Electro-hydraulic control engine power output device

A technology of power output and electro-hydraulic control, which is applied to harvesters, agricultural machinery and implements, etc. It can solve the problems of easy wear of the spline shaft, large cab space, inconvenient use and maintenance, etc., so as to reduce adjustment links and power The effect of large coverage and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

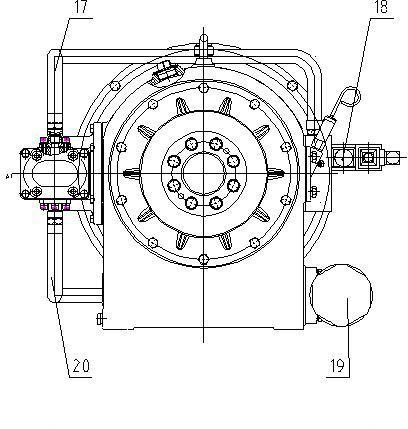

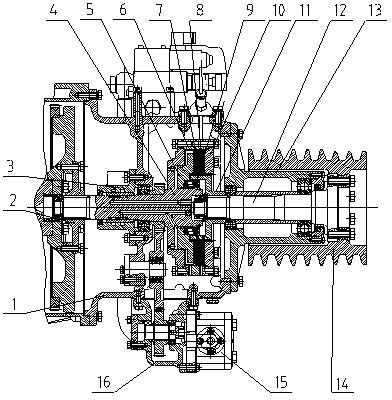

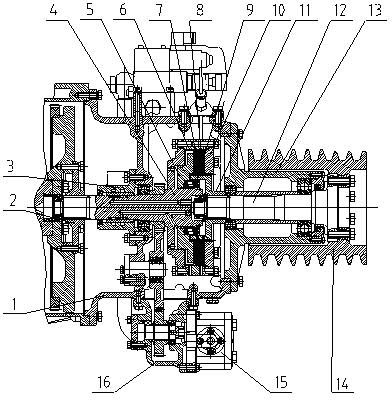

[0010] Such as figure 1 As shown, the present invention mainly includes: housing 1, spline hub 2, oil distribution seat assembly 3, input shaft 4, piston 5, driving ring gear 6, driving friction plate 7, driven friction plate 8, return spring 9 , fixed pressure plate 10, driven gear hub 11, output shaft 12, output shaft housing 13, pulley 14, gear pump 15, transfer case assembly 16, oil pump outlet pipe 17, solenoid valve assembly 18, filter Assembly 19, oil pump oil inlet pipe 20 etc. The housing 1 is connected to the engine flywheel housing with bolts, the output shaft housing 13 is connected with the rear end of the housing 1 with bolts; the spline hub 2 is fixed on the engine flywheel with bolts, and the oil distribution seat assembly 3 is installed in the housing 1 The front end of the center hole and the spline at the front end of the input shaft 4 are inserted into the spline hub 2, and the rear end is supported on the housing 1 through bearings; Engagement, the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com