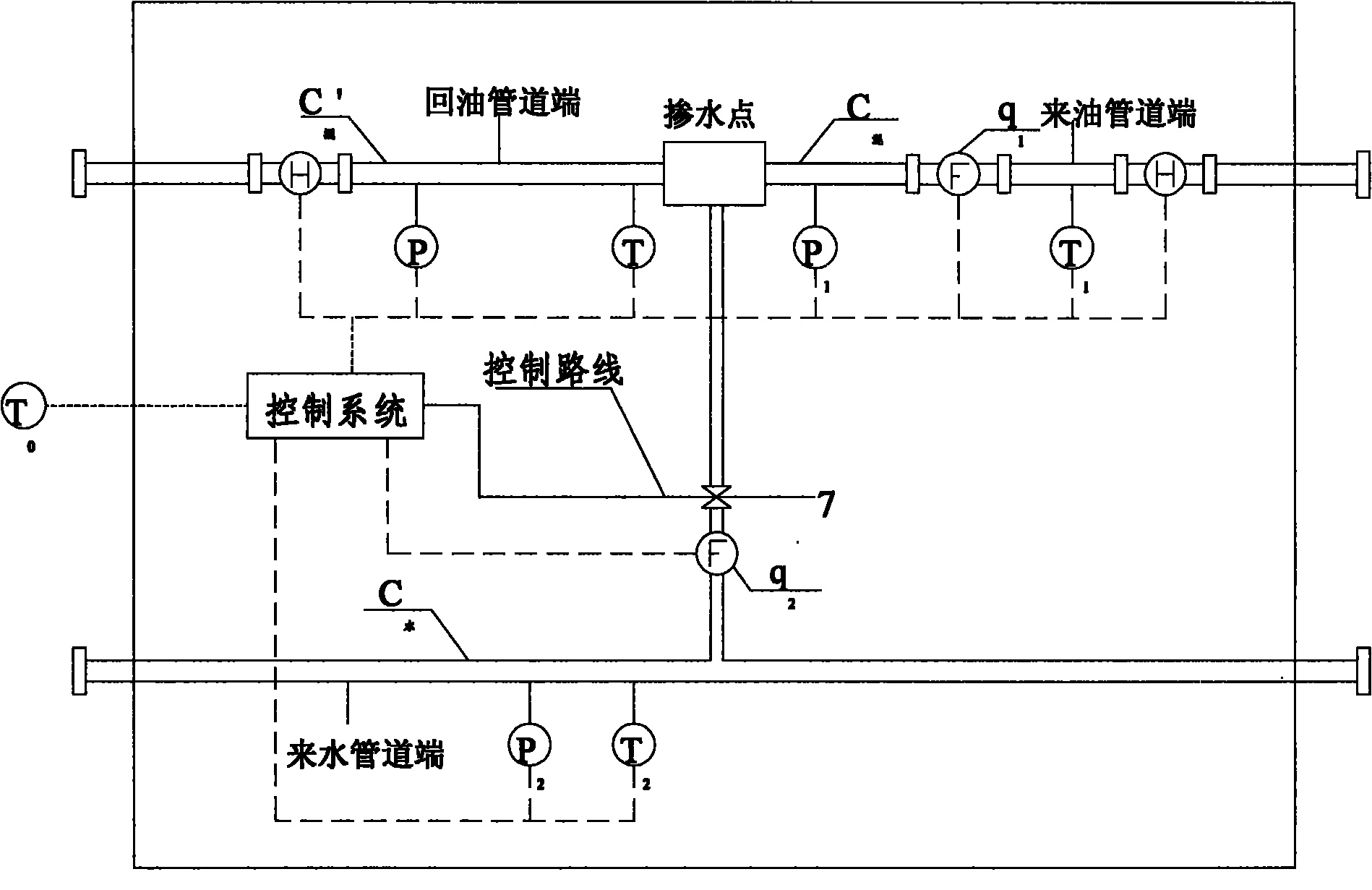

Multi-parameter energy-saving control method for watering pipe network of oil field

InactiveCN101787872APrecise temperature controlImprove efficiencyFluid removalProgramme control in sequence/logic controllersControl signalEnergy balance equation

The invention relates to a multi-parameter energy-saving control method for a watering pipe network of an oil field, which mainly solves the problem that the existing crude oil watering transportation method is difficult to meet the on-site production requirement. The method is characterized in that a PLC control system acquires data sent from an instrument arranged on the on-site pipe network; the data is substituted to a physical equation to calculate a specific heat capacity C of the oil water mixture before the watering point and a specific heat capacity C of the hot water in a water inlet pipeline; the obtained known parameters into an energy balance equation set to calculate a flow rate q2 of the hot water in a required watering pipeline; and the PLC control system outputs a control signal according to the obtained flow rate q2 of the hot water to control an electric control valve to be adjusted to the corresponding opening.

