Water solubility high-speed grinding fluid for machining settlement bearing and preparation method thereof

A bearing processing, water-soluble technology, applied in the field of water-soluble grinding fluid, can solve problems such as difficult settlement, achieve the effects of improving grinding efficiency, solving grinding dust settlement, and excellent lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

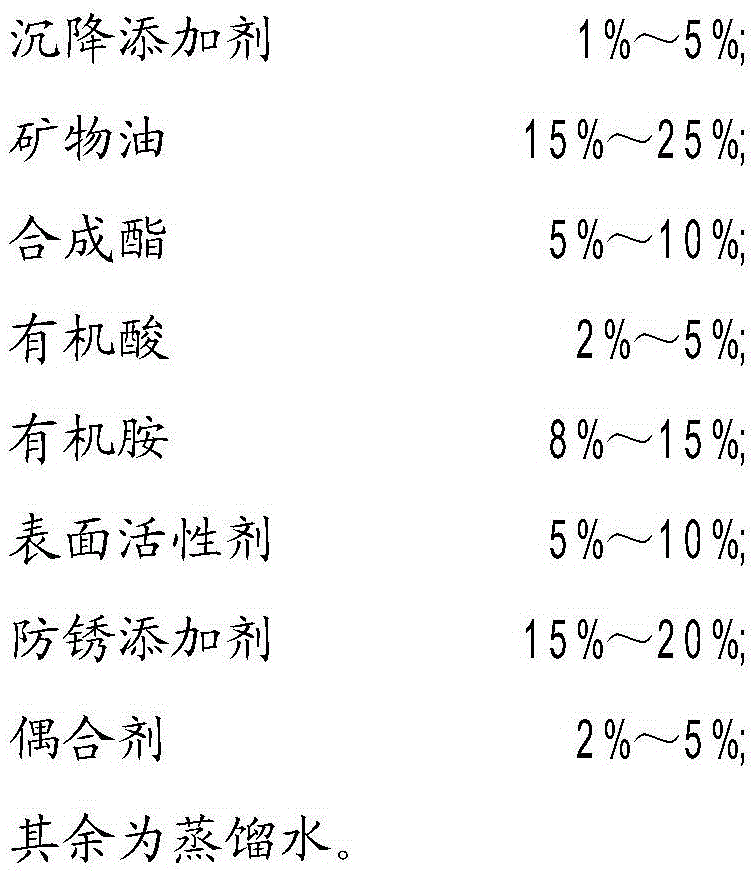

[0039] A kind of sinking bearing processing water-soluble high-speed grinding fluid, according to the formula composition of table 1:

[0040]

[0041] Table 1

Embodiment 2

[0043] A kind of sinking bearing processing water-soluble high-speed grinding fluid, according to the formula composition of table 2:

[0044]

[0045]

[0046] Table 2

Embodiment 3

[0048] A kind of sinking bearing processing water-soluble high-speed grinding fluid, according to the formula composition of table 3:

[0049]

[0050] table 3

[0051] A kind of preparation method of water-soluble high-speed grinding fluid for subsidence bearing processing provided by the invention comprises the following steps:

[0052] Step A, weighing mineral oil, synthetic ester, organic acid, organic amine, surfactant, sedimentation additive, antirust additive, coupling agent and distilled water according to weight percentage;

[0053] Step B, sequentially add mineral oil, synthetic ester, organic acid, organic amine, surfactant and sedimentation additive into the stirring tank, mix evenly at 40-50°C, and control the stirring speed at 400-800rpm;

[0054] Step C, after the components in step B are stirred evenly, add the anti-rust additive, coupling agent and distilled water into the stirring tank in turn, and stir at room temperature until they are evenly mixed.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com