Patents

Literature

113results about How to "Reduce the chance of spawning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

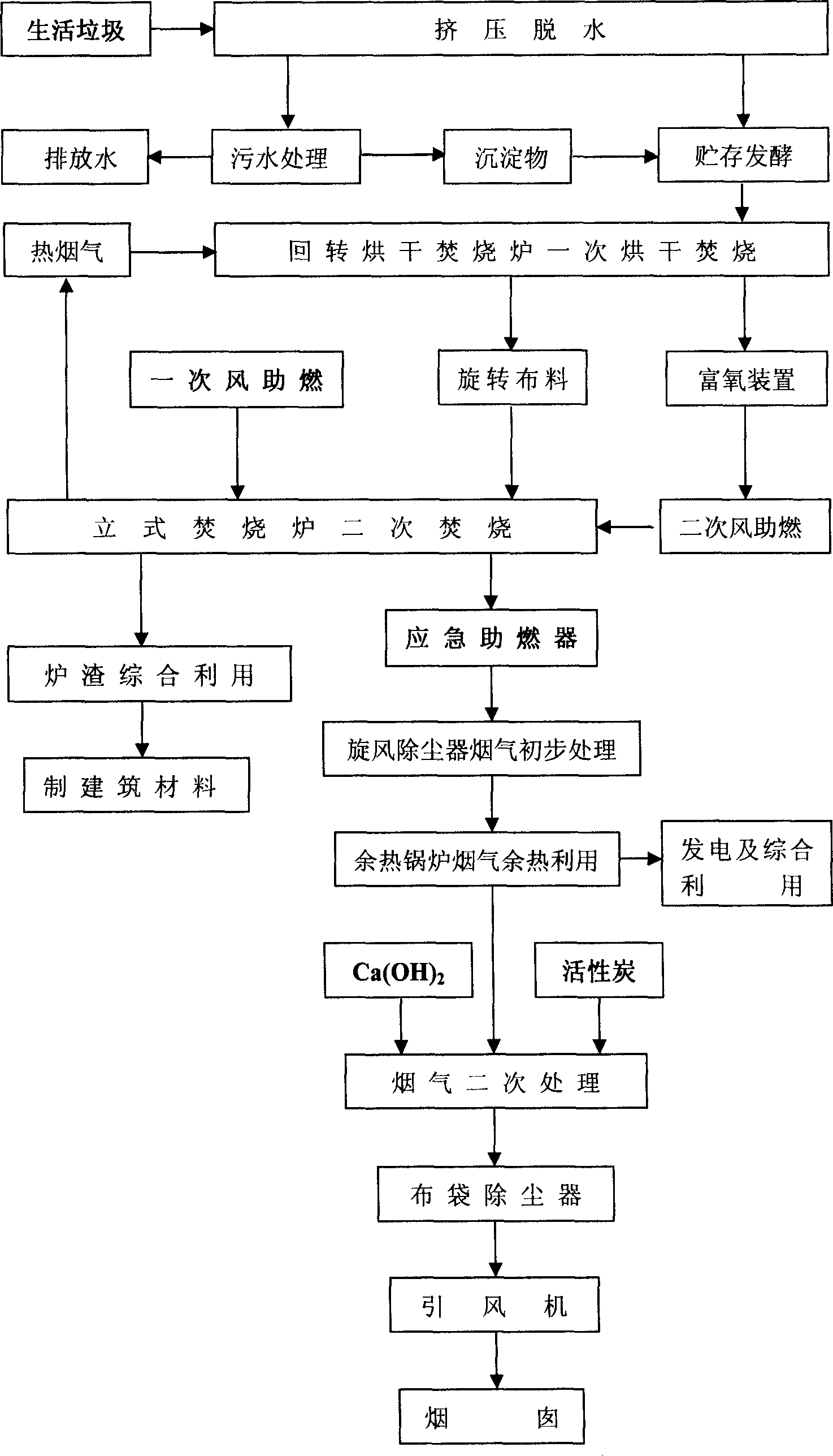

Life-garbage comprehensive treatment technology

InactiveCN1850370AIncrease temperatureExtended burn timeSolid waste disposalIncreasing energy efficiencySlagEnvironmental engineering

The present invention relates to a comprehensive treatment process of house refuse. Said treatment process includes the following steps: (1), squeezing and dehydrating; (2), storing and making fermentation, (3), using rotary baking incinerator to make firest incineration; (4), using vertical incinerator to make secondary incineration; (5), smoke primary treatment; (6), smoke waste heat utilization for power goneration and heating water; (7), secondary treatment of smoke; and (8), utilization of incinerator slag to make building material.

Owner:滕清华 +1

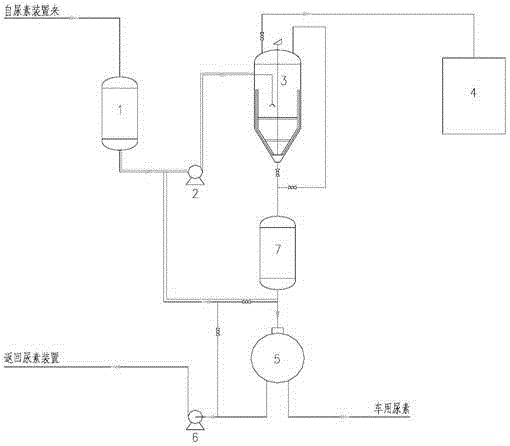

Diesel exhaust fluid production method

ActiveCN104557617AHigh riskIncrease costUrea derivatives preparationOrganic compound preparationCooling effectCrystallization temperature

The invention provides a diesel exhaust fluid production method. The method comprises the following steps: sending an ammonia-and-carbon dioxide removed urea synthesis reaction liquid from the synthesis workshop section of a urea production device to a crystallization kettle, carrying out vacuum flash evaporation crystallization, centrifuging the obtained crystallization kettle material after the vacuum flash evaporation crystallization to obtain separated crystals as a diesel exhaust fluid product, and returning the obtained liquid phase material to the urea production device. The method uses a flash evaporation cooling effect to make a urea solution supersaturated and crystallized in order to obtain the high quality diesel exhaust fluid product, so the energy utilization efficiency is increased, and the diesel exhaust fluid yield is obviously higher than that in the prior art at a same crystallization temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