Owner:DAQING GASOLINEEUM INST

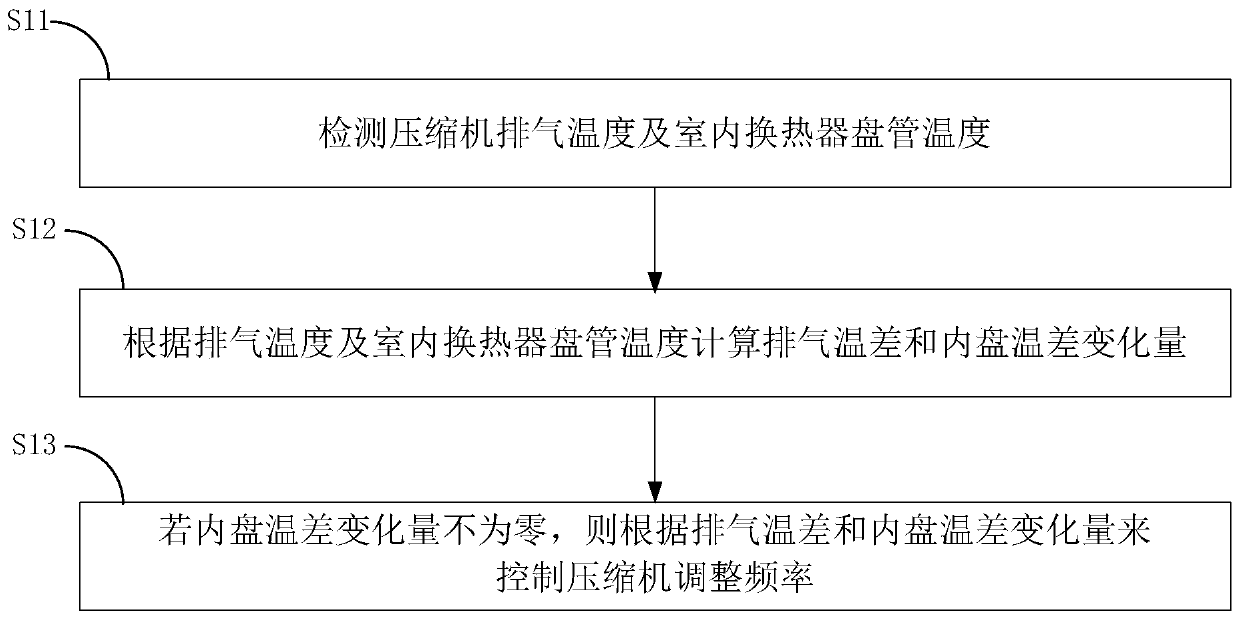

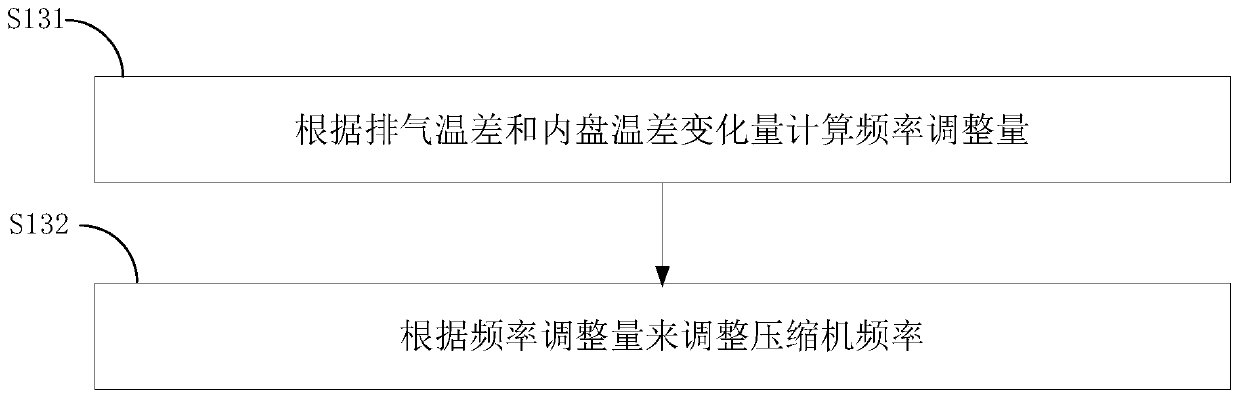

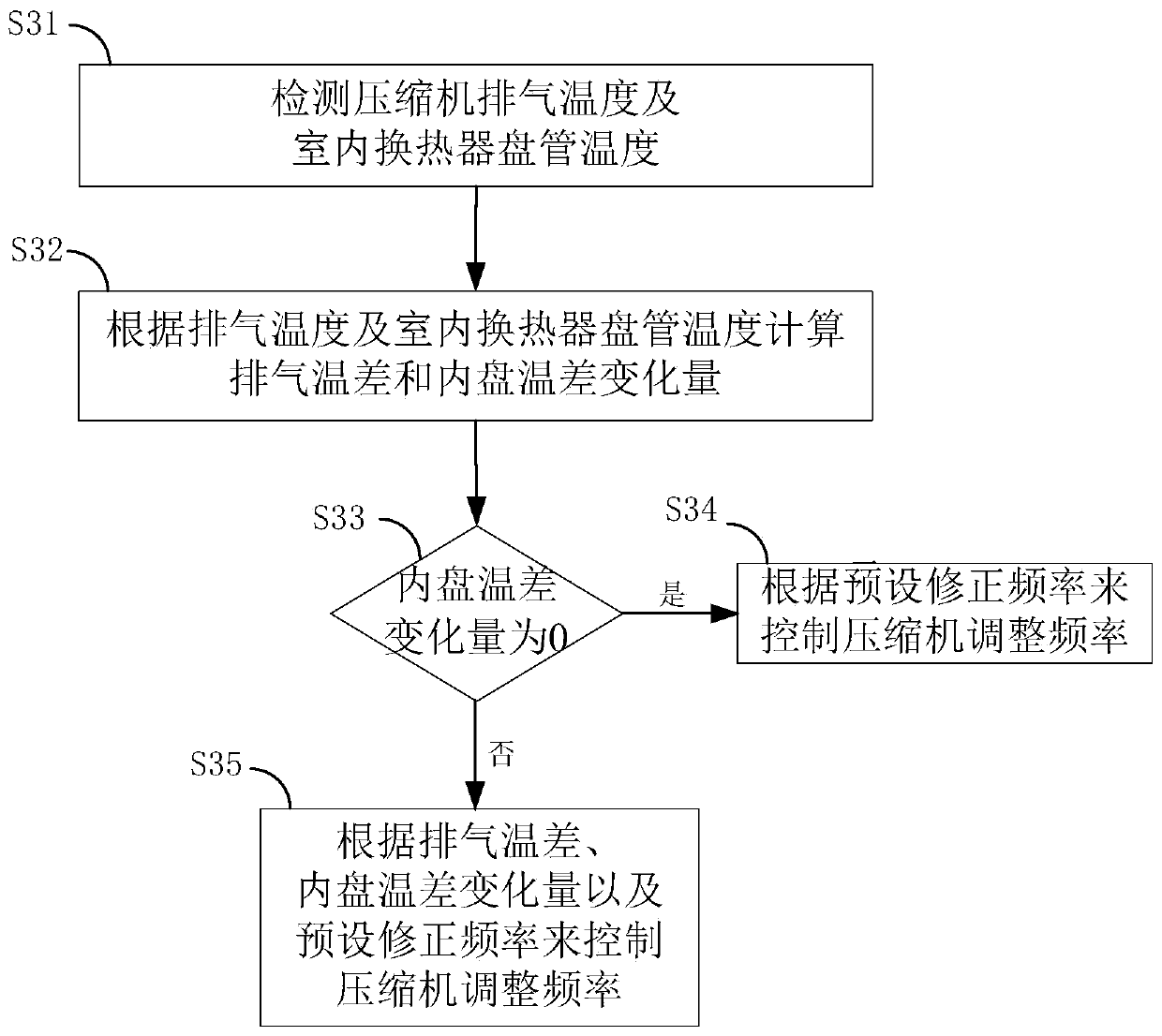

Control method and device for improving comfort of air conditioner, air conditioner and storage medium

ActiveCN110296515AAvoid frequent up/down frequencyExtended service lifeMechanical apparatusSpace heating and ventilation safety systemsEngineeringEnergy consumption

The invention provides a control method and device for improving comfort of an air conditioner, the air conditioner and a storage medium, and relates to the technical field of air conditioners. The control method comprises detecting exhaust temperature of a compressor and coil temperature of an indoor heat exchanger; calculating variation amount of exhaust temperature difference and inner plate temperature difference according to the exhaust temperature and the coil temperature of the indoor heat exchanger; and if the variation amount of the inner plate temperature difference is not zero, controlling the compressor to adjust frequency according to the variation amount of the exhaust temperature difference and the inner plate temperature difference. According to the control method and device, frequency adjustment amount of the compressor is corrected according to the variation amount of the exhaust temperature difference and the inner plate temperature difference of the compressor, so that operation frequency of the compressor is accurately controlled; frequent frequency rise and fall of the compressor can be effectively avoided; service life of the compressor is prolonged; energy consumption of the system is reduced; operation reliability of the system is improved; temperature fluctuation caused by excessive adjustment of operating frequency of the compressor can be effectivelyavoided; and use comfort of a user is improved.

Owner:NINGBO AUX ELECTRIC

Manufacturing process of toothed rubber roller

InactiveCN102658510AIdeal geometric accuracyIdeal Surface RoughnessRevolution surface grinding machinesAbrasive surface conditioning devicesHigh-speed grindingSurface roughness

The invention discloses a manufacturing process of a toothed rubber roller. The manufacturing process comprises the following steps of: inspecting a mandrel; cleaning the mandrel; coating rubber onto the mandrel; molding a blank of a silicon rubber roller; trimming the working surface of a grinding wheel; grinding the silicon rubber roller; and reshaping the silicon rubber roller. In the manufacturing process of the toothed rubber roller disclosed by the invention, an ordinary circular grinding machine is adopted, and the working surface of the grinding wheel is ground into a toothed surface which is matched with that of the toothed rubber roller, so that adjusting procedures can be reduced, grinding efficiency is high, and high-speed grinding and automatic production are easy to realize. The geometric accuracy and surface roughness of the toothed rubber roller are ideal after grinding, the quality of a product reaches the levels of national and international products, and the production cost is reduced greatly.

