Grinding head dedicated to planar double-enveloping worm

A plane secondary envelope, toroidal worm technology, applied in the direction of components with teeth, gear teeth, belts/chains/gears, etc., can solve the problems of low degree of automation of grinding wheels and low precision of grinding heads, and achieve ingenious design , Improve grinding efficiency and reduce the effect of adjustment links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

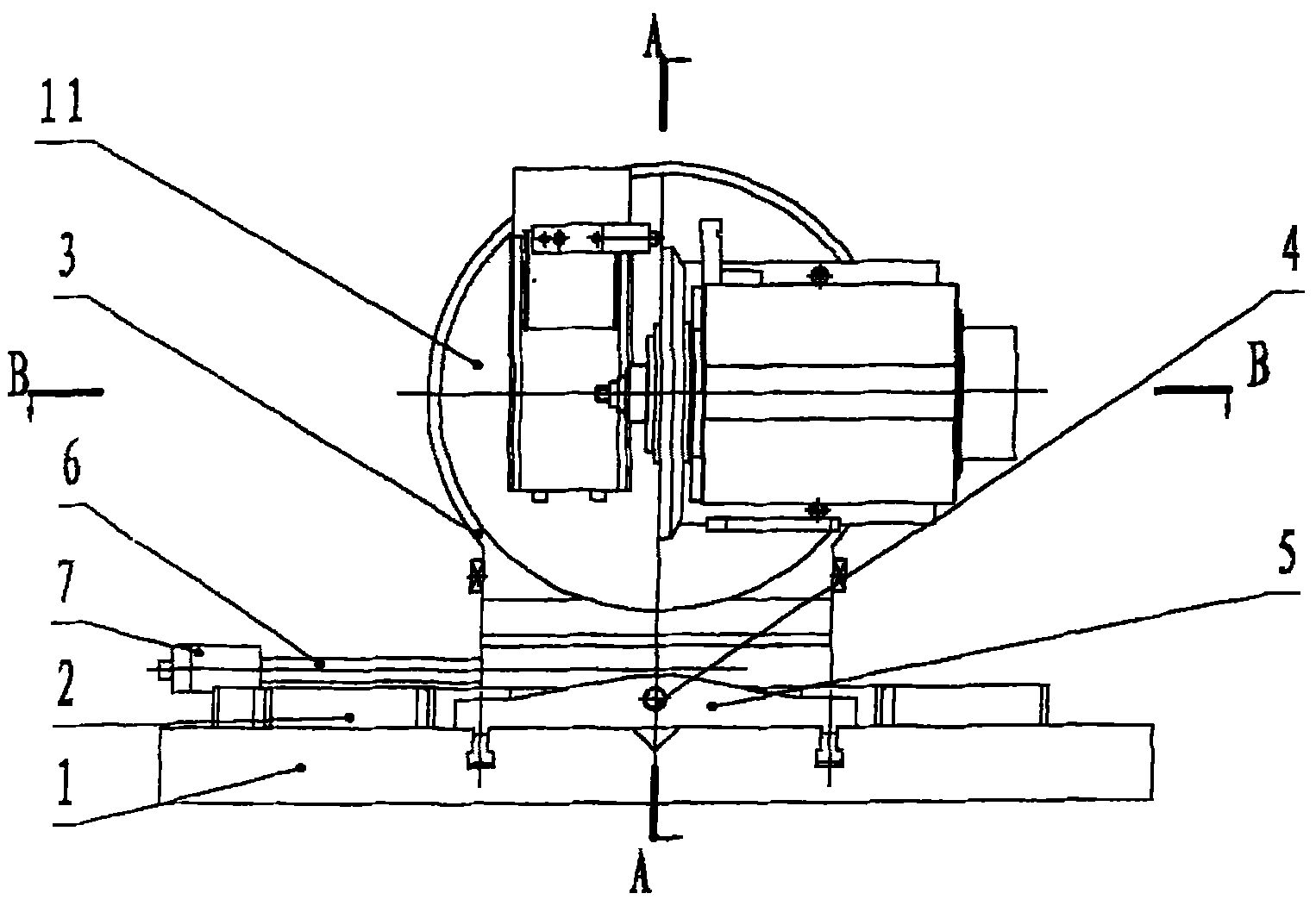

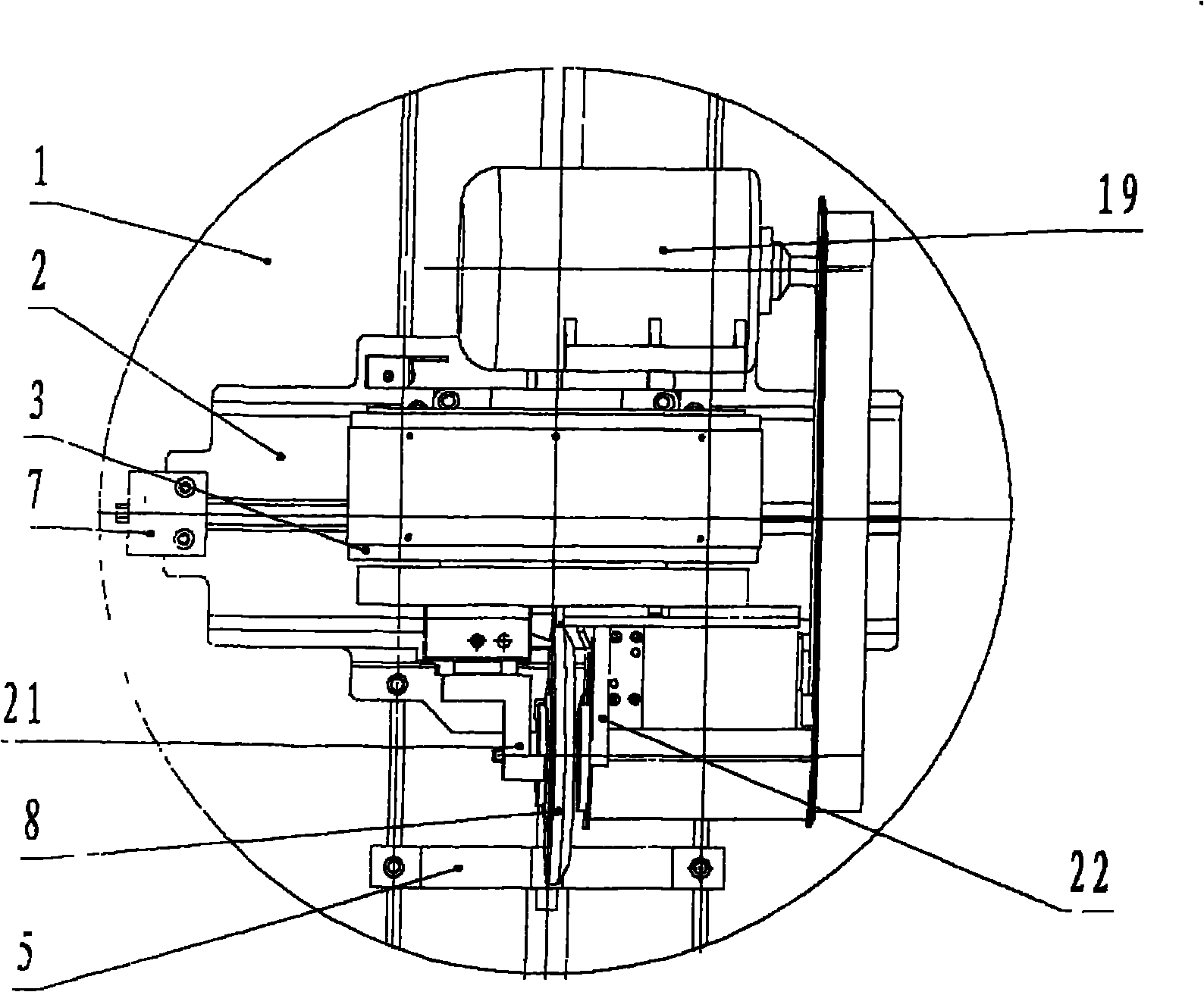

