Patents

Literature

56results about How to "Meet raw material requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel edible antibacterial food packaging film and preparation method thereof

InactiveCN106750580AWide variety of sourcesMeet raw material requirementsFlexible coversWrappersEmulsionChemistry

The invention discloses a novel edible antibacterial food packaging film and a preparation method thereof. The novel edible antibacterial food packaging film is prepared from chitosan, gelatin and cinnamon essential oil. The preparation process is simple, and the preparation method only comprises the following steps: respectively preparing a chitosan solution and a gelatin solution, respectively adding glycerin plasticizing agents for mixing, adding a natural antibacterial agent cinnamon essential oil, emulsifying, fully dispersing the emulsion, performing film casting, thereby obtaining the product. The obtained food packaging film has excellent tensile strength (TS is equal to 42.17+ / -1.84MPa) and ductility (EAB is equal to 62.34+ / -2.66%), has obvious effects of inhibiting common spoilage microorganisms such as Escherichia coli and staphylococcus aureus in foods higher than those of PE preservative films in the market, is suitable for packaging various foods and meets the market requirements.

Owner:FUZHOU UNIV

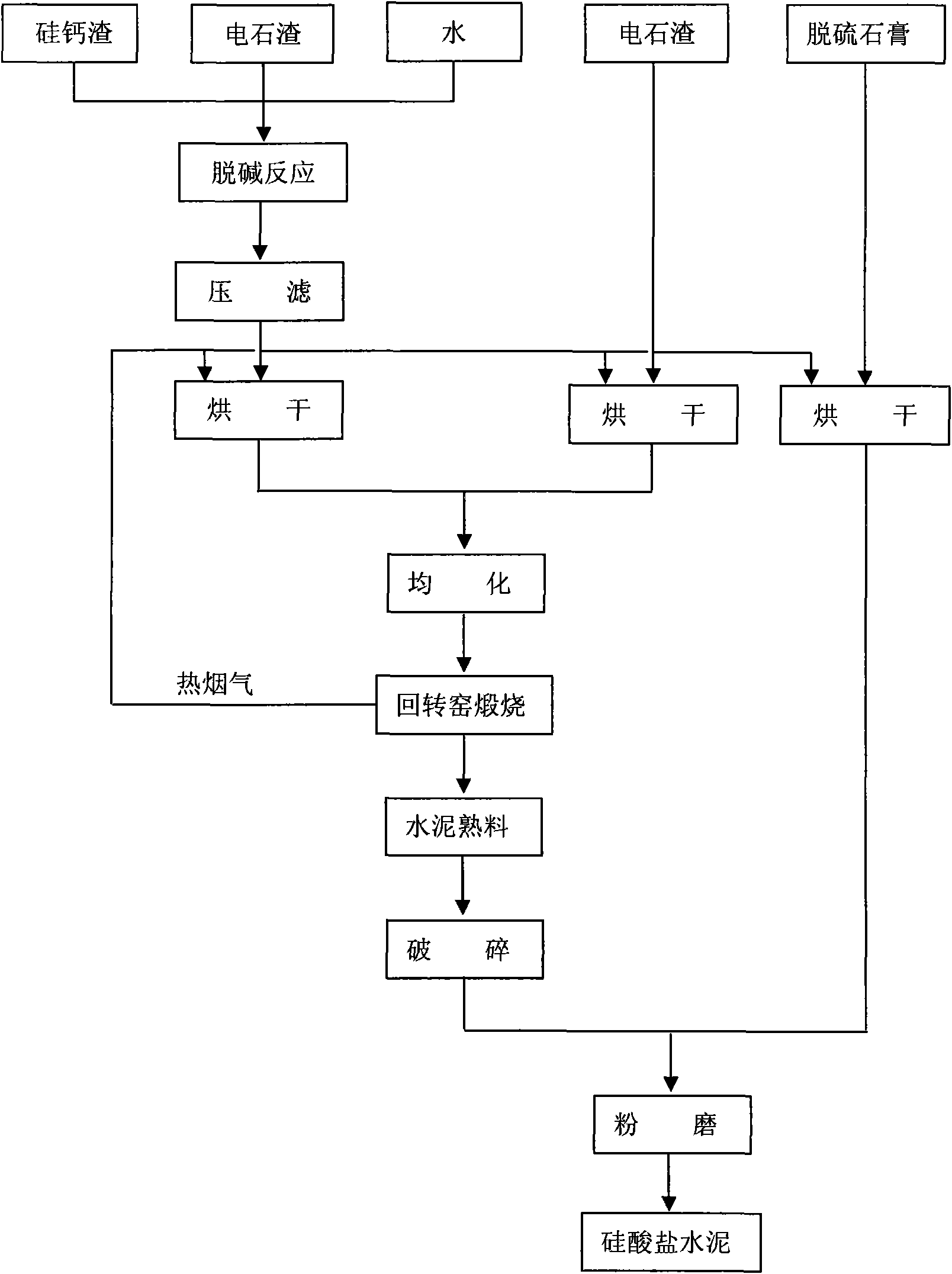

Method for producing silicate cement by using silico-calcium dregs and carbide dregs

InactiveCN101591150AReduce contentMeet the requirements of alkali contentCement productionCalcinationMaterials science

The invention provides a method for producing silicate cement by using silico-calcium dregs and carbide dregs, relating to the technical field of building materials. The method has the following steps: 1. adding carbide dregs and water into silico-calcium dregs followed by dealkalization and carrying out pressure filtering and drying on the dealkalized silico-calcium dregs if the alkali content in the silico-calcium dregs is high, or directly drying the silico-calcium dregs if the alkali content in the silico-calcium dregs is low; and drying the carbide dregs and desulfurated plaster respectively; 2. dosing and homogenizing the dealkalized silico-calcium dregs and carbide dregs after drying; 3. sending the homogenized crude materials into a rotary kiln for high temperature calcinations and obtaining the cement clinker after cooling; and 4. smashing the cement clinker and sending the smashed cement clinker and the dried desulfurated plaster into a cement grinding mill for grinding to prepare the silicate cement. Compared with the prior art, the method of the invention is simple in process, low in investment, low in production cost, low in energy consumption, and stable in the prepared silicate cement performance.

Owner:TONGFANG ENVIRONMENT

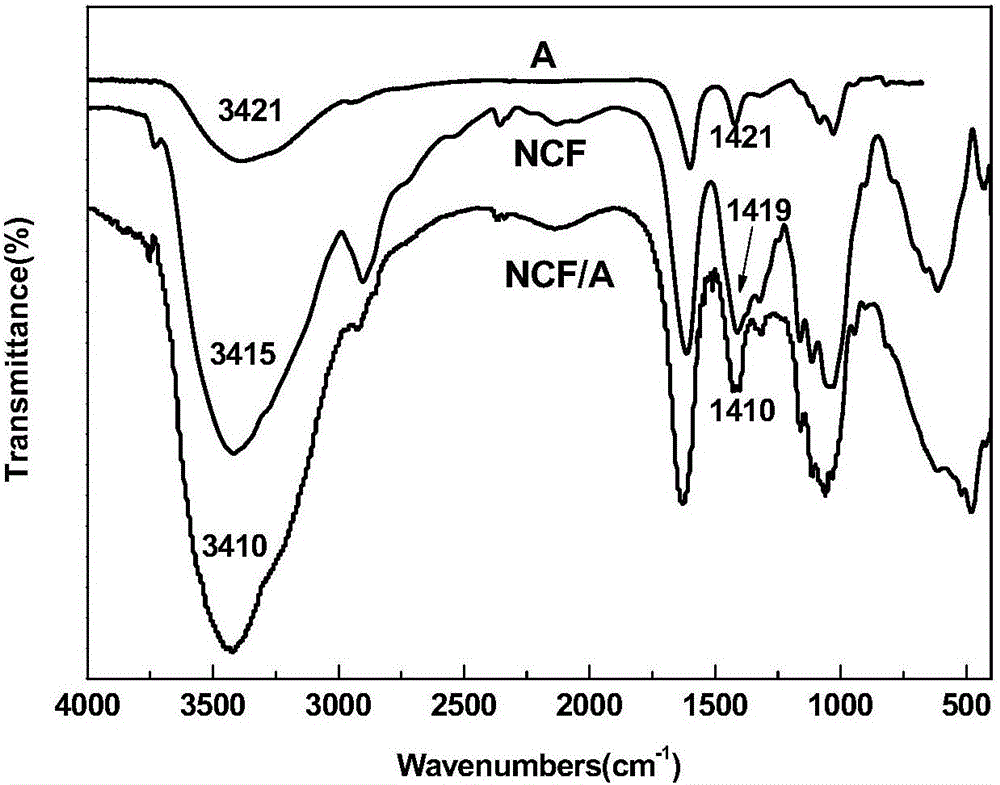

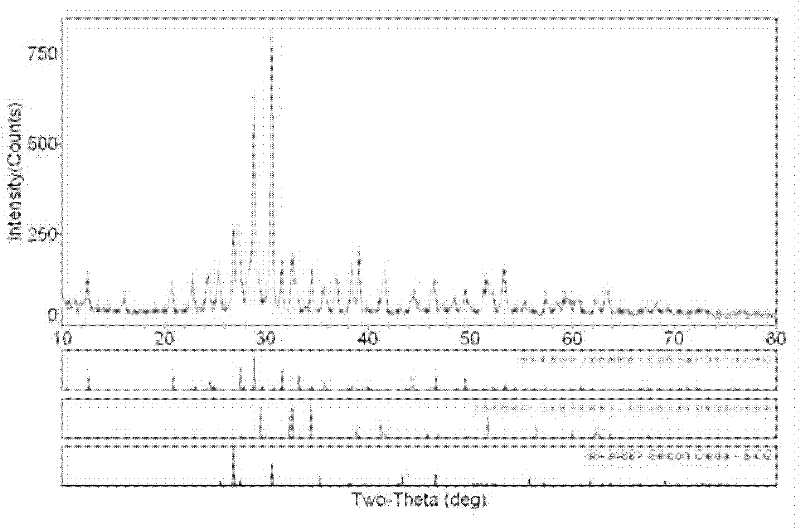

Preparation method of composite fiber of cellulose nanometer fibrils/alginate

ActiveCN106521706ALarge specific surface areaHigh crystallinityConjugated cellulose/protein artificial filamentsArtifical filament manufactureCelluloseFiber

The invention discloses a preparation method of composite fiber of cellulose nanometer fibrils / alginate. The method includes steps of evenly dispersing cellulose nanometer fibrils under ultrasound wave function, and preparing aqueous suspension; then evenly mixing with alginate solution and obtaining the mixed solution of cellulose / sodium alga acid as spinning raw liquid; spinning by wet method and obtaining the composite fiber of cellulose nanometer fibrils / alginate. The preparation method is simple and easy to operate, the technique is green and environmental-friendly; the prepared composite fiber of cellulose nanometer fibrils / alginate is an environment-friendly recycled material, and has the same excellent biocompatibility and biological degradability as the pure alginate fiber; the oriental controllability of cellulose nanometer fibrils is enhanced, and the cellulose nanometer fibrils and the base alginate are formed to be an interpenetrating polymer network structure, thereby effectively improving the intensity and flexibility of composite fiber and greatly improving the adaptation of alginate fiber in textile and garment and medical treatment health domain.

