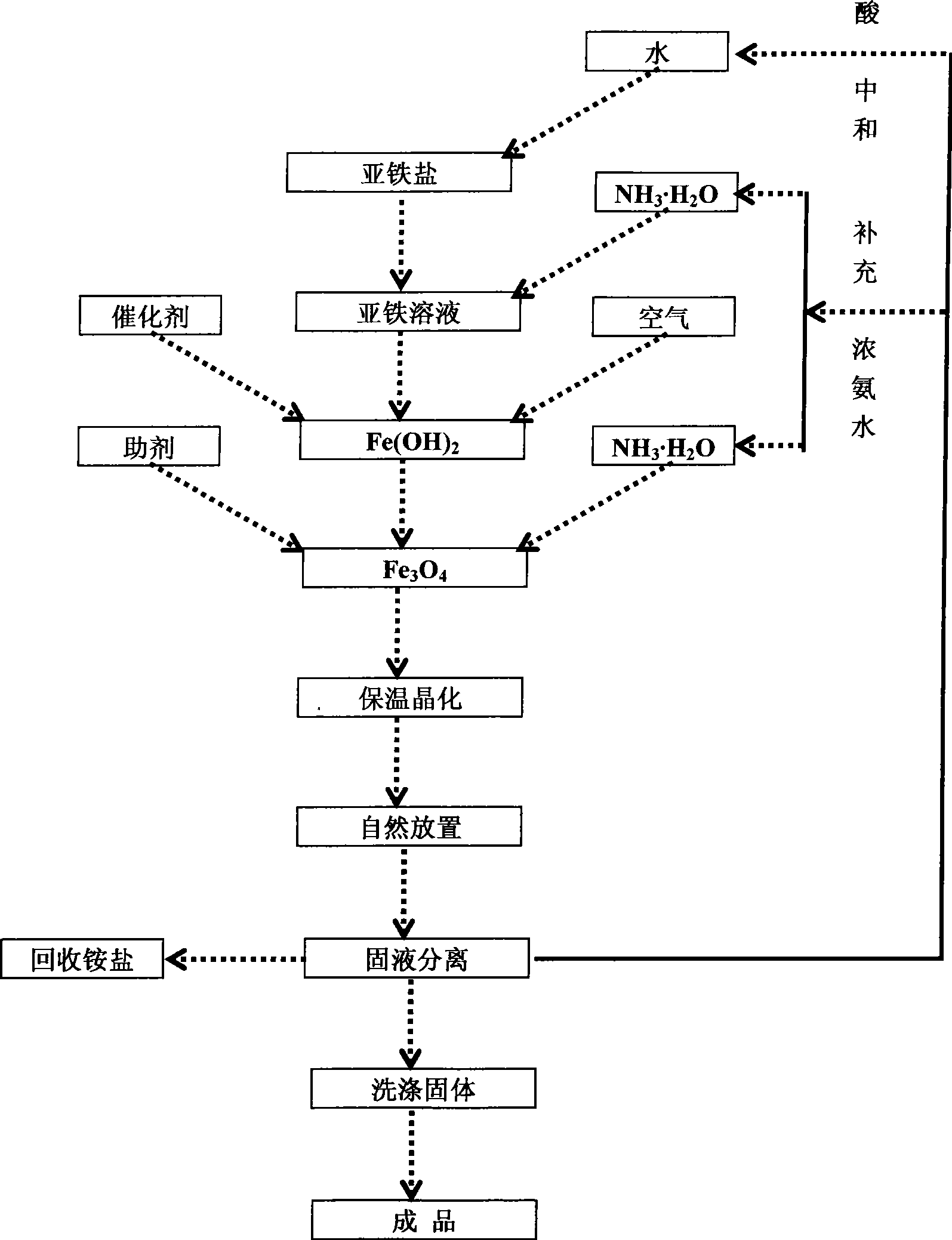

Method for preparing spherical Fe3O4 nano powder

A technology of nano-powder and spherical shape, which is applied in the field of preparation of spherical Fe3O4 nano-powder, which can solve the problems of irregular spherical shape, large powder particle size, and high price, and achieve the effects of reducing energy consumption, shortening time, and easy washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