Owner:上海茂霖高分子科技有限公司

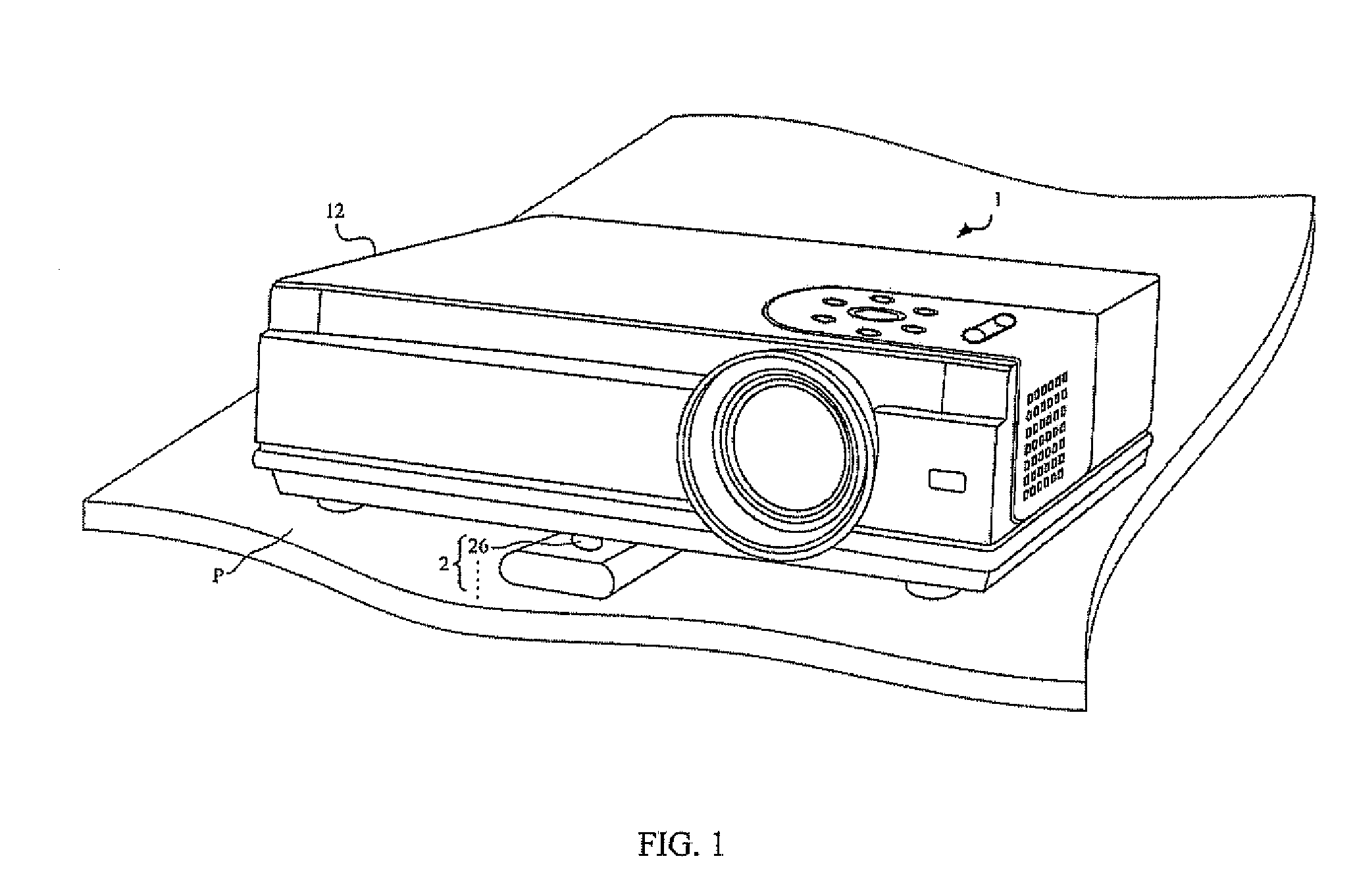

Lifting apparatus for projecting system

InactiveUS20070138451A1Comfortable and goodRealize automatic adjustmentTelevision system detailsGearingProjection systemControl theory

The invention provides a lifting apparatus for a projecting system. The lifting apparatus according to the invention includes an adjustable lifting device and a controlling device. The adjustable lifting device is used for moving a housing of the projecting system. The controlling device is coupled to the adjustable lifting device, and used for accessing, responsive to a request signal, a height datum to control the adjustable lifting device to move the housing of the projecting system in accordance with the accessed height datum.

Owner:BENQ CORP

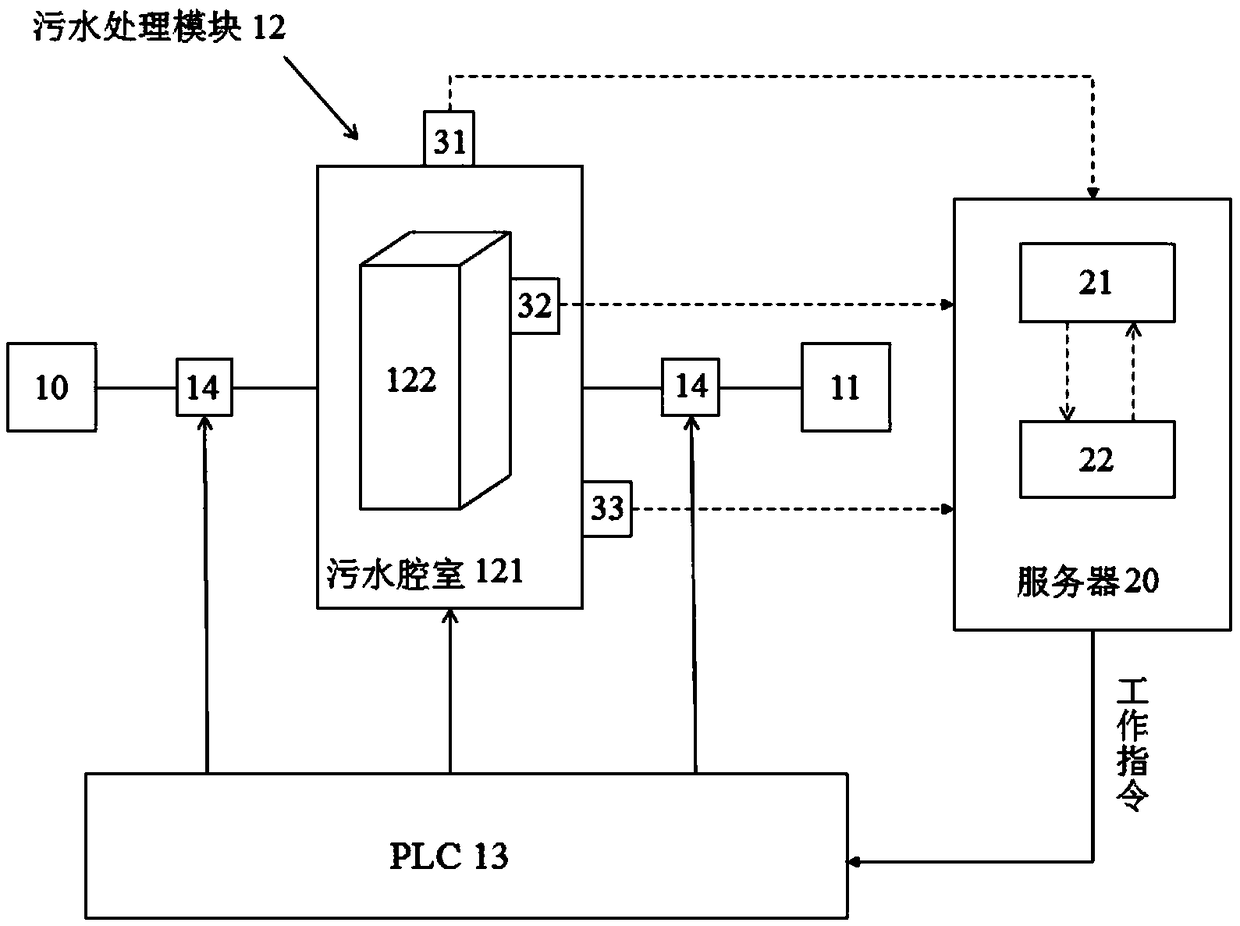

Automatic control sewage treatment system

InactiveCN109399738AImprove emergency performanceAvoid over-regulationWater treatment parameter controlTreatment control/steeringAutomatic controlState parameter

The invention relates to an automatic control sewage treatment system. The automatic control sewage treatment system comprises a sewage treatment module, a PLC (programmable logic controller), a levelsensor for detecting the water level inside a sewage tank, a state detector for detecting the working state parameters of sewage treatment equipment, a water quality data monitor for acquiring waterquality monitoring data in the sewage treatment module, and a server, wherein the server can compute and analyze the water level, the working state parameters of the sewage treatment equipment and thewater quality monitoring data to comprehensively determine the working state of the automatic control sewage treatment system; when the automatic control sewage treatment system is abnormal, the server can at the first time transmit corresponding working instructions to the PLC, and then the PLC automatically controls and adjusts the working equipment and the program parameters of the automatic control sewage treatment system. The automatic control sewage treatment system can achieve comprehensive information collection and analysis, and once abnormality occurs, can timely handle the abnormality, thereby improving the emergency capacity of enterprise sewage treatment and facilitating sewage discharge control for enterprises.

Owner:高瓴环境科技有限公司

Brake apparatus having automatic clearance adjusting mechanism with overadjustment preventer

InactiveUS7178645B2Reduce the number of partsSimple structureAxially engaging brakesBrake actuating mechanismsMechanical engineeringPiston

A brake apparatus having an automatic clearance adjusting mechanism with an overadjustment preventer constituted such that a piston is constituted by a structure of being divided in a plug piston 16 and a ring piston 14. The plug piston 16 is integrated with an adjusting nut 20, a bearing 21, a bearing support plate 22 and a spring holder 23. An outer side claw portion 23a of the holder is locked by an outer side groove 16 of the plug piston. The plug piston 16 integrated with the respective parts is inserted to fit to the ring piston 14 to thereby prevent the outer side claw portion 23a of the holder from being detached.

