Method for preparing monodisperse large-particle-diameter silica sol through organic-inorganic complex catalysis

A technology of composite catalysis and silica sol, applied in the direction of silicon oxide, silicon dioxide, etc., can solve the problems of unsatisfactory use requirements, high cost, complicated procedures, etc., to avoid the generation of new particles, good sphericity, and improve the scope of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A method for preparing monodisperse large particle size silica sol by organic-inorganic composite catalysis, comprising the following steps:

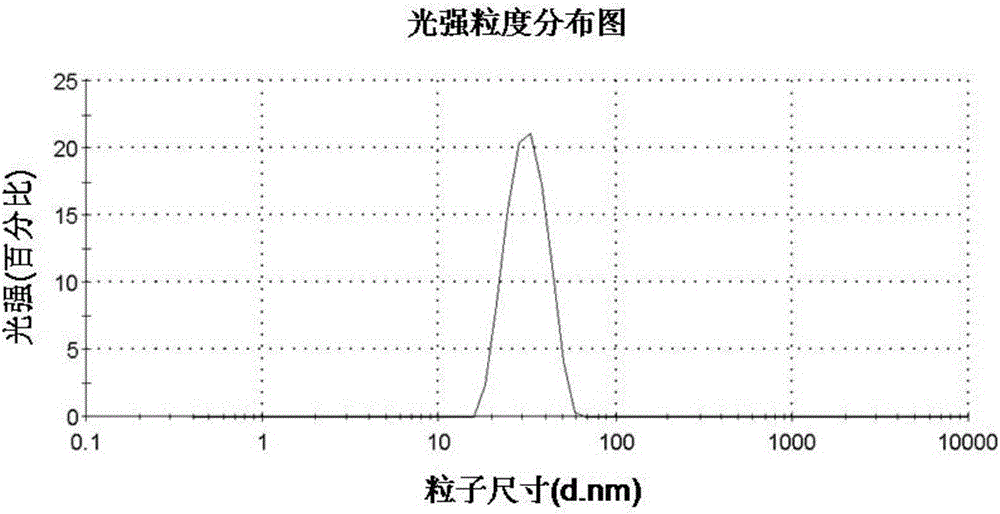

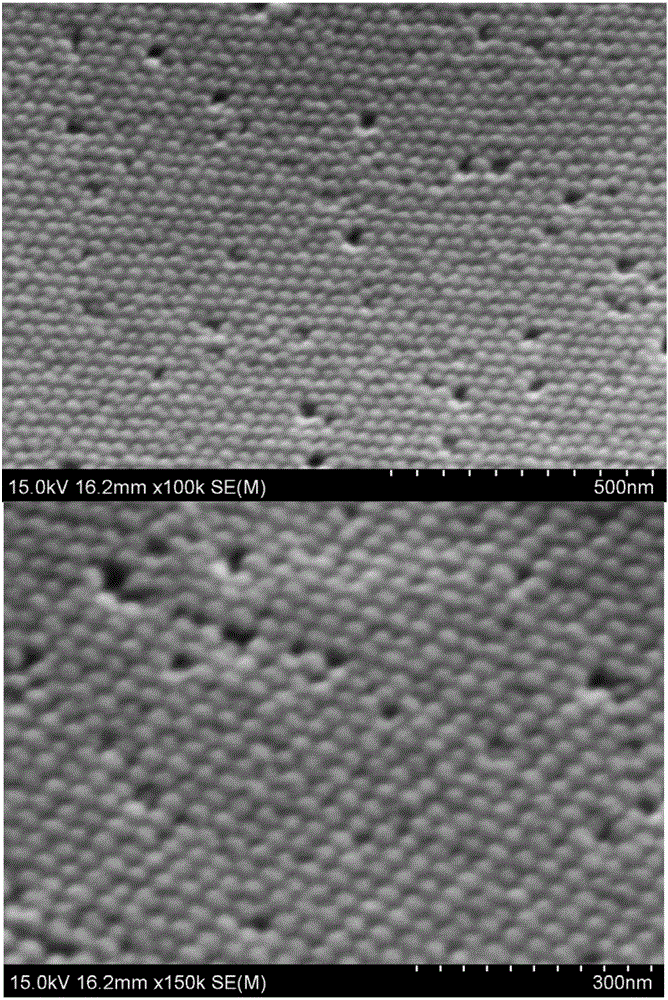

[0057] (1) Take 1000 grams of deionized water and add it to the reaction kettle equipped with a reflux condenser, so that the liquid level is at 3 / 4 of the reaction kettle, start the agitator, stir at a speed of 500 rpm, and heat the water to 70°C , add catalyst sodium hydroxide 0.8 gram to water, be mixed with the aqueous solution of 0.08wt% sodium hydroxide, be warming up to 80 ℃, add silicon powder 100 grams (purity > 99%, particle size 100~200 mesh) at one time, stir React for 1 hour at a speed of 500 rpm to obtain a uniform silica sol mother solution with an average particle size of 13 nm and a concentration of 1.6 wt%, which serves as the basis for further growth of the particle size.