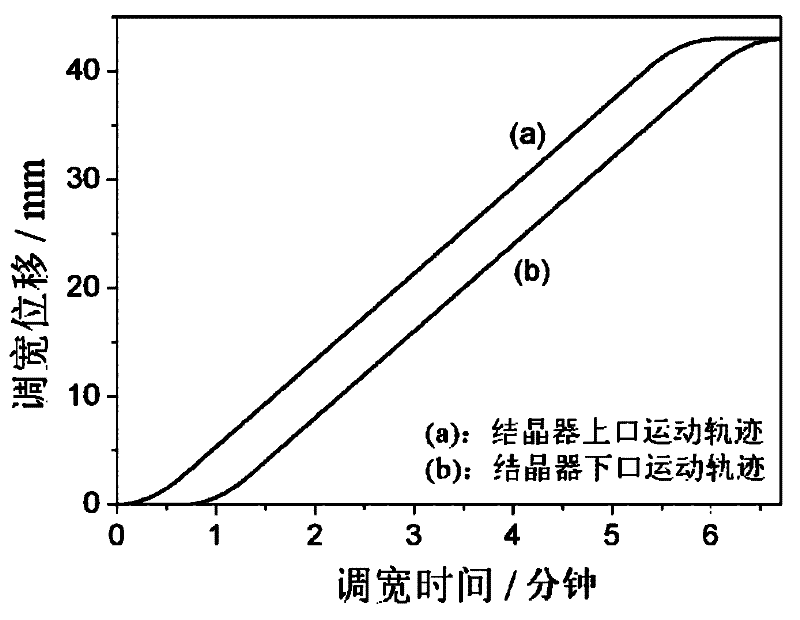

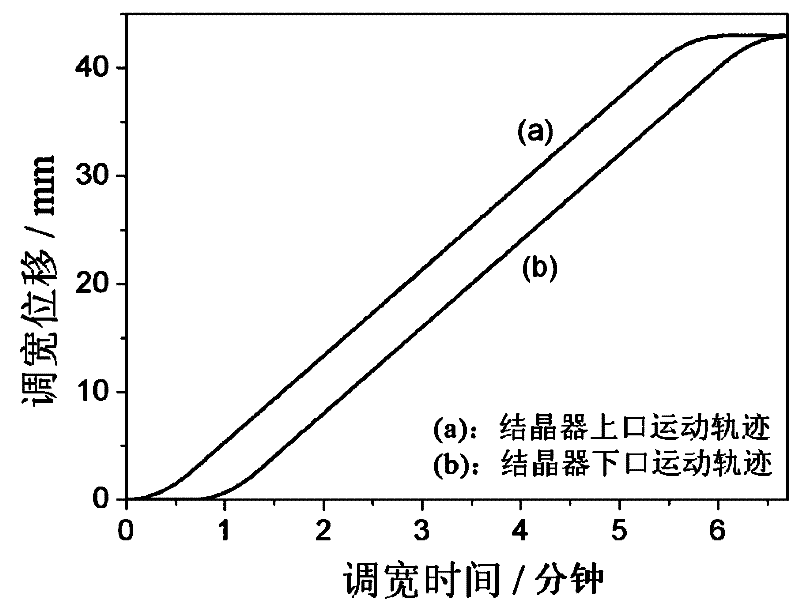

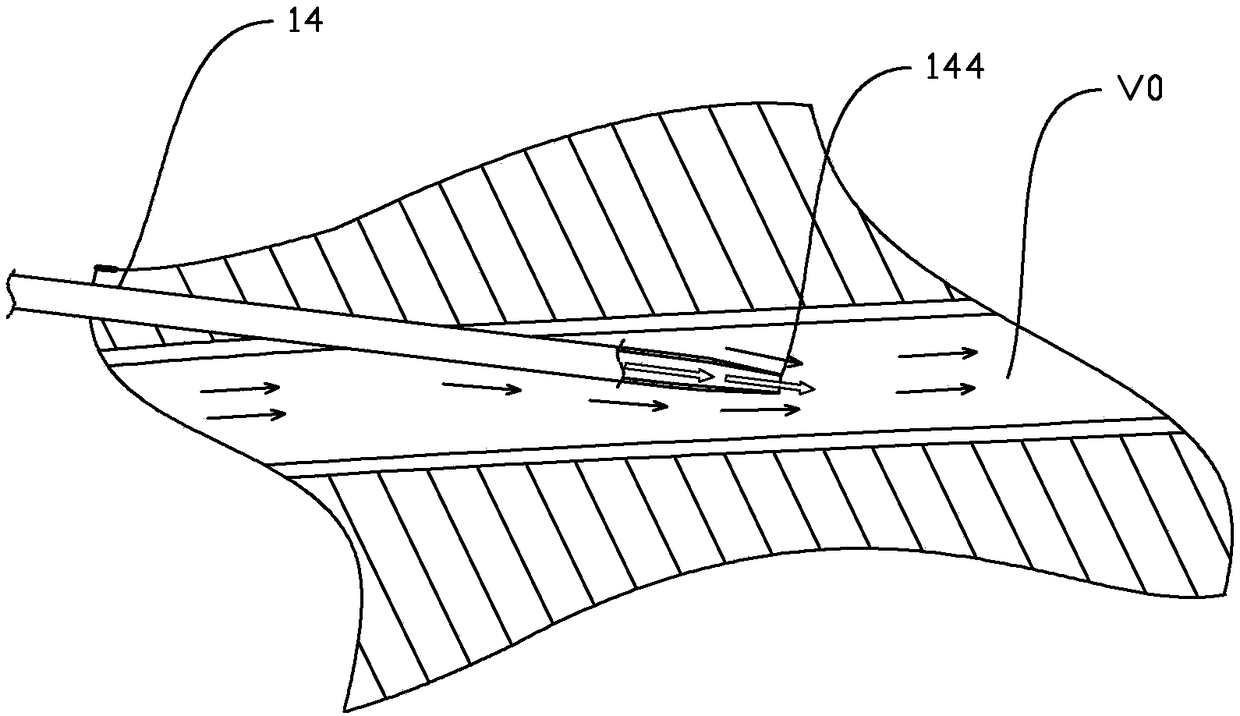

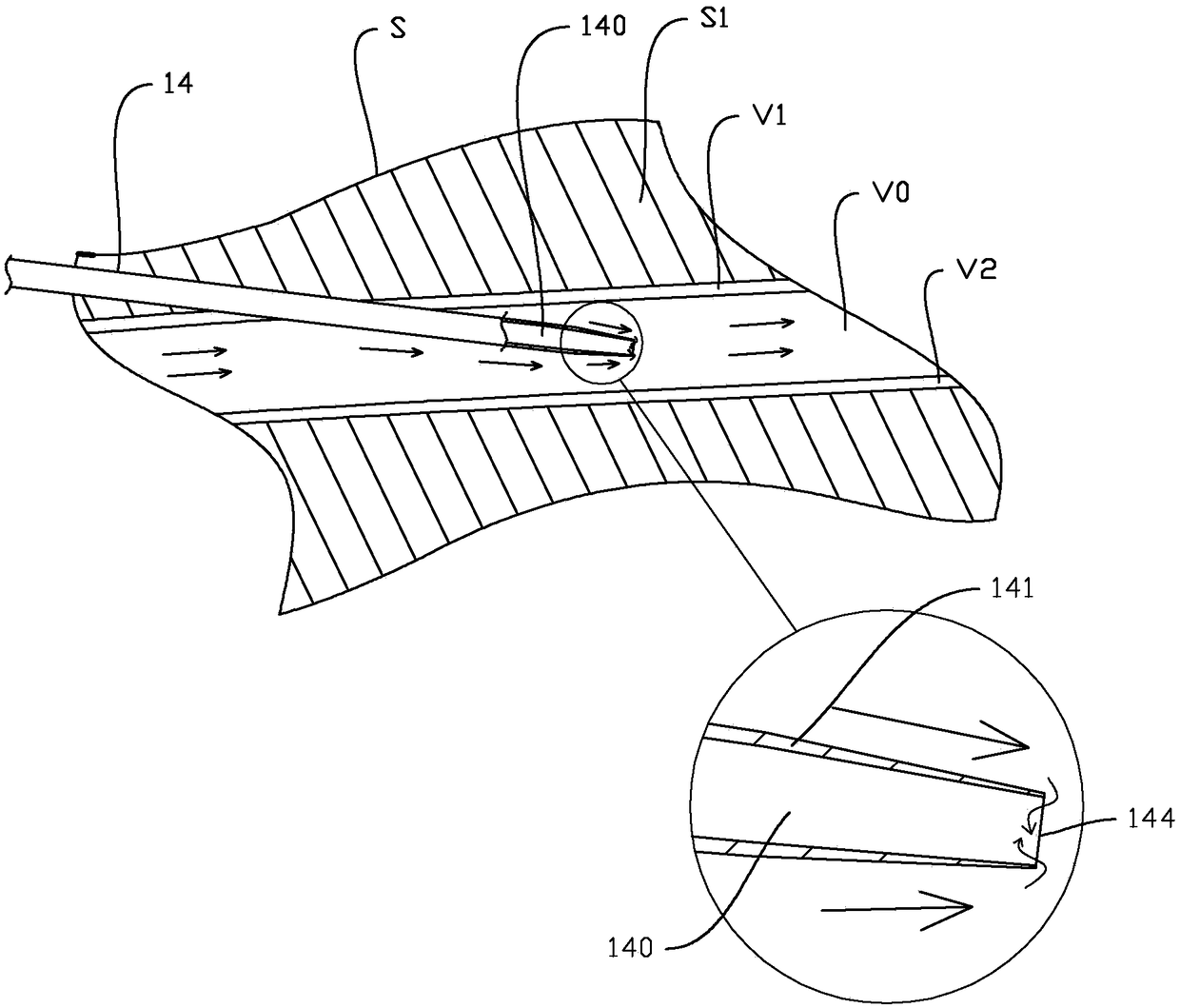

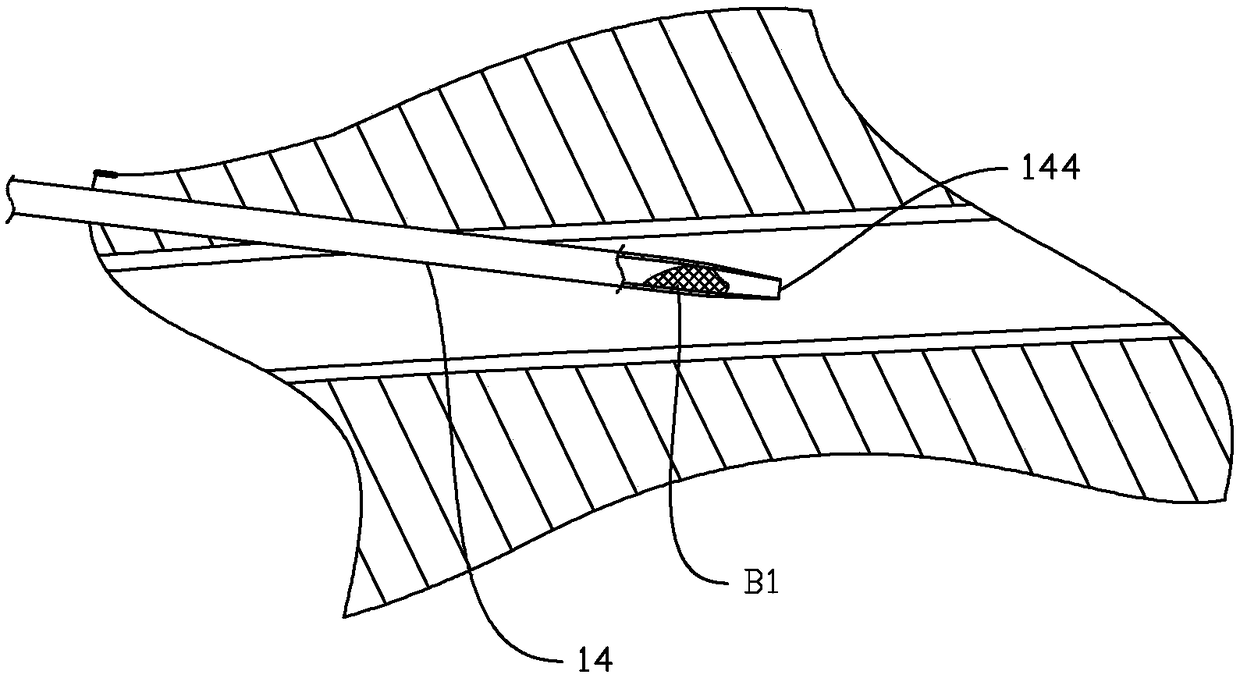

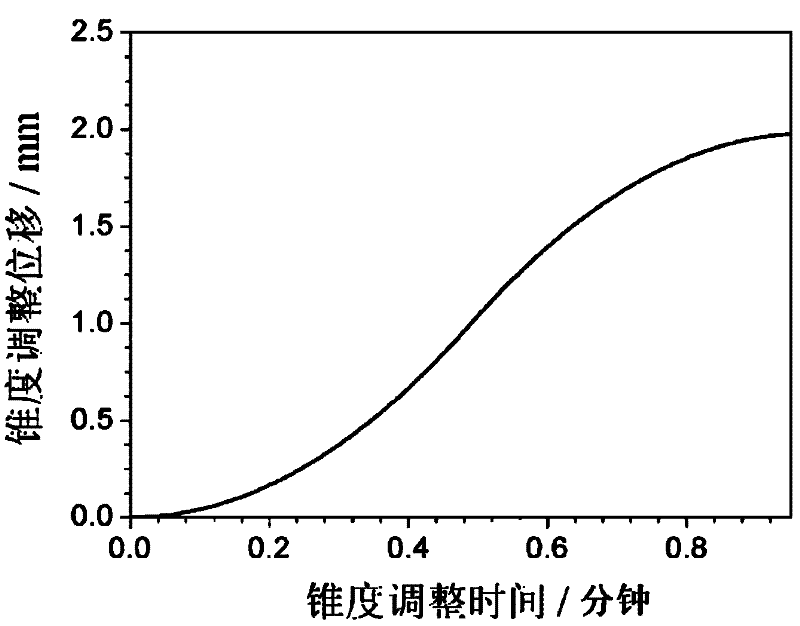

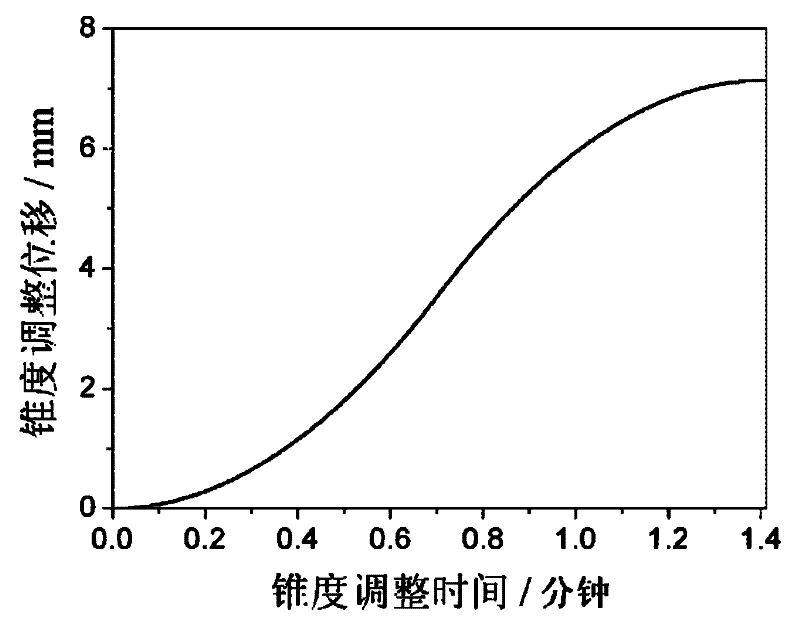

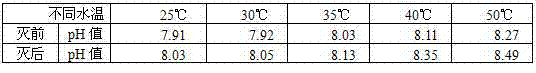

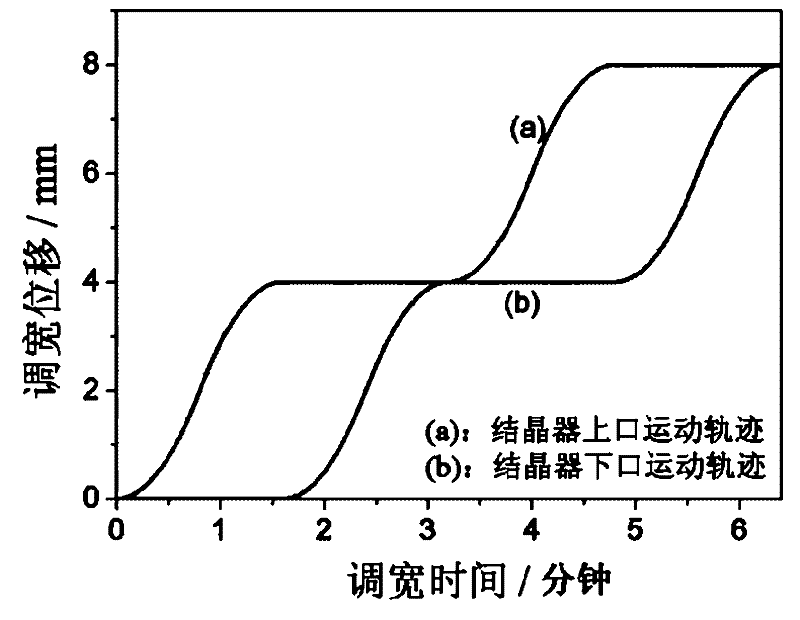

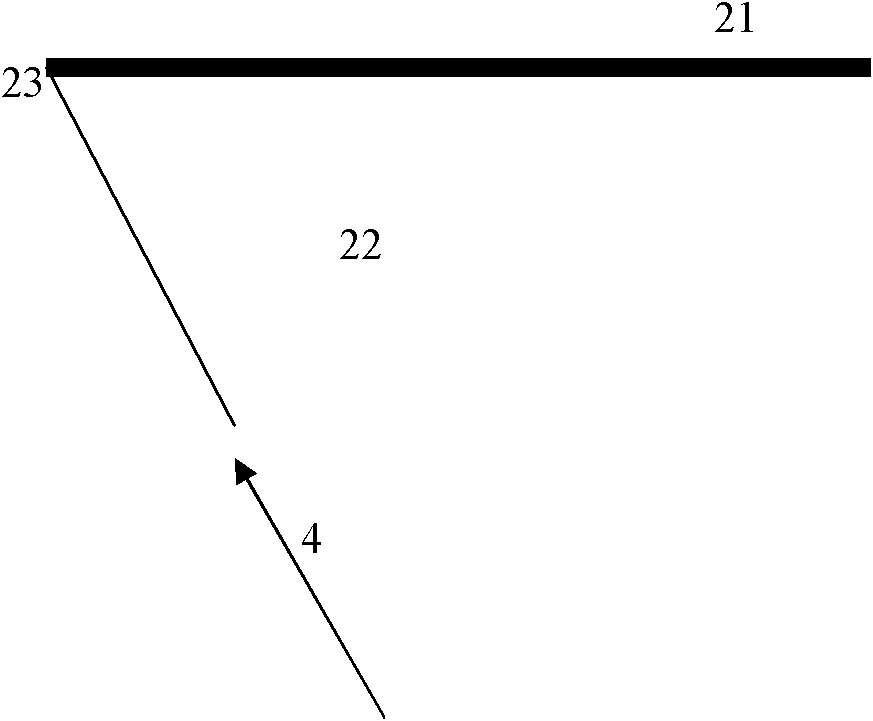

Online adjusting method for extensively reducing width of continuous casting mold

The invention discloses an online adjusting method for extensively reducing the width of a continuous casting mold, particularly comprising the steps of: with the solidifying contraction of a blank shell as a start point, leading the width reducing process of the casting mold into the online width adjustment process, wherein the process is for reducing the width; rapidly determining control parameters of the width adjustment process, wherein the parameters comprise a width adjusting speed, width adjusting time and a wedge section length; directing the online width adjustment process of the continuous casting mold according to the parameters so as to realize the extensive online adjustment process, wherein the process is for reducing the width. In the method, in consideration of the solidifying contraction characteristic of the casting blank, the frictional force of the casting blank to a copper plate is slowed, therefore, the method is easy and feasible and convenient to operate, and has the advantages of reducing the production cost, improving the product quality, and synchronously providing a feasible way for the high-efficiency casting production, improvement of the production capacity and efficiency of the continuous casting machine, and increase of the metal efficiency.

Owner:中国冶金科工股份有限公司

Blocking type intravenous infusion catheter device

PendingCN108578825AEliminates the risk of thrombosisEliminate dead spaceMedical devicesHaemostasis valvesInfusion catheterIntravenous Infusions

The invention provides a blocking type intravenous infusion catheter device which comprises a rigid needle tube, a needle tube base, a flexible infusion catheter and an infusion catheter base, whereinthe rigid needle tube is used for piercing skin and vein walls; the bottom end of the needle tube is fixed in the needle tube base; the infusion catheter base is hermetically connected with the bottom end of the infusion catheter; the front end of the needle tube penetrates through a sealing plug and is positioned in the inner cavity of the infusion catheter; and the tip of the needle tube is exposed from an opening in the top end of the infusion catheter. The blocking type intravenous infusion catheter device is characterized by also comprising a movable blocking component which is externally isolated, at least the blocking part of the blocking component can enter the inner cavity of the infusion catheter through the inner cavity of the infusion catheter base under the driving of the external force, and the blocking part of the blocking component can move to the opening in the top end of the infusion catheter along the inner cavity of the infusion catheter and block the opening so asto prevent the blood from entering the inner cavity of the infusion catheter and simultaneously prevent the liquid medicine from entering veins.