Owner:AKEBONO BRAKE IND CO LTD

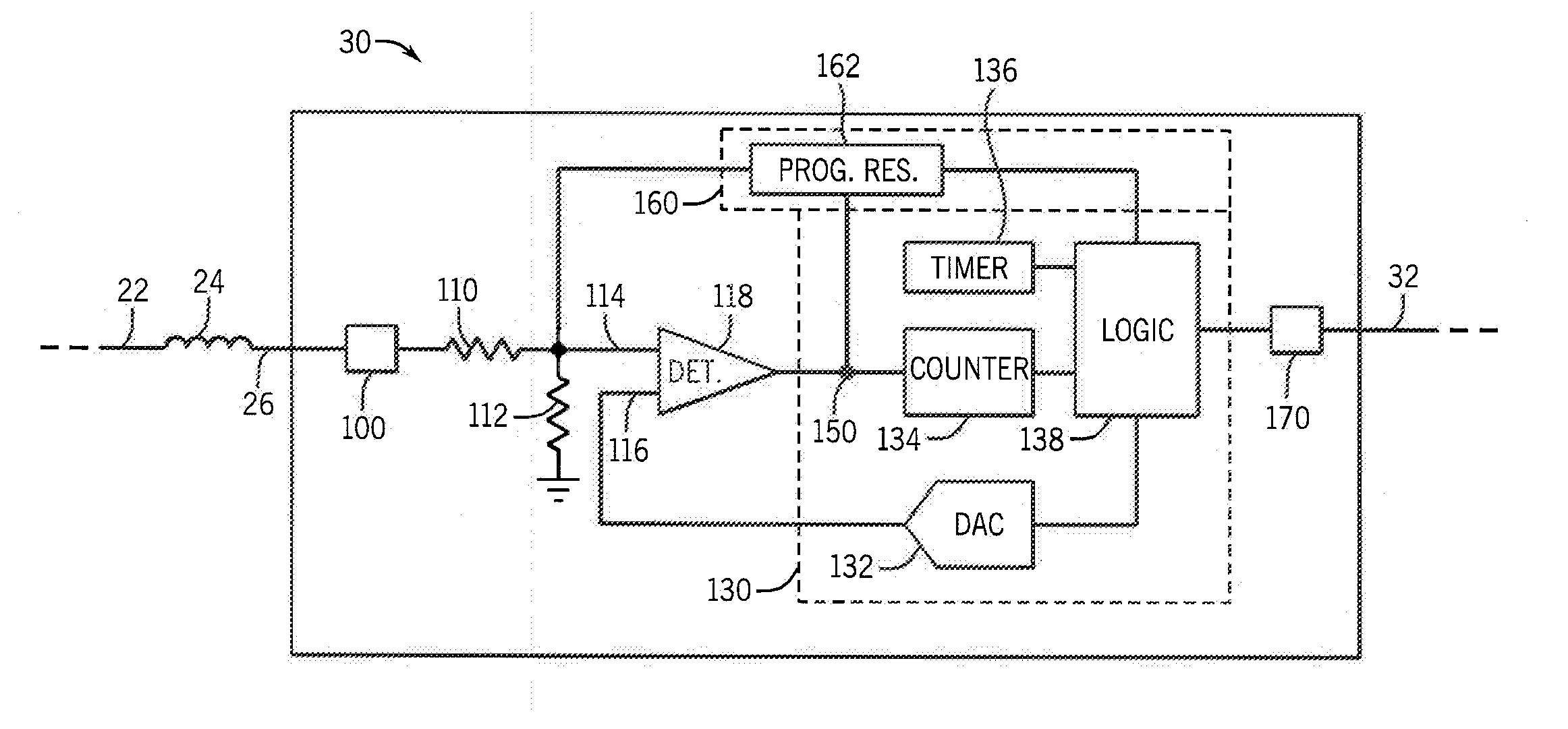

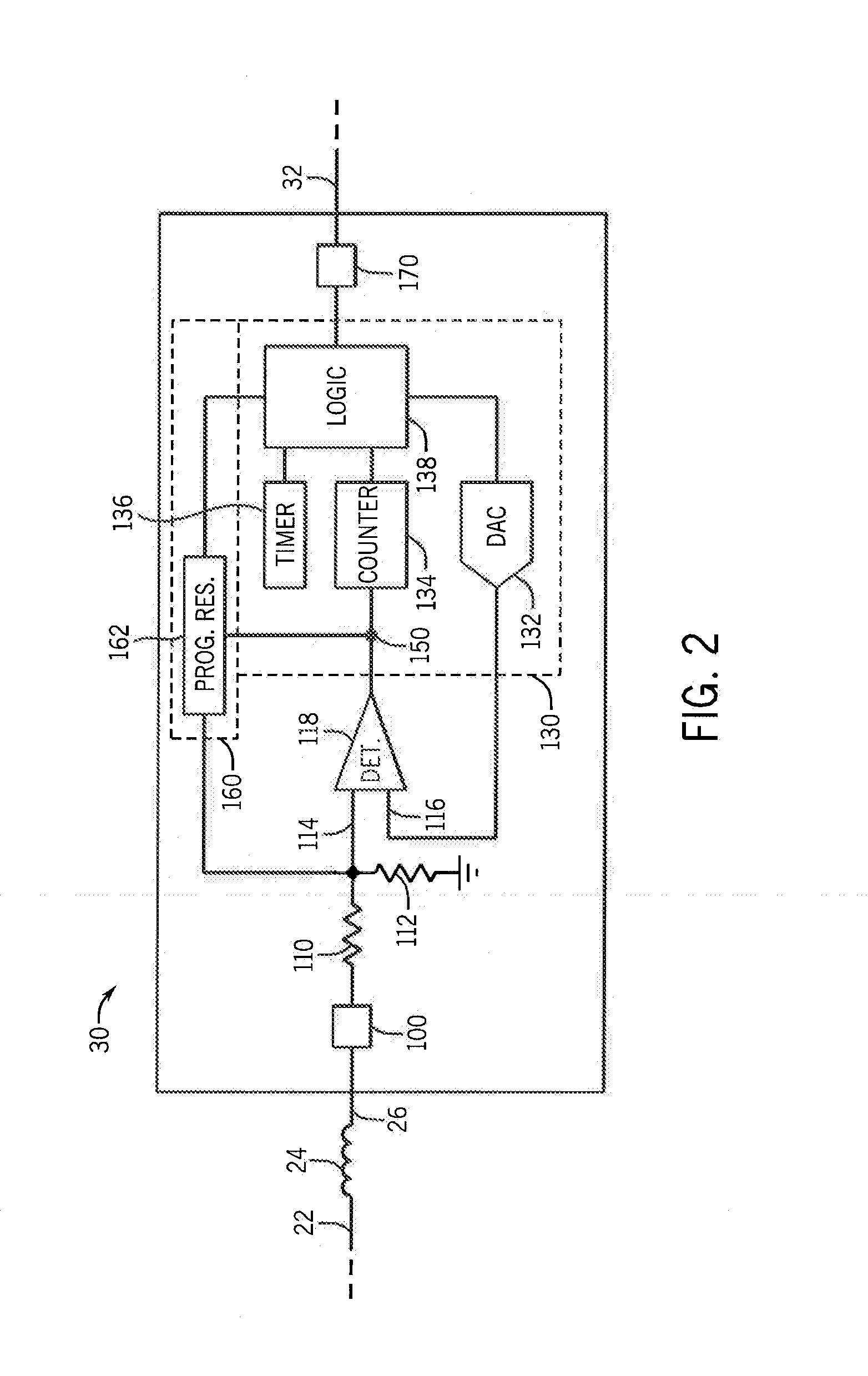

Adaptive Threshold Voltage For Frequency Input Modules

ActiveUS20130271112A1Easy to distinguishQuantity maximizationSpectral/fourier analysisConverting sensor outputHysteresisElectricity

Systems and methods for an industrial I / O controller circuit for frequency input modules that measure the frequency of an electrical input signal using adaptive threshold voltage and / or adaptive hysteresis feedback are shown and described. The systems and methods provide advantages in that the I / O controller circuit can better distinguish between actual input pulses from the electrical input signal, as opposed to unwanted Electromagnetic Interference (EMI) induced input pulses. This maximizes the amount of EMI rejection, independent of the frequency of the moving machine, and results in less time to commission and adjust a sensor, fewer false frequency measurements and less system down time.