[0058] (2) Weigh 5 grams of ethanolamine (boiling point 170°C, easily soluble in water, strong alkalinity), add it to 95 grams of deionized...

Embodiment 2

[0063] A method for preparing monodisperse large particle size silica sol by organic-inorganic composite catalysis, comprising the following steps:

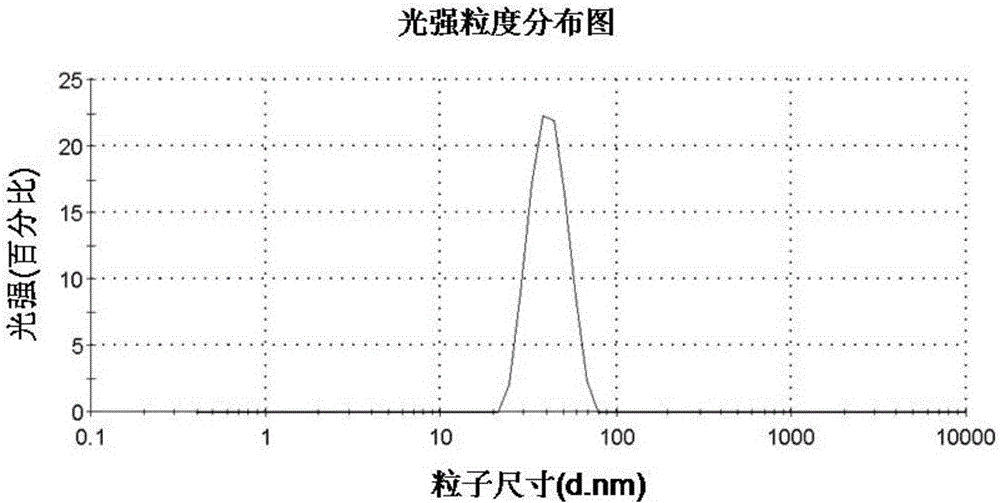

[0064] (1) Take 1000 grams of deionized water and add it to the reaction kettle equipped with a reflux condenser, so that the liquid level is at 3 / 4 of the reaction kettle, start the agitator, stir at a speed of 500 rpm, and heat the water to 70°C , add catalyst sodium hydroxide 0.3 gram to water, be mixed with the aqueous solution of 0.03wt% sodium hydroxide, be warmed up to 80 ℃, add silicon powder 100 grams (purity > 99%, particle size 100~200 mesh) at one time, stir React for 1 hour at a speed of 500 rpm to obtain a uniform silica sol mother solution with an average particle size of 14 nm and a concentration of 0.78%, which serves as the basis for further growth of the particle size.

[0065] (2) Weigh 5.5 grams of ethanolamine (boiling point 170° C., easily soluble in water, strong alkalinity), add it into 94.5 grams of deio...

Embodiment 3

[0070] A method for preparing monodisperse large particle size silica sol by organic-inorganic composite catalysis, comprising the following steps:

[0071] (1) Take 1000 grams of deionized water and add it to the reaction kettle equipped with a reflux condenser, so that the liquid level is at 3 / 4 of the reaction kettle, start the agitator, stir at a speed of 500 rpm, and heat the water to 70°C , add catalyst sodium hydroxide 0.1 gram to water, be mixed with the aqueous solution of 0.01wt% sodium hydroxide, be warming up to 75 ℃, add silicon powder 125 grams (purity > 99%, particle size 40~120 orders) at one time, stir React for 1 hour at a speed of 500 rpm to obtain a uniform silica sol mother solution with an average particle size of 18 nm and a concentration of 0.28%, which serves as the basis for further growth of the particle size.

[0072] (2) Weigh 5 grams of 1,1,3,3-tetramethylguanidine (boiling point 160°C, easily soluble in water, strong alkalinity), add it to 95 gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com