Owner:ZHEJIANG BAIHUO HEALTH TECH CO LTD

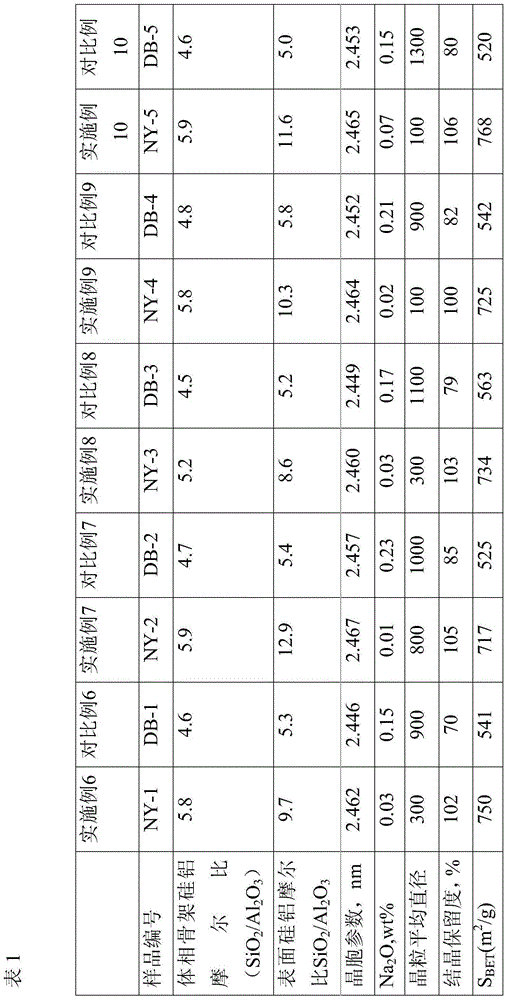

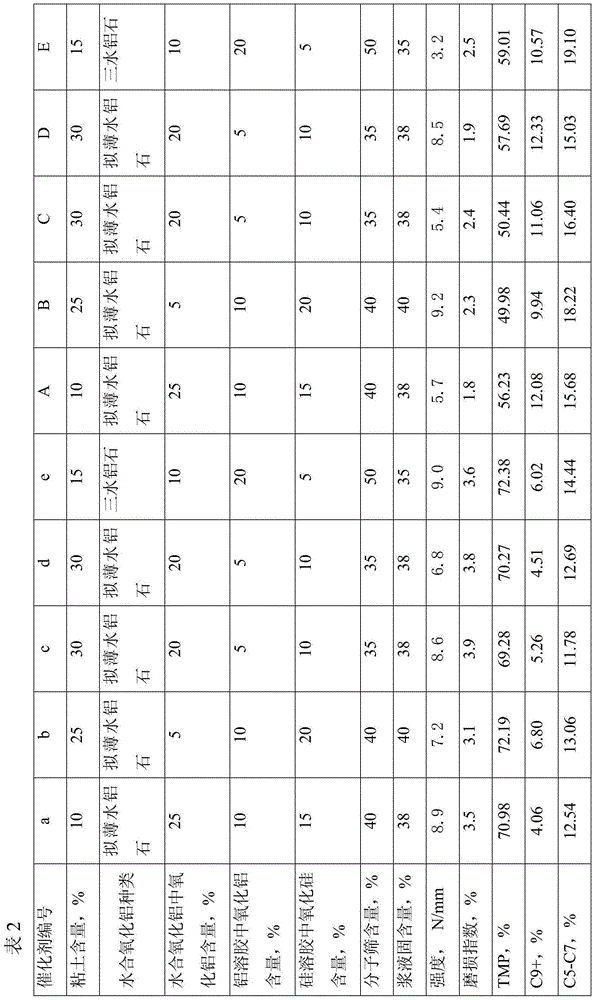

Catalyst containing Y-type molecular sieve and preparation method therefor

ActiveCN105080589AContinuous dischargeFlat surfaceMolecular sieve catalystsAlkyl transferMolecular sieve

The present invention provides a catalyst containing a Y-type molecular sieve. The catalyst comprises a small grain Y-type molecular sieve, aluminium oxide, oxide silicon and clay. The catalyst is characterized in that silicon is rich on the surface of the small grain Y-type molecular sieve, the molar ratio of a molecular sieve body phase skeleton SIO2 / AI2O3 is 5.0-6.0, the molar ratio of surface SiO2 / AI2O3 is 8.0-13.0, a unit cell parameter is 2.460-2.468 nm, the content of sodium oxide is less than or equal to 0.1% by weight, and the average diameter of a grain is 50-800 nm. The catalyst provided by the present invention shows better selectivity of trimethyl pentane in an alkylation reaction of isobutane / butene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Washing power-assisting device

ActiveCN103938414AWell formedImprove production efficiencyOther washing machinesTextiles and paperElectrolysisHydrogen

The invention relates to a washing power-assisting device, and belongs to the technical field of washing. The washing power-assisting device comprises an electrolysis power supply and a water quality adjustment unit arranged on the outside of a washing device, wherein the water quality adjustment unit comprises at least a cathode electrode and an anode electrode in pairs, the electrolysis power supply is used for supplying power to the cathode electrode and the anode electrode, a water-pervious diaphragm is arranged between the cathode electrode and the anode electrode which are in pair, the water-pervious hole diameter of the water-pervious diaphragm is smaller than or equal to 2 millimeters and larger than or equal to 1 nanometer, and the distance between the cathode electrode and the anode electrode is larger than or equal to the thickness of the water-pervious diaphragm and smaller than or equal to 20 millimeters. The washing power-assisting device can generate a large number of ultramicro bubbles whose content is mainly hydrogen and super-oxidized factors and has good reducing washing water; a water in-out port of the water quality adjustment unit and the external washing device form a sealed water supply and discharge channel, circulating water flow is maintained in the washing process, water quality is adjusted continuously, and the effects of using washing agents as few as possible or even being free of using the washing agents, saving water and reducing emission are achieved.

Owner:DALIAN SHUANGDI INNOVATIVE TECH RES INST

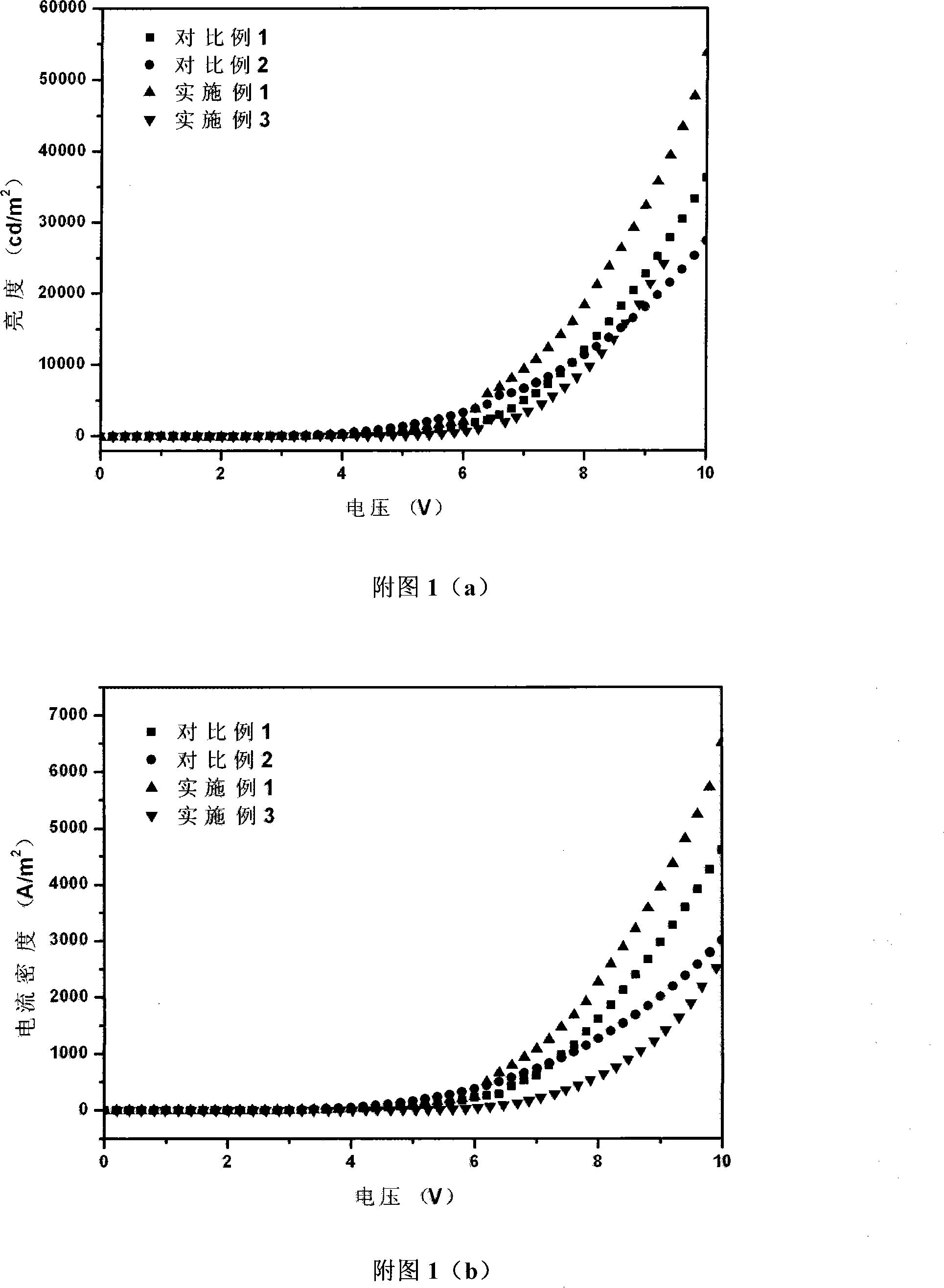

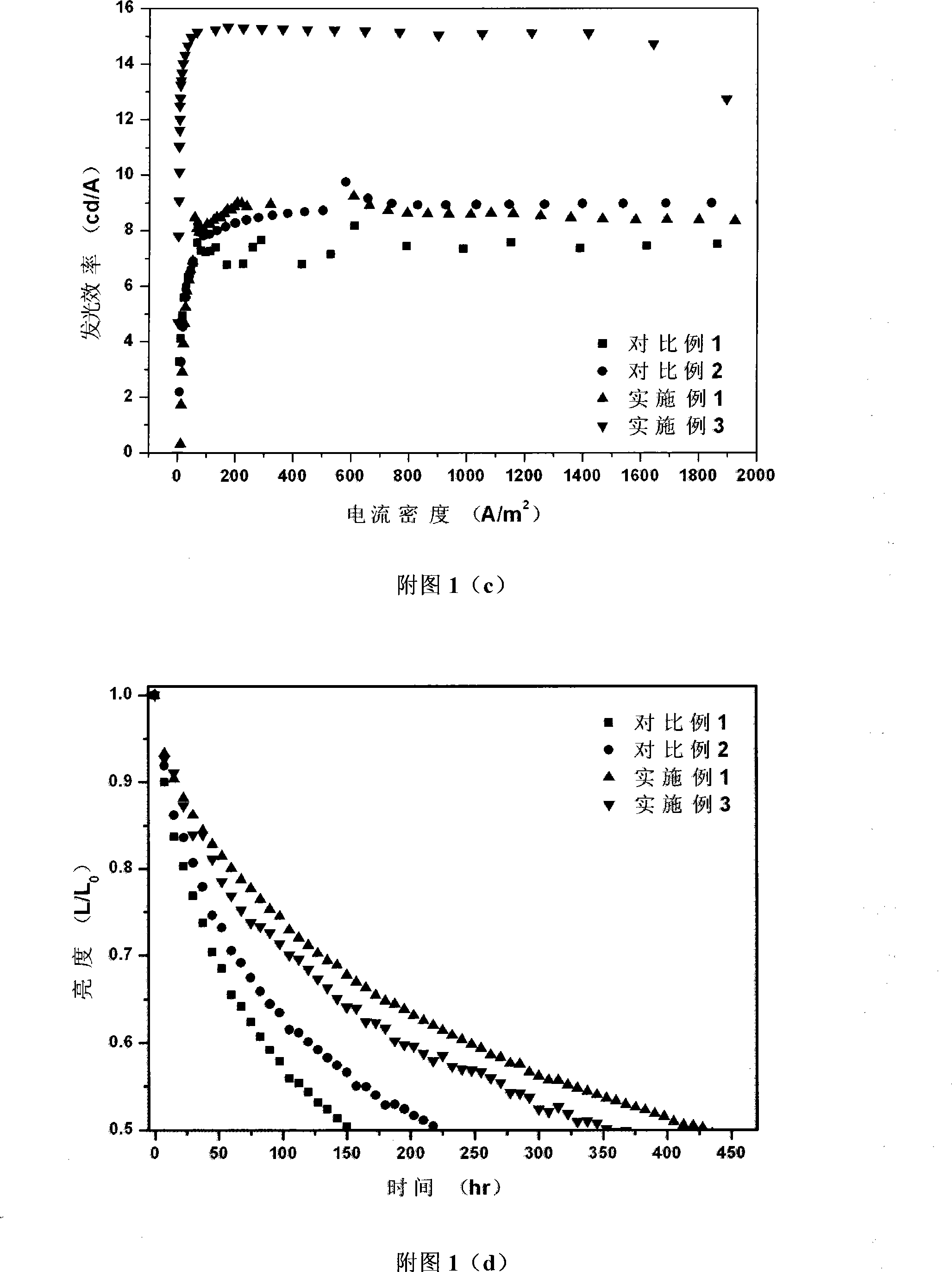

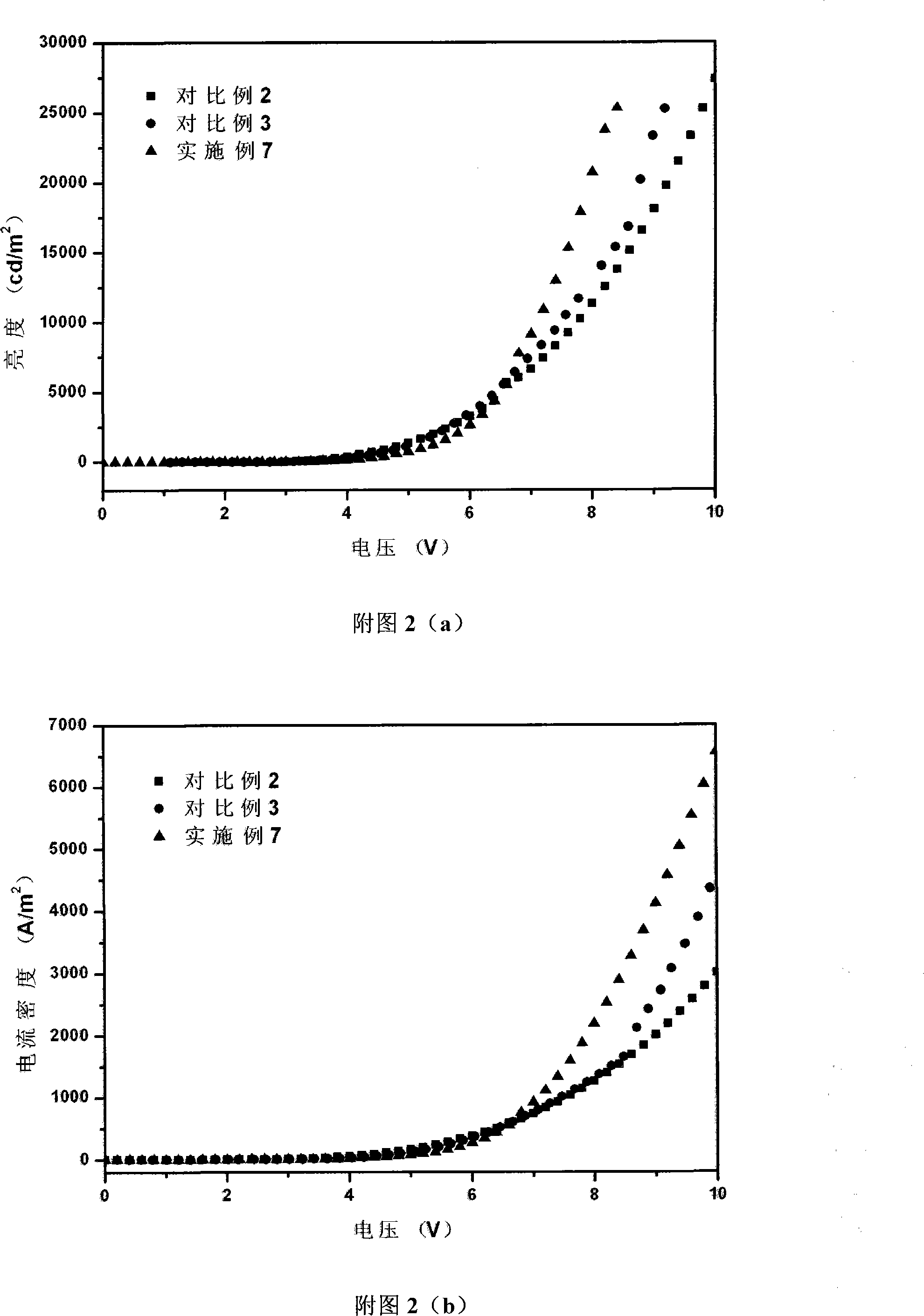

Organic electroluminescent device

InactiveCN101163359AImprove luminous efficiencyImprove compound efficiencyElectrical apparatusElectroluminescent light sourcesHole injection layerMixed materials

The invention relates to an organic electroluminescent part comprising an anode, a cathode and an organic functional layer arranged between the two electrodes; at least one of a hole infusion layer and a hole transmission layer contains matrix and mixed material; the mixed material is inorganic insulation material and chosen from the metal halide, metal oxide or metal carbonate. The invention overcomes the defect that the present OLED part is not very stable and the service life is short; with the structure of mixing insulation material in the part, the luminescent rate of part is effectively promoted and at the same time, the structure is beneficial to relieving the aging of working parts; the thermal stability of the part is properly increased and the service life of the part is greatly prolonged.

