Preparation method of nano-structure iron phosphate

A nanostructure, iron phosphate technology, applied in the field of chemical materials, can solve the problems of large influence of raw material addition, increased process complexity, complicated process, etc., and achieves the effect of shortening time, simple process and reducing usage amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

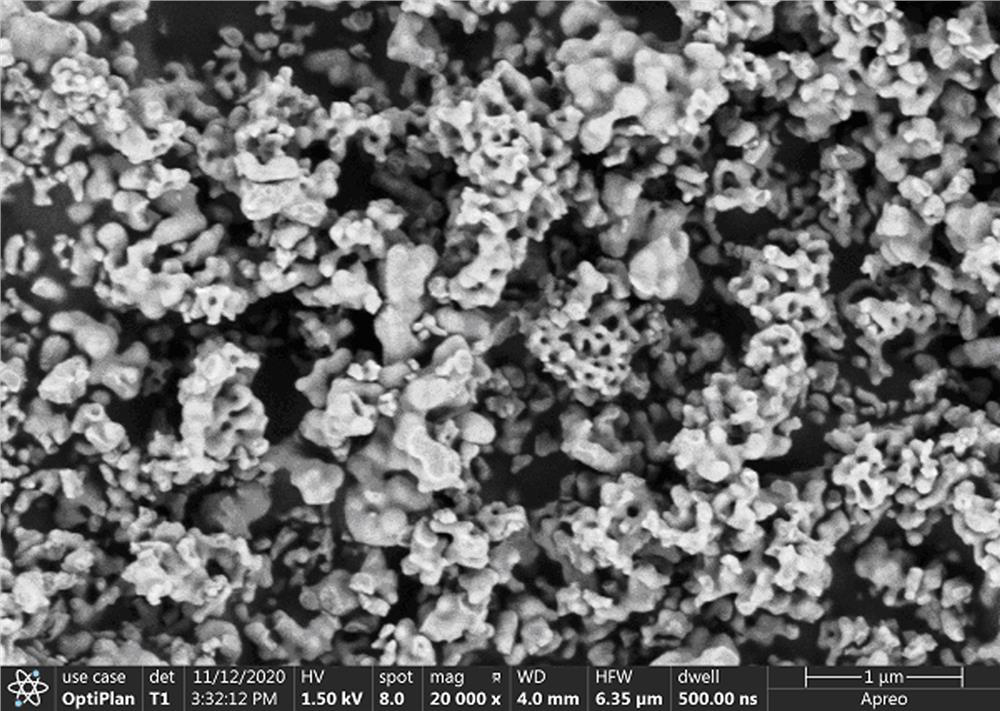

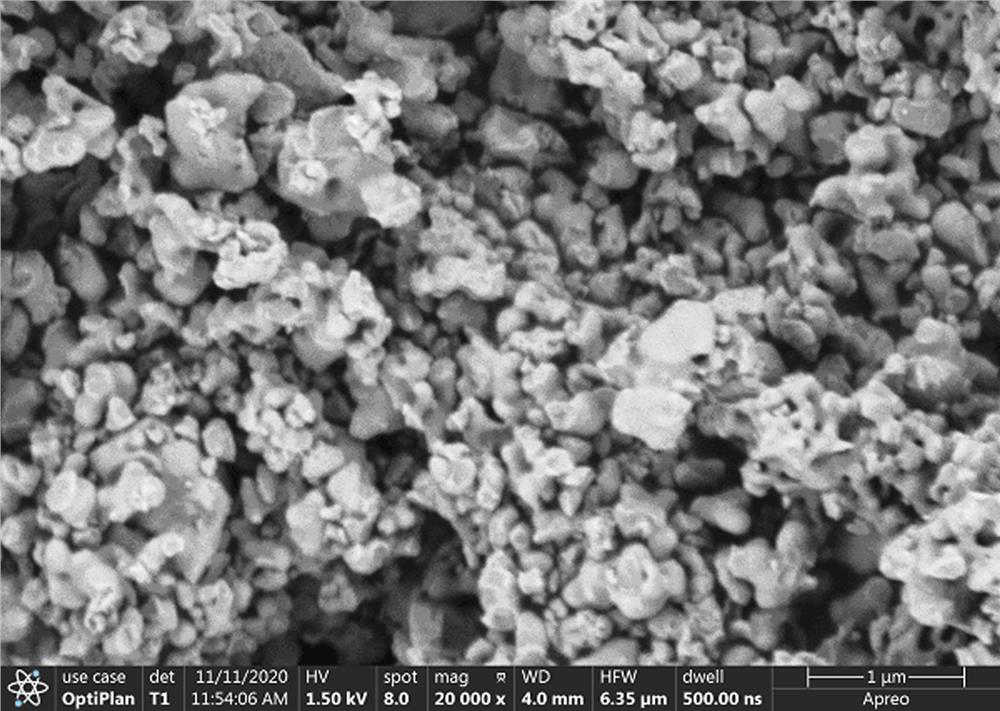

Image

Examples

Embodiment 1

[0036] Step S1, preparation of ferrous sulfate solution:

[0037] Take a certain amount of titanium dioxide by-product ferrous sulfate heptahydrate, add pure water to dissolve, filter, take the filtrate, add ferric phosphate slurry mother liquor to it to adjust its pH value<2.0, then add concentrated sulfuric acid to adjust its pH value<1.0, and finally Add pure water to prepare 100L solution A with a molar concentration of 1.2 mol / L, and set aside;

[0038] Step S2, preparation of the mixed solution of phosphoric acid and hydrogen peroxide:

[0039] Take a certain amount of industrial-grade phosphoric acid, first add 100L of pure water to prepare a phosphoric acid solution with a molar concentration of 1.2 mol / L, and then add hydrogen peroxide at a molar ratio of phosphoric acid to hydrogen peroxide of 1:0.6 to obtain a mixed solution B for later use;

[0040] Step S3, synthesis reaction process:

[0041]Add solution A in step S1 into the reactor, heat up to 50°C, stir at a...

Embodiment 2

[0048] Step S1, preparation of ferrous sulfate solution:

[0049] Take a certain amount of titanium dioxide by-product ferrous sulfate heptahydrate, add pure water to dissolve, filter, take the filtrate, add ferric phosphate slurry mother liquor to it to adjust its pH value<2.0, then add concentrated sulfuric acid to adjust its pH value<1.0, and finally Add pure water to prepare 100L of a solution with a molar concentration of 1.5 mol / L, and set aside;