Owner:QINGDAO UNIV

Process for screening and refining wheat starch

The invention discloses a process for screening and refining wheat starch. The process comprises the following steps: screening starch slurry material by a 250-mesh primary centrifugal screen at the rotation speed of 900r / min, screening oversize materials by a 200-mesh secondary centrifugal screen at a rotation speed of 900r / min, collecting the undersized materials screened out by the primary and the secondary centrifugal screen and feeding into a primary horizontal-spiral decanter centrifuge for separation treatment, wherein obtained light-phase substances such as soluble proteins and sugar can be treated in other ways, the obtained starch phase is concentrated by a secondary horizontal-spiral decanter centrifuge to obtain the finished starch slurry; and drying the finished starch slurry to obtain the standard finished starch product. Compared with the prior art, the process has the advantages of simple technology and reduction of energy consumption due to the use of the horizontal-spiral decanter centrifuge instead of the cyclone separator unit used in the conventional processes.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

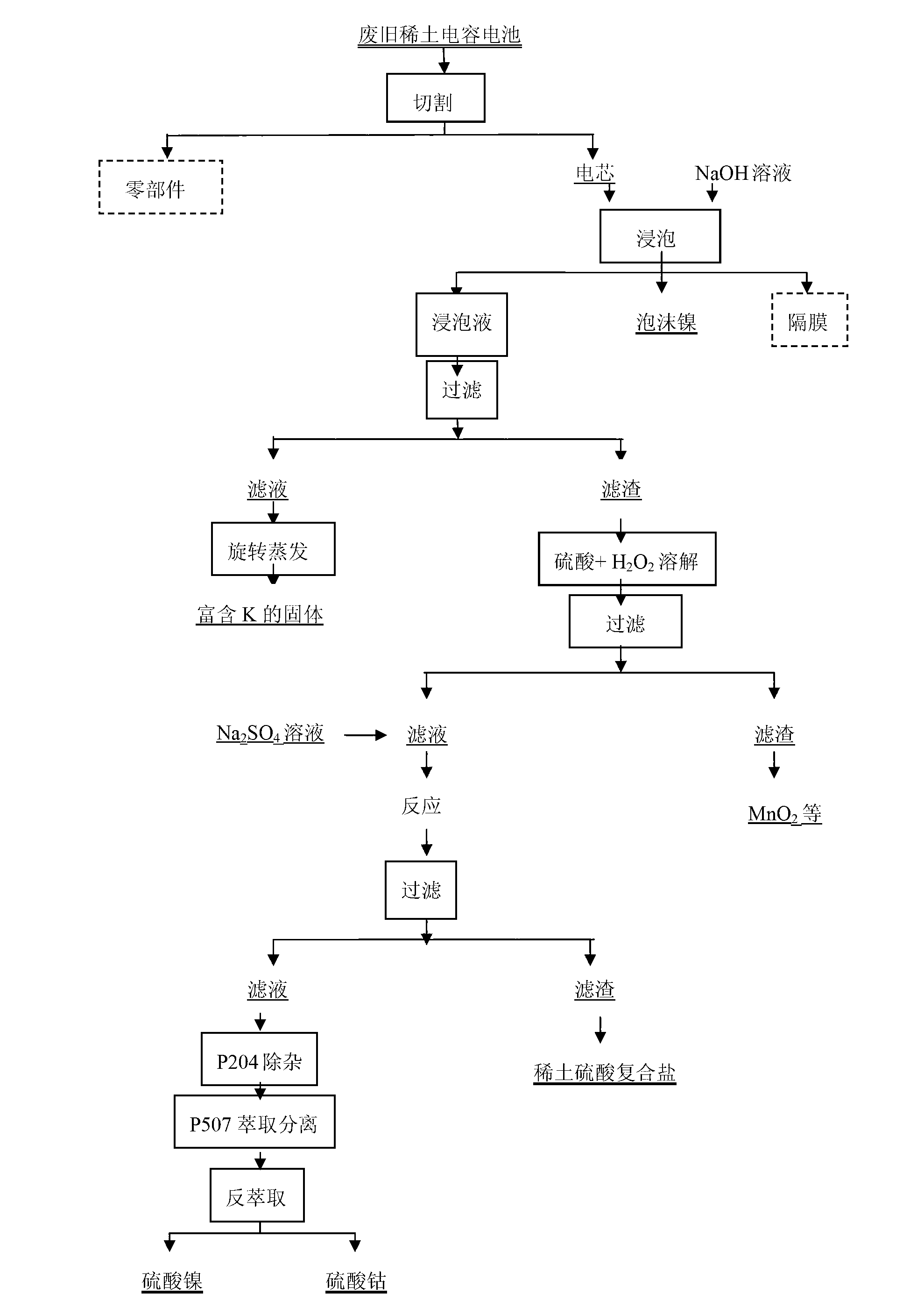

Integrated recovery method of waste and old rare earth capacitance battery

ActiveCN103233123AImplement step by stepAchieve recyclingProcess efficiency improvementCapacitanceRecovery method

The invention relates to an integrated recovery method of waste and old rare earth capacitance battery, which belongs to the colored metallurgy technology field of rare earth, nickel and other metal resources. The method comprises the following steps: cutting waste and old rare earth capacitance battery, separating electrical core and components; adding NaOH into electrical core for ultrasonic immersion, and then separating diaphragm and foamed nickel, and obtaining the soak solution; filtering, dissolving filter residues with sulfuric acid and H2O2; filtering, adding Na2SO4 into the filtrate for reaction; filtering the reaction solution, and the filter residue is a rare earth sulfuric acid composite salt, and obtaining battery grade nickel sulfate and cobalt sulphateby P204 edulcoration, P507 extraction separation and re-extraction. The invention realizes the grading recovery of battery spare and accessory parts and battery materials, and separation of battery spare and accessory parts and electrical core, and recycle of battery housing and pole, and separation and re-utilization of rare earth, nickel and cobalt, thereby establishing a base for dynamic reservations of rare earth, nickel and other rare resources with low cost and obvious economic benefit.