Owner:TSINGHUA UNIV +2

Purifying agent for air purifiers and method for preparing purifying agent

InactiveCN107362680ARaw material safety and environmental protectionImprove adsorption capacityBiocideGas treatmentFiberToxic gas

The invention discloses a purifying agent for air purifiers and a method for preparing the purifying agent, and relates to the technical field of purifying agents. The purifying agent comprises, by weight, 55-65 parts of modified bamboo pulp fibers, 40-42 parts of nanometer bacterium removing agents, 35-40 parts of sustained-release particles, 30-35 parts of expanded vermiculite, 15-25 parts of modified attapulgite, 10-15 parts of mildew-proof and insect-proof agents and 5-7 parts of stabilizers. The purifying agent and the method have the advantages that raw materials for the purifying agent are safe and environmentally friendly, excellent effects of adsorbing toxic gas such as formaldehyde, toluene and dimethylbenzene in the air can be realized, effects of killing germs can be realized, and accordingly indoor environments can be effectively improved.

Owner:HEFEI DONGHENGRUI ELECTRONICS TECH CO LTD

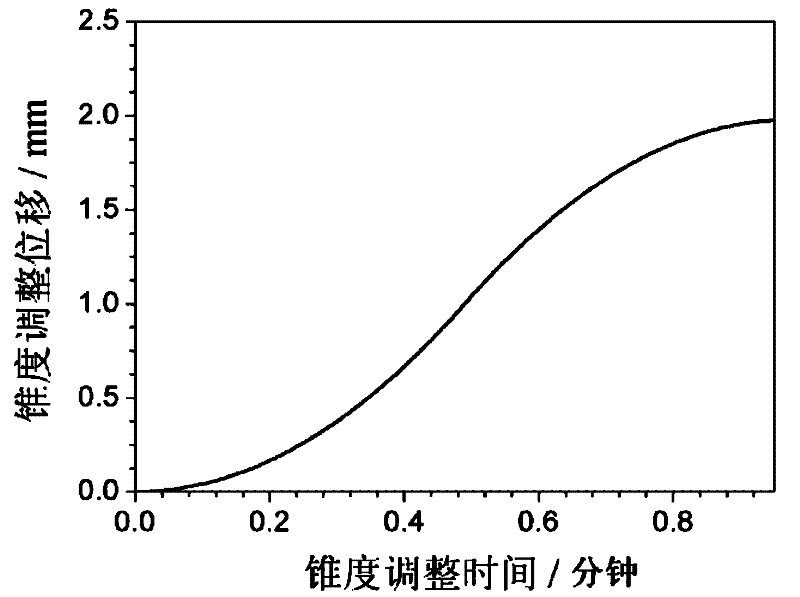

On-line adjustment method of taper change when continuous casting mold width reduction process is hindered

ActiveCN102266920AStable solidification heat transfer processReduce wearCasting moldMaterials science

The invention relates to a method for changing a conical degree at the moment of obstructing a process of on-line width reduction of a continuous casting crystallizer. The method comprises the following steps: taking solidifying contraction of a blank shell as a starting point, and then introducing a process obstructing condition in the process of reducing the width of the continuous casting crystallizer into the process of on-line width reduction at real time, so as to confirm a control parameter which contains an accelerated speed and a resetting time for adjusting a conical degree in the conical degree changing process of a casting machine, thereby reliably ensuring the safety continuous production of the casting machine. The method provided by the invention has significance on lowering the production cost, promoting the production quality, promoting the metal yield and promoting the market competitiveness of products.

Owner:中国冶金科工股份有限公司

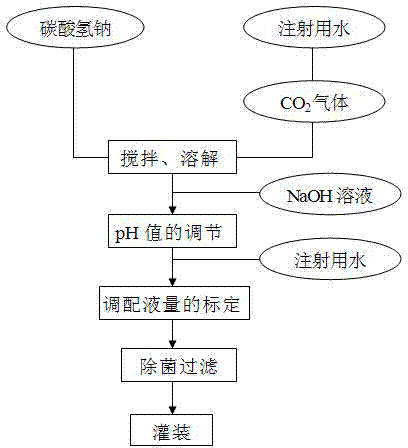

Sodium bicarbonate injection and preparation method thereof

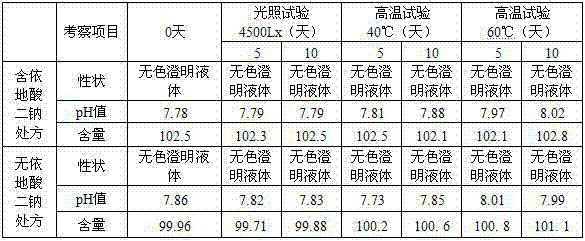

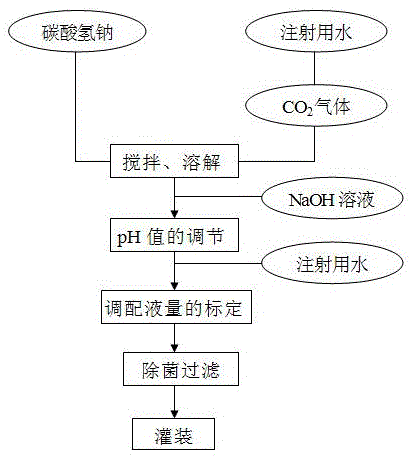

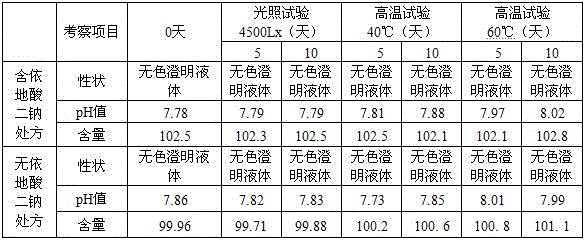

ActiveCN103768091APrevent hypocalcemia or bone calcium lossReduce visible foreign matterMetabolism disorderInorganic active ingredientsBlood calciumSodium calcium edetate

The invention provides a sodium bicarbonate injection. The injection consists of sodium bicarbonate, a pH value regulating agent and injection water, wherein the pH value regulating agent comprises a sodium hydroxide solution and carbon dioxide gas. The preparation method comprises the following steps: injecting the injection water into a preparation tank, controlling the water temperature to be 20-35 DEG C, introducing CO2 gas until the solution is saturated; putting sodium bicarbonate, stirring to sufficiently dissolve the put sodium bicarbonate; regulating the pH value to be 7.40-8.5; keeping on injecting the injection water to the preparation tank to a standard proportion; stirring the liquid medicine for 10 minutes to enable the content of the liquid medicine to be uniform; sterilizing and filtering; filling. The sodium bicarbonate injection does not contain edetate disodium and sodium calcium edentate, so that blood calcium or bone calcium caused by addition of edetate disodium can be prevented; the pH value of the liquid medicine is controlled to be 7.4-8.50, so that the stability of the pH value of the liquid medicine in the sterilizing and storing processes can be guaranteed.

Owner:CHINA OTSUKA PHARM CO LTD

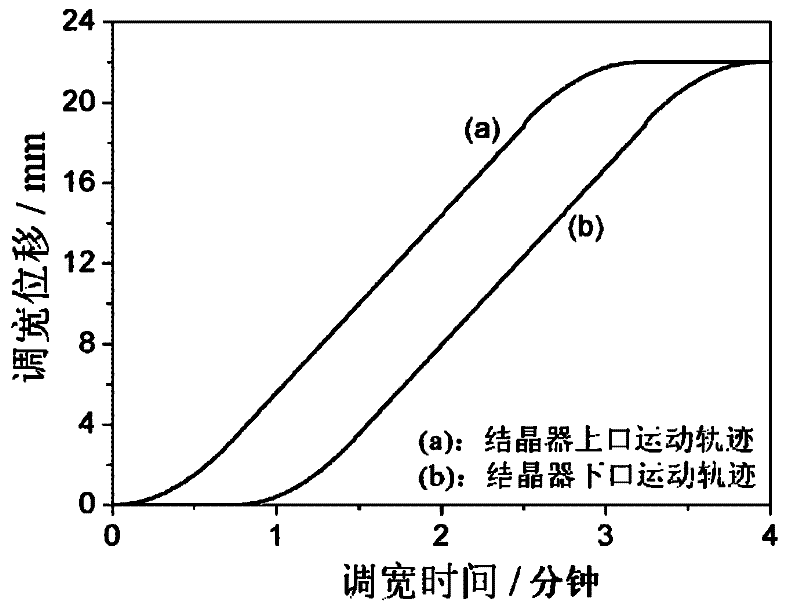

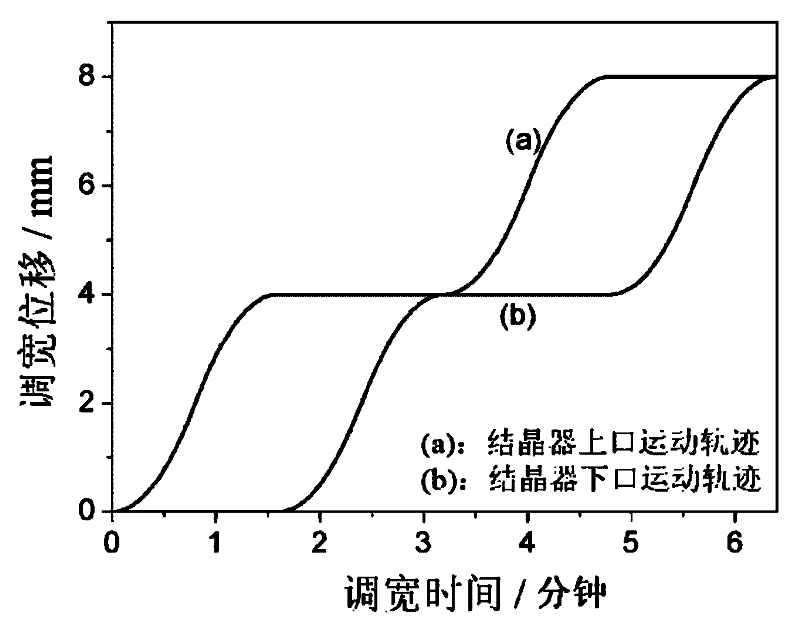

Online width-increasing adjustment method for continuous casting crystallizer in small range

The invention discloses an online width-increasing adjustment method for a continuous casting crystallizer in a small range, specifically comprising the following steps of: by considering solidification contractile properties of a high-temperature billet shell, leading the width-increasing process of the crystallizer in an online width adjustment process, which is a width-increasing process; and rapidly determining control parameters in the width-increasing process, wherein the control parameters comprise width adjustment speed, width adjustment time and the length of a wedge-shaped section; therefore, the online width adjustment operation of the crystallizer is guided; the small-range online thermal width adjustment process is realized; and the process is the width-increasing process. Byconsidering the solidification contractile properties of a casting stock and reducing friction force of a copper plate by the casting stock, the method disclosed by the invention is not only simple, feasible and convenient in operation but also has a very important significance for reducing the production cost, improving the production quality, increasing the metal yield and improving the productmarket competitiveness.