Owner:ROCKWELL AUTOMATION TECH

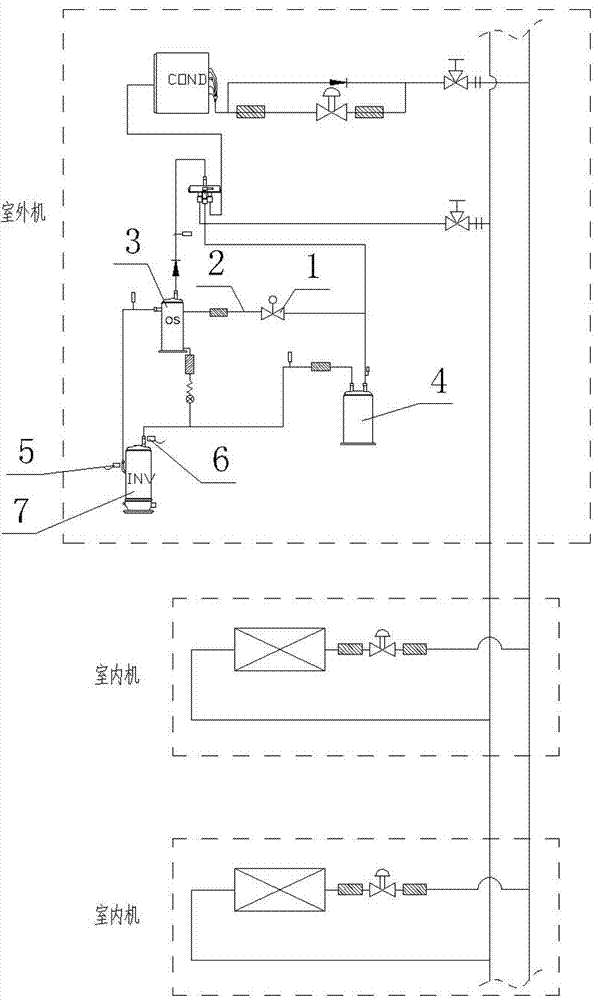

Oil mass regulating and controlling method for multi-connected air conditioning unit

ActiveCN103791658AAvoid oil starvationDoes not affect legacy functionalityCompressorPressure sensorVapor–liquid separator

The invention discloses an oil mass regulating and controlling method for a multi-connected air conditioning unit. The oil mass regulating and controlling method includes the following concrete steps that a, an oil separator (3) and a gas-liquid separator (4) are communicated through an auxiliary oil return pipe (2); b, the outlet pressure value of a compressor (7) is collected through a first pressure sensor (5), and the inlet pressure value of the compressor (7) is collected through a second pressure sensor (6); c, the high and low pressure ratio of the compressor (7) and the unit load ratio are calculated; d, whether the two conditions that the high and low pressure ratio is larger than 2.6 for 60 min, and the load ratio of the unit is larger than 75% for 60 min are met or not is judged, and if the one or two conditions are met, the next step is executed; e, an auxiliary oil return valve (1) is opened, so that oil in the oil separator (3) is pressed into the gas-liquid separator (4). The method can prevent lubricating oil in the compressor (7) from entering a refrigerating or heating circulating pipeline.