Owner:淄博国利新电源科技有限公司

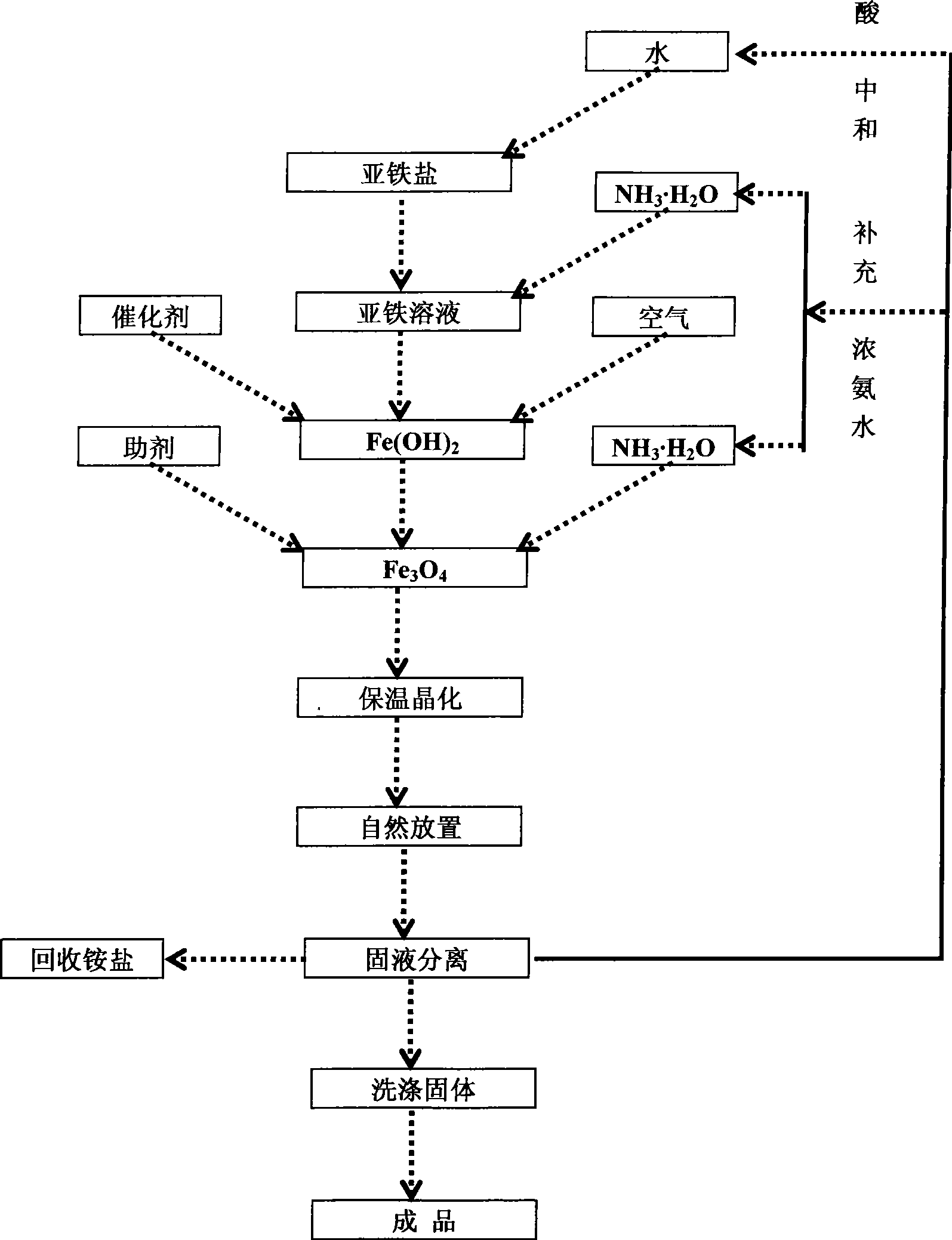

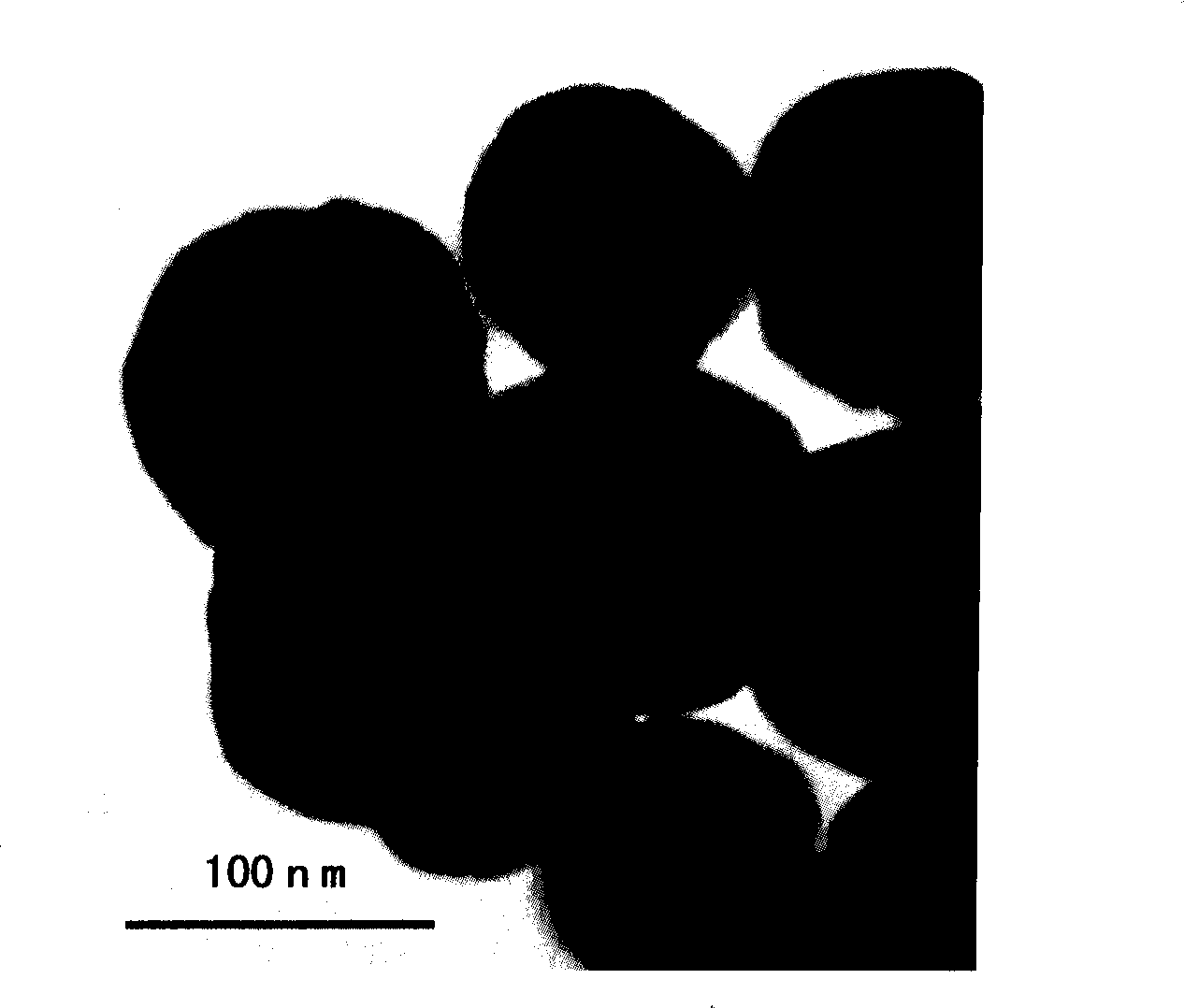

Method for preparing spherical Fe3O4 nano powder

ActiveCN101381109AShorten the time of the oxidation reactionReduce energy consumptionFerroso-ferric oxidesFerrous saltsSpherical shaped

The invention discloses a method for preparing spherical Fe3O4 nanometer powder body. The method comprises the following steps: (1) an aqueous solution of ferrous salt is prepared, heated and stirred to regulate the PH value of between 4.0 and 8.0: (2) the solution is put to a reactor with a gas distributor, stirred and communicated with air; 5 to 15 minutes later after the air is communicated, NH4NO2 or NaNO2 is added for reaction; when the molar ratio of Fe<3+> and Fe<2+> is between 1.6 and 2.6, the air is stopped to communicate; (3) the solution is stirred to regulate the PH value of between 8.0 and 14.0 and react for 1.0 to 5.0 hours; (4) stirring and heating are stopped to naturally cool the solution to the temperature of between 20 and 35 DEG C; and (5) the solution is subjected to solid-liquid separation; solid is washed by deionized water and is dried to prepare the spherical Fe3O4 nanometer powder body. The method can use an industrial byproduct which is cheap and easy to obtain as a raw material, shorten time for oxidation reaction and reduce energy consumption; and the product meets the requirement on the raw material of high-grade ink powder and has no environmental pollution.

Owner:TIANJIN UNIV

Method for comprehensively recovering aluminum, silicon and titanium from pyrite tailings

ActiveCN102409177AEfficient separationHigh aspect ratioPolycrystalline material growthFrom normal temperature solutionsSodium silicateSolid product

The invention discloses a method for comprehensively recover aluminum, silicon and titanium from pyrite tailings. The method comprises the following steps: performing oxidizing roasting on the pyrite flotation tailings, adding a sodium hydroxide solution to stir and dissolve out silica in roasted tailings, performing solid-liquid separation to obtain a solid product and a liquid product, wherein the solid product is aluminum oxide concentrate and the liquid product is a solution containing silica and alkali; using the aluminum oxide concentrate as the raw material and adopting the Bayer process to extract aluminum oxide, purifying the Bayer process white clay to prepare a material with rich titanium; adding active quick lime in the solution containing silica and alkali to control the synthesis reaction of sodium silicate and calcium oxide and generate calcium silicate hydrate whisker, regenerating the sodium hydroxide solution; and sending the regenerated caustic alkali solution back to leach the new roasted tailings. By adopting the method, the step separation and concentration and value-added processing of aluminum, silicon and titanium in the pyrite resource can be realized, the problem that the solid waste of the tailings is stocked to occupy the land, pollute the environment and cuase potential public safety hazards can be solved and the economic, social and environmentalbenefits are great; and a new method is provided to realize no-waste mining.

Owner:CENT SOUTH UNIV

Method for separating and preparing hydroxytyrosol from olive fruit water

InactiveCN106883102AHigh extraction rateAvoid not being broken downOrganic chemistryOrganic compound preparationHydroxytyrosolCentrifugation

The invention discloses a method for separating and preparing hydroxytyrosol from olive fruit water. According to the method, a great deal of waste fruit water generated while olive oil is squeezed from olive fruit is adopted as a raw material, and a hydroxytyrosol extract is prepared by using integral techniques such as centrifugation, extraction, low-temperature concentration and drying. Strong acid or alkali and high temperature are not involved in the whole production process, and enrichment and purification are implemented without chemical materials, so that the hydroxytyrosol extract can meet security requirements of food, healthcare food and special medicinal food raw materials, the purity of hydroxytyrosol of the extract is 20-50%, and thus requirements of different products can be met. The method is efficient, energy-saving, environmentally friendly, convenient, easy to industrialize and low in operation cost.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

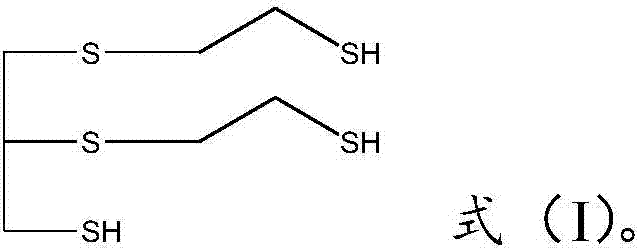

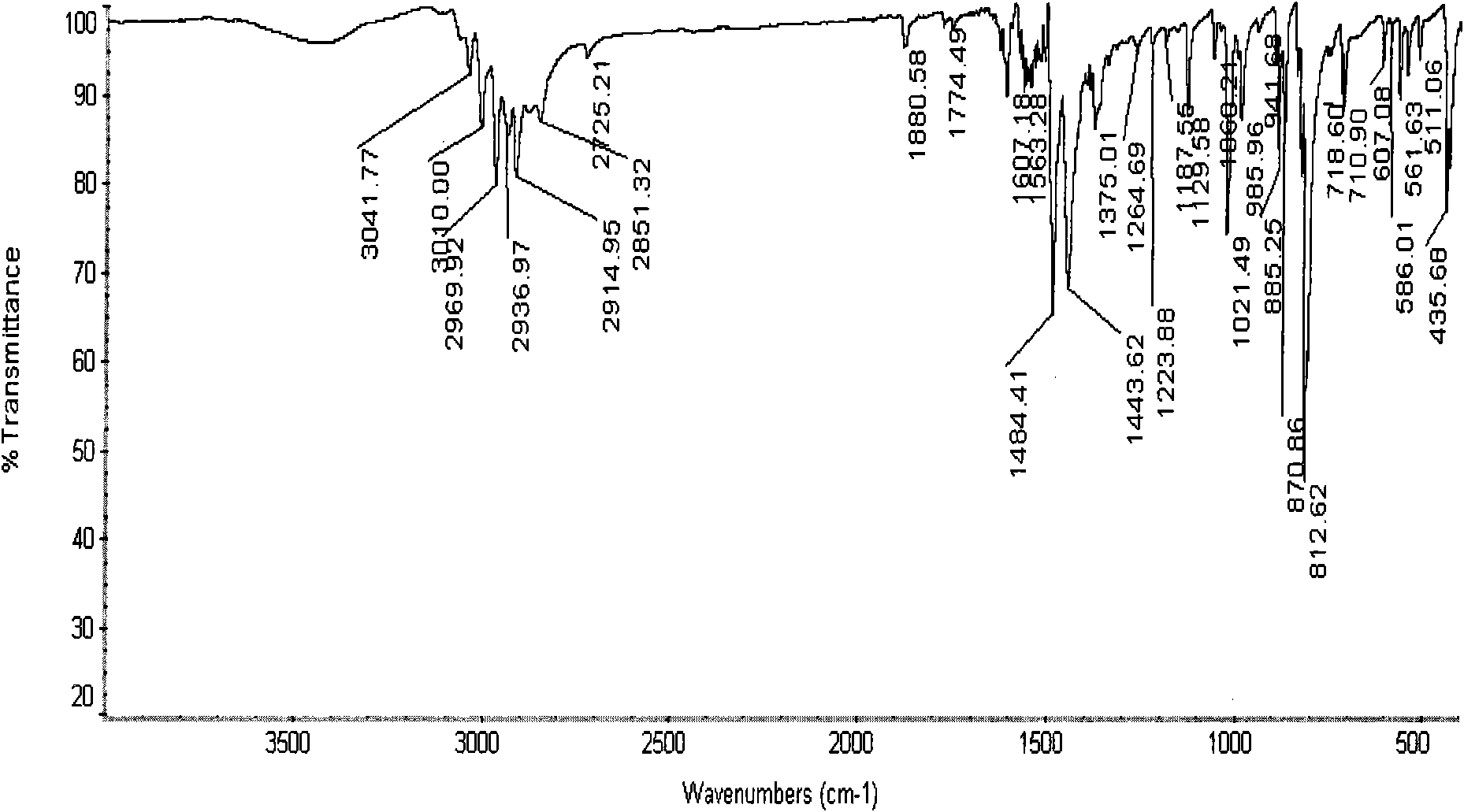

Preparation method of polythiol compound for optical resin

InactiveCN107311898AReduce chromaMeet raw material requirementsOrganic compound preparationSulfide preparationEpoxyPolyol