Owner:WISDRI ENG & RES INC LTD

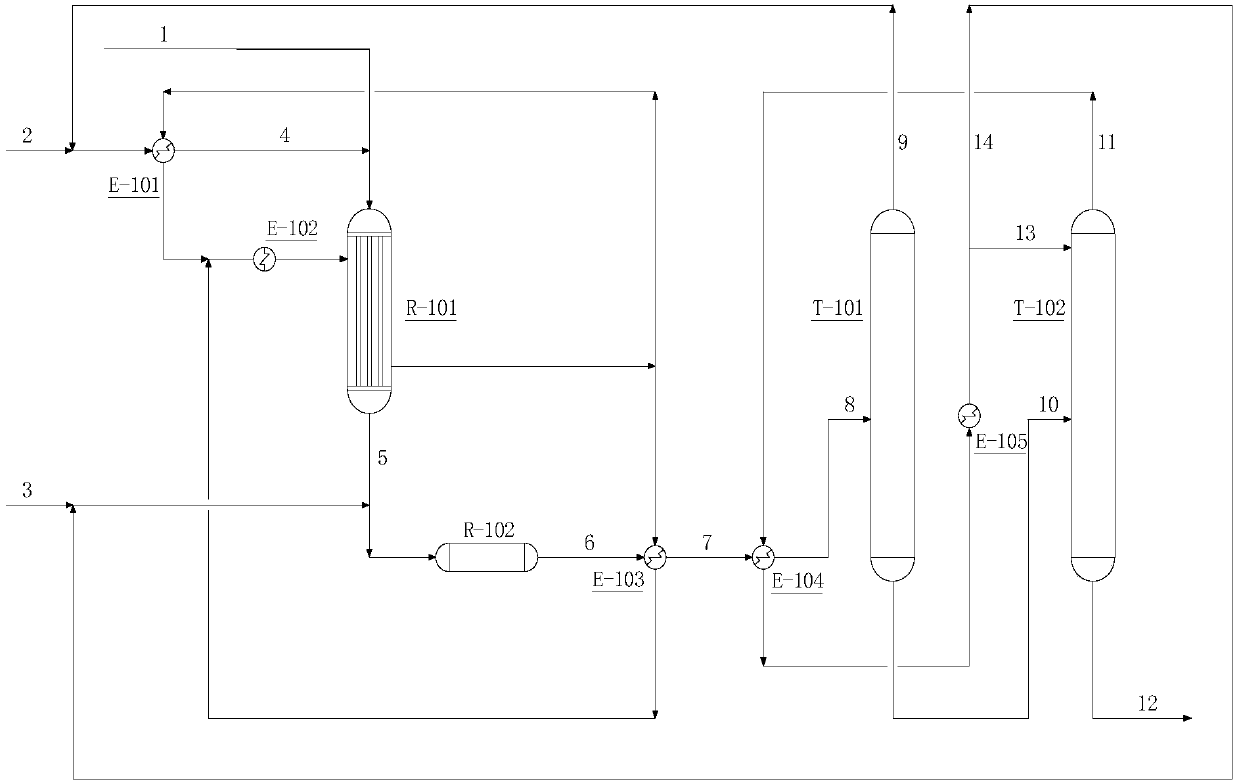

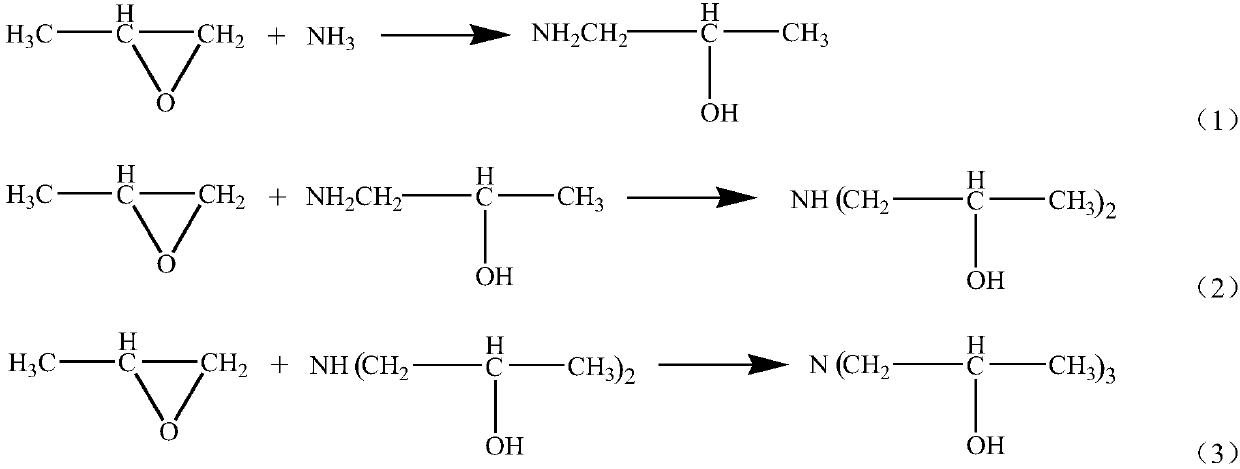

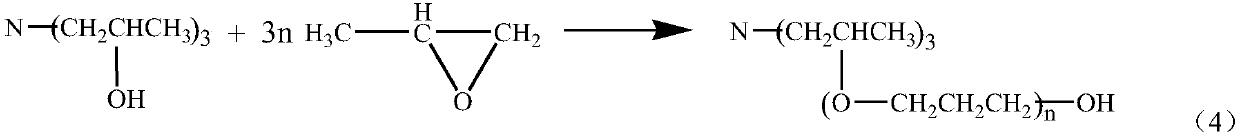

Isopropanolamine production method

ActiveCN109748804AReduce concentrationReduce the chance of spawningOrganic compound preparationChemical industryHigh concentrationFixed bed

The invention relates to an isopropanolamine production method and mainly solves problems of high device investment, large floor space, high dewatering energy consumption, large quantity of byproductsand the like in use of a long tube reactor with water serving as a catalyst in the prior art. The isopropanolamine production method is characterized in that a tubular fixed-bed reactor and a heat insulating tube reactor are adopted to guarantee complete conversion of epoxypropane; anhydrous liquid ammonia and epoxypropane are used as reaction raw materials in the tubular fixed-bed reactor, and high-concentration ammonium hydroxide and epoxypropane are used as raw materials in the heat insulating tube reactor; in the tubular fixed-bed reactor, by circulating hot water heat removal, heat removal hot water is used for preheating raw materials and pressure-reduced reaction products to realize reaction heat recovery, the reaction products sequentially passes through an ammonia recovery towerand a dewatering tower to recover ammonia and water, and overhead gas of the dewatering tower is used for preheating pressure-reduced reaction raw materials to reduce energy consumption. The method islow in byproduct quantity, equipment investment and device energy consumption can be reduced, and the method can be applied to industrial production of isopropanolamine.

Owner:CHINA PETROLEUM & CHEM CORP +1

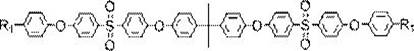

Preparation method of double-terminated polysulfone

The invention belongs to the technical field of high polymer materials, and particularly relates to a preparation method of double-terminated polysulfone, thepreparation method comprises the following steps: taking bisphenol A and 4, 4 '-dichlorodiphenyl sulfone as reaction monomers, adding an end-capping reagent A with activity lower than that of the bisphenol A, a salt-forming agent and a solvent for reaction until the molecular weight reaches the target molecular weight, adding an end-capping reagent B with activity higher than that of the bisphenol A for continuous reaction, and after the reaction is finished, carrying out post-treatment to obtain the double-terminated polysulfone. The end-capping reagent A with activity lower than that of bisphenol A is added in the early stage of the reaction to reduce the low molecular weight polymer part in the final product so that the mechanical property, heat resistance, thermal stability and other properties of the product are improved. When the reaction is about to be finished, the end-capping reagent B with higher activity than bisphenol A is added so that the molecular weight is controlled through rapid end capping, the performance of products in different batches can be more stable, and the method is more suitable for the field of preparation of hollow fiber membranes.

Owner:FUHAI (DONGYING) ADVANCED MATERIAL TECH CO LTD

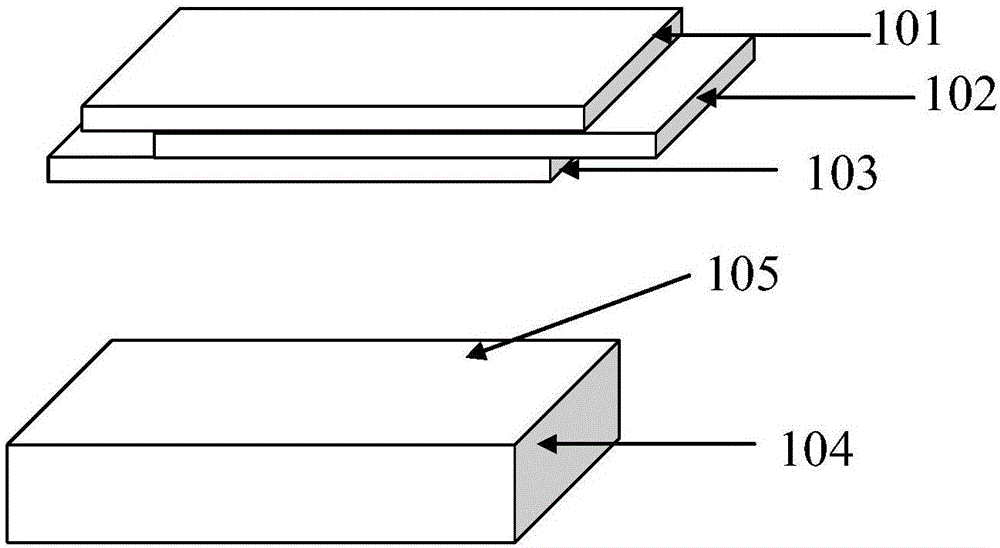

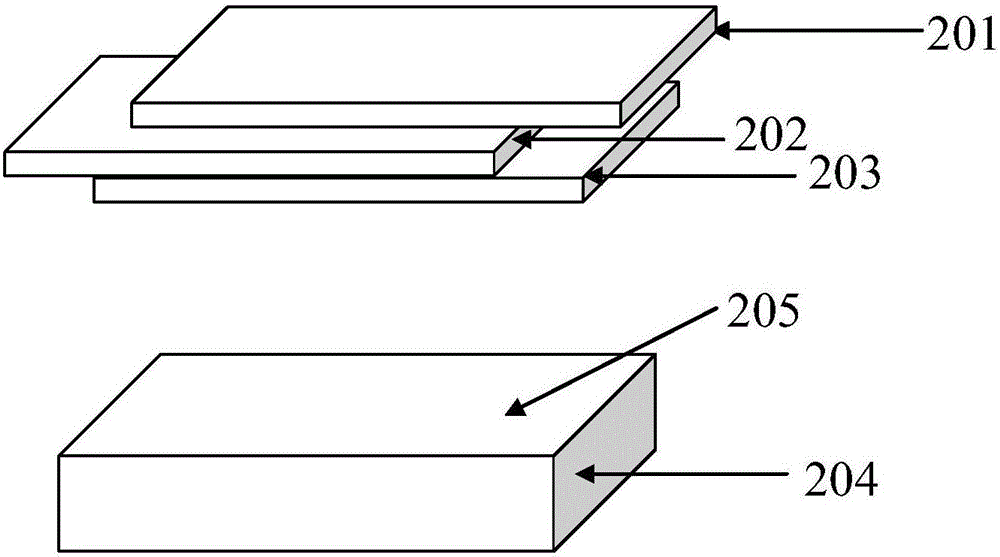

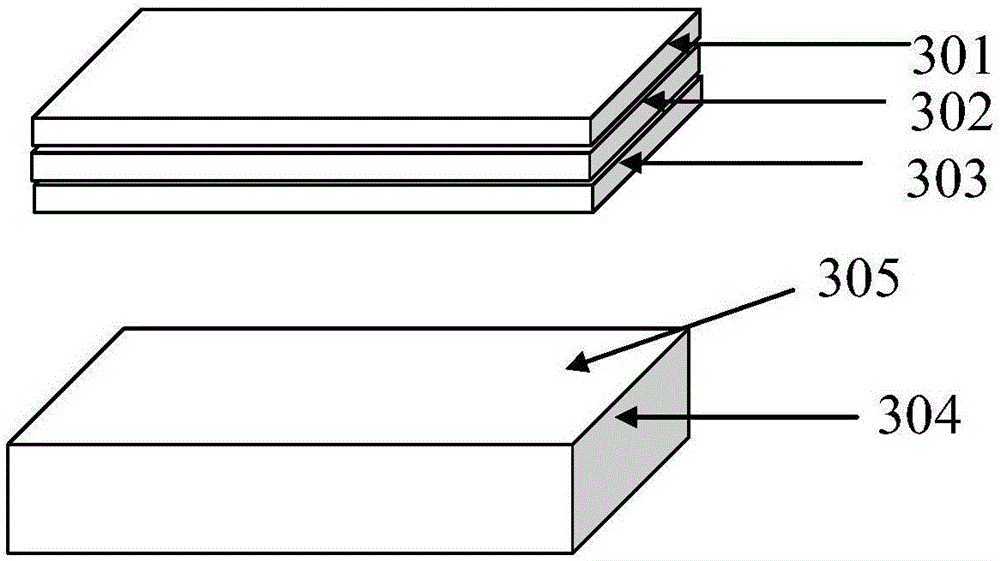

Image display device and method

ActiveCN106249491AReduce the chance of spawningReduce the chance of occurrenceNon-linear opticsOptical elementsLiquid crystalDisplay device

The invention discloses an image display device and method. The device comprises a backlight module and a plurality of liquid crystal boxes. The front projections of any two of the liquid crystal boxes have overlaid regions. Light incident faces of the liquid crystal boxes and light emitting faces of the backlight modules are oppositely arranged. According to the image display device and method, on the basis of the structure of a display panel needing to be tested, the corresponding liquid crystal box is selected, the liquid crystal boxes and the backlight module are assembled to simulate the structure of the display panel needing to be tested, and therefore images can be formed through the image display device and method, whether moire is generated or not is observed, whether moire can be generated or not on the display panel or not can be detected in the product designing stage, and the moire generation probability is decreased.

Owner:BOE TECH GRP CO LTD +1

Perlite partition board and its preparation method

InactiveCN107619227AEffective and long-lasting insulationExtend the heat preservation timePerliteFiber

The invention discloses a perlite partition board and its preparation method, and relates to the technical field of a partition board. The perlite partition board is prepared from, by weight, 55-65 parts of Portland cement, 45-50 parts of enveloped expanded perlite, 32-35 parts of phenolic resin, 29-31 parts of filler, 24-26 parts of modified glass beads, 19-21 parts of mildew-proof insect-resistagent, 14-16 parts of anti-cracking fiber, 14-16 parts of assistant and 60-65 parts of water. The perlite partition board is featured by light weight, heat insulation and being not easy to crack, andothers; the preparation method is simple and the construction performance is good.

