Preparation method of wave-absorbing material with layered structure

A wave absorbing material, layered structure technology, applied in electrical components, antennas, magnetic field/electric field shielding and other directions, can solve the problems of high temperature resistance and low corrosion resistance, improve high temperature resistance and corrosion resistance, and improve density , the effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method in this embodiment can be applied to absorbing materials. For example, the following corrosion-resistant carbon-based absorbing material is provided in this embodiment. The preparation method in this embodiment can be used for corrosion-resistant carbon-based absorbing materials. wave material.

[0030] It includes a wave-absorbing material, and the two sides of the wave-absorbing material are respectively provided with a limit inserting rod and a limit slot, and the limit slot and the limit inserting rod are set in one-to-one correspondence, and the bottom of the wave-absorbing material is close to the limit One side of the insertion rod is equipped with a clamping device, and the other side of the wave-absorbing material is provided with a fixing plate. The rod and the adjustment cylinder are respectively fixedly connected to the bottom of the wave-absorbing material. The top support spring rod is movably inserted into the adjustment cylinder, a...

Embodiment 1

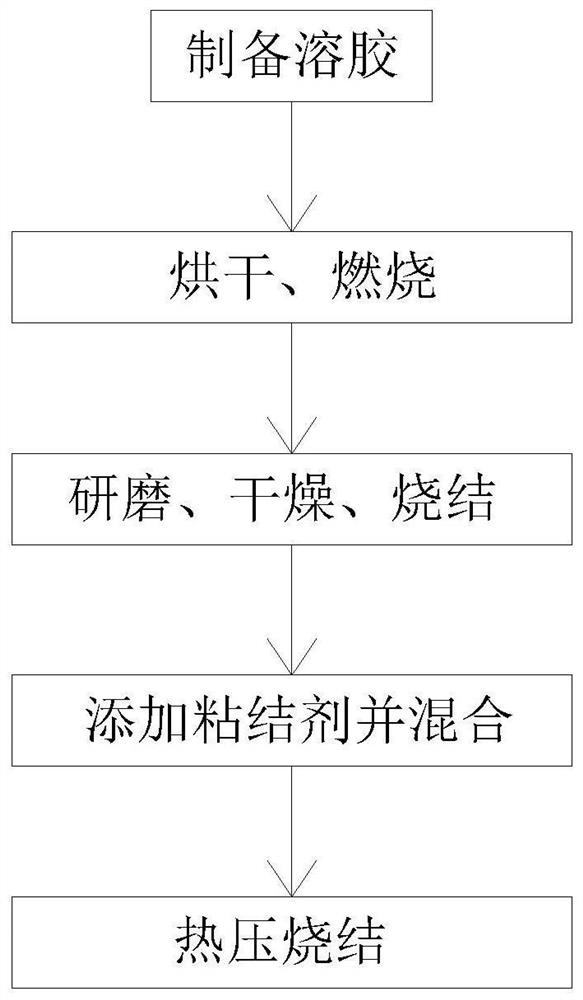

[0034] The preparation method of the layered structure absorbing material comprises the following steps:

[0035] (1) prepare sol;

[0036] (2) After drying the sol, burn it;

[0037] (3) Repeatedly grinding and drying the burned ash to make powder;

[0038] (4) Add an organic binder to the powder and mix evenly;

[0039] (5) The mixed material is hot-pressed and sintered into shape.

[0040]In the step (1), when preparing the sol, add metal nitrate, modified binder and complexing agent to water, stir to form a solvent, then adjust the pH value of the solvent to 7, after the adjustment is completed, heat again Stir to form a sol.

[0041] The complexing agent in the step (1) is polyphosphate or aminocarboxylic acid, and the modified adhesive can be butyl titanate. When adjusting the pH value, add ammonia water to the inside of the solvent several times in small amounts. After adding During the process, the pH value of the solvent needs to be measured repeatedly.

[0042]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com