The invention provides a preparation method of a polythiol compound for optical resin. The preparation method comprises the following steps: a), carrying out polyalcoholation reaction on mercaptoethanol and epoxy chloropropane in an alkaline solution to obtain a reaction mixture containing a polyalcohol compound; b), carrying out thiolation reaction on the reaction mixture containing the polyalcohol compound obtained in the step a) and thiourea in an acid solution to obtain a reaction mixture containing a polythiol compound; and c), carrying out hydrolysis reaction on the reaction mixture containing the polythiol compound obtained in the step b), and then washing and drying to obtain the polythiol compound for the optical resin, wherein the iron content of the mercaptoethanol is greater than 0 and less than 10 ppm and the iron content of the epoxy chloropropane is greater than 0 less than 10 ppm. According to the preparation method disclosed by the invention, by strictly controlling the iron content of raw materials, the polythiol compound with relatively low chroma is obtained by a specific preparation technology, and thereby the requirements on the raw materials for preparing an optical resin lens with excellent performance can be satisfied.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

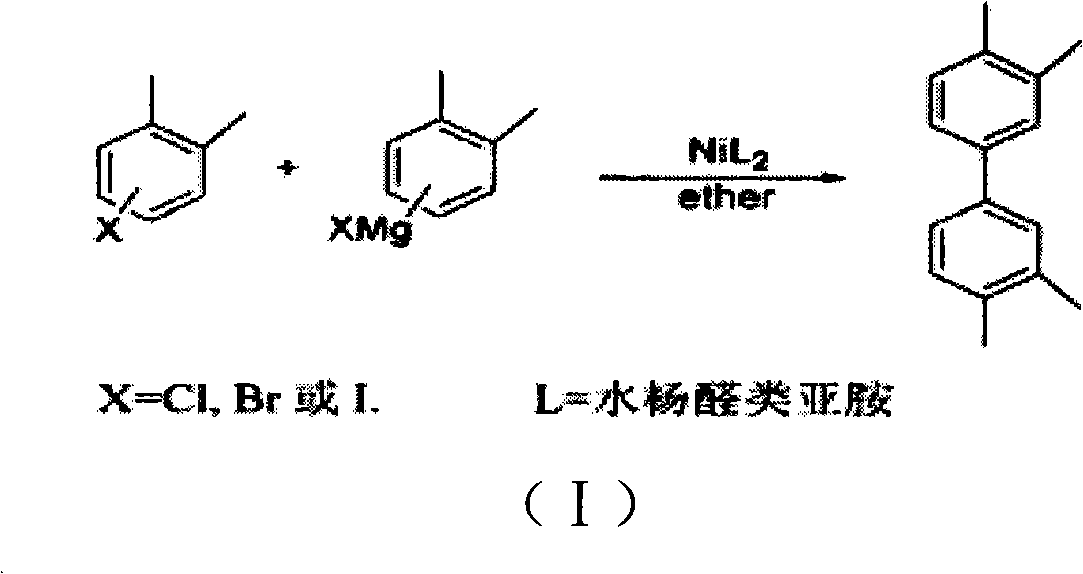

Tetramethylbiphenyl preparation method

InactiveCN101638354AEasy to follow upGood for recyclingHydrocarbon from halogen organic compoundsSolventPalladium

Owner:BYD CO LTD

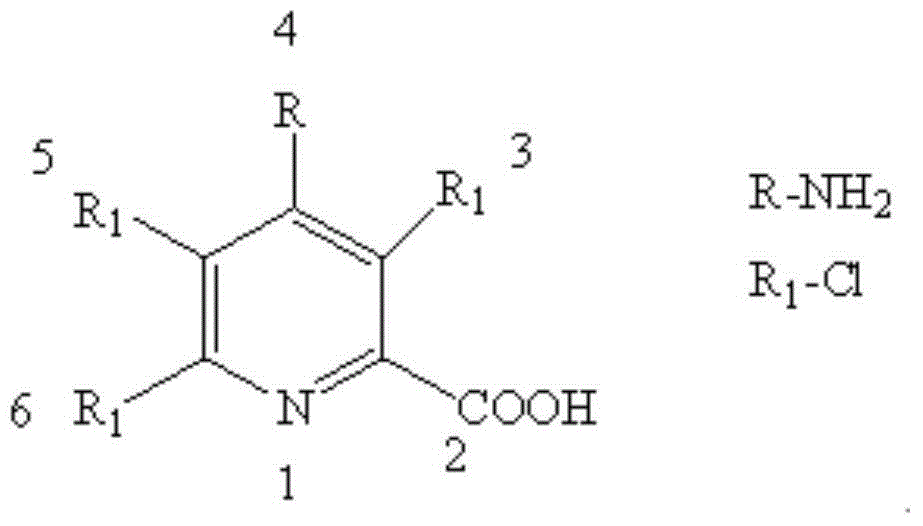

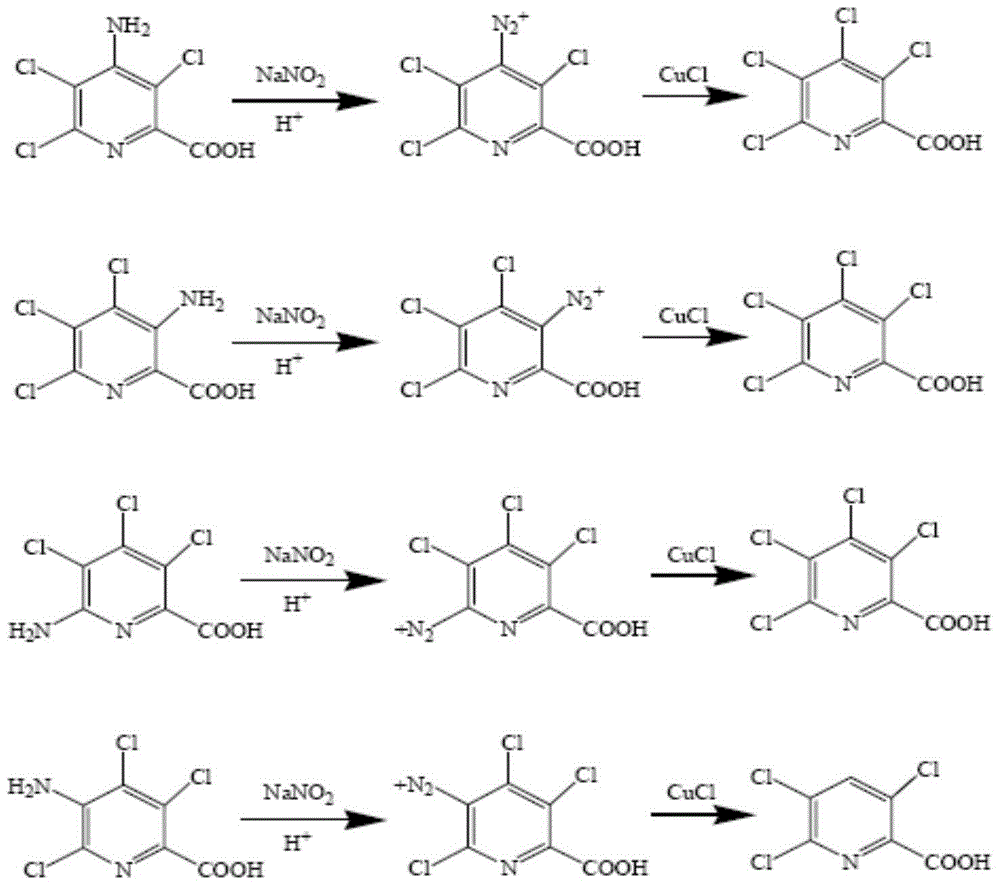

Preparation method of 3,4,5,6-tetrachloropyridine-2-carboxylic acid

The invention provides a preparation method of 3,4,5,6-tetrachloropyridine-2-carboxylic acid. The method comprises the following steps: with waste residue generated in production of picloram or waste obtained after further purification of the waste residues generated in production of the picloram as raw material, adding nitrite for diazotization by the effects of strong acid and an inert diluent; adding a chlorine substituting agent for chlorination reaction to prepare the 3,4,5,6-tetrachloropyridine-2-carboxylic acid. A small amount of other isomerides generated during an ammonolysis process of tetrachloropyridine-2-carboxylic acid during circular processing and treatment of the method can be used for transforming non-pesticide components in the waste residues into raw production materials with practical values, so that the emission of the waste residues is reduced as far as possible. The prepared 3,4,5,6-tetrachloropyridine-2-carboxylic acid is higher than 95% in effective content and can satisfy the requirements on raw materials for industrial production of the picloram.

Owner:HUNAN BIDE BIOTECH

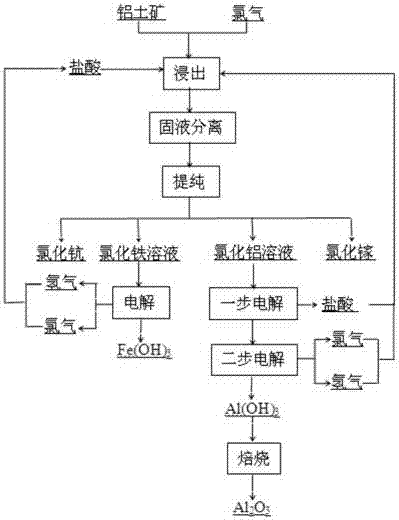

Method for preparing aluminum oxide through hydrochloric acid leaching and two-stage electrolysis of bauxite and comprehensively utilizing aluminum oxide

ActiveCN107128959AHigh degree of automationHigh purityAluminium compoundsRare earth metal chloridesAluminium chlorideElectrolysis

The invention relates to a method for preparing aluminum oxide through hydrochloric acid leaching and two-stage electrolysis of bauxite and comprehensively utilizing aluminum oxide. The method comprises the following steps: carrying out hydrochloric acid leaching, solid-liquid separation and purification on bauxite on bauxite, so as to obtain an iron chloride mixed solution and an aluminum chloride mixed solution; respectively separating and purifying the iron chloride mixed solution and the aluminum chloride mixed solution, so as to obtain scandium chloride, gallium chloride, an aluminum chloride water solution and an iron chloride water solution; setting electrolytic voltage and current density, and respectively carrying out two-stage electrolysis on the aluminum chloride water solution and the iron chloride water solution, so as to respectively obtain aluminum hydroxide, hydrogen and chlorine as well as iron hydroxide, hydrogen and chlorine; preparing a hydrochloric acid solution by using the generated hydrogen and chlorine, and returning the hydrochloric acid solution to a leaching stage for recycling; and roasting aluminum hydroxide, so as to obtain metallurgy level aluminum oxide or chemical aluminum oxide. Compared with a traditional acid method, the electrolysis method for recycling aluminum oxide in the bauxite and processing the bauxite has the advantages that the evaporation step and equipment, the concentration step and equipment are omitted, the operation is simplified, meanwhile, the cost is substantially lowered, and the product has relatively high purity.