Owner:HEFEI XIANZHIFENG AGRI TECH CO LTD

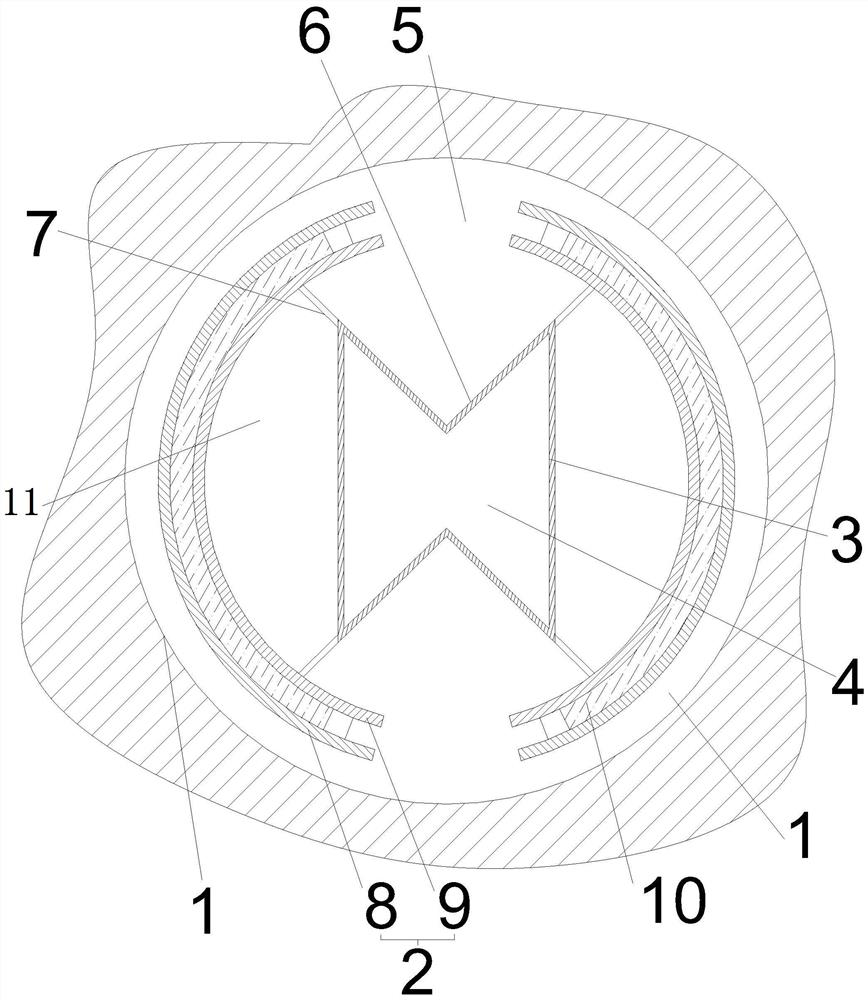

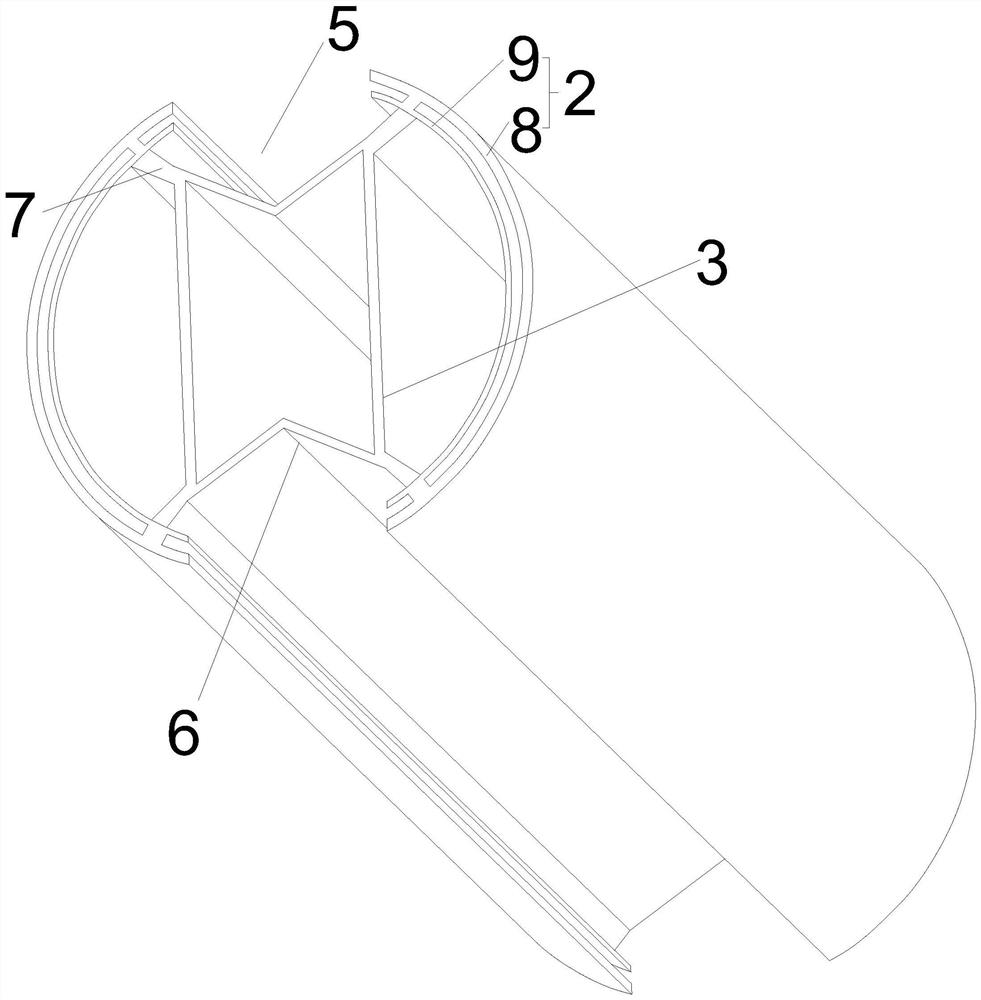

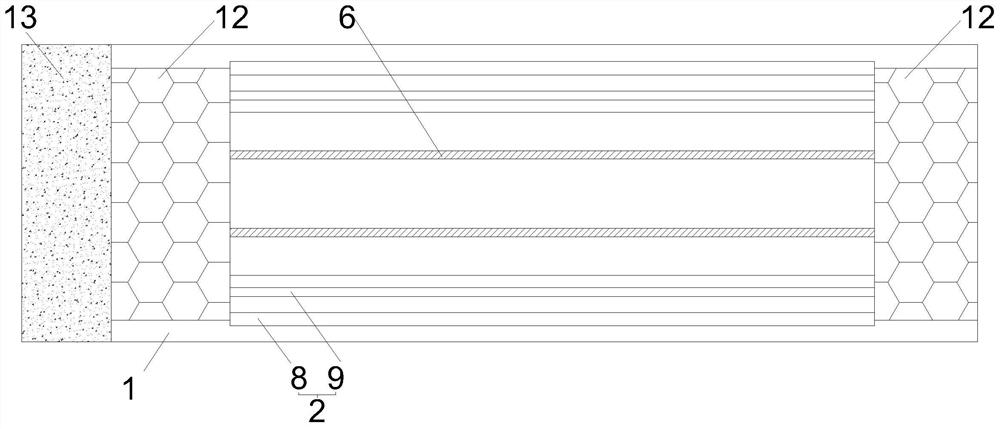

Bidirectional shaped charge blasting charging structure with slotted sleeve

ActiveCN112393654APlay a guiding roleConcentrated explosion energyBlastingDetonationExplosive Agents

The invention relates to a bidirectional shaped charge blasting charging structure with a slotted sleeve, and belongs to the technical field of explosive blasting. The bidirectional shaped charge blasting charging structure comprises a sleeve, a shaped charge liner and explosive, wherein the sleeve is arranged in a blast hole in an inserted mode, the shaped charge liner is coaxially arranged in the sleeve and is filled with the explosive; through kerfs are formed in the two sides of the sleeve in the axial direction; the center lines of the two kerfs are coplanar with the axis of the sleeve; the two sides, close to the kerfs, of the shaped charge liner are sunken inwards in a V shape to form a wedge-shaped shaped charge groove; and the outer side edge of the shaped charge liner is fixedlyconnected to the inner wall of the sleeve through an axial supporting partition plate. According to the bidirectional shaped charge blasting charging structure, detonation energy can be concentrated in the specific direction, the utilization rate of the explosion energy is increased, damage to rock mass in other directions is reduced, and a smooth wall surface is conveniently formed.

Owner:ARMY ENG UNIV OF PLA

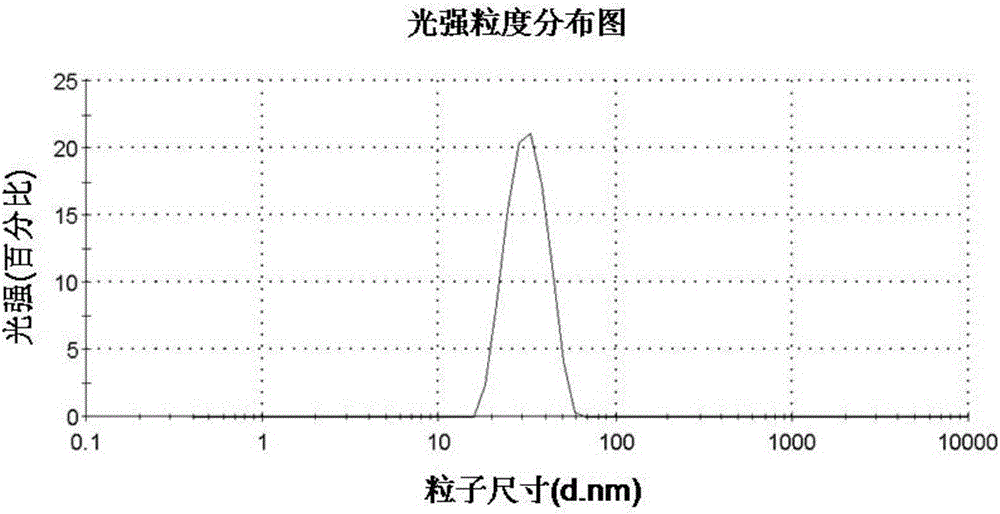

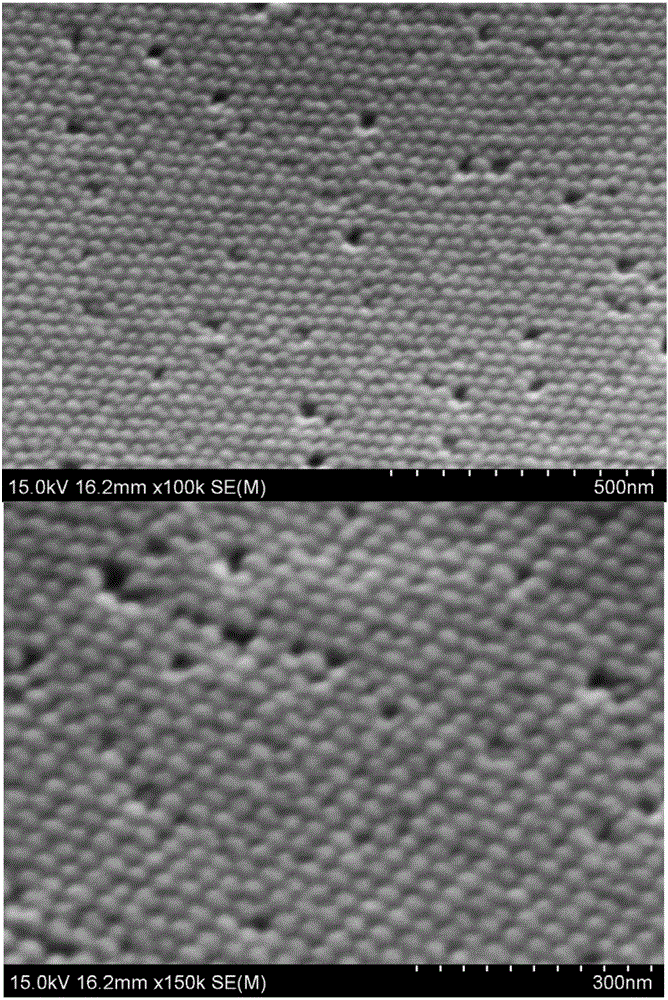

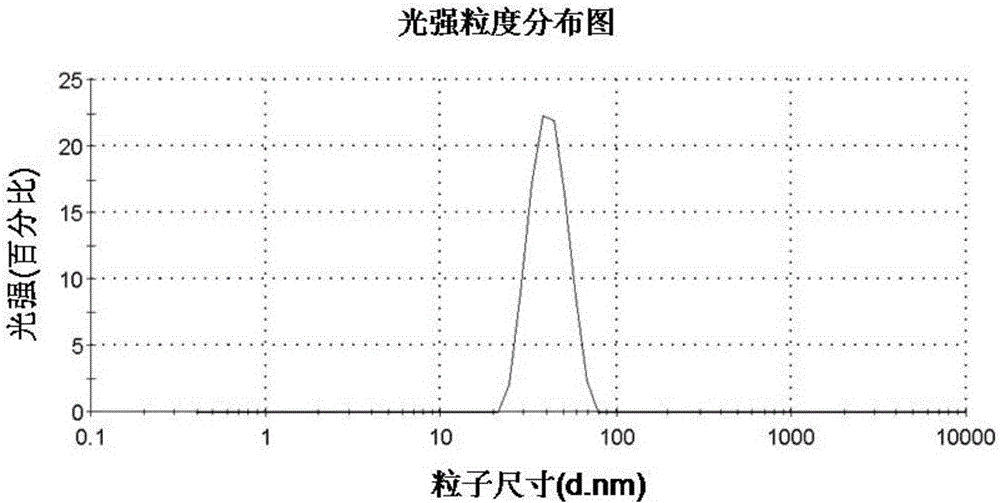

Method for preparing monodisperse large-particle-diameter silica sol through organic-inorganic complex catalysis

The invention relates to a method for preparing monodisperse large-particle-diameter silica sol through organic-inorganic complex catalysis. The method includes the following steps that 1, silica powder is added into an inorganic alkali solution, the mass ratio of the silica powder to water is controlled to be 1:8-15, and a reaction is conducted to obtain a silica sol mother solution with the pH of 9.5-10.5; 2, an organic alkali solution is added into the silica sol mother solution, a reaction is conducted at 70-90 DEG C to increase the particle diameter, and the system pH value in the reaction process is controlled to be 9.5-10.5; 3, after the reaction is finished, unreacted solid impurities in reaction liquid are removed, the product is concentrated to needed concentration, and then the monodisperse large-particle-diameter silica sol is obtained. According to the difference of the relative use quantities and proportions of two kinds of catalysts added in two steps and the difference of the particle diameters, activities and use quantities of the selected silica powder, the monodisperse large-particle-diameter silica sol with the mean particle diameter ranging from 20 nm to 100 nm or so is prepared.

Owner:SHANDONG YINFENG NANOMETER NEW MATERIAL CO LTD

Preparation of creatine monohydrate

ActiveCN101434563AAvoid decompositionInhibition of polymerizationOrganic chemistryOrganic compound preparationSal ammoniacDecomposition

The invention relates to a preparation method of kreatine monohydrate, wherein, calcium cyanamide and sodium sarcosine react in the water. The specific technological process of the preparation method is as follows: chlorhydric acid is firstly adopted for adjusting the pH value of an aqueous solution of the sodium sarcosine to 9 to 10, and the solution is heated to 60 DEG C to 90 DEG C, and then a calcium cyanamide aqueous solution with temperature below 20 DEG C is slowly added; during the addition of the calcium cyanamide aqueous solution, the chlorhydric acid is continuously used for adjusting the pH value of a reaction solution to between 9 and 10; and after the addition of the calcium cyanamide aqueous solution, kreatine monohydrate is generated in the reaction at the temperature of 60 DEG C to 90 DEG C. In the preparation method, the pH value during the whole reaction is strictly controlled so as to effectively inhibit the decomposition and polymerization of calcium cyanamide, reduce the generation probability of dicyandiamide and improve the purity of the kreatine monohydrate. The kreatine monohydrate obtained by the preparation method has the purity of more than 99.9 percent; in addition, the preparation method has high yield.