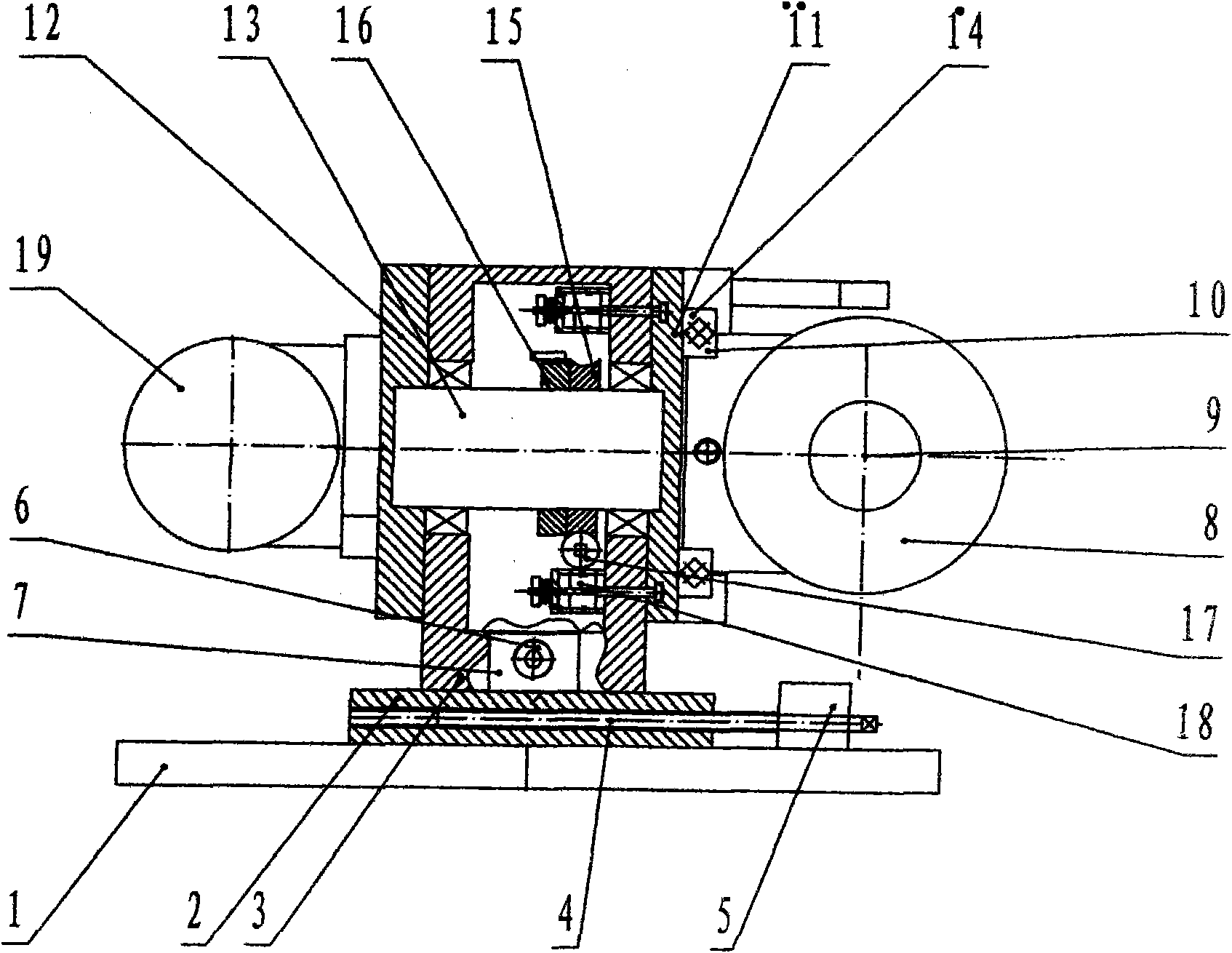

[0025] Attached below figure 1 , 2 , 3, 4, 5, 6, 7 describe an embodiment of the present invention in detail.

[0026] A kind of special grinding head for plane double-enveloping toroidal worm, the upper and lower ends of the cross slide 2 are formed with mutually perpendicular "V"-shaped guide rails, the lower "V"-shaped guide rails and the upper end surface of the machine tool round tool table 1 The "V" groove fits, the upper "V" guide rail fits with the "V" groove on the lower end surface of the grinding head column 3; one end of the radial adjustment screw 4 is installed on the round table 1 through the bearing block 5, and the other end is connected The cross slide 2 is threaded, and one end of the horizontal adjustment screw rod 6 is installed on the cross slide 2 through the bearing block 7, and the other end is threaded with the grinding head column 3.

[0027] The grinding head column 3 is installed on the cross slide 2 through the "V" guide rail on its lower end su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com