[0050] Step S2, preparation of phosphate solution:

[0051] Take a certain amount of industrial-grade phosphoric acid, first add 100L of pure water to prepare a phosphoric acid solution with a molar concentration of 1.5 mol / L, and then add hydrogen peroxide at a molar ratio of phosphoric acid to hydrogen peroxide of 1:0.8 to obtain a mixed solution B for later use;

[0052] Step S3, synthesis reaction process:

[0053] Add solution A in step S1 into the reactor, heat up to 60°C, stir at a frequency of 500rpm, then pump solut...

Embodiment 3

[0060] Step S1, preparation of ferrous sulfate solution:

[0061] Take a certain amount of titanium dioxide by-product ferrous sulfate heptahydrate, add pure water to dissolve, filter, take the filtrate, add ferric phosphate slurry mother liquor to it to adjust its pH value to <2.0, then add concentrated sulfuric acid to adjust its pH value <1.0, Finally, add pure water to prepare 100 L of a solution with a molar concentration of 1.8 mol / L, and set aside;

[0062] Step S2, preparation of the mixed solution of phosphoric acid and hydrogen peroxide:

[0063] Take a certain amount of industrial-grade phosphoric acid, first add 100L of pure water to prepare a phosphoric acid solution with a molar concentration of 1.8mol / L, and then add hydrogen peroxide at a molar ratio of phosphoric acid to hydrogen peroxide of 1:1 to obtain a mixed solution B for later use;

[0064] Step S3, synthesis reaction process:

[0065] Add solution A in step S1 into the reactor, heat up to 100°C, stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com