Owner:太仓市新毛涤纶化工有限公司

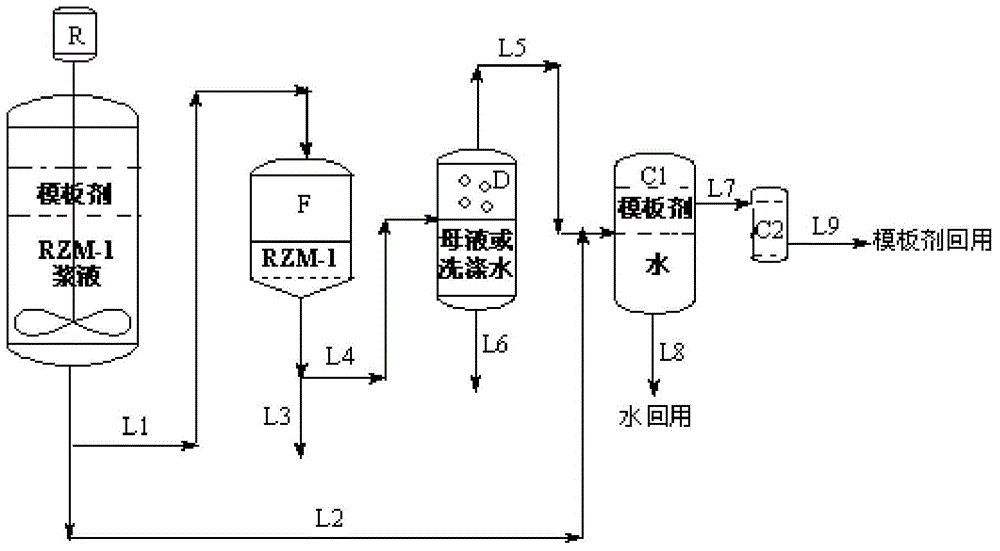

Preparation method of MWW structure molecular sieve

InactiveCN105753010AReduce the chance of spawningAvoid pollutionCrystalline aluminosilicate zeolitesMolecular sieveSlurry

The invention provides a preparation method of an MWW structure molecular sieve. The method comprises the following steps: 1, mixing a silicon source, an aluminum source, an alkali agent, a template and water, crystallizing the obtained glue solution, and cooling the crystallized glue solution to obtain a layered system with the upper layer being an organic phase and the lower layer being a molecular sieve slurry, wherein the template contains hexamethyleneimine and aniline; 2, separating the layered system to obtain the organic phase and the molecular sieve slurry; and 3, filtering the molecular sieve slurry, sequentially washing, drying and roasting the obtained filter cake, and distilling or rectifying the obtained filtrate to recover a hexamethyleneimine and water azeotrope and an aniline and water azeotrope. The method allows the superfluous template obtained after crystallization to be fully removed and recovered, and the generation probability of mixed crystals can be reduced when the template is reused; and the method can avoid environment pollution induced by hexamethyleneimine in discharged wastes.

Owner:CHINA PETROLEUM & CHEM CORP +2

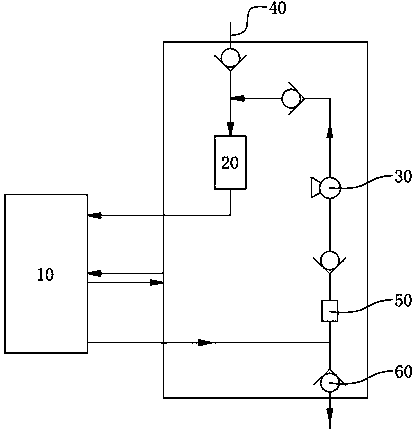

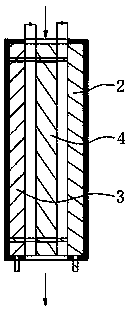

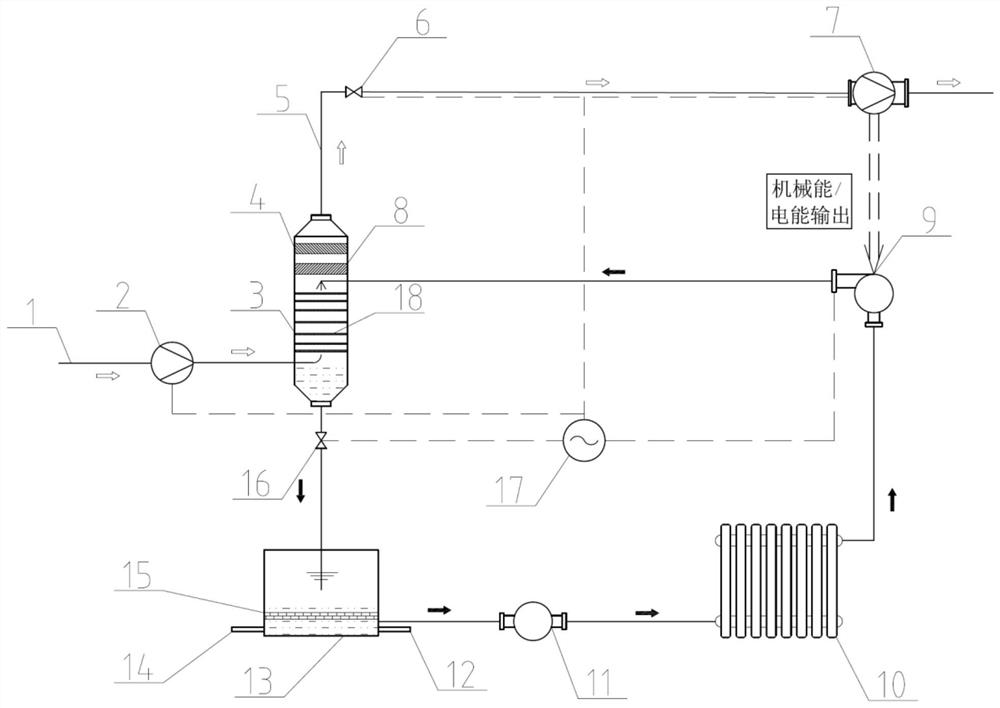

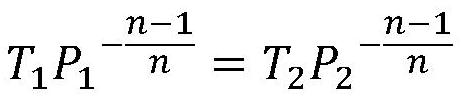

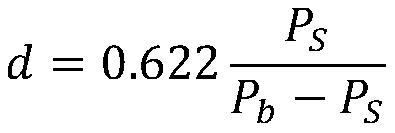

Wet flue gas source heat pump system capable of controlling input flue gas pressure

ActiveCN113091477AMeet the needs of useMeet heating requirementsGas treatmentDispersed particle separationData connectionEngineering

The invention provides a wet flue gas source heat pump system capable of controlling input flue gas pressure. The system comprises a flue gas inlet, a heat exchanger, a flue gas pressure adjusting device, a pressure control valve, a controller, a turbine, a circulating water tank and a user side heat output device. A temperature and / or pressure sensor is mounted on a flue gas outlet at the upper portion of the heat exchanger and used for detecting the temperature and / or pressure of discharged flue gas. The flue gas pressure adjusting device and the temperature and / or pressure sensor are in data connection with the controller, the controller automatically adjusts the power of the flue gas pressure adjusting device according to the detected temperature and / or pressure, and the pressure adjusting valve and the temperature and / or pressure sensor are in data connection with the controller. The controller automatically adjusts the control threshold value of the pressure adjusting valve according to the detected temperature and / or pressure. The power of the flue gas pressure adjusting device and the threshold value of the pressure adjusting valve can be controlled according to the flue gas temperature and pressure of the outlet of the heat exchanger, it can be guaranteed that the temperature and flow of a hot water outlet of the heat exchanger meet the heat supply requirement, then parameters of flue gas entering the turbine are changed, and meanwhile use of electric energy of equipment in the system is met.

Owner:SHANDONG UNIV

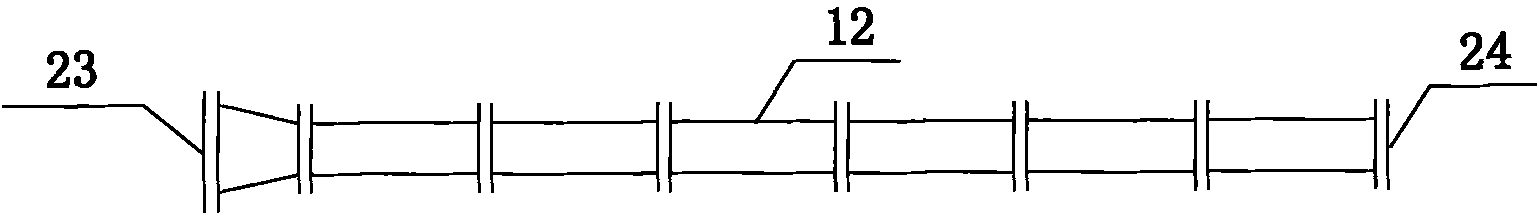

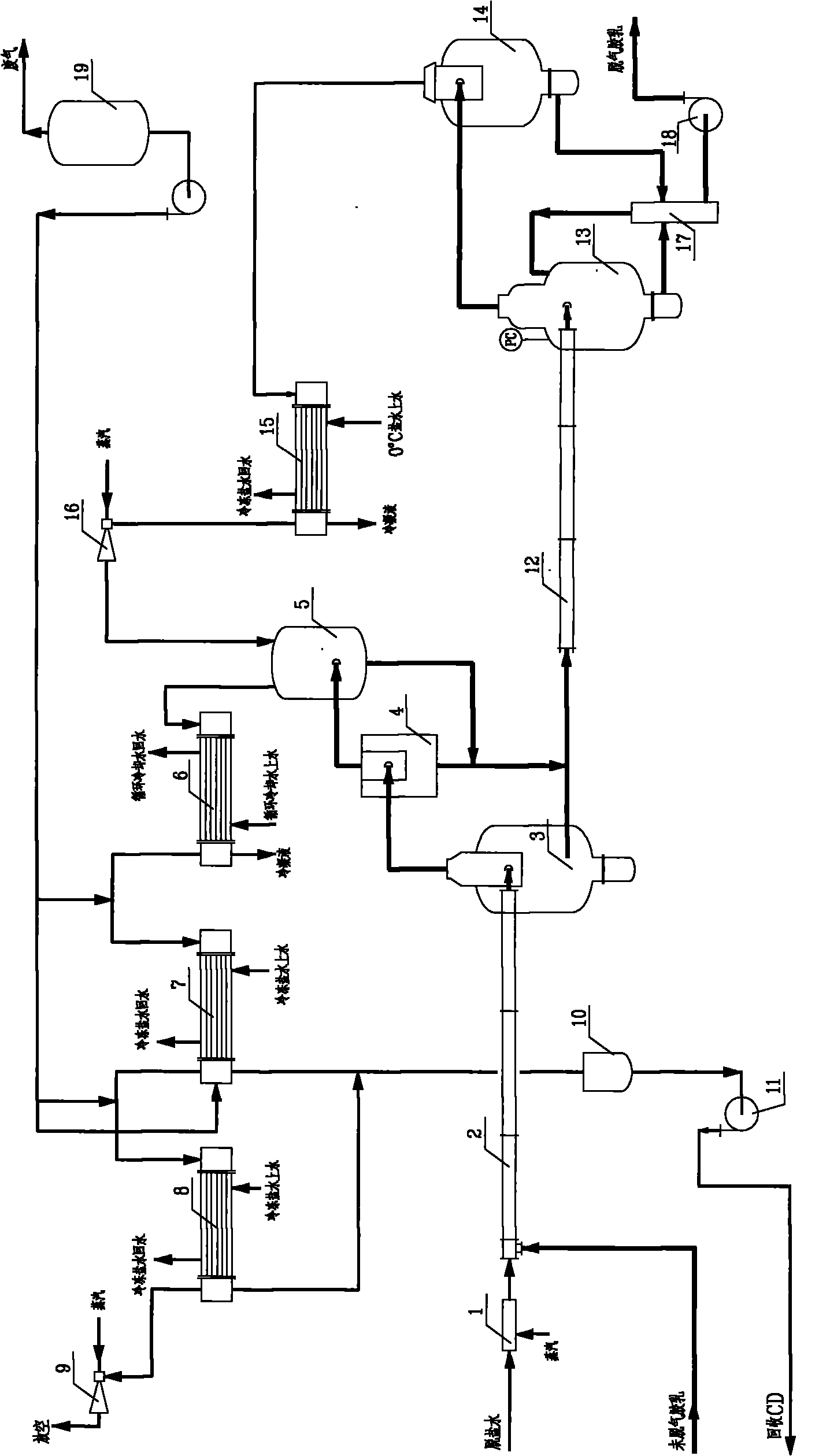

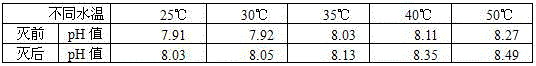

Degassing technology in synthetic process of neoprene

InactiveCN102120789AThe amount of non-condensable gas decreasesImprove heat transfer efficiencyLiquid degasificationNeopreneToluene

The invention discloses a degassing technology in the synthetic process of neoprene. The technology comprises the following steps: neoprene latex with chloroprene monomer enters a first-stage degassing pipe; under the vacuum condition, steam and neoprene latex enter a first-stage separator after steam stripping to obtain first-stage separated gas and first-stage separated neoprene latex; the first-stage separated gas enters a second-stage separator to obtain second-stage separated gas and second-stage separated neoprene latex, the second-stage separated gas enters a third-stage separator to obtain third-stage separated gas and third-stage separated neoprene latex, the third-stage separated gas passes through a water condenser, a chloroprene recycling condenser and a tail gas condenser so that water, chloroprene monomer and toluene are condensed, tail gas is sucked in a first-stage ejector, the ejector is emptied; the first-stage separated neoprene latex, the second-stage separated neoprene latex and the third-stage separated neoprene latex are mixed to enter a second-stage degassing pipe, the mixed gas is flashed under high vacuum degree and then performs first-stage separation twice to obtain final neoprene latex and twice separated gas; the twice separated gas enter first-stage separation twice to obtain final separated gas and final neoprene latex; and the final separated gas is cooled, is sucked by a second-stage ejector and enters a third-stage separator. The process disclosed by the invention has high degree of degassing and high monomer recovery rate which can be more than 90%, the process has low energy consumption; and by adopting the process, the quality of the neoprene product can be increased.

Owner:SEDIN ENG

Method for accessorily obtaining minitype cutter with high-accuracy cutting edge by utilizing film coating technology

InactiveCN102101641AReduce the chance of spawningGood repeatabilityNanostructure manufactureMicro nanoManufacturing technology

The invention relates to a method for accessorily obtaining a minitype cutter with a high-accuracy cutting edge by utilizing a film coating technology, belonging to the technical field of machining and manufacture of complex micro-nano structures and devices. The method comprises the following steps of: carrying out rough machining on a minitype cutter blank by utilizing focused ion beams in a focused ion beam vacuum sample chamber to obtain the rake face of the minitype cutter; finishing and polishing the rake face by utilizing a focused ion beam milling method; carrying out film coating treatment on the machined rake face of the minitype cutter; placing the minitype cutter with a film coated into the focused ion beam vacuum sample chamber, and machining the flank face and the lateral face of the minitype cutter according to the requirements for shape and dimension of the cutting edge by utilizing focused ion beam milling. The method has high accuracy and repeatability and is suitable for multiple materials and different cutter shapes.

