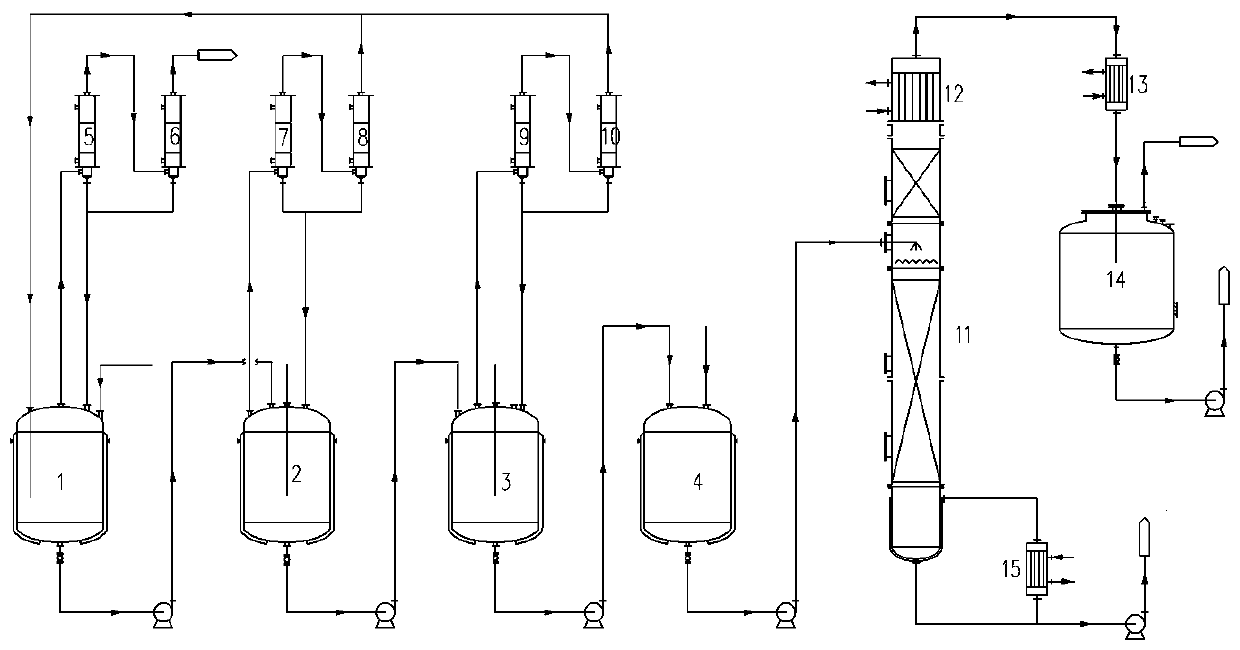

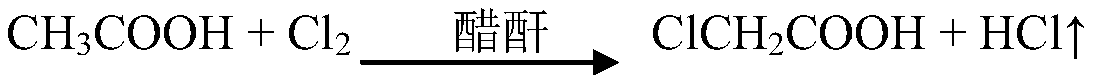

Process for continuously producing chloroacetic acid through acetic anhydride catalytic method

A technology of chloroacetic acid and acetic anhydride, which is applied in chemical instruments and methods, preparation of organic compounds, separation/purification of carboxylic acid compounds, etc. It can solve the problem of poor quality of by-product hydrochloric acid, large equipment footprint, and difficult purification and purification, etc. Problems, to achieve the effect of being beneficial to downstream use, occupying a large area, and improving the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1) Take acetic acid and chlorine as raw materials, use acetic anhydride as a catalyst, control the temperature of the feed liquid at 98°C in the primary chlorination reaction main kettle, and make the concentration of monochloroacetic acid in the reaction solution reach 73% by the chlorine reaction, pump the The reaction liquid is delivered to the secondary chlorination reaction main kettle;

[0051] 2) In the secondary chlorination reaction main kettle, keep the temperature of the feed liquid at 97 ° C, continue to feed chlorine so that the concentration of monochloroacetic acid in the reaction solution reaches 88%, and terminate the chlorination reaction, pump the secondary chlorination reaction main kettle The reaction solution in the tank is transported to the hydrolysis tank;

[0052] 3) Raise the temperature of the reaction solution in the hydrolysis tank to 110°C, add an appropriate amount of water in the hydrolysis tank, control the water content in the reaction...

Embodiment 2

[0058] 1) Take acetic acid and chlorine as raw materials, use acetic anhydride as a catalyst, control the temperature of the feed liquid at 97°C in the primary chlorination reaction main kettle, and the chlorine reaction makes the concentration of monochloroacetic acid in the reaction solution reach 71%. The reaction liquid is delivered to the secondary chlorination reaction main kettle;

[0059] 2) In the secondary chlorination reaction main kettle, keep the temperature of the feed liquid at 99 ° C, continue to feed chlorine so that the concentration of monochloroacetic acid in the reaction solution reaches 87%, and terminate the chlorination reaction, pump the secondary chlorination reaction main kettle The reaction solution in the tank is transported to the hydrolysis tank;

[0060] 3) Raise the temperature of the reaction solution in the hydrolysis tank to 112°C, add an appropriate amount of water in the hydrolysis tank, control the water content in the reaction solution a...

Embodiment 3

[0066] 1) Take acetic acid and chlorine as raw materials, use acetic anhydride as a catalyst, control the temperature of the feed liquid at 100°C in the primary chlorination reaction main kettle, and make the concentration of monochloroacetic acid in the reaction solution reach 74% by the chlorine reaction, and pump the The reaction liquid is delivered to the secondary chlorination reaction main kettle;

[0067] 2) In the secondary chlorination reaction main kettle, keep the temperature of the feed liquid at 102 ° C, continue to feed chlorine so that the concentration of monochloroacetic acid in the reaction solution reaches 89%, and terminate the chlorination reaction, pump the secondary chlorination reaction main kettle The reaction solution in the tank is transported to the hydrolysis tank;

[0068] 3) Raise the temperature of the reaction solution in the hydrolysis tank to 114°C, add an appropriate amount of water in the hydrolysis tank, control the water content in the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com