Owner:NINGBO AUX ELECTRIC

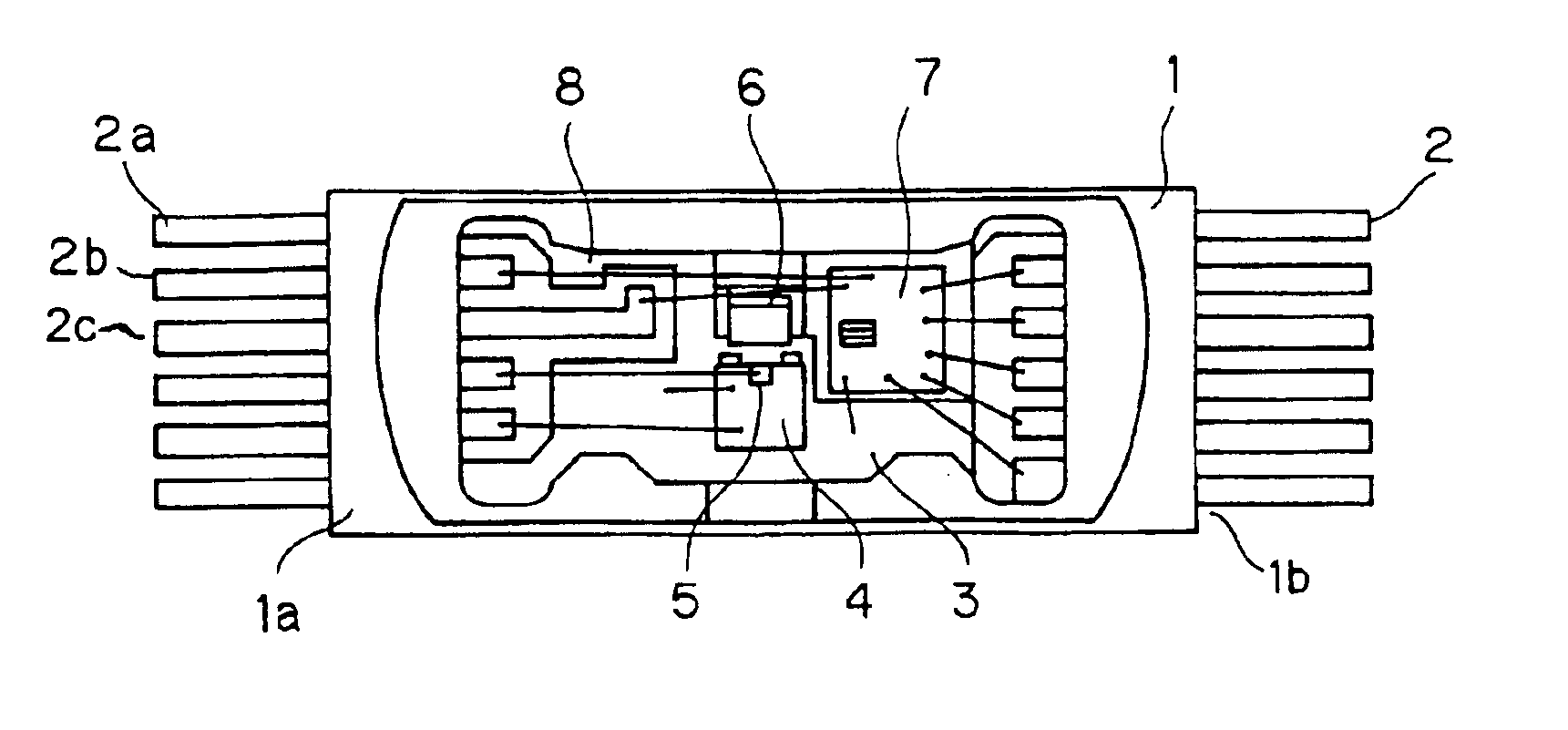

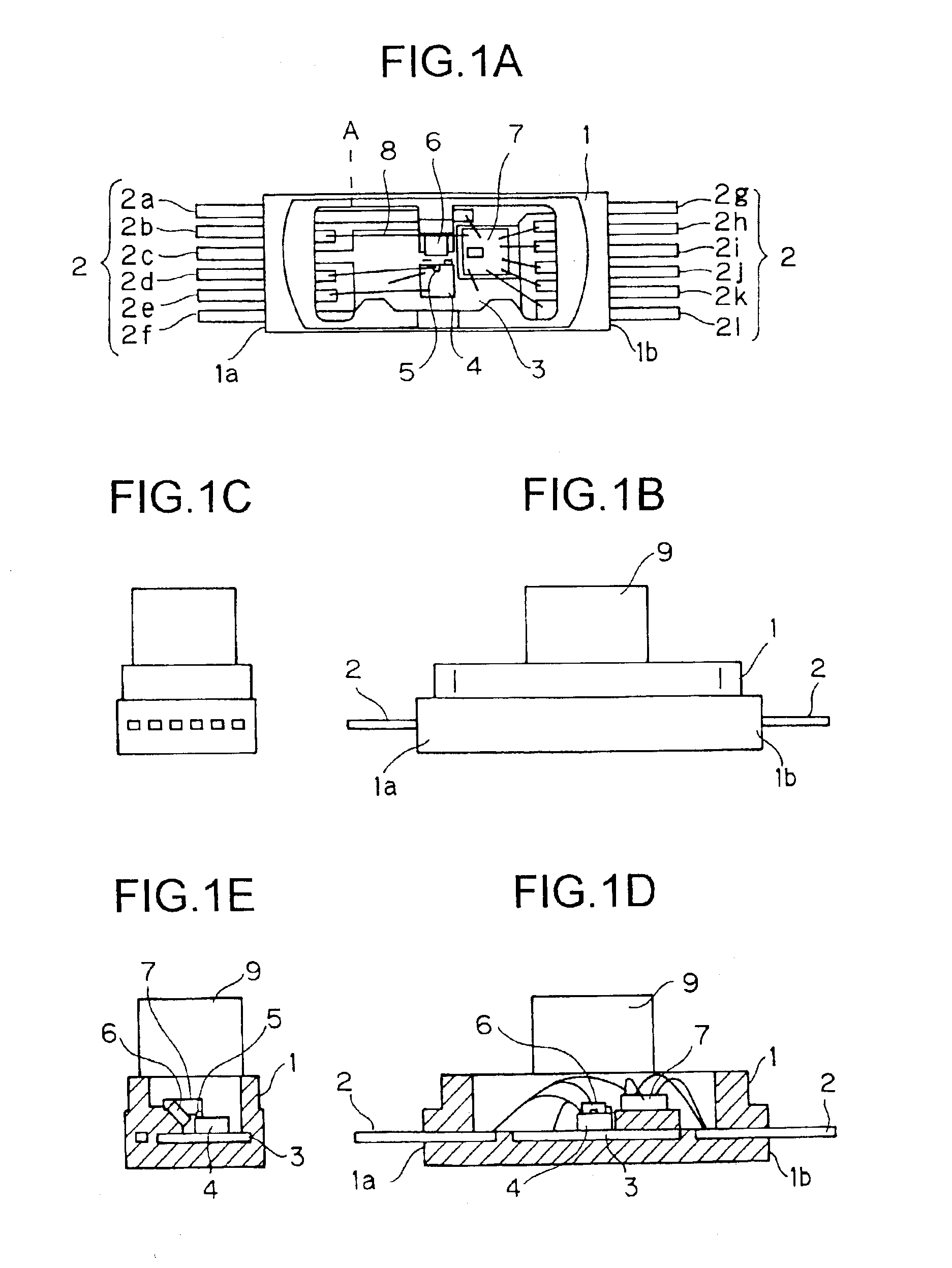

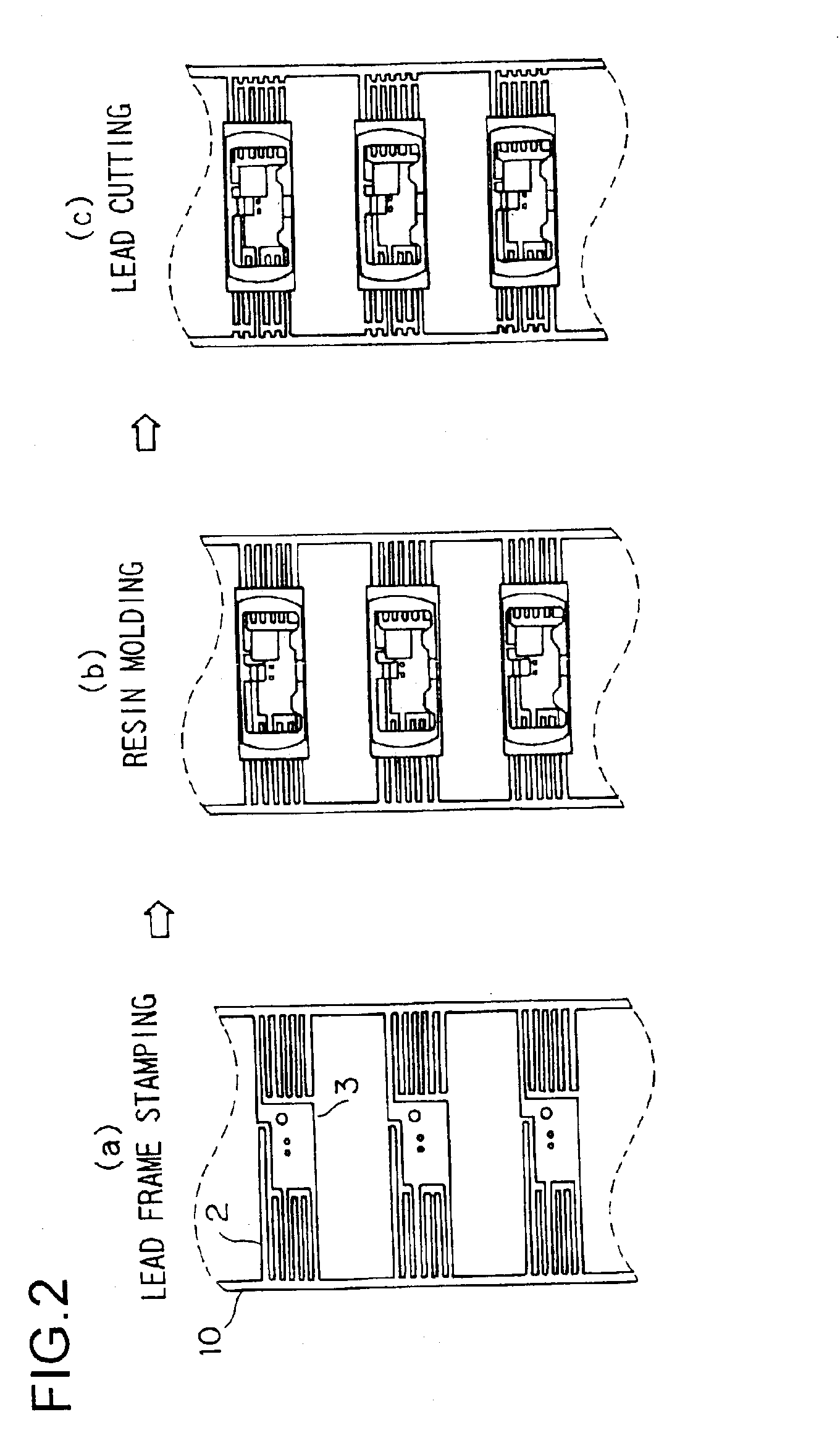

Semiconductor laser device, method of fabricating the same, and optical pickup employing the same

InactiveUS6868105B2Satisfactory wire connectionEasy to adjust the positionOptical beam sourcesSemiconductor laser structural detailsOptical pickupMiniaturization

A semiconductor laser device that is suitable for mass production, that permits an improved wire layout, and that permits miniaturization includes leads disposed through each of two side faces of an insulating frame member so as to run from outside to inside the insulating frame member, an LD and a light-receiving element mounted inside the insulating frame member, and wires laid inside the insulating frame member so as to connect the leads to the electrodes of the LD and the light-receiving element. Inside the insulating frame member, the tip of one lead is extended farther inward than the edge of an element mount portion that faces the tip of another lead that is disposed through the same side face of the insulating frame member.