Owner:NORTHEASTERN UNIV

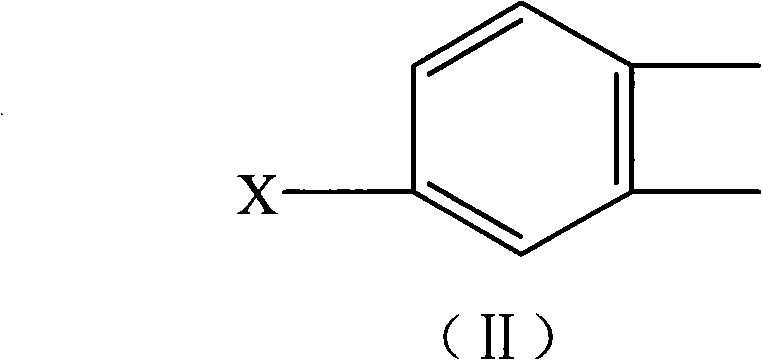

Process for synthesizing p-tert-butylbenzoic acid

ActiveCN102617335AReduce usageReduce recycling stepsOrganic compound preparationCarboxylic compound separation/purificationOxygenMoisture

The invention relates to a process for synthesizing p-tert-butylbenzoic acid. The process comprises the following steps of: adding p-tert-butyltoluene and cobalt acetate into a reaction kettle, introducing oxygen-containing gas, triggering at the temperature of between 150 and 155 DEG C, performing oxidation reaction for 0.5 to 1 hour, and continuously reacting at the temperature of between 135 and 145 DEG C for more than 5 hours to obtain a p-tert-butylbenzoic acid crude product; cooling the p-tert-butylbenzoic acid crude product to crystallize, performing centrifuge dripping, and striking and washing by using p-tert-butyltoluene to obtain a centrifugation crude product; and adding the centrifugation crude product into a dissolution kettle, adding methylbenzene, raising temperature and dissolving, filtering when a mixture is hot to remove impurities, adding water to wash, transferring materials to a recrystallization kettle, cooling to crystallize, centrifuging, striking and washing by using methylbenzene, and drying to obtain a p-tert-butylbenzoic acid finished product. The prepared p-tert-butylbenzoic acid is white crystals and does not contain mechanical impurities; and the melting point is 164.0 to 167.0 DEG C, the acid value is 312 to 316mgKOH / g, high performance liquid chromatography (HPLC) purity is more than or equal to 99.2 percent, moisture is less than or equal to 0.08 percent, and methylbenzene is less than or equal to 0.05 percent.

Owner:SUQIAN COSMOS CHEM +1

Method for preparing high-efficiency modified asphalt

InactiveCN102140254AHigh carbon contentImprove liquidityFibre chemical featuresBuilding insulationsTowerAsphalt

The invention discloses a method for preparing high-efficiency modified asphalt, which is performed according to the following steps: (1) adding the asphalt, a modifier and an oxidizer into a reaction kettle according to a weight ratio of 100:(1-15):(1-15), heating the reaction kettle to 200 to 300 DEG C, and preparing molten asphalt; (2) adding the prepared molten asphalt into an atomization conditioning tower, and performing the atomization conditioning of the molten asphalt for 2 to 6 hours; (3) adding the atomization-conditioned molten asphalt into an emulsifying device at 250 to 400 DEG C, and adding an emulsifier to perform emulsification conditioning; and (4) cooling to 170 to 200 DEG C and discharging to obtain high-efficiency asphalt. In the invention, the atomization technique improves the carbon content of the asphalt, and the emulsification technique makes the asphalt easily flowable and uniform, the preparation process is simple and quick, the softening point of the product is low, and the comprehensive cost of the product is low.

Owner:BEIJING ZHONGSHIHONG INSTALLATION ENG

Method for recovering and recycling chlorosilane slag slurry

InactiveCN108569700AIncrease lossLarge amount of processingSilicon organic compoundsChlorine/hydrogen-chloride purificationSlagSlurry

The invention relates to a method for recovering and recycling chlorosilane slag slurry and belongs to the technical field of chlorosilane recovery and recycling. The method comprises conveying chlorosilane slag slurry into a solid-liquid separation device, carrying out solid-liquid separation to obtain a liquid phase material and chlorosilane slag slurry, feeding the chlorosilane slag slurry intoa washing device, washing the chlorosilane slag slurry through a hydroxyl-containing solvent and / or a stabilizer to obtain a liquid phase material and a solid phase material, and recovering chlorosilane in the liquid phase materials collected through two processes. According to the method for recovering and recycling chlorosilane slag slurry, the materials participating in a reaction are pure, areaction speed, side reactions and a desired product conversion rate can be effectively controlled, the desired product has high purity, the by-products are less and the disposal and environmental costs of the by-products are greatly reduced.

Owner:四川绿源聚能环保科技有限责任公司

Coal tar hydrogenation process for maximizing utilization of coal tar residues

ActiveCN103881750AEliminate heating equipmentEasy to extract and dissolveTreatment with hydrotreatment processesDistillationCoke

The invention discloses a coal tar hydrogenation process which comprises the following steps: (1), carrying out distillation onto the coal tar; (2), carrying out hydrogenation treatment onto distilled heavy distillate oil; (3), carrying out gas-liquid separation onto the hydrogenated product; (4), feeding a liquid-phase material obtained by gas-liquid separation into a first separator, and feeding a vapor-phase material into a low-temperature separator; (5), mixing heavy residual oil obtained through separation of the first separator, a liquid-phase separated out by a low-temperature separator and light distillate oil, and then feeding into a second separator; (6), mixing light oil obtained by the first separator and the second separator and then filtering, and distilling the filtrate to obtain light oil, medium-weight oil and heavy oil; and (7), feeding the heavy oil into a delayed coking system to produce needle cokes and circulation oil, feeding the circulation oil into a slurry-bed reactor, and carrying out hydrorefining onto the light oil and the medium-weight oil to obtain petroleum and aviation kerosene. According to the coal tar hydrogenation process disclosed by the invention, the coal tar hydrogenation and residual oil extraction are combined together, so that utilization rate of active ingredients in the heavy residues and gas-oil recovery rate of the coal tar are increased.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

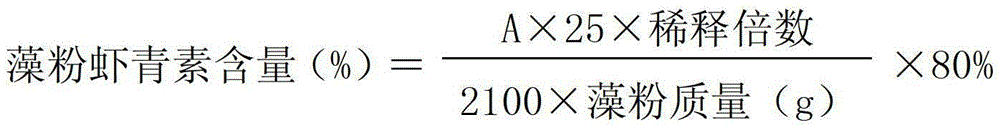

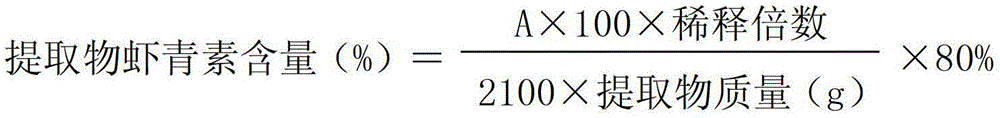

Novel high-efficiency extraction process for astaxanthin in Haematococcus pluvialis

ActiveCN103232375BMeet raw material requirementsThe method of breaking the wall is simpleOrganic chemistryOrganic solventBetaxanthins

The invention discloses a process for extraction of astaxanthin in Haematococcus pluvialis. According to the process, wall-broken Haematococcus pluvialis is obtained by using an acid method, and then an astaxanthin extract is obtained through ethanol dehydration and organic solvent extraction. The wall breaking and extraction process provided by the invention has the advantages of easiness, high efficiency, convenient operation, low energy consumption and controllable quality, and the wall breaking rate and the extraction ratio of Haematococcus pluvialis can reach more than 95%. The astaxanthin extract prepared by using the process is a dark red oily viscous substance and can meet requirements for raw materials needed in production of health food, cosmetics and medicines.

Owner:INNOBIO CORP LTD

Method for preparing polyether polyol by catalytic solvothermal liquefaction of straws

The invention provides a preparation method of biomass-based polyether polyol, and belongs to the technical fields of chemical new materials and high-quality utilization of biomass. Starch liquefaction products, straw powder and a dispersing agent are used as raw materials, a solvothermal reaction is catalyzed to prepare polyether polyol, and under a proper liquefaction reaction condition, the liquefaction rate of straws reaches 65% at most. The hydroxyl value of the obtained polyether polyol is 426.0 mg KOH / g, and the viscosity of the obtained polyether polyol is 430.5 mPa.s. The method is simple in equipment and operation and wide in raw material source, and the obtained polyether polyol is suitable for being used as a raw material for preparing an environment-friendly rigid polyurethanethermal insulation material.

Owner:CHANGCHUN UNIV OF TECH

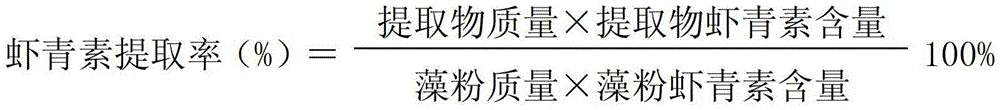

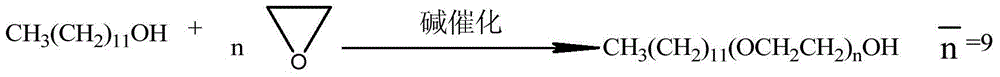

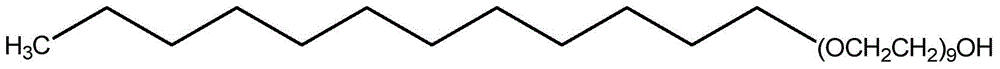

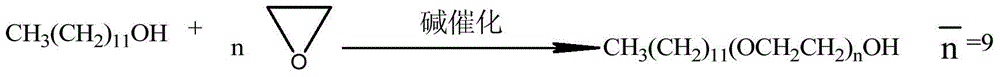

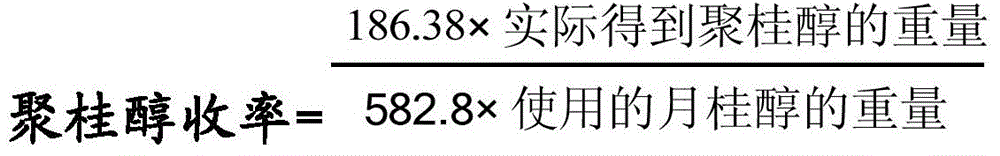

Laurinol purification method and lauromacrogol preparation method

InactiveCN104649863AMeet raw material requirementsReduce self-aggregationOrganic active ingredientsOrganic compound preparationActivated carbonAlcohol

The invention relates to a preparation technology of lauromacrogol. The preparation technology takes lauryl alcohol, potassium hydroxide, oxirane, absolute ethyl alcohol and activated carbon as raw materials. The preparation technology is simple; no special equipment is required; a solvent can be recycled, so that the industrial production cost is lowered; potassium hydroxide serves as a catalyst, so that operation is simplified; the content of heavy metal is controlled easily according to a medicinal quality standard requirement; lauromacrogol is high in yield.

Owner:BEIJING WANCHENG WEIYE MEDICAL TECH

A method for purifying lauryl alcohol and a method for preparing lauryl alcohol

InactiveCN104649863BMeet raw material requirementsReduce self-aggregationOrganic active ingredientsOrganic compound preparationActivated carbonPurification methods

The invention relates to a preparation technology of lauromacrogol. The preparation technology takes lauryl alcohol, potassium hydroxide, oxirane, absolute ethyl alcohol and activated carbon as raw materials. The preparation technology is simple; no special equipment is required; a solvent can be recycled, so that the industrial production cost is lowered; potassium hydroxide serves as a catalyst, so that operation is simplified; the content of heavy metal is controlled easily according to a medicinal quality standard requirement; lauromacrogol is high in yield.