Owner:TIANJIN UNIV

External thermal insulation board for building wall

ActiveCN103982019AReduce chance of spawningReduce breeding rateCovering/liningsThermal insulationCement board

The invention discloses an external thermal insulation board for a building wall. The thermal insulation board comprises a cement plate decorative layer which is arranged on an external layer, a cement plate base layer which is used for connecting the building wall and a sound-proof thermal insulation interlayer which is connected between the cement plate decorative layer and the cement plate base layer; the cement plate decorative layer is formed by the following components which comprise 95 parts of cement, 4 parts of lepiota brunneo-incarnata powder and one part of butterfly orchid petal powder. The thermal insulation board has the advantages of effectively reducing egg reproduction probabilities of worm, moths and the like at the position of the thermal insulation board, greatly reducing the worm breeding rate, effectively avoiding bird excrement polluting buildings due to the facts that the lepiota brunneo-incarnata powder is added to the cement plate decorative layer and birds hardly stay at building tops and at the modeling design position and being good in sound proof effect and good in thermal insulation effect due to the sound proof thermal insulation interlayer.

Owner:赵国平

High-strength lightweight environment-friendly composite board and preparation method thereof

InactiveCN108084702ACompletely brokenIncrease added valueWood working apparatusHeat proofingInorganic phosphateEmulsion

The invention discloses a high-strength lightweight environment-friendly composite board and a preparation method thereof. The high-strength lightweight environment-friendly composite board is prepared from the following raw materials in parts by weight: 30-40 parts of polyamide fiber, 6-8 parts of dispersible emulsion powder, 6-8 parts of capsular perlite, 30-40 parts of plant fiber, 5-7 parts ofantibacterial mothproof additive, 18-24 parts of inorganic phosphate adhesive, 2-4 parts of waterproof agent, 1-3 parts of silicon oxide, 10-16 parts of adhesive auxiliary, 10-12 parts of flame retardant additive, and 3-5 parts of zinc stearate. The high-strength lightweight environment-friendly composite board disclosed by the invention is light in weight, high in strength, waterproof and wearable, and has good antibacterial mothproof performance; the material is free from formaldehyde and peculiar smell, and is environmentally friendly; furthermore, the preparation method disclosed by the invention is low in cost, easy to obtain raw materials, concise in process, has higher practical value and good application prospect.

Owner:ANHUI YINUO WOOD PLASTIC SHEET TECH CO LTD

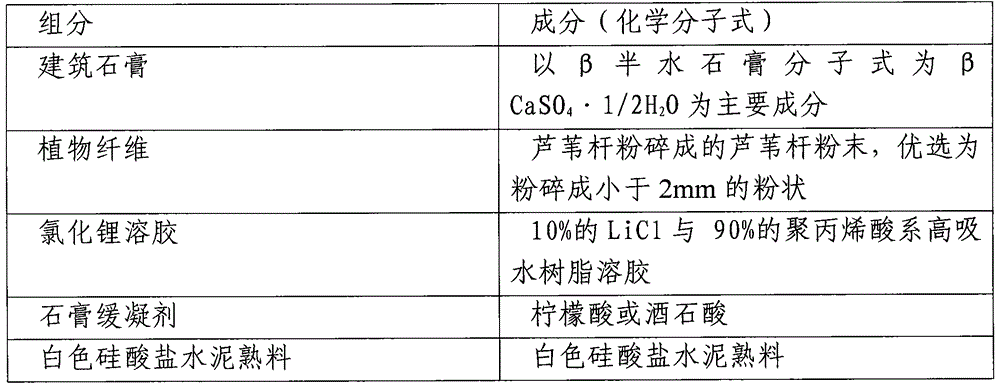

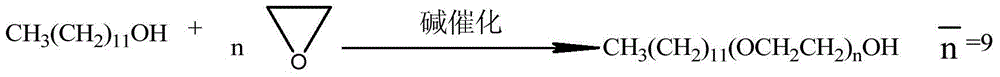

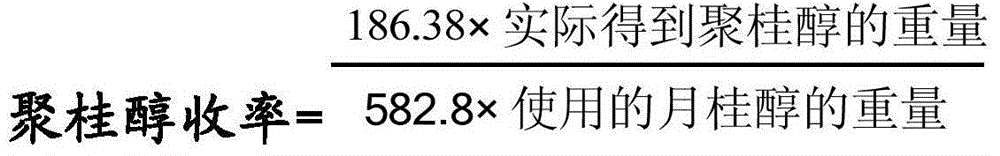

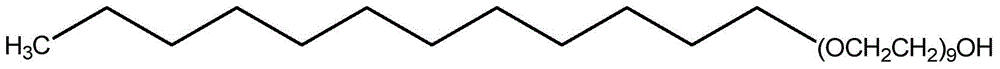

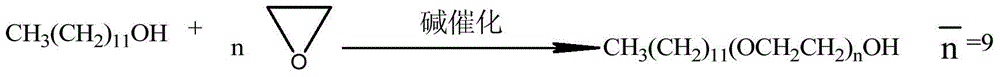

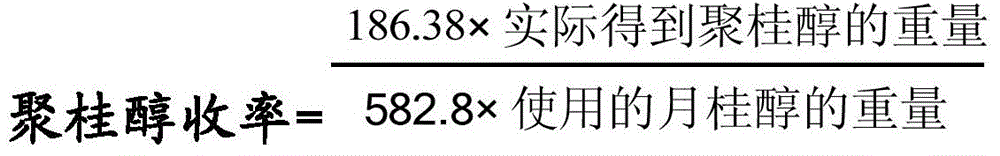

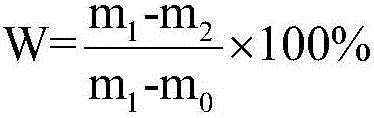

Laurinol purification method and lauromacrogol preparation method

InactiveCN104649863AMeet raw material requirementsReduce self-aggregationOrganic active ingredientsOrganic compound preparationActivated carbonAlcohol

The invention relates to a preparation technology of lauromacrogol. The preparation technology takes lauryl alcohol, potassium hydroxide, oxirane, absolute ethyl alcohol and activated carbon as raw materials. The preparation technology is simple; no special equipment is required; a solvent can be recycled, so that the industrial production cost is lowered; potassium hydroxide serves as a catalyst, so that operation is simplified; the content of heavy metal is controlled easily according to a medicinal quality standard requirement; lauromacrogol is high in yield.

Owner:BEIJING WANCHENG WEIYE MEDICAL TECH

A method for purifying lauryl alcohol and a method for preparing lauryl alcohol

InactiveCN104649863BMeet raw material requirementsReduce self-aggregationOrganic active ingredientsOrganic compound preparationActivated carbonPurification methods

The invention relates to a preparation technology of lauromacrogol. The preparation technology takes lauryl alcohol, potassium hydroxide, oxirane, absolute ethyl alcohol and activated carbon as raw materials. The preparation technology is simple; no special equipment is required; a solvent can be recycled, so that the industrial production cost is lowered; potassium hydroxide serves as a catalyst, so that operation is simplified; the content of heavy metal is controlled easily according to a medicinal quality standard requirement; lauromacrogol is high in yield.

Owner:BEIJING WANCHENG WEIYE MEDICAL TECH

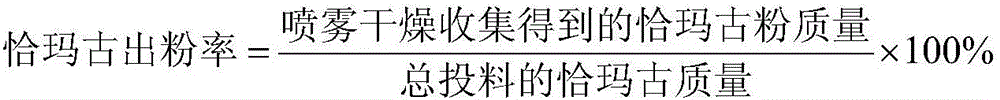

Preparation method of Brassica rapa powder

InactiveCN106562292AUniform particlesNo lumpsFruit and vegetables preservationFood homogenisationBrassica rapaRoom temperature

The invention relates to the technical field of Brassica rapa powder preparation, and specifically relates to a preparation method of Brassica rapa powder. The method comprises the following steps: S1, cutting fresh Brassica rapa into pieces, making the solid-liquid ratio of Brassica rapa pieces to water be 1:1 to 1:5, putting the mixture of Brassica rapa pieces and water in a tissue stamp mill for pulping to get Brassica rapa pulp; S2, pouring the Brassica rapa pulp into a colloid mill for colloid milling to get colloid-milled Brassica rapa pulp; and S3, adding anti-caking agent to the colloid-milled Brassica rapa pulp to get anti-caking Brassica rapa pulp. The invention discloses a preparation method of Brassica rapa powder. The Brassica rapa powder prepared by the method is yellow, has uniform particles, is non-caking and fragrant, and tastes of Brassica rapa. The Brassica rapa powder is easy to eat, and can be eaten directly after being mixed with water. Moreover, the Brassica rapa powder can be preserved at room temperature for a long time, so that the supply period of the product is prolonged, and the production and sale peaks can be balanced.

Owner:柯坪县圣泉实业有限公司 +1

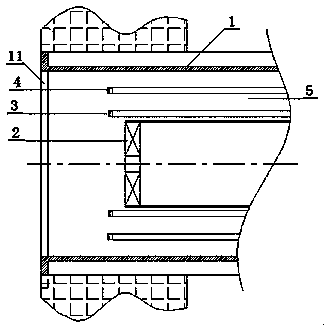

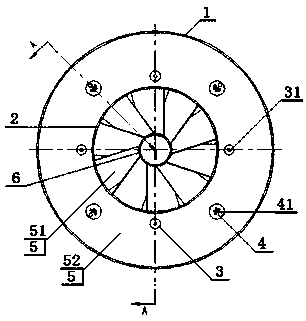

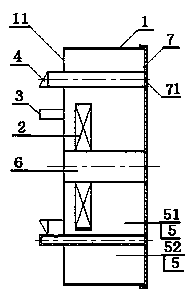

Smoke classifying and inner circulating type low-NOx and high-calorific-value fuel gas combustion device

PendingCN108488794AReduce generationEnsure production volumeGaseous fuel feeder/distributionAir/fuel supply for combustionCycloneCombustor

The invention relates to a smoke classifying and inner circulating type low-NOx and high-calorific-value fuel gas combustion device. The device is characterized in that a device body comprises a combustor throat port, a central barrel, a flame stabilizer or a cyclone, a combustion supporting air channel which consists of a direct-flow air channel and a spiral-flow air channel, and a plurality of inner fuel gas guns and outer fuel gas guns, wherein gun heads of the plurality of inner fuel gas guns and the outer fuel gas guns are arranged at the outer side of the combustor throat port in an extending manner; a plurality of front fuel gas injecting holes, side injecting holes and inclined injecting holes are formed in the plurality of inner fuel gas guns and the outer fuel gas guns. When in work, fuel gas is injected out in different directions by class through the front fuel gas injecting holes, the side injecting holes and the inclined injecting holes and is fully uniformly mixed with combustion supporting air to realize combustion, and thus the distribution uniformity and the fullness of flame can be improved; relatively-high-pressure high-temperature smoke produced by combusting close to the gun heads can flow back to a combustion supporting air area under the sucking effect of low-air-pressure combustion supporting air at the upstream and is mixed to obtain low-oxygen-contentcombustion supporting air, and the combustion supporting air is used in following uniformly-distributed flame combustion, and thus the inner smoke circulation with the same effect as an outer smoke circulating technology can be achieved on the premise that any smoke circulating facilities are not increased. The device is simple and reasonable in structure, is low in cost, and is innovation in thefield of low-NOx combustion devices.

Owner:SHANGHAI WISEBOND TECH

Sodium bicarbonate injection and preparation method thereof

ActiveCN103768091BGuaranteed stabilityAvoid churnMetabolism disorderInorganic active ingredientsDisodium EdetateWater temperature

The invention provides a sodium bicarbonate injection. The injection consists of sodium bicarbonate, a pH value regulating agent and injection water, wherein the pH value regulating agent comprises a sodium hydroxide solution and carbon dioxide gas. The preparation method comprises the following steps: injecting the injection water into a preparation tank, controlling the water temperature to be 20-35 DEG C, introducing CO2 gas until the solution is saturated; putting sodium bicarbonate, stirring to sufficiently dissolve the put sodium bicarbonate; regulating the pH value to be 7.40-8.5; keeping on injecting the injection water to the preparation tank to a standard proportion; stirring the liquid medicine for 10 minutes to enable the content of the liquid medicine to be uniform; sterilizing and filtering; filling. The sodium bicarbonate injection does not contain edetate disodium and sodium calcium edentate, so that blood calcium or bone calcium caused by addition of edetate disodium can be prevented; the pH value of the liquid medicine is controlled to be 7.4-8.50, so that the stability of the pH value of the liquid medicine in the sterilizing and storing processes can be guaranteed.

Owner:CHINA OTSUKA PHARM CO LTD

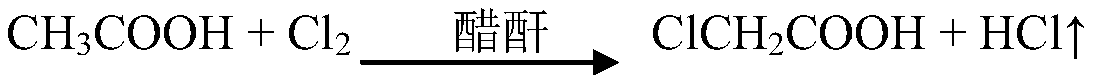

Process for continuously producing chloroacetic acid through acetic anhydride catalytic method

PendingCN109851490ATo achieve the purpose of continuous chlorinationImprove product qualityOrganic compound preparationCarboxylic compound separation/purificationAcetic acidCatalytic method

The invention discloses a process for continuously producing chloroacetic acid through an acetic anhydride catalytic method. The production process comprises the steps: using acetic acid and chlorineas raw materials, using acetic anhydride as a catalyst, introducing chlorine for a reaction in a first-stage chlorination main kettle, conveying a reaction liquid to a second-stage chlorination main kettle through a pump, introducing chlorine for a reaction continuously in the second-stage chlorination main kettle, conveying the reaction liquid in the second-stage chlorination main kettle to a hydrolysis kettle through a pump, adding an appropriate amount of water to the hydrolysis kettle, removing unreacted intermediate products through a hydrolysis reaction, conveying the hydrolyzed reactionliquid to a rectification column through a pump, introducing steam into a reboiler of the rectification column for material heating, and separating the light component acetic acid and the heavy component chloroacetic acid from the reaction liquid; and condensing liquid foam in the reaction gas of the chlorination reaction kettles through a first-stage condenser and a second-stage condenser, returning the condensed liquid foam to the chlorination reaction kettles through reflux pipes separately, and sending the reaction gas condensed by the condensers to an exhaust gas treatment process for further treatment.

Owner:HUBEI TAISHENG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com