Owner:SHARP KK

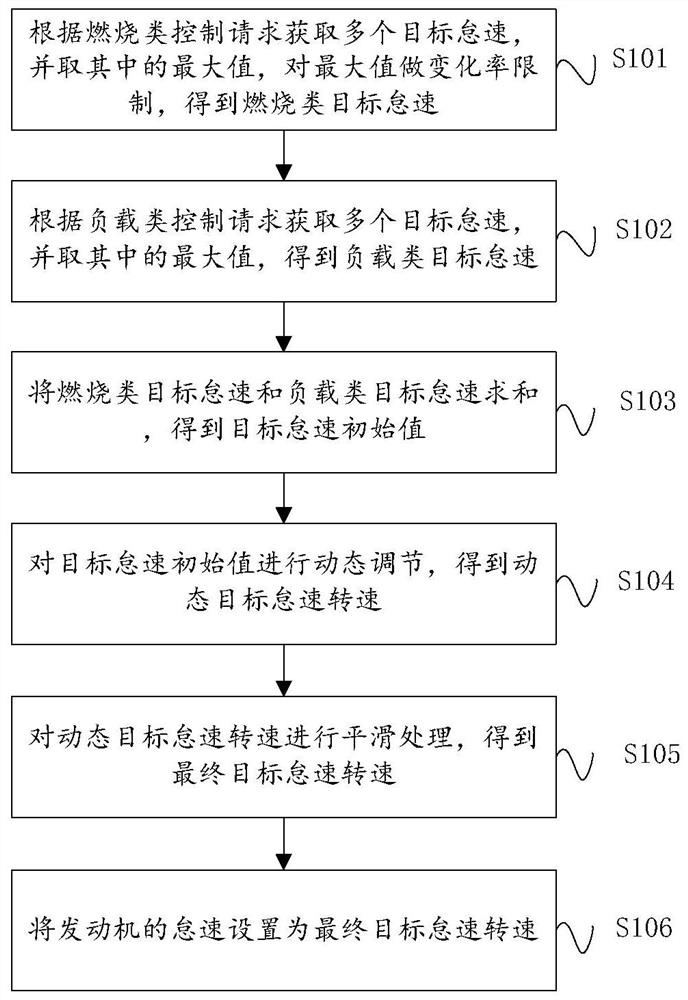

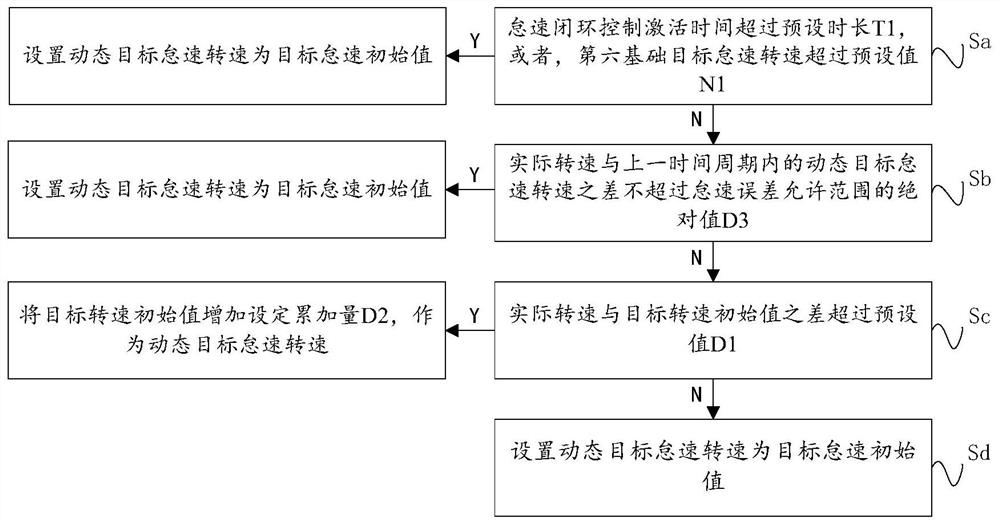

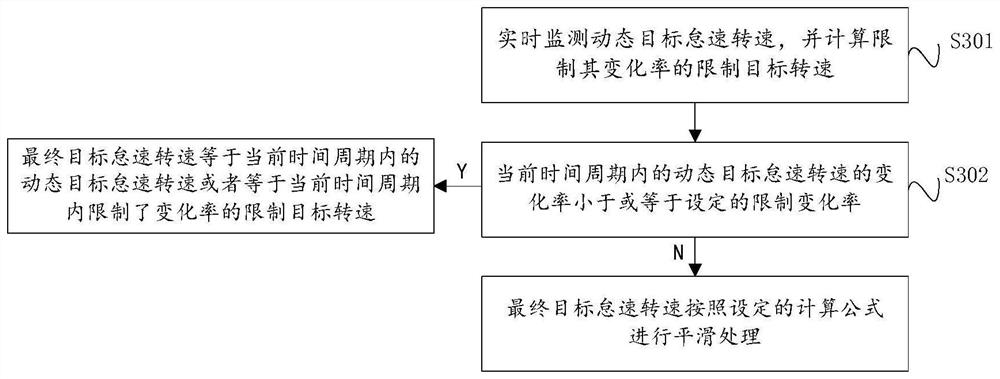

Engine idle speed target rotation speed control method

ActiveCN111765012AImprove response rateImprove stabilityElectrical controlSpeed sensing governorsLoop controlIdle speed

The invention relates to an engine idle speed target rotation speed control method. The method comprises the following steps that a plurality of target idle speeds are obtained according to combustioncontrol requirements, the maximum one of the target idle speeds is taken and subjected to change rate limiting, and a combustion target idle speed n<SetpointComb> is obtained; a plurality of target idle speeds are obtained according to load control requirements, the maximum one of the target idle speeds is taken, and a load target idle speed n<SetpointLoad> is obtained; the sum of the combustiontarget idle speed n<SetpointComb> and the load target idle speed n<SetpointLoad> is calculated to obtain a target idle speed initial value n<SetpointRaw>; the target idle speed initial value n<SetpointRaw> is subjected to dynamic regulation to obtain a dynamic target idle speed rotation speed n<SetpointDyn>; the dynamic target idle speed rotation speed n<SetpointDyn> is subjected to smoothing treatment to obtain a final target idle speed rotation speed n<SetpointFinal>; and the idle speed of an engine is set to the final target idle speed rotation speed n<SetpointFinal>. According to the engine idle speed target rotation speed control method provided by the invention, sufficient consideration is performed at the final target idle speed rotation speed of the engine, the situation that the rotation speed is too high or too low can be avoided, and in addition, the stability of idle speed closed-loop control is high.