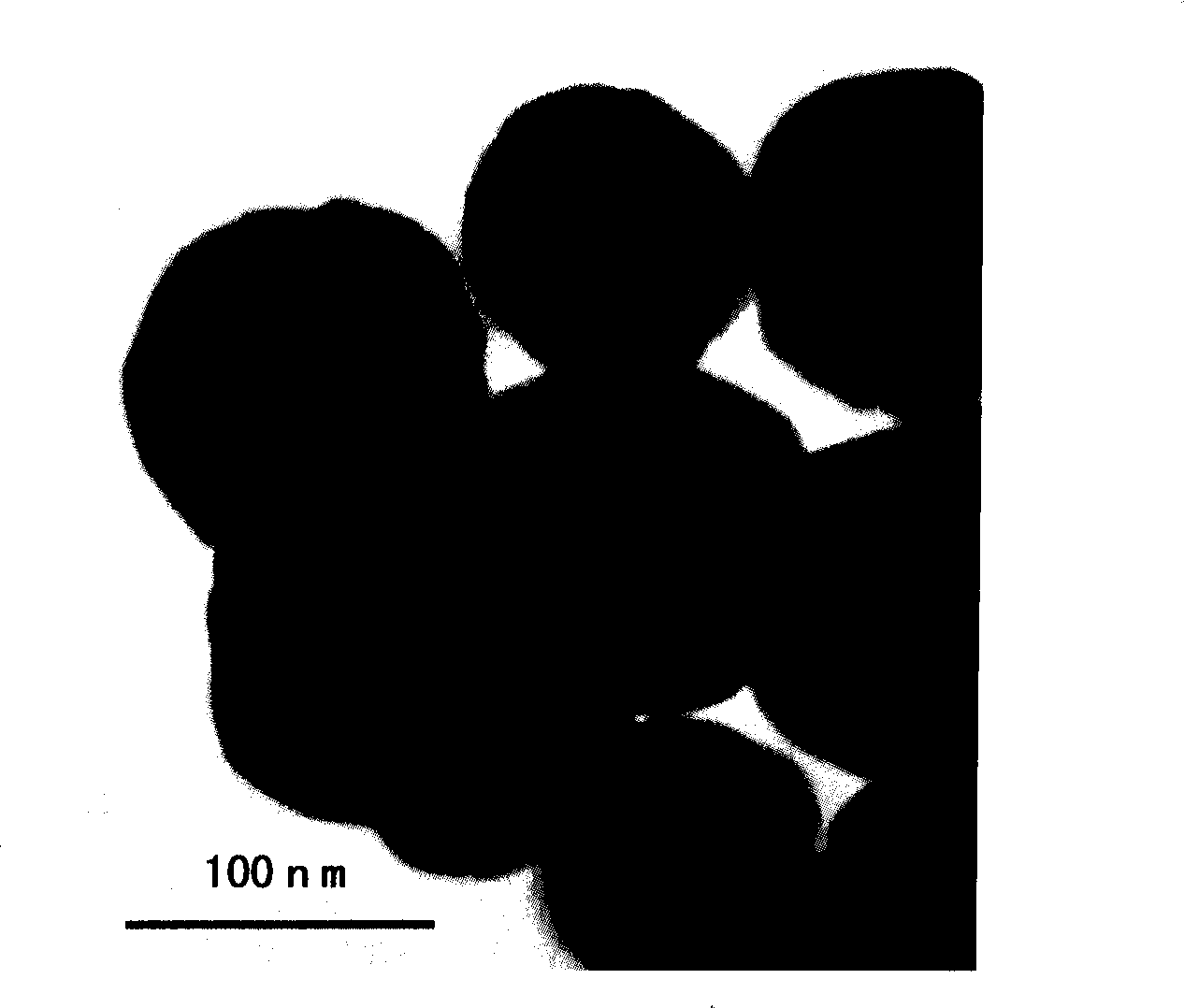

Embodiment 1

[0028] A spherical Fe 3 O 4 The preparation method of nano powder consists of the following steps:

[0029] (1) The preparation concentration is 0.5mol·L -1 An aqueous solution of ferrous sulfate; heated to 80°C within 0.6h, stirred at a speed of 400 rpm, added ammonia water, and adjusted the pH to 6.5;

[0030] (2) Put the solution prepared in step (1) into a reactor equipped with a gas distributor, stir, at a speed of 400 rpm, at 80°C, and blow in air with a flow rate of 0.8m 3 / h, add NH after 10 minutes with air 4 NO 2 Is a catalyst, the addition amount of the catalyst is 0.5% of the mass of the ferrous salt, and the reaction is carried out to detect Fe in the system 3+ With Fe 2+ When the molar ratio of is 1.8, stop the air flow;

[0031] (3) Continue to stir, the speed is 400 rpm, at 80 ℃, add ammonia water to adjust the pH to 9.5, and then heat the reaction for 2.0 hours;

[0032] (4) Stop stirring and heating, and cool to 25°C naturally;

[0033] (5) Solid-liquid separatio...

