Online adjusting method for extensively reducing width of continuous casting mold

A continuous casting mold and width reduction technology, which is applied to the field of large-scale continuous casting mold online thermal adjustment width reduction, can solve the problems of affecting the production rhythm of steel mills, unfavorable use of equipment, and reducing the output of slabs, etc. Metal yield, ease of operation, improved productivity and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

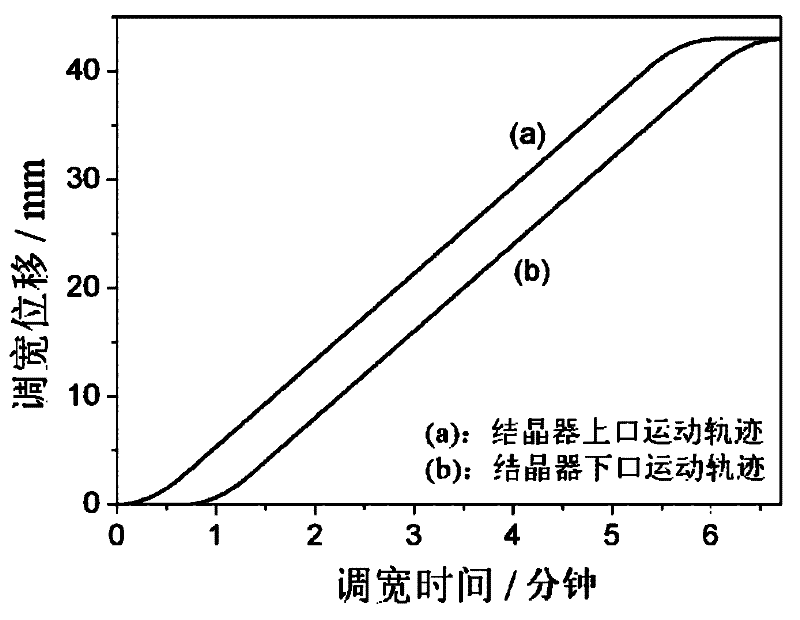

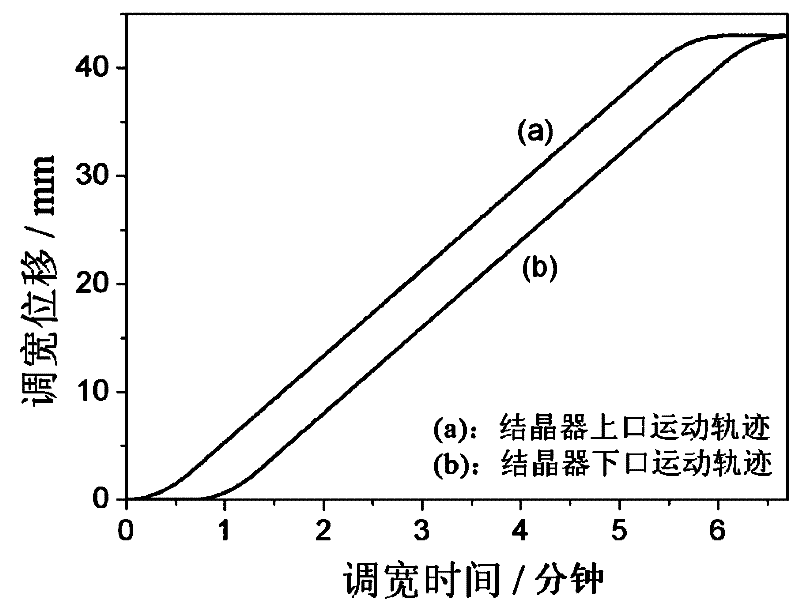

[0047] The taper on one side of the mold is 6 mm, the taper variable in the width adjustment process is 6 mm, the casting speed is 1.2 m / min, the mold height is 900 mm, the meniscus height is 800 mm, the width is reduced by 86 mm when both sides are widened , to get the corresponding width adjustment process speed, time and wedge length relationship.

[0048] From the above analysis, it can be seen that the width of the crystallizer is adjusted on both sides, and the width of the single side is 43 mm. The relevant parameters in the process of width adjustment can be set as:

[0049] tanα=6 / 900, tanθ=(6-6) / 900, V c =1200 mm / min, l =800 mm, Δl= 6mm, W=43mm

[0050] therefore:

[0051] 1. Width adjustment speed:

[0052] (1)

[0053] 2. Widening time:

[0054] (2)

[0055] 3. Length of wedge segment:

[0056] (3)

[0057] In this embodiment, during the width adjustment process, the time displa...

Embodiment 2

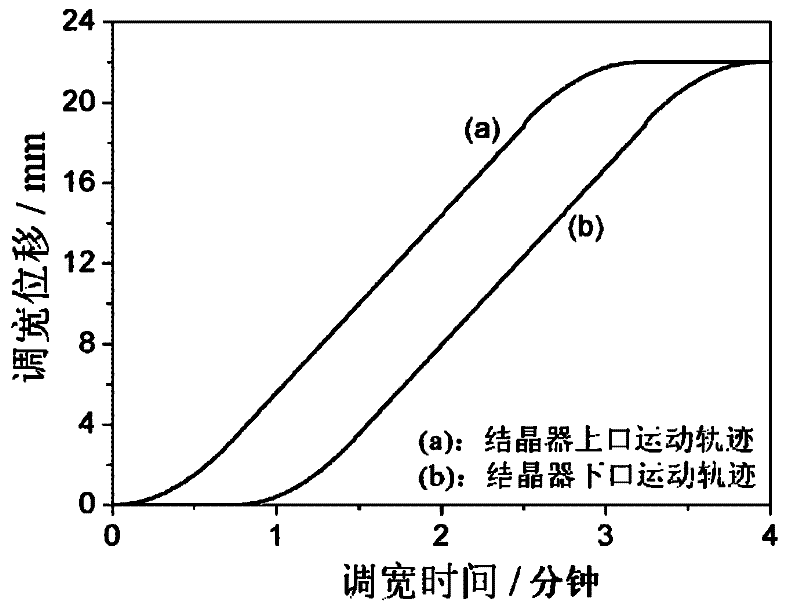

[0059] The taper on one side of the mold is 8.4 mm, the taper variable in the width adjustment process is 7.2 mm, the casting speed is 1.1 m / min, the mold height is 900 mm, the meniscus height is 800 mm, and the width is reduced by 44 mm when the width is adjusted on both sides. Obtain the corresponding width adjustment process speed, time and wedge segment length relationship.

[0060] From the above analysis, it can be seen that the width of both sides of the crystallizer is adjusted, and the width of one side is 22 mm. The relevant parameters in the process of width adjustment can be set as:

[0061] tanα=8.4 / 900, tanθ=(8.4-7.2) / 900, V c =1100 mm / min, l =800 mm, Δl= 7.2mm, W=22mm

[0062] therefore:

[0063] 1. Width adjustment speed:

[0064] (1)

[0065] 2. Widening time:

[0066] (2)

[0067] 3. Length of wedge segment:

[0068] (3)

[0069] In this embodiment, duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com