Owner:BEIJING WANCHENG WEIYE MEDICAL TECH

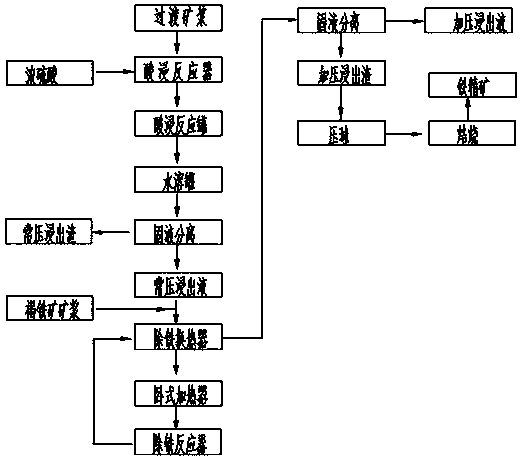

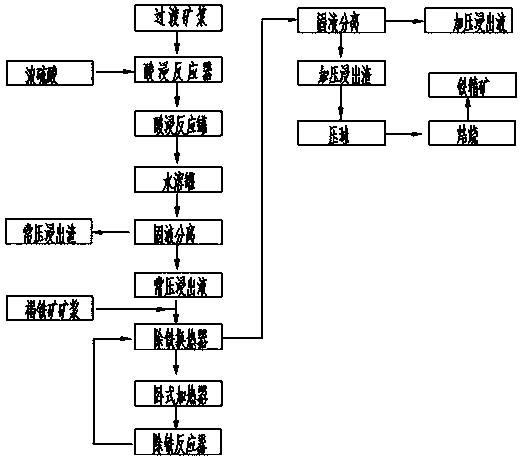

Hydrometallurgy method for treating low-grade laterite-nickel ore through normal pressure and pressurization combined acid leaching

InactiveCN111154974AAchieve iron contentMeet raw material requirementsProcess efficiency improvementLeaching rateLeaching (metallurgy)

The invention relates to a hydrometallurgy method for treating low-grade laterite-nickel ore through normal pressure and pressurization combined acid leaching. The method comprises the following stepsthat transition ore pulp is prepared, the heated transition ore pulp and heated concentrated sulfuric acid are mixed according to a certain proportion, an acid leaching reaction is generated, and after water solution, normal-pressure leaching residues and normal-pressure lixivium are obtained through solid-liquid separation; limonite pulp is prepared, after the limonite pulp and the normal-pressure lixivium are mixed, heating is carried out, pressurization leaching is carried out under the conditions that the pressure ranges from 2.0 MPa to 4.0 MPa and the temperature ranges from 220 DEG C to240 DEG C, and after cooling, pressurization leaching residues and pressurization lixivium are obtained through solid-liquid separation; and briquetting and sintering processes are carried out on pressurization leaching residues to form iron powder. According to the hydrometallurgy method, acid consumption is low, the leaching rate of NiCoFe is high, the needed equipment cost is low, silicon andiron can be effectively separated, and iron concentrates high in iron content are obtained.

Owner:JINCHUAN GROUP LIMITED

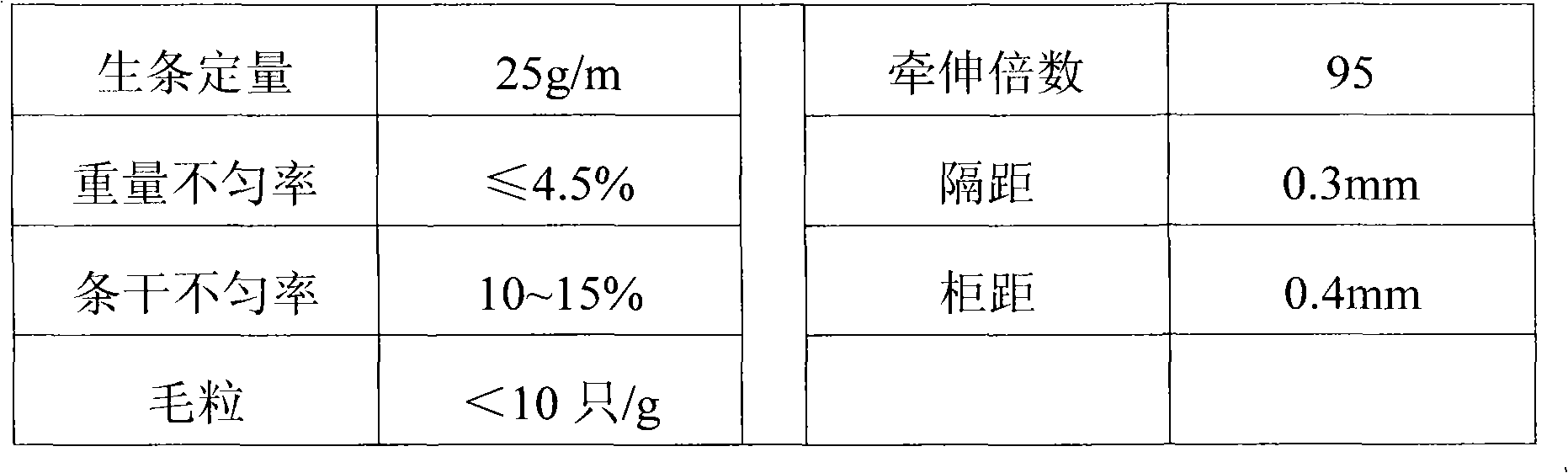

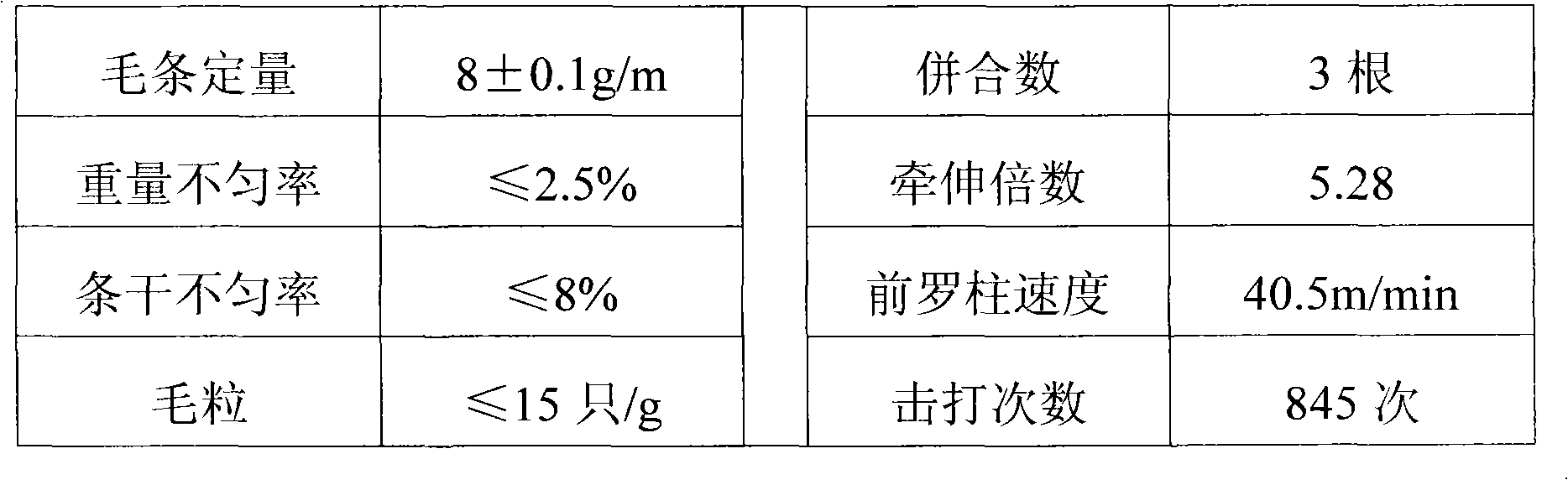

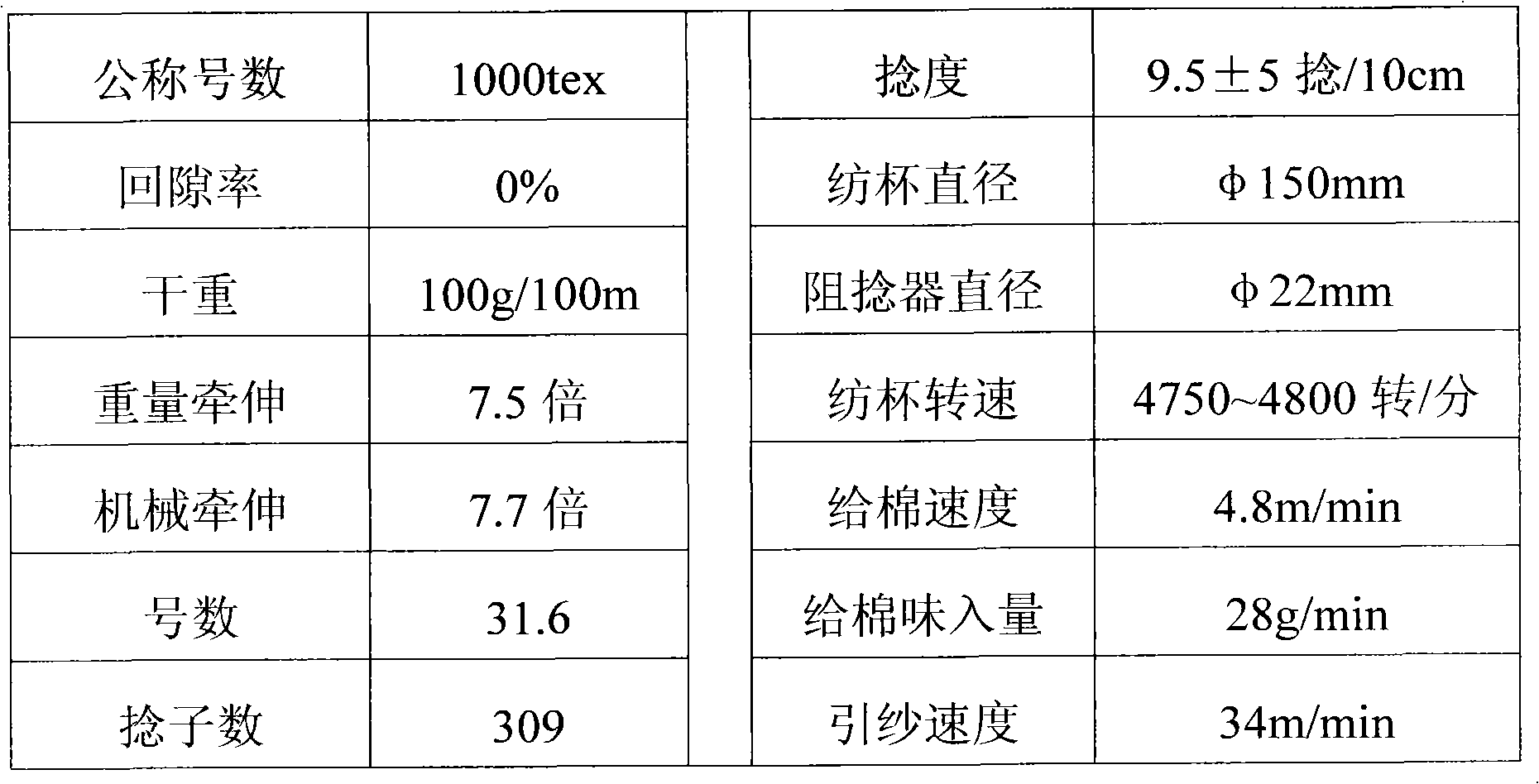

Revolving cup spinning profiled polypropylene fiber rough yarn and its spinning method