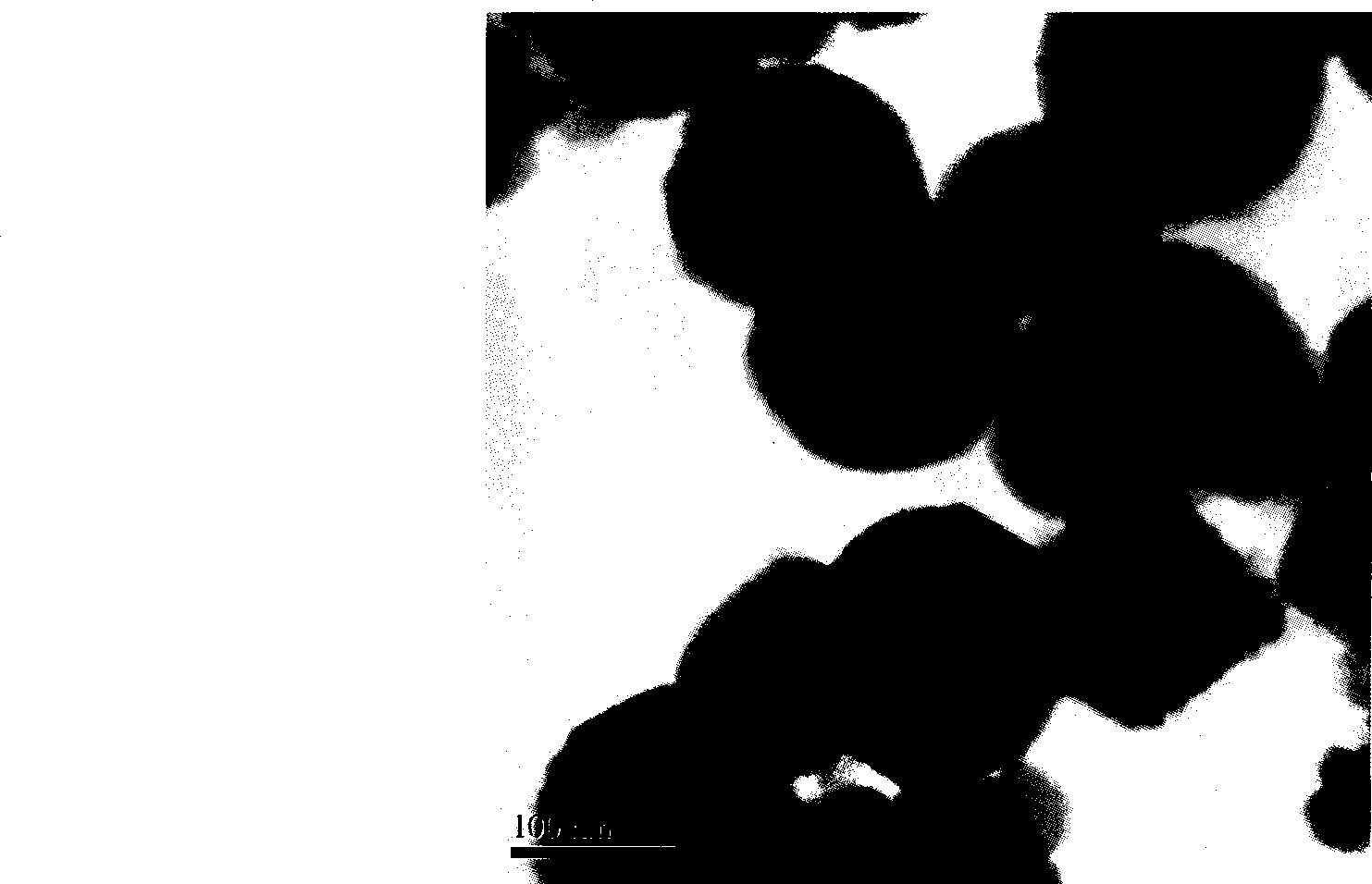

Embodiment 2

[0035] A spherical Fe 3 O 4 The preparation method of nano powder consists of the following steps:

[0036] (1) The preparation concentration is 0.6mol·L -1 An aqueous solution of ferrous sulfate; heated to 85°C within 1.0h, stirred at a speed of 500 rpm, added ammonia water, and adjusted the pH to 6.0;

[0037] (2) Put the solution prepared in step (1) into a reactor equipped with a gas distributor, stir, rotate at 500 rpm, at 85°C, blow in air, and air flow rate is 0.6m 3 / h, add NH after 11 minutes of air 4 NO 2 As a catalyst, the addition amount of the catalyst is 0.8% of the mass of the ferrous salt, the reaction is carried out, and the Fe in the detection system (that is, the reaction system at this time) 3+ With Fe 2+ When the molar ratio of is 1.91, stop the air flow;

[0038](3) Continue to stir at a speed of 500 rpm, add ammonia water to adjust the pH to 9.0 at 85°C, and then heat the reaction for 3.0 hours;

[0039] (4) Stop stirring and heating, and cool to 20°C natura...

Embodiment 3

[0042] A spherical Fe 3 O 4 The preparation method of nano powder consists of the following steps:

[0043] (1) The preparation concentration is 0.1mol·L -1 An aqueous solution of ferrous chloride; heated to 70°C within 0.5h, stirred at a speed of 100 rpm, added ammonia water, and adjusted the pH to 7.0;

[0044] (2) Put the solution prepared in step (1) into a reactor equipped with a gas distributor, stir at a speed of 100 rpm, at 70°C, blow in air, and an air flow rate of 1.0 m 3 / h, add NaNO after 12 minutes with air 2 Is a catalyst, the addition amount of the catalyst is 0.6% of the mass of the ferrous salt, the reaction is carried out, and the Fe in the system is detected 3+ With Fe 2+ When the molar ratio of is 2.4, stop the air flow;

[0045] (3) Continue to stir at a speed of 100 rpm, at 70°C, add ammonia water to adjust the pH to 10.0, then add ammonium silicate, the amount of which is 3% of the mass of ferrous sulfate, and the insulation reaction for 4.0h;

[0046] (4) S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com