Owner:DONGFENG MOTOR CORP HUBEI

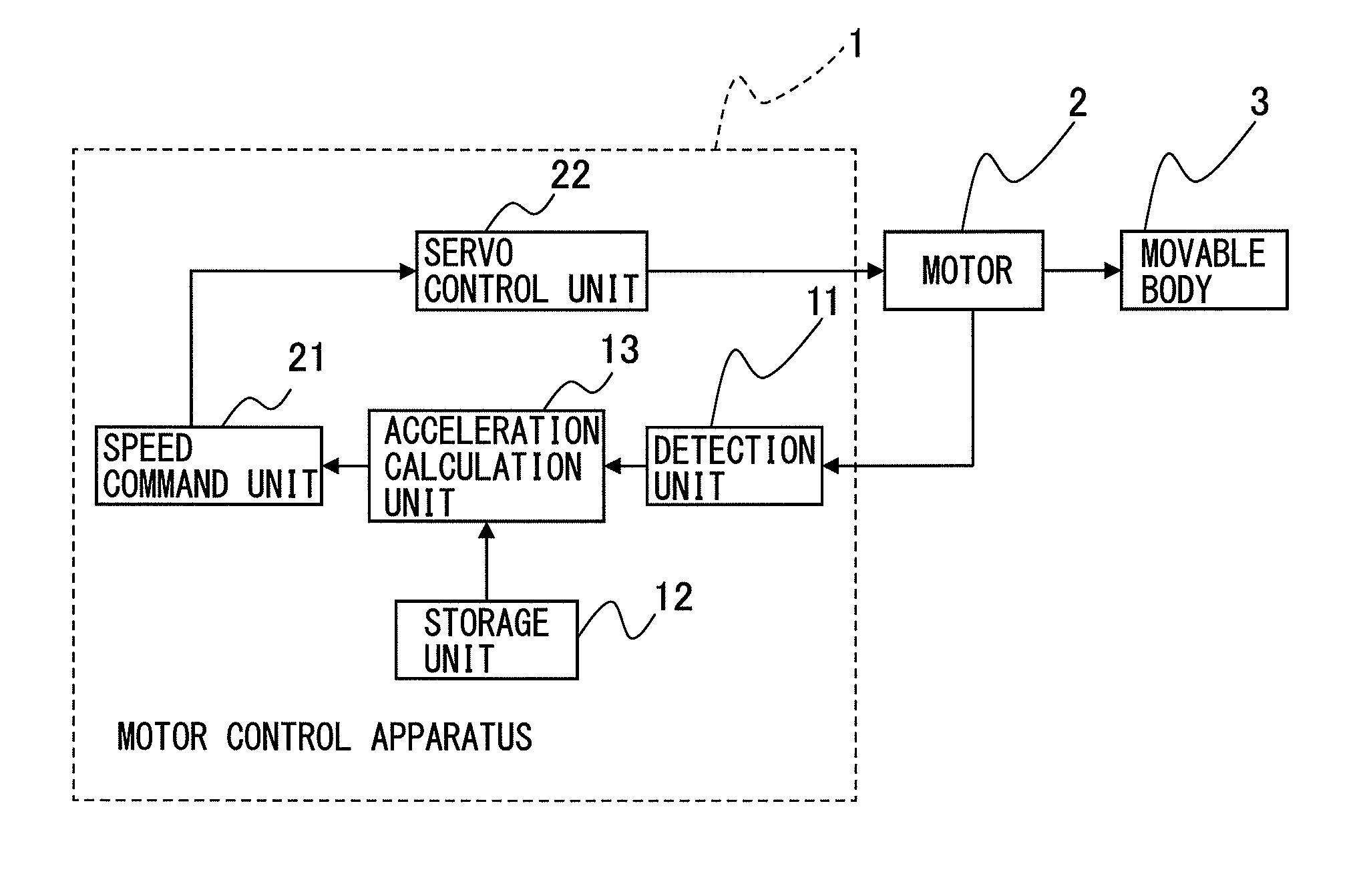

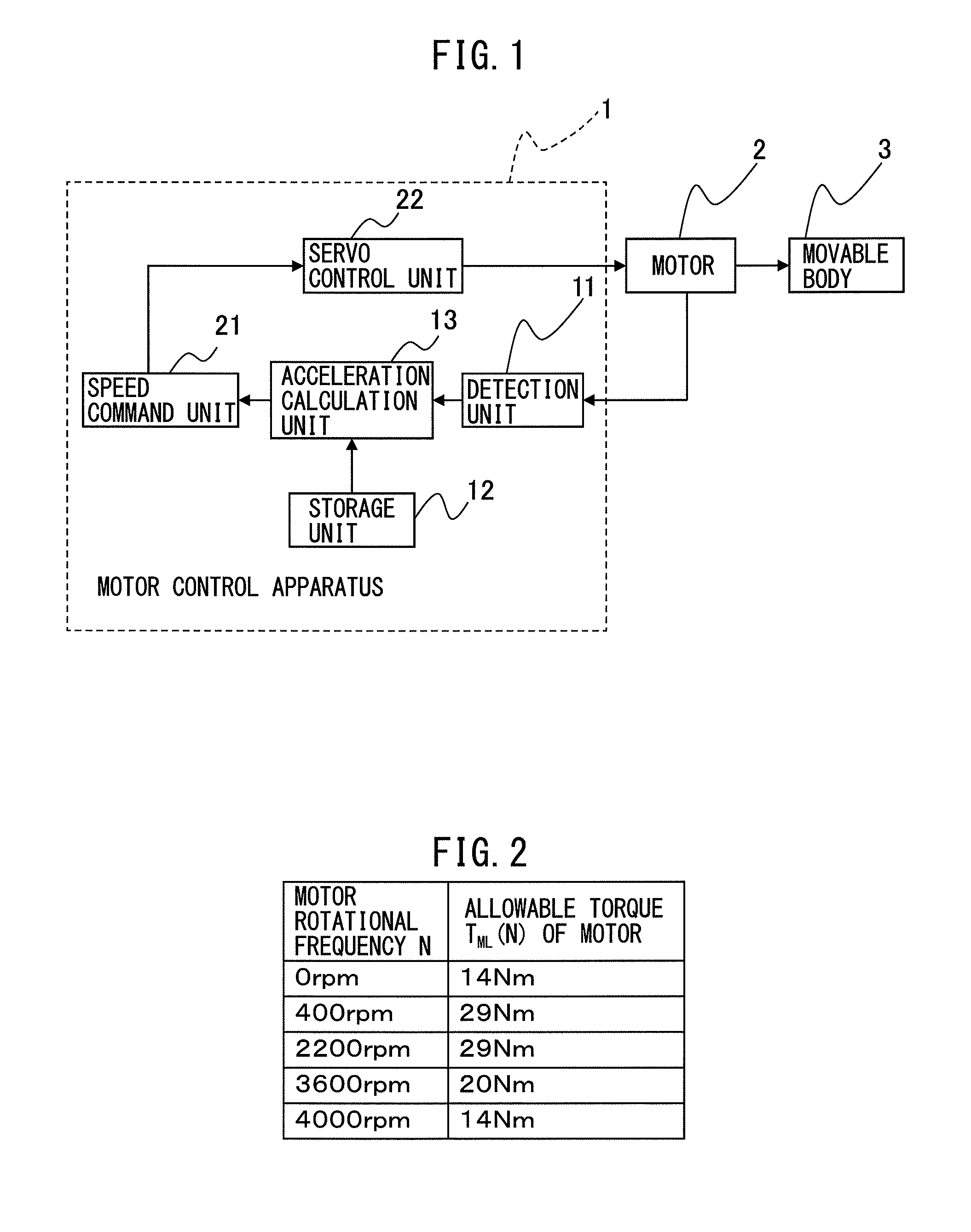

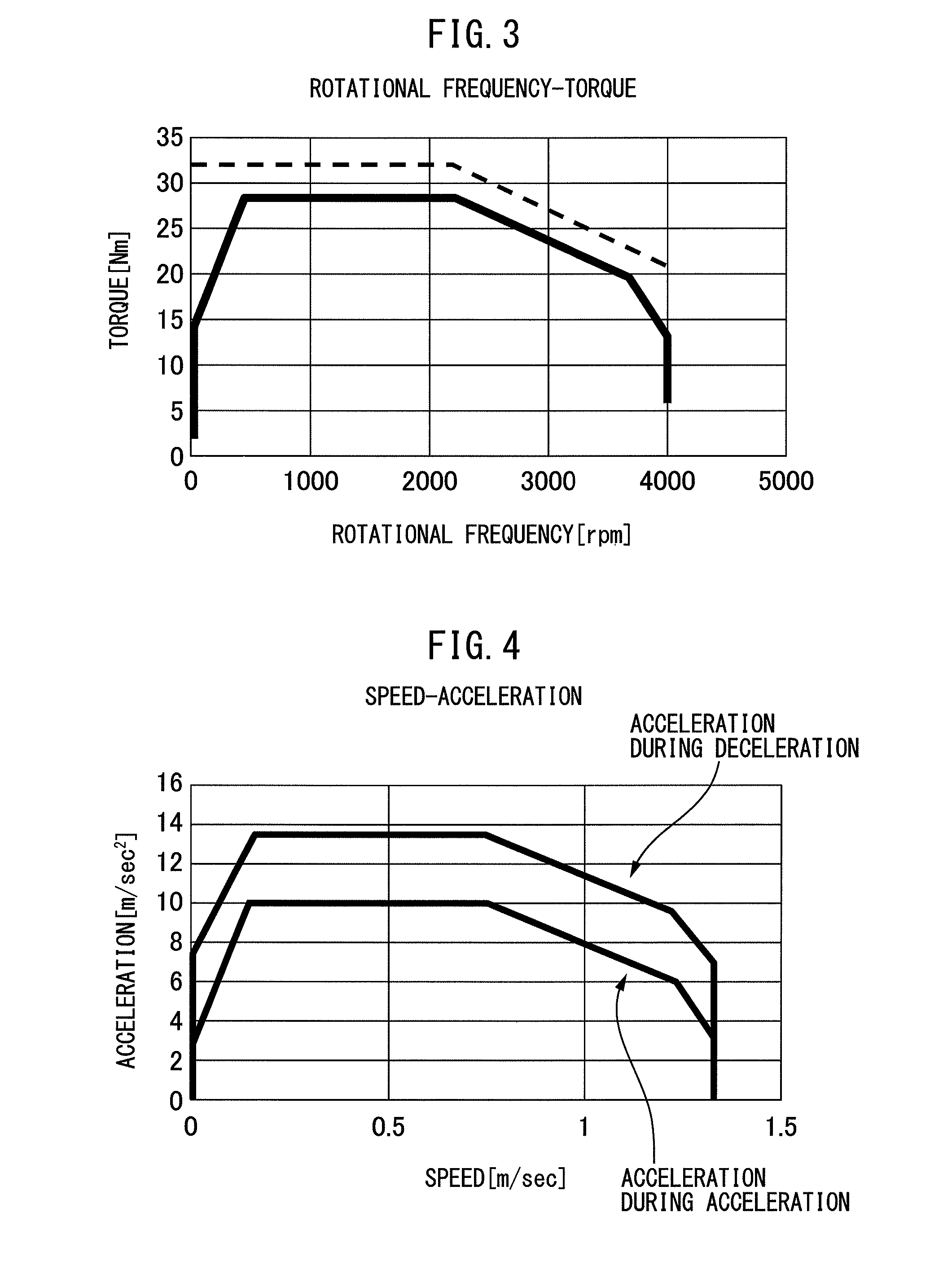

Motor control apparatus generating command limited by motor torque

ActiveUS20160132041A1Easy to useImprove motor performanceComputer controlSimulator controlLinear motionConversion factor

A motor control apparatus includes a detection unit detecting a motor rotational frequency, a storage unit storing an allowable torque at the motor rotational frequency detected by detection unit, a first torque offset generated in a direction opposite to a moving direction of a movable body, a second torque offset generated in one direction regardless of the moving direction of the movable body, a rotor inertia moment, a load inertia moment, and a conversion factor for converting a motor rotation angle in rotary motion of the motor to a moving distance in linear motion of the movable body, and an acceleration calculation unit calculating an acceleration command of the motor for each moving direction of the movable body and each acceleration operation and deceleration operation using the allowable torque, the first torque offset, the second torque offset, the rotor inertia moment, the load inertia moment, and the conversion factor.

Owner:FANUC LTD

Grinding head dedicated to planar double-enveloping worm

The invention relates to a grinding head dedicated to a planar double-enveloping worm. A cross-shaped sliding table is provided with a grinding head stand column, a front flange and a rear flange are arranged at the two ends of a shaft sleeve; an adjustment worm gear arranged on the shaft sleeve is meshed with an adjustment worm arranged on the grinding head stand column; a compensation guide rail strip arranged at the inner end face of a grinding tool is matched with the compensation guide rail strip arranged on the outer end face of the front flange; a grinding wheel is arranged on the principal axis of the grinding tool and the working surface of the grinding wheel coincides with the central axis of the shaft sleeve; the grinding head stand column is internally provided with a clamp mechanism, the outer end face of the rear flange is provided with a TV, and a belt pulley fixed on the principal axis of the TV is connected with the belt pulley fixed on the principal axis of the grinding tool through the belt. In the invention, no matter how the operating angle of the grinding wheel changes, the working surface of the grinding wheel always coincides with a grinding wheel inclination angle adjustment shaft, the adjustment of the angle of the grinding wheel does not affect the height change of the grinding wheel, the automation degree of grinding wheel compensation and finishing is high, and the structure of the complete machine features in delicate design, convenient adjustment and stable and reliable performance.

Owner:宝鸡市广环机床有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com