InactiveCN101343800APenetrating and denseImprove filtering effectContinuous wound-up machinesOpen-end spinning machinesYarnPenetration force

Owner:扬州华美丙纶纺织有限公司

Method of producing phosphorus potassium compound fertilizer using straw ash of biomass energy straw electric generation plant

InactiveCN100378040CEfficient use ofFast and timely digestionOrganic fertilisersFertilizer mixturesAcrylic resinPhosphate

The process of producing composite phosphate and potash fertilizer with the stalk ash from stalk power plant belongs to the field of environment protecting and fertilizer producing technology. The composite phosphate and potash fertilizer consists of stalk ash 80-94.8 weight portions, acidity regulator 1.2-10 weight portions, and adhesive 4-12 weight portions. The acidity regulator is two or three of phosphoric acid, sulfuric acid and citric acid; and the adhesive is the composition of magnesia powder, gypsum powder and acrylic resin in the weight ratio of 3-4 to 0.5-2 to 0.1-1.5. The preparation process includes the steps of crushing material, drum palletizing, stoving and packing. The present invention has low fertilizer producing cost and high effective component content in fertilizer, and the fertilizer is suitable for different kinds of soil and different kinds of crops.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

Method for comprehensively recovering aluminum, silicon and titanium from pyrite tailings

ActiveCN102409177BMeet raw material requirementsIncrease generation speedPolycrystalline material growthFrom normal temperature solutionsLiquid productSilicon dioxide

The invention discloses a method for comprehensively recover aluminum, silicon and titanium from pyrite tailings. The method comprises the following steps: performing oxidizing roasting on the pyrite flotation tailings, adding a sodium hydroxide solution to stir and dissolve out silica in roasted tailings, performing solid-liquid separation to obtain a solid product and a liquid product, wherein the solid product is aluminum oxide concentrate and the liquid product is a solution containing silica and alkali; using the aluminum oxide concentrate as the raw material and adopting the Bayer process to extract aluminum oxide, purifying the Bayer process white clay to prepare a material with rich titanium; adding active quick lime in the solution containing silica and alkali to control the synthesis reaction of sodium silicate and calcium oxide and generate calcium silicate hydrate whisker, regenerating the sodium hydroxide solution; and sending the regenerated caustic alkali solution back to leach the new roasted tailings. By adopting the method, the step separation and concentration and value-added processing of aluminum, silicon and titanium in the pyrite resource can be realized, the problem that the solid waste of the tailings is stocked to occupy the land, pollute the environment and cuase potential public safety hazards can be solved and the economic, social and environmentalbenefits are great; and a new method is provided to realize no-waste mining.

Owner:CENT SOUTH UNIV

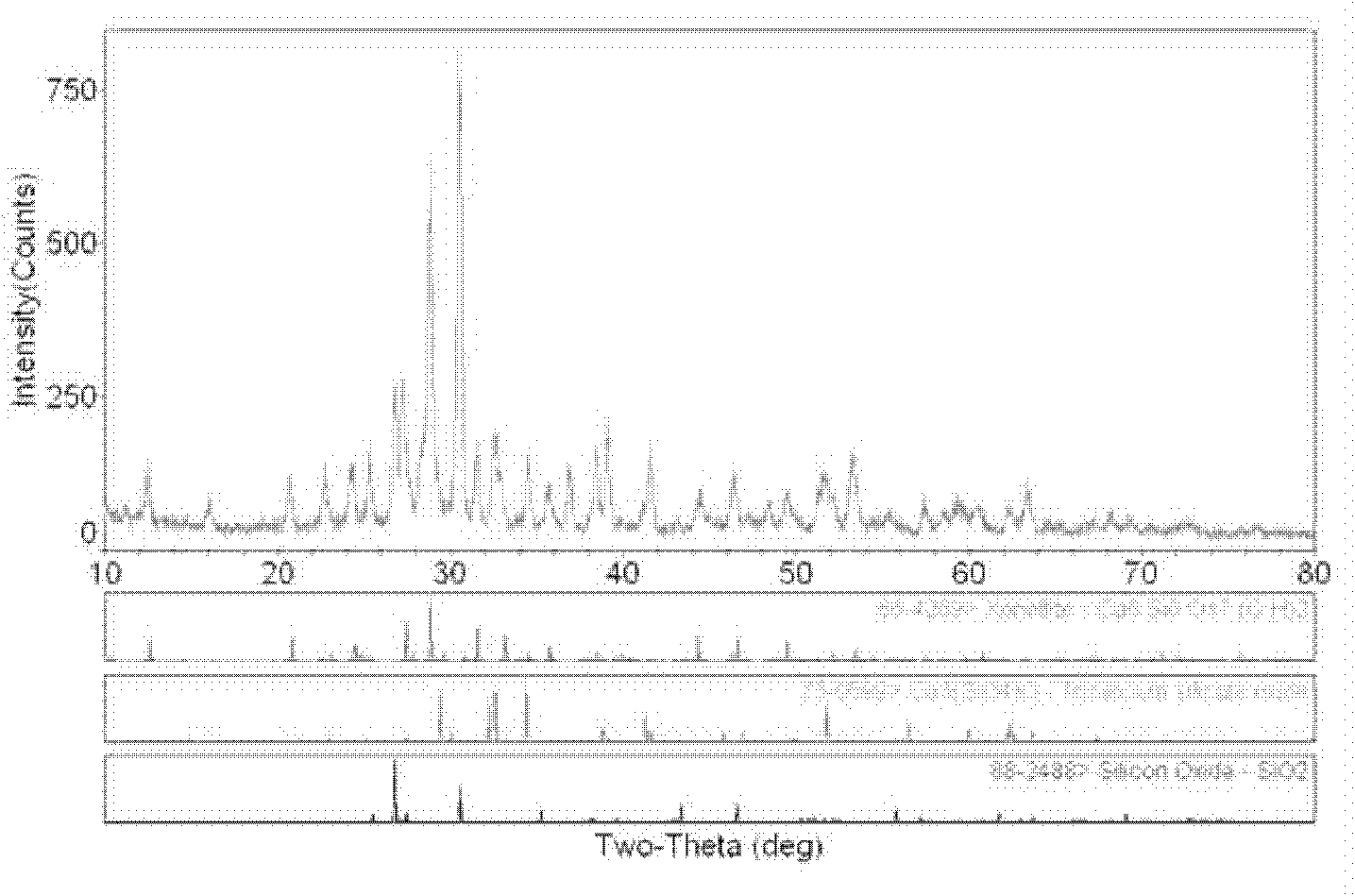

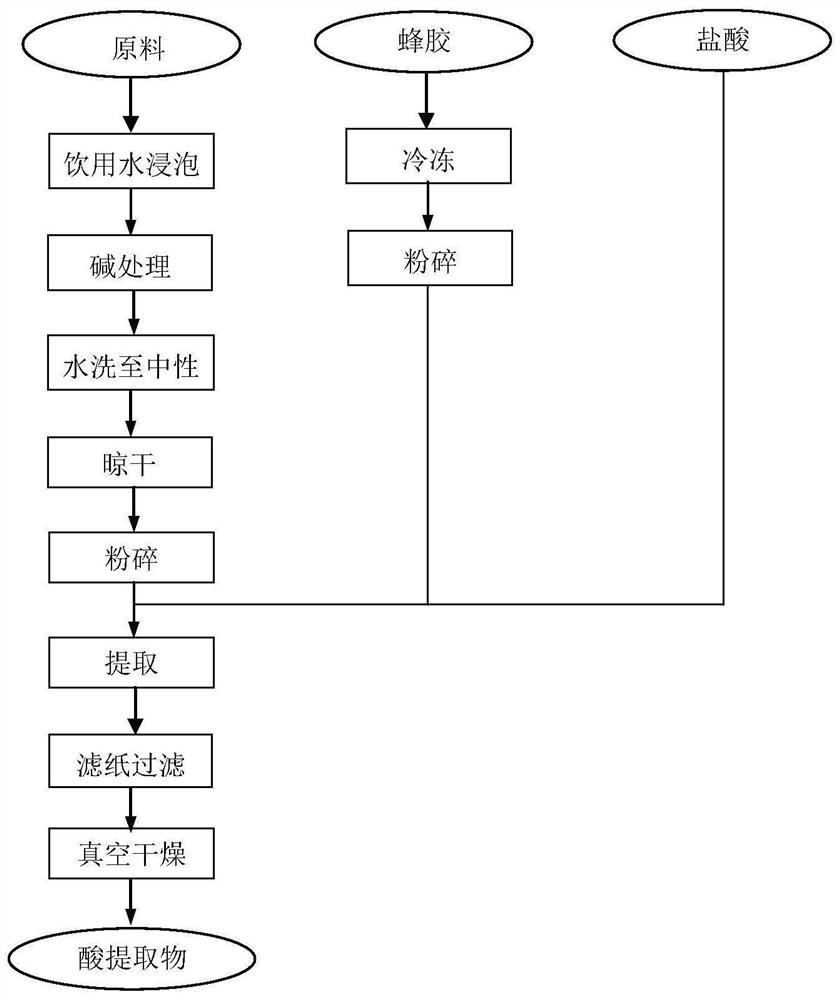

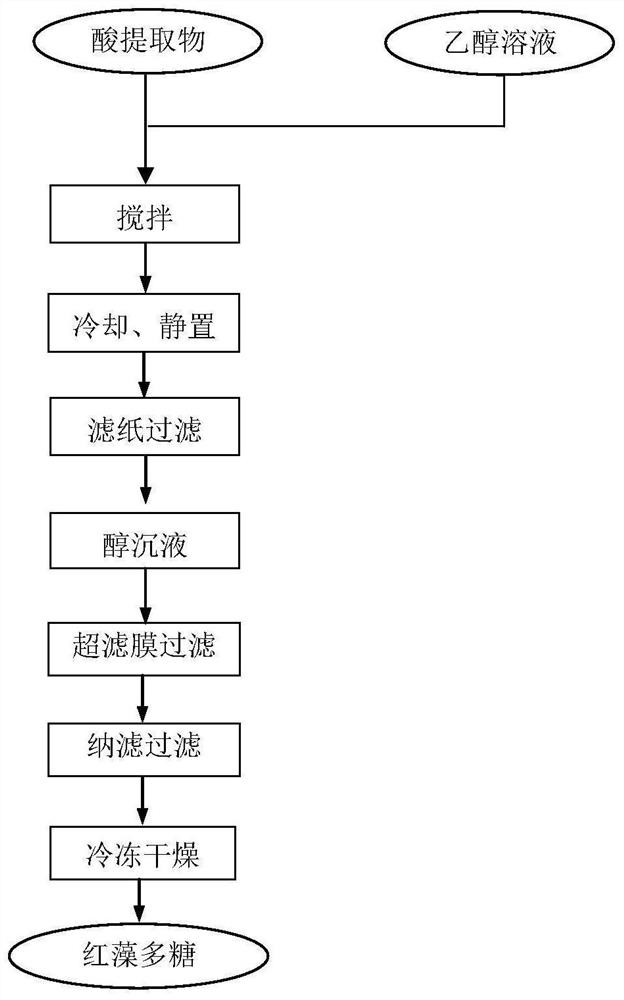

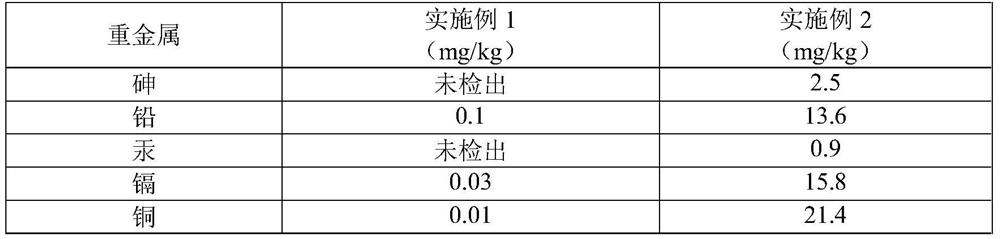

Preparation method of red alga polysaccharide

The invention belongs to the technical field of extraction of algal polysaccharides, and relates to a preparation method of red algal polysaccharides, which comprises the following steps: by using redalgal plants as raw materials, washing the raw materials with water, carrying out alkali treatment, performing washing to neutrality, performing airing, performing pulverizing, adding propolis, extracting acid-soluble polysaccharides from the propolis by using a hot acid extraction method, and removing macromolecular polysaccharide components by alcohol precipitation, recovering ethanol from theresidual solution, performing cooling, performing filtering to remove propolis, filtering the filtrate with an ultrafiltration membrane, concentrating with a nanofiltration membrane, and performing freeze-drying to obtain the red alga polysaccharide. The preparation method of the red alga polysaccharides can effectively reduce the content of heavy metals in the red alga polysaccharides, and combines the technologies of red alga polysaccharide extraction and heavy metal removal.

Owner:FUZHOU NEPTUNUS FUYAO PHARMA

Hydrogen desulfurization catalyst and preparation method thereof

InactiveCN103230798AMeet raw material requirementsEfficient use ofCatalyst carriersCatalyst activation/preparationHydrogenAdhesive

The invention relates to a hydrogen desulfurization catalyst and a preparation method of the hydrogen desulfurization catalyst. The hydrogen desulfurization catalyst comprises alumina, an additive and an active ingredient, wherein the alumina is a product formed by roasting the alumina waste at the temperature of 450-550 DEG C; and the content of the active ingredient is 20-30 weight percent. According to the method for preparing the hydrogen desulfurization catalyst, the temperature of roasting the oxidant waste is defined at the temperature of 450-550 DEG C, filling of adhesives, pore-forming substances and the like on the original pore volume can be reduced under the roasting temperature and roasting time, the porosity and pore diameter on the alumina waste are increased, the raw material requirements in the kneading method for preparing the hydrogen desulfurization catalyst are met, and the catalyst has high catalytic activity.

Owner:SHENYANG SANJUKAITE CATALYST

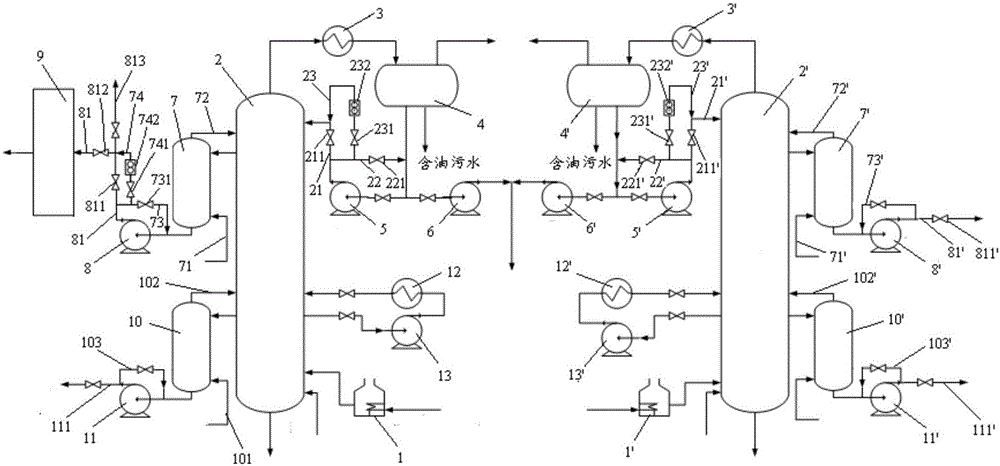

Fischer-Tropsch synthesis system and method for Fischer-Tropsch synthesis by utilizing Fischer-Tropsch synthesis system

ActiveCN106753525AReduce product volumeReduce the reflux ratioTreatment with plural serial refining stagesHydrocarbon oils treatment productsFischer–Tropsch processProcess engineering

The invention provides a Fischer-Tropsch synthesis system which comprises a rectification unit, wherein the rectification unit comprises a first heating furnace, a rectification tower, a first diesel oil stripper, a first diesel oil pump, a first overhead condenser, a first overhead reflux tank, a first reflux pump and a first naphtha pump. The invention also provides a method for Fischer-Tropsch synthesis by utilizing the Fischer-Tropsch synthesis system. The Fischer-Tropsch synthesis system provided by the invention can be obtained only by transforming a small part on a basis of the existing device, and therefore, the investment is less, and the cost is low; and the invention provides the novel method for obtaining diesel oil by Fischer-Tropsch synthesis, and fractions can be segmented only by adjusting technological parameters, and therefore, the cost is lowered, the yield of naphtha is increased, and the additional value of the diesel oil obtained by Fischer-Tropsch synthesis is increased.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Method for preparing agricultural microbial soil conditioner by solid fermentation of industrial and agricultural wastes

InactiveCN111116274AMeet raw material requirementsAccelerated ripeningCalcareous fertilisersBio-organic fraction processingAgricultural engineeringFermentation

The invention belongs to the field of microbial soil conditioners, and particularly relates to a method for preparing an agricultural microbial soil conditioner through solid fermentation of industrial and agricultural wastes. According to the method provided by the invention, industrial and agricultural wastes are used as main raw materials, and bacillus subtilis is used for solid fermentation toprepare the agricultural microbial soil conditioner. The invention provides the solid fermentation method of the soil conditioner; by using low-price organic wastes as raw materials, the production cost is far lower than that of a liquid fermentation inoculant and is about 3-5 times lower than that of the liquid fermentation inoculant, and the product has high viable bacteria content which is more than 5 billion / g and up to 10 billion / g, and completely meets the requirements of raw materials for processing the soil conditioner. In the production process, organic materials are properly decomposed through microbial culture, decomposition of macromolecular organic matters is accelerated, and meanwhile, multiple crop growth promoting components are secreted, so that the process is very suitable for processing requirements of products such as biological soil conditioners, biological organic fertilizers and the like.

Owner:QILU UNIV OF TECH +1

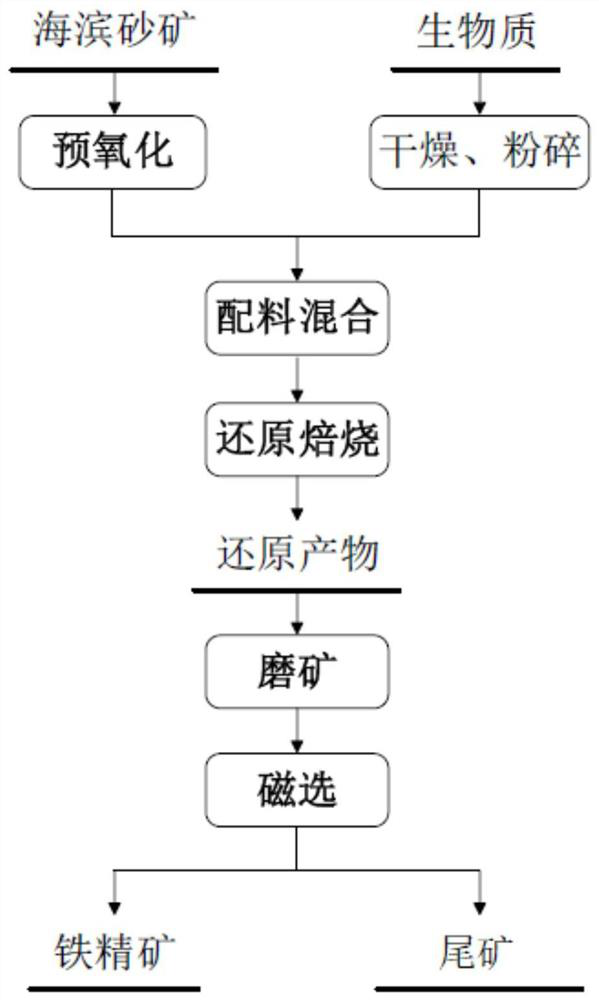

Method for improving metallization ratio and concentrate iron grade of beach placer reduction product

PendingCN113604657AIn line with green environmental protectionMeet the requirementsFluidised-bed furnacesIron powderTube furnace

The invention discloses a method for improving the metallization ratio and concentrate iron grade of a beach placer reduction product, and belongs to the field of comprehensive utilization of metallurgical resources. The method comprises the following steps: pre-oxidizing beach placer by adopting a rotary tube furnace; fully mixing the pre-oxidized beach placer with the biomass; carrying out reduction roasting on the mixture; and performing ore grinding-magnetic separation on the roasted product to obtain directly reduced iron powder. According to the method, the metallization ratio and the concentrate iron grade of the biomass reduced beach placer product are increased, the process is simple, the production cost is low, the method is environmentally friendly, and the method has great significance in relieving domestic iron ore shortage and achieving comprehensive utilization of beach placer and has good application prospects.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Screening and Refining Process of Wheat Starch

The invention discloses a wheat starch sieving and refining process, which comprises the following steps: sieving the raw material of starch slurry through a first-stage centrifugal sieve; Net is 250 mesh, rotating speed 900r / min, the screen cloth of secondary centrifugal sieve is 200 mesh, rotating speed 900r / min, collect the undersize of primary and secondary centrifugal sieve, send into primary decanter and carry out separation treatment, obtain The light phase substances such as soluble protein and sugar are treated separately, and the obtained starch phase enters the secondary decanter for concentration to obtain the finished starch slurry, and after drying, the finished starch product meeting the standard can be obtained. The invention has the advantages that compared with the prior art, the process is simple, and the cyclone group in the traditional process is replaced by a decanter screw machine, thereby reducing energy consumption.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com