Manufacturing process of toothed rubber roller

A manufacturing process and rubber roller technology, which is applied in the manufacturing process of toothed rubber rollers, can solve the problems of inability to produce toothed rubber roller surfaces without parting lines, high cost and price, and achieve ideal geometric accuracy and surface roughness. The effect of lower production cost and fewer adjustment links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

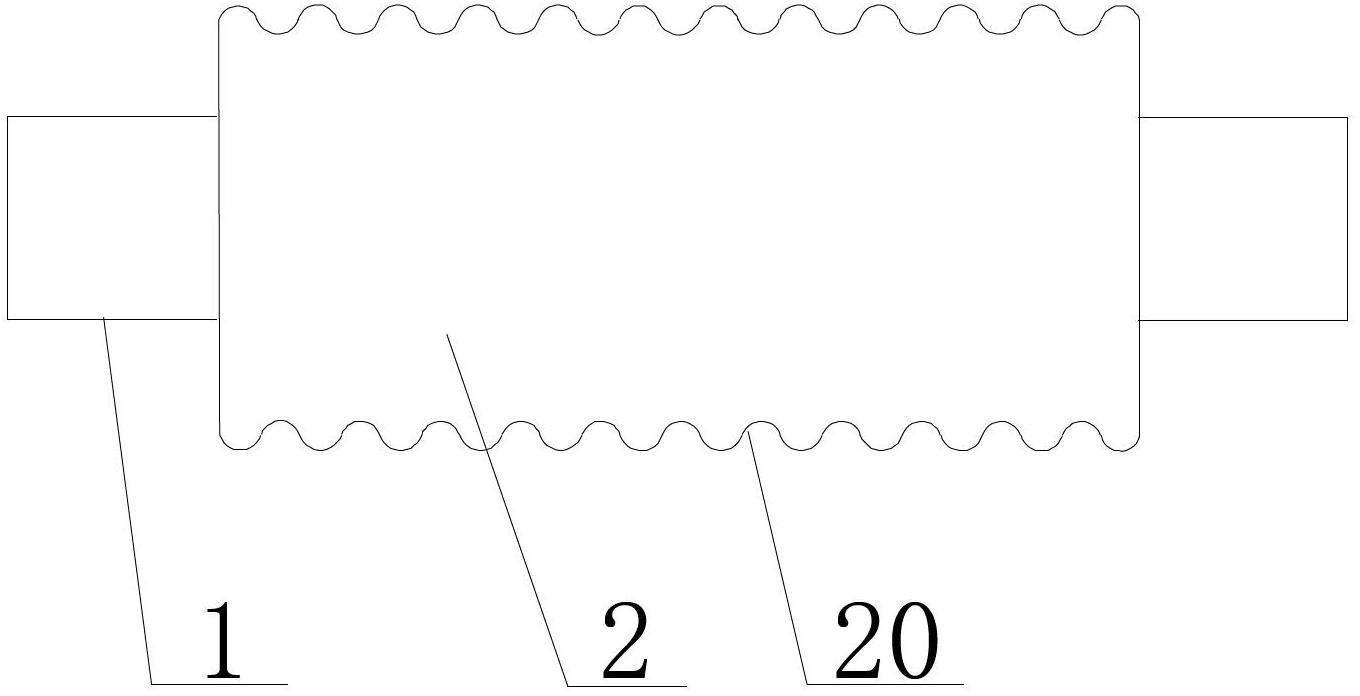

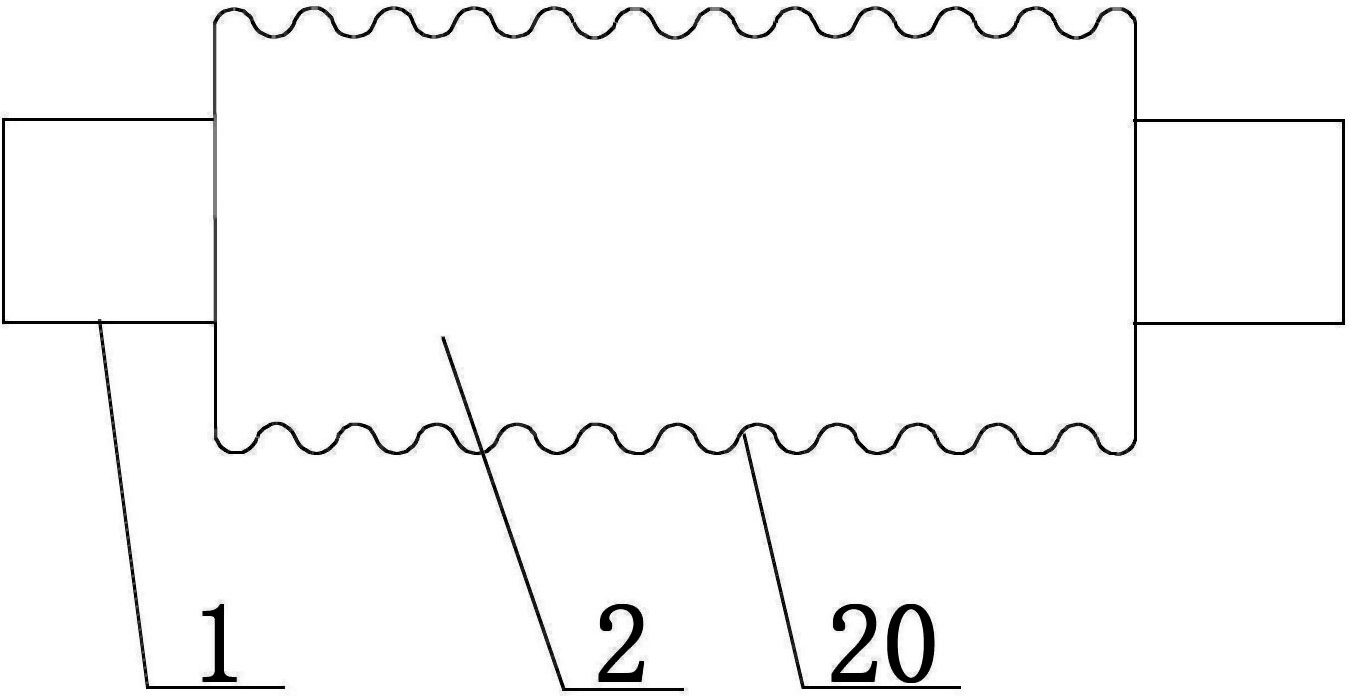

[0018] see figure 1 The toothed rubber roller includes a metal mandrel 1 with joints at both ends and a silicon rubber roller 2 wrapped on the outer surface of the metal mandrel 1. The outer surface of the silicon rubber roller 2 is uniformly provided with grooves 20 along the length direction, so as to The outer surface of the silicone rubber roller 2 is formed into a toothed surface.

[0019] The manufacturing process of toothed rubber roller of the present invention comprises the following steps:

[0020] The step of inspecting the mandrel to ensure that the radial runout of the mandrel 1 is less than 0.02-0.04mm;

[0021] The step of cleaning the mandrel, removing the oil on the mandrel 1;

[0022] The step of gluing the mandrel is to paint